Super-large hanging vibration test fixture structure

A vibration test, suspension technology, used in vibration testing, machine/structural component testing, measuring devices, etc., can solve the problems of motion parameters not maintaining the same value, high fixture resonance frequency, heavy weight, etc., to achieve the installation test. components and tests, high resonance frequency, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

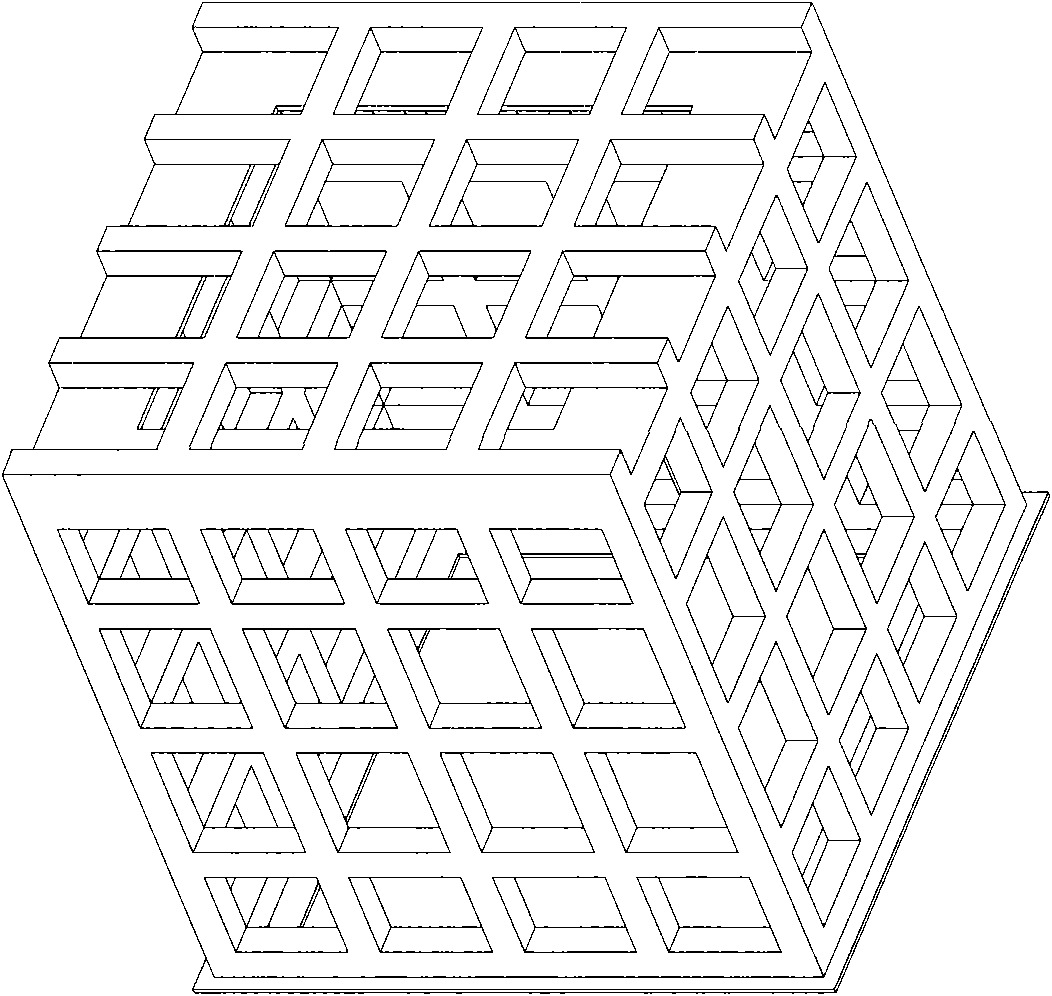

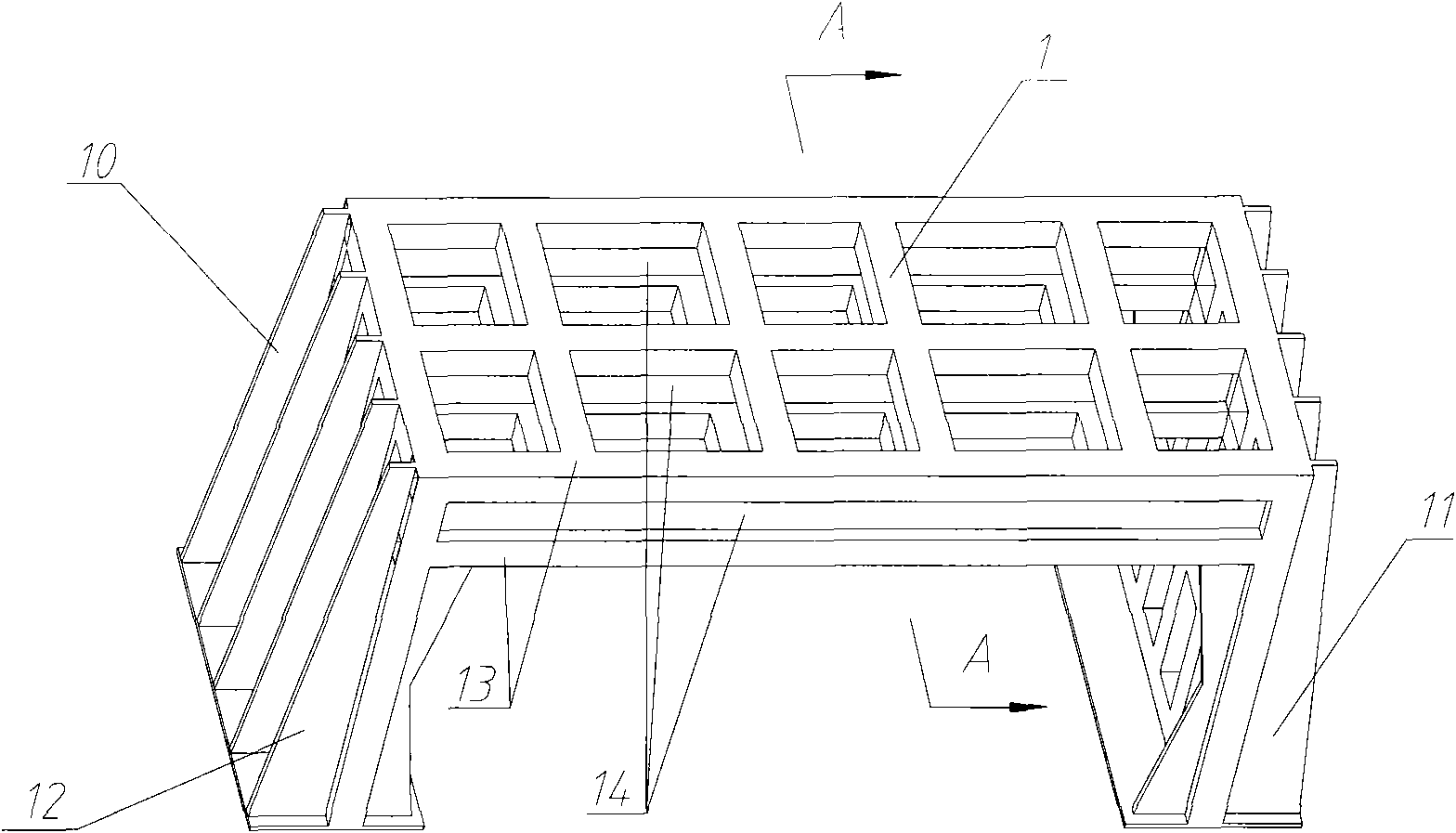

[0028] Embodiment 1 As can be seen from Figures 3 and 4, the super-large suspended vibration test fixture structure is an integral frame structure 1 welded by hollow steel pipes and steel plates, and the test piece 3 can be installed in the integral frame structure 1. According to the structural characteristics of the test piece itself, a suitable installation method can be selected, and the test piece can be hung in the overall frame structure 1 with common parts such as bolts, which is a known technology and will not be described again. The front and back of the overall frame structure 1 are open, and the left and right columns 10, 11 are welded by trapezoidal ribs 12 and hollow steel, and the upper part is welded by two layers of square frames 13; Structure 1 is fixed on the extension platform 8 of vibrating table 9; ( image 3 , 4 , Parts 8,9 are not drawn in 5).

[0029] The left and right columns 10, 11 are welded by trapezoidal ribs 12 and hollow steel, which means th...

Embodiment 2

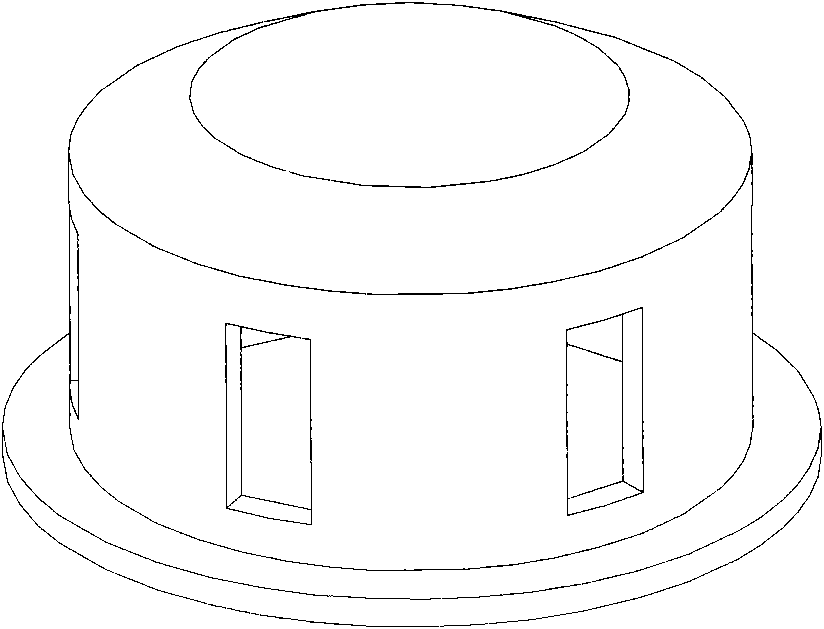

[0031] Embodiment 2 see below Image 6 , 7 , 8. The present embodiment is a further extended scheme on the basis of embodiment 1. The frame structure is a main frame 2 with the same structure as the overall frame structure 1 of embodiment 1. The front and rear of the main frame 2 are open The main frame 2 is welded together with a square frame 4 above it, and the square frame 4 is also an integral frame structure welded by hollow steel pipes and steel plates, and a square steel plate 5 is also welded on the top of the square frame 4 , in the center of the square steel plate 5, a flange 6 with a rectangular seam is fixed with bolts, and between the two sides of the square frame 4 and the main frame 2, three parallel triangular ribs 7 are respectively welded; The test piece 3 can be suspended in the integral frame structure 1 by the spigot flange 6 and the bolt. Due to the structure of the test piece 3 itself, the test piece 3 can be horizontally rotated 360° along the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com