Low-voltage capacitance compensating cabinet

A technology of low-voltage capacitors and compensation cabinets, applied in reactive power compensation, reactive power adjustment/elimination/compensation, electrical components, etc., can solve the problems of messy internal structure, unsightly, randomness, etc., and achieve convenient maintenance and upgrades safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

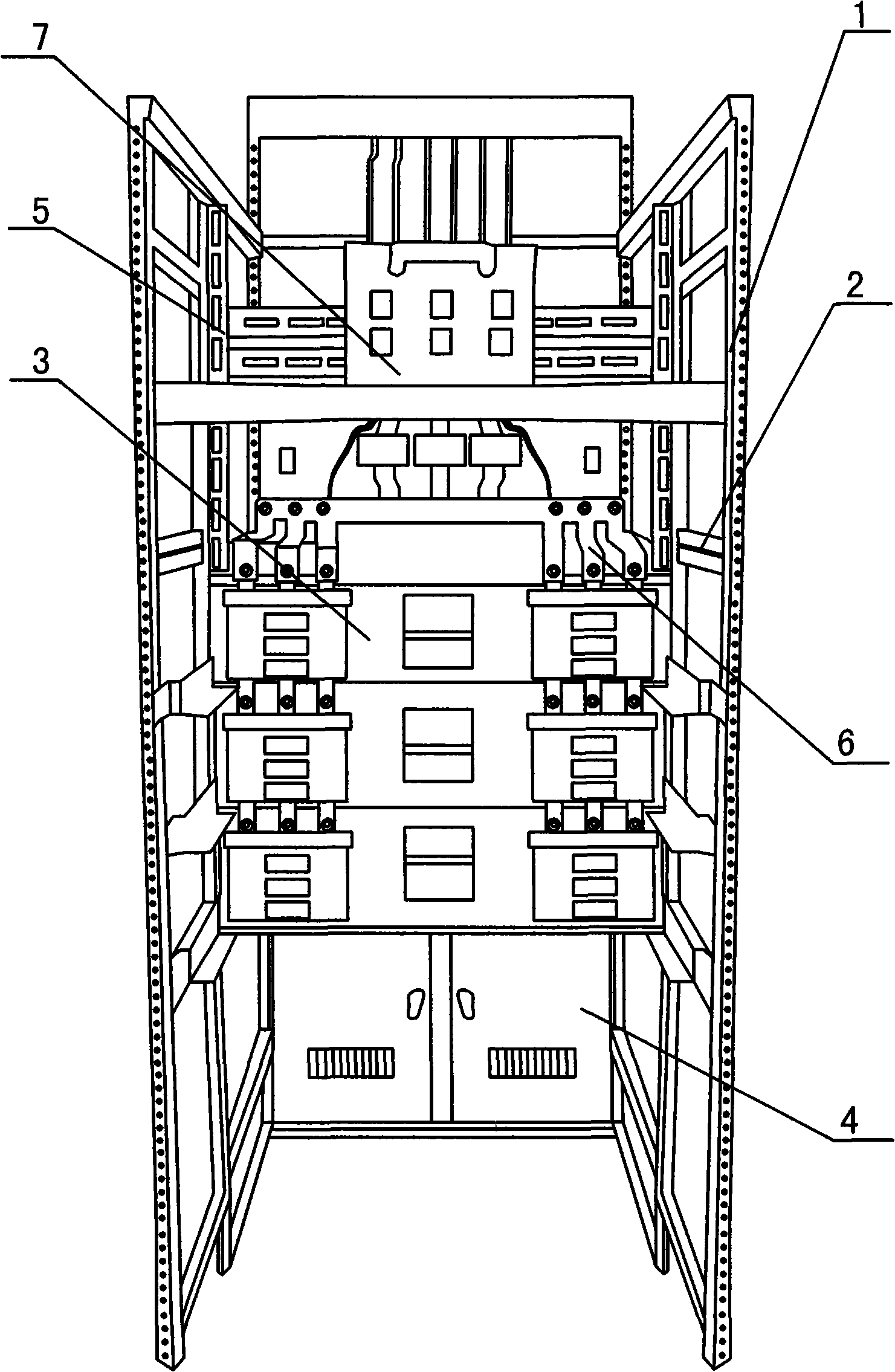

[0011] Such as figure 1 As shown, the low-voltage capacitance compensation cabinet of the present invention includes a support body 1 composed of several supports, and several beams 2 are respectively installed on the left and right sides of the support body at a certain distance from top to bottom, and the support body 1 A core board 3 for arranging electrical components is provided on the rear side frame body, and a bent copper bar 6 is provided on the core board 3 and connected with the incoming line knife fusion, and the lower part of the core board 3 is provided with a rear cabinet door 4. The upper rear side of the support body 1 is provided with a vertical beam 5 for reinforcing and supporting. Capacitors, reactors, contactors or thyristor switching modules of a certain capacity, vertical busbars, and fuses are installed on the core board 3 drawer-type modules, and the modules are connected through special busbar connection clips.

[0012] The main features and advanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com