Manufacturing method of multifunctional unmanned ship

A manufacturing method and unmanned ship technology, applied in two-dimensional position/channel control, non-electric variable control, control/regulation system, etc., can solve problems such as high cost, difficult maintenance, and small coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

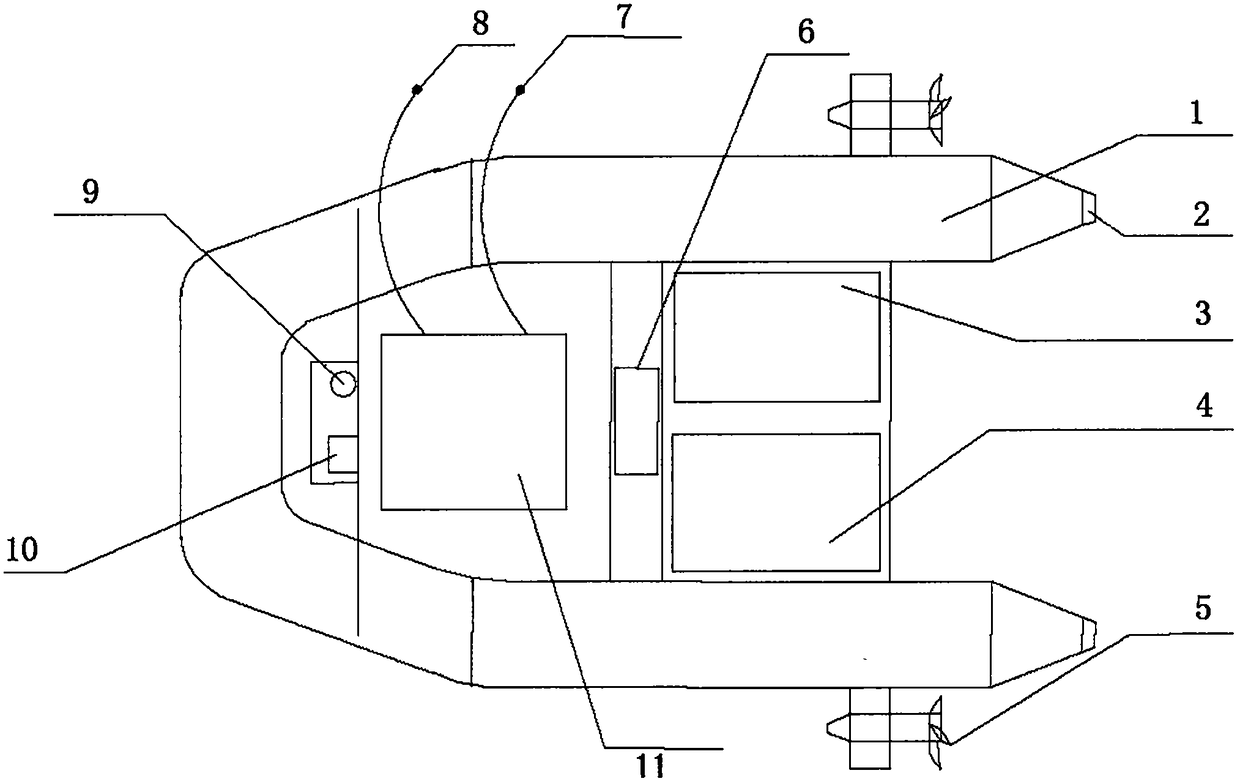

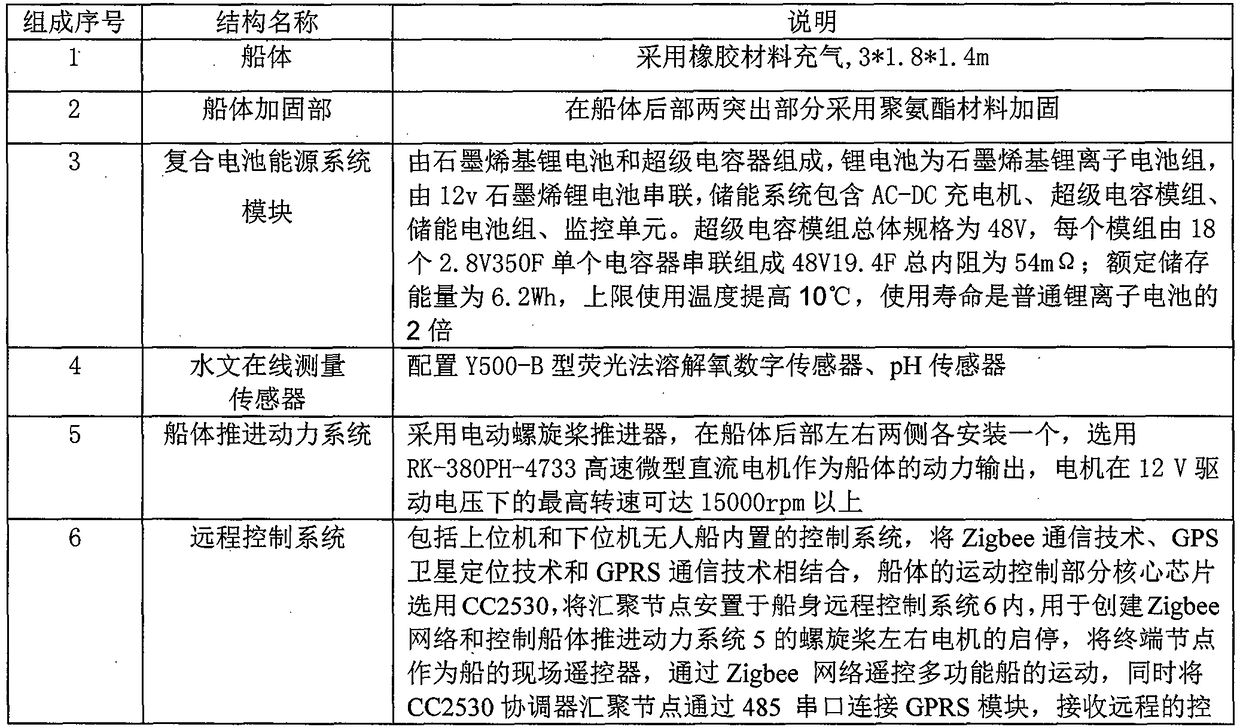

[0008] A multifunctional and multifunctional unmanned ship consists of 11 parts, as shown in the attached manual figure 1 As shown in Table 2, the main components include 1 hull, 2 hull reinforcement, 3 composite battery energy system, 4 hydrographic measurement sensor system, 5 hull propulsion power system, 6 remote control system, 7 micro-nano bubble water treatment device water inlet , 8 micro-nano bubble water treatment device water vapor mixing outlet, 9 camera pan-tilt, 10 obstacle avoidance device, 11 micro-nano bubble water treatment device.

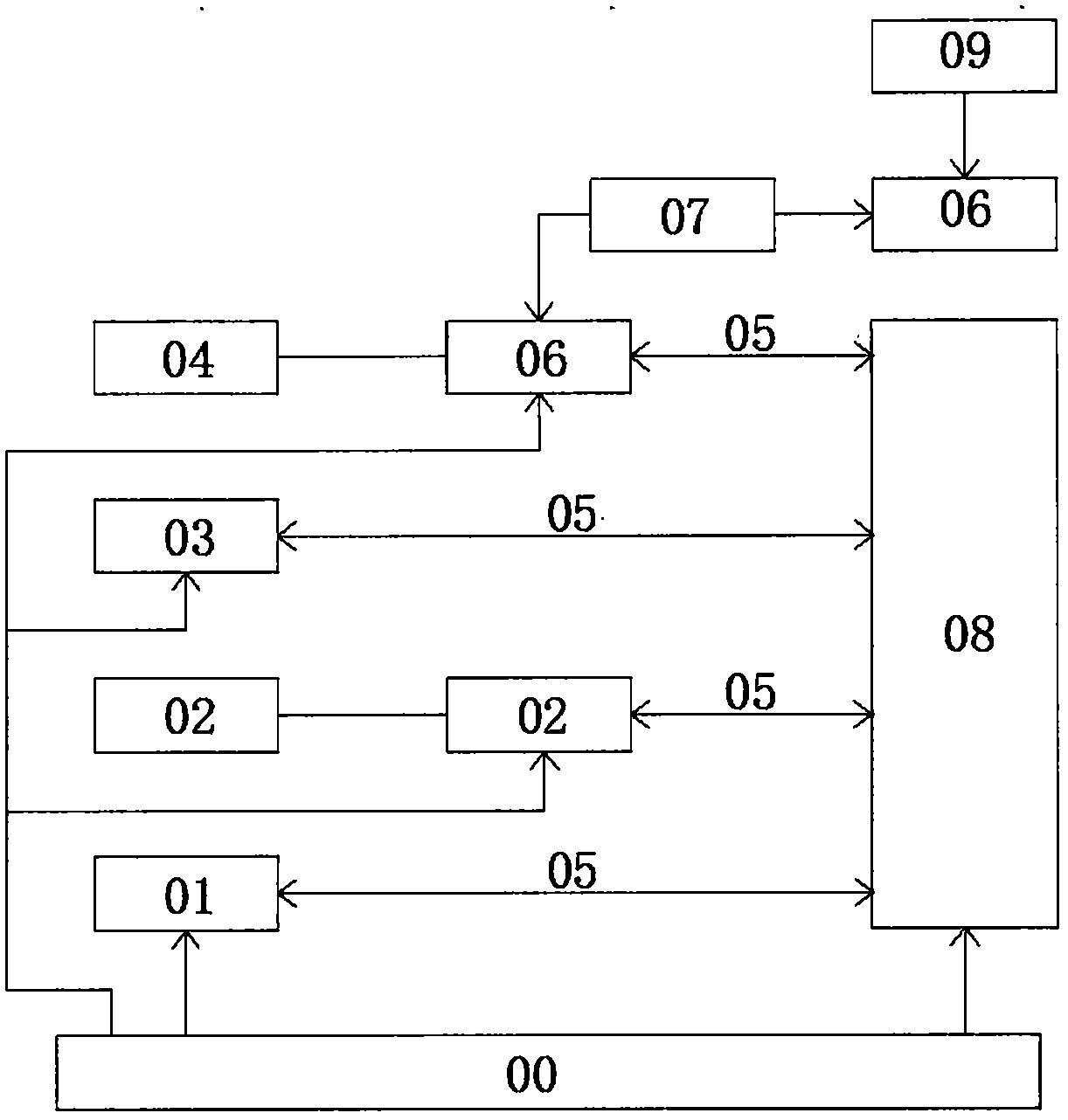

[0009] The main performance indicators are shown in Table 2. The hull 1 is made of inflatable rubber material, with a length, width and height of 3*1.8*1.4m; the composite battery energy system 3 uses a DC power supply as the driving force of a 36V / 750W DC motor; for the remote control of unmanned ships, see figure 2 , which consists of the upper computer and the lower computer built-in control system of the unmanned ship. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com