Preparation method of metallographic sample of cast iron oxidizing layer

A technology for sample preparation and oxide layer, applied in the preparation of test samples, etc., can solve the problems of tissue changes, easy heating of the oxide layer, pollution of the oxide layer, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The step of metallographic sample preparation method of cast iron oxide layer of the present invention is:

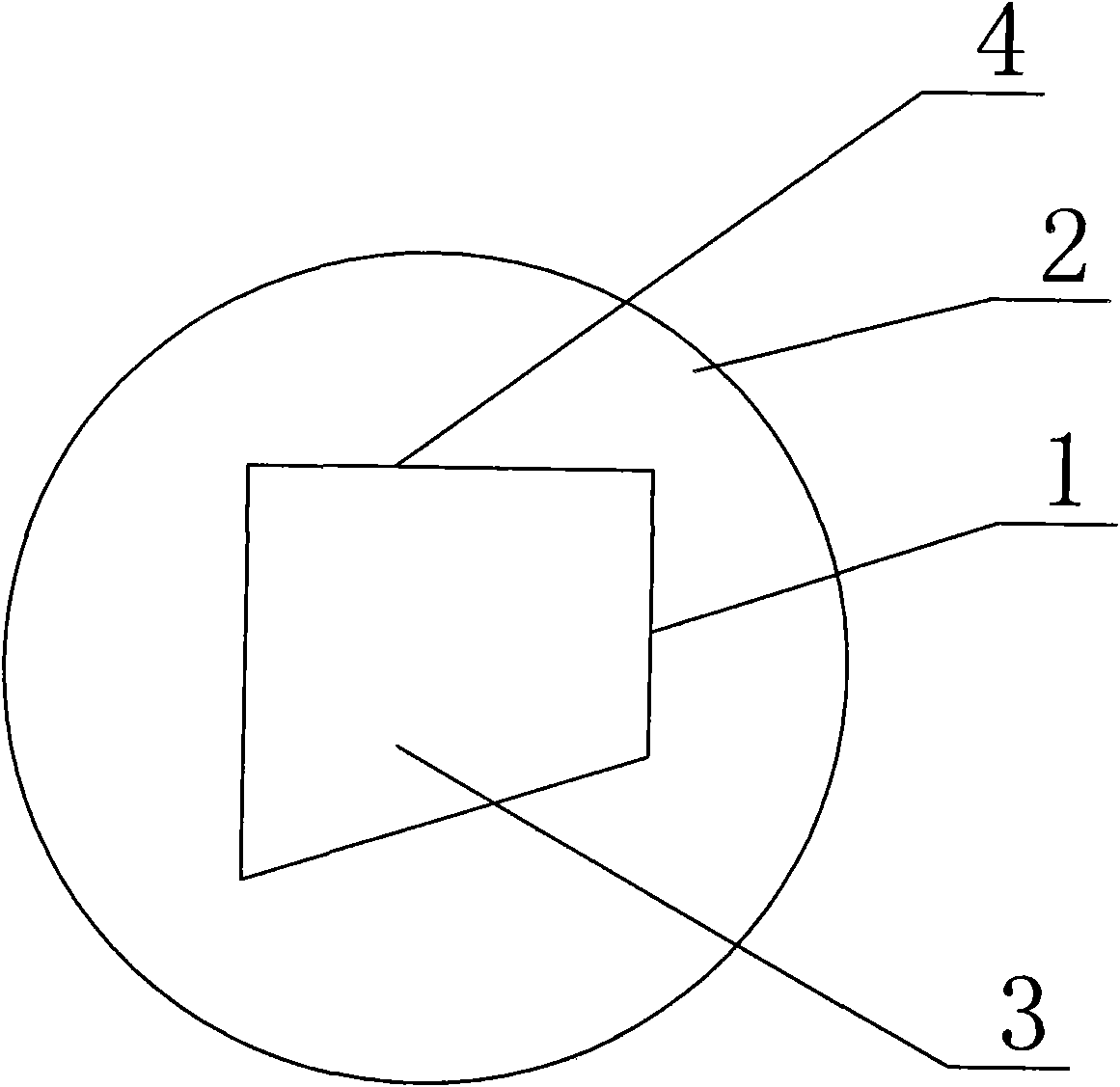

[0018] 1. Manually cut the sample: cut the sample on the cast iron workpiece with a hand-held hacksaw. The cut sample is a hexahedron whose top and bottom surfaces are right-angled trapezoids, and the oxidation layer to be tested is on the side where the right-angled sides of the right-angled trapezoid are located. , so that the oxidation level of the sample to be tested is easily identified and located; the frequency of sawing the cast iron workpiece is 2 times per second, and the slower cutting speed can avoid the heating of the workpiece from affecting the structure of the oxide layer and avoid the oxidation of the oxide layer. peeling off.

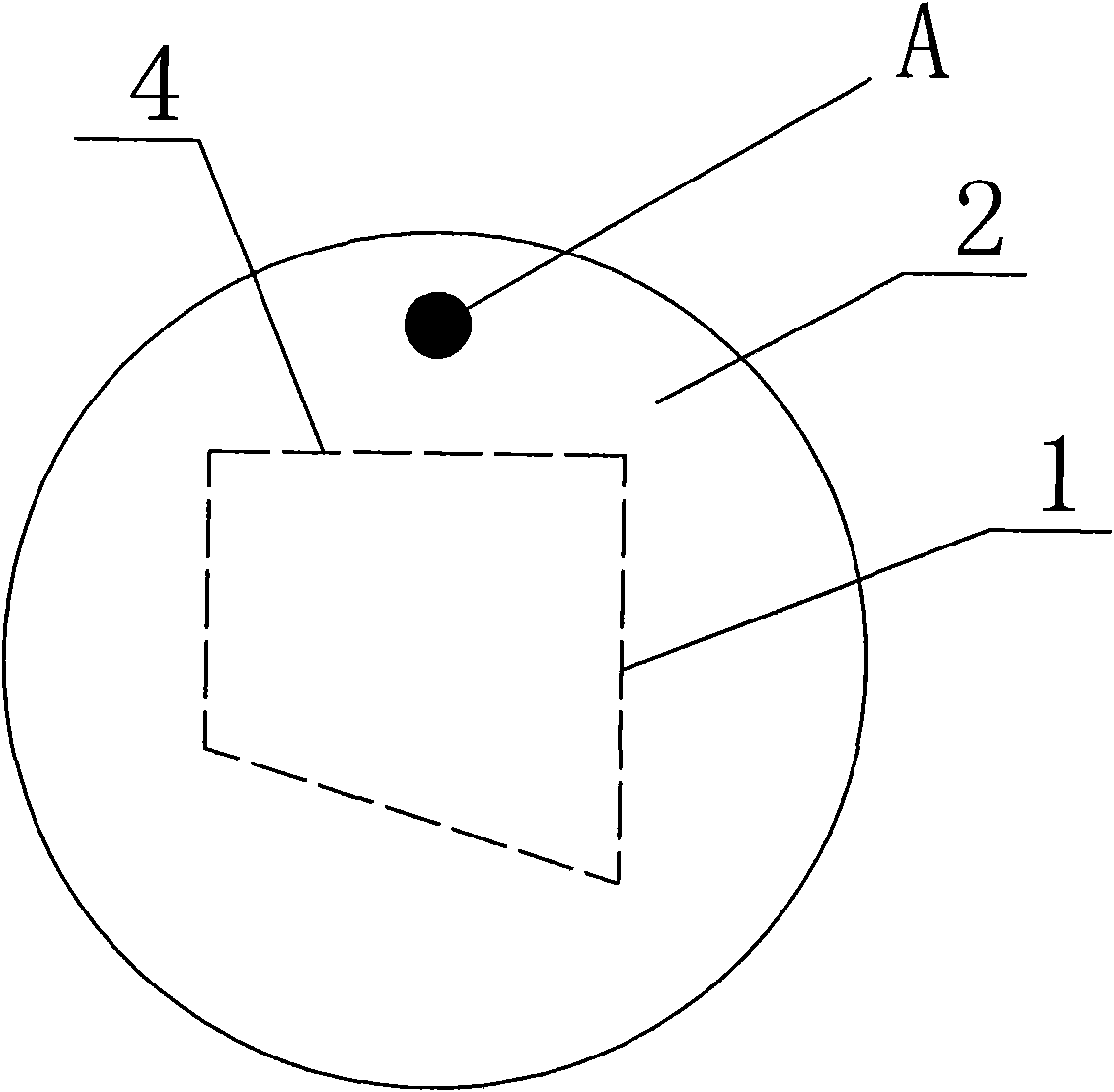

[0019] 2. Grinding the grinding surface of the sample: Use a grinder to grind any one of the right-angled trapezoidal top and bottom surfaces of the hexahedron sample, remove the burrs on the surface, and make the right-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com