Coaxial double-layer barrel linkage mechanism of watch

A technology of linkage mechanism and barrel, which is applied to the driving mechanism of clocks, clocks, mechanically driven clocks, etc., can solve the problems of increasing the overall size of the movement and occupying a large movement plane, so as to increase the power duration and prolong the duration. The effect of passing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below by accompanying drawing and specific embodiment the present invention is described in further detail:

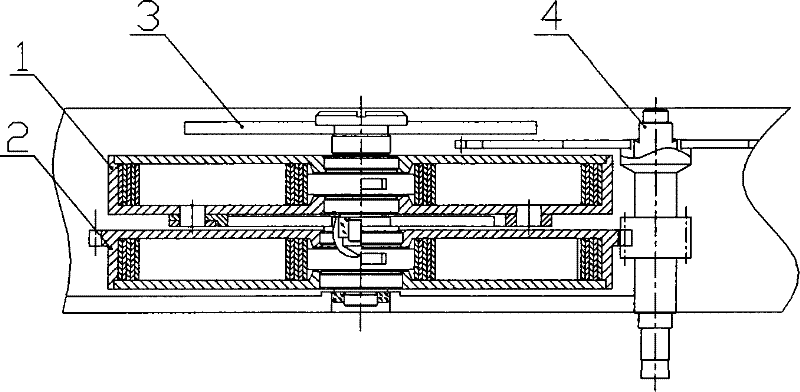

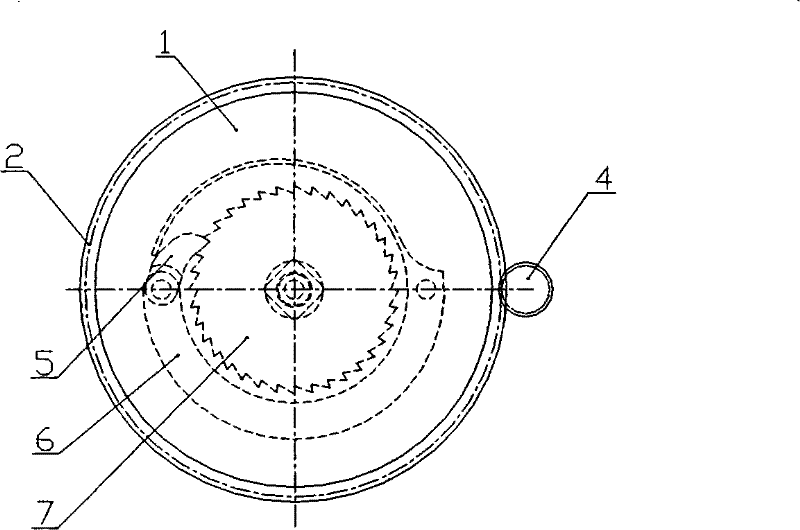

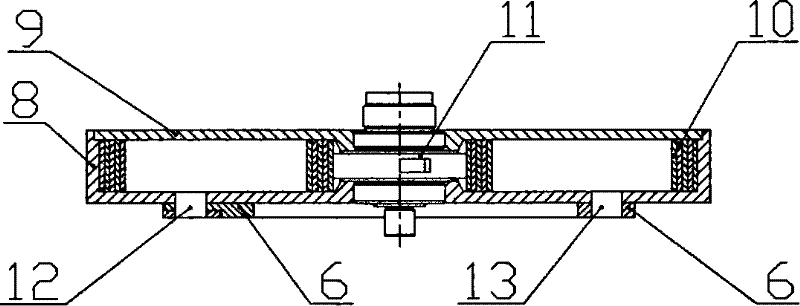

[0021] Such as Figure 1 to Figure 6 As shown, the coaxial double-layer barrel linkage mechanism in the watch movement of the present invention includes a driving barrel part 1, a driven barrel part 2 and a second wheel part 4; the driving barrel part 1 and the driven barrel part A linkage mechanism is installed between the parts 2, the active barrel part 1, the driven barrel part 2 and the linkage mechanism are installed coaxially; the active barrel part 1 is installed above the driven barrel part 2, and the active barrel part 2 The box part 1 comprises a driving barrel 8, a driving barrel cover 9, a driving spring 10, and a driving barrel shaft 11, and the upper and lower ends of the driving barrel shaft 11 pass through the centers of the driving barrel 8 and the driving barrel cover 9 respectively. hole, the driving barrel cover 9 and the driving barrel 8 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com