Vacuum cleaner with dust separation structure

A vacuum cleaner and dust separation technology, applied in the direction of vacuum cleaners, suction filters, household appliances, etc., can solve the problems of blocking the filter part, the dust separation performance of the dust separation part being reduced, and the dust foreign matter cannot be effectively separated, etc., so as to achieve air flow. The effect of smooth and improved dust separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

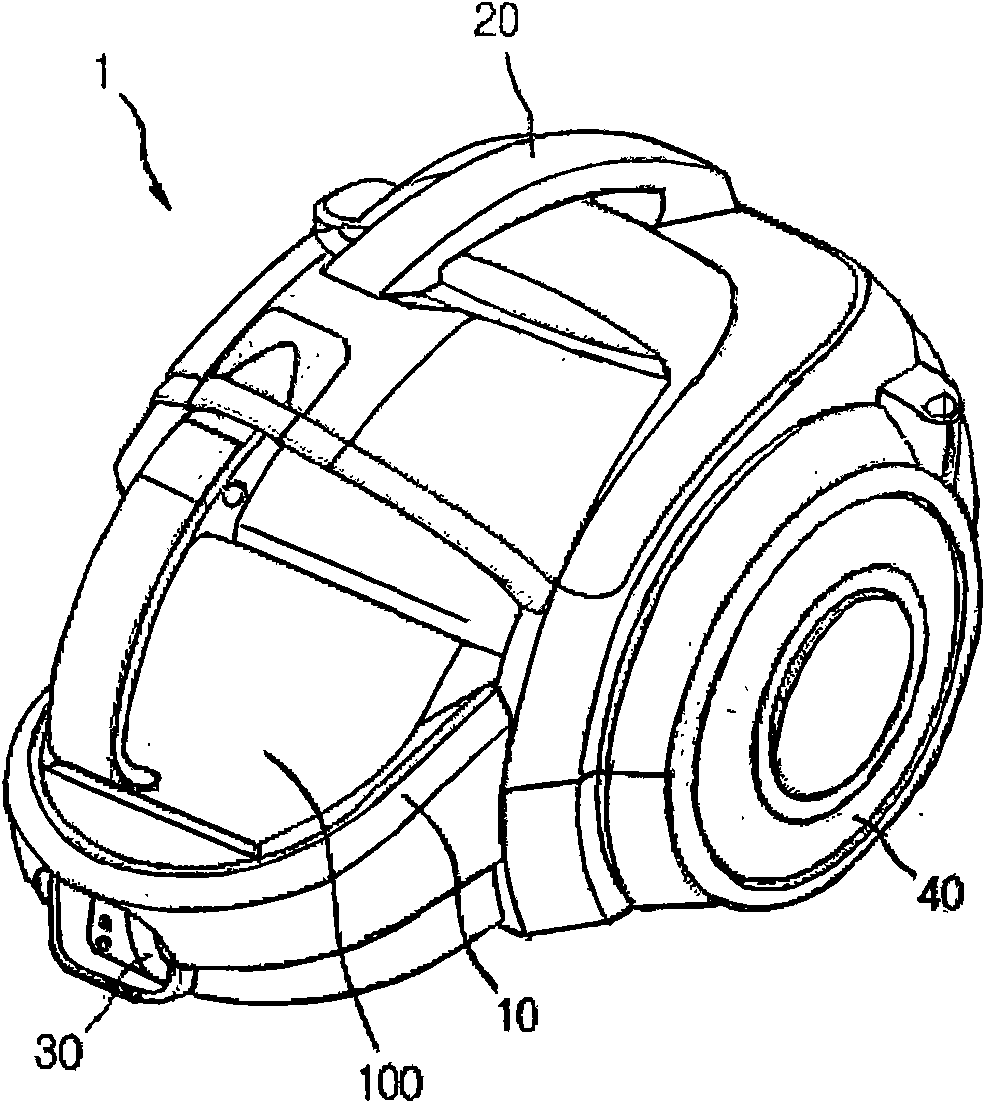

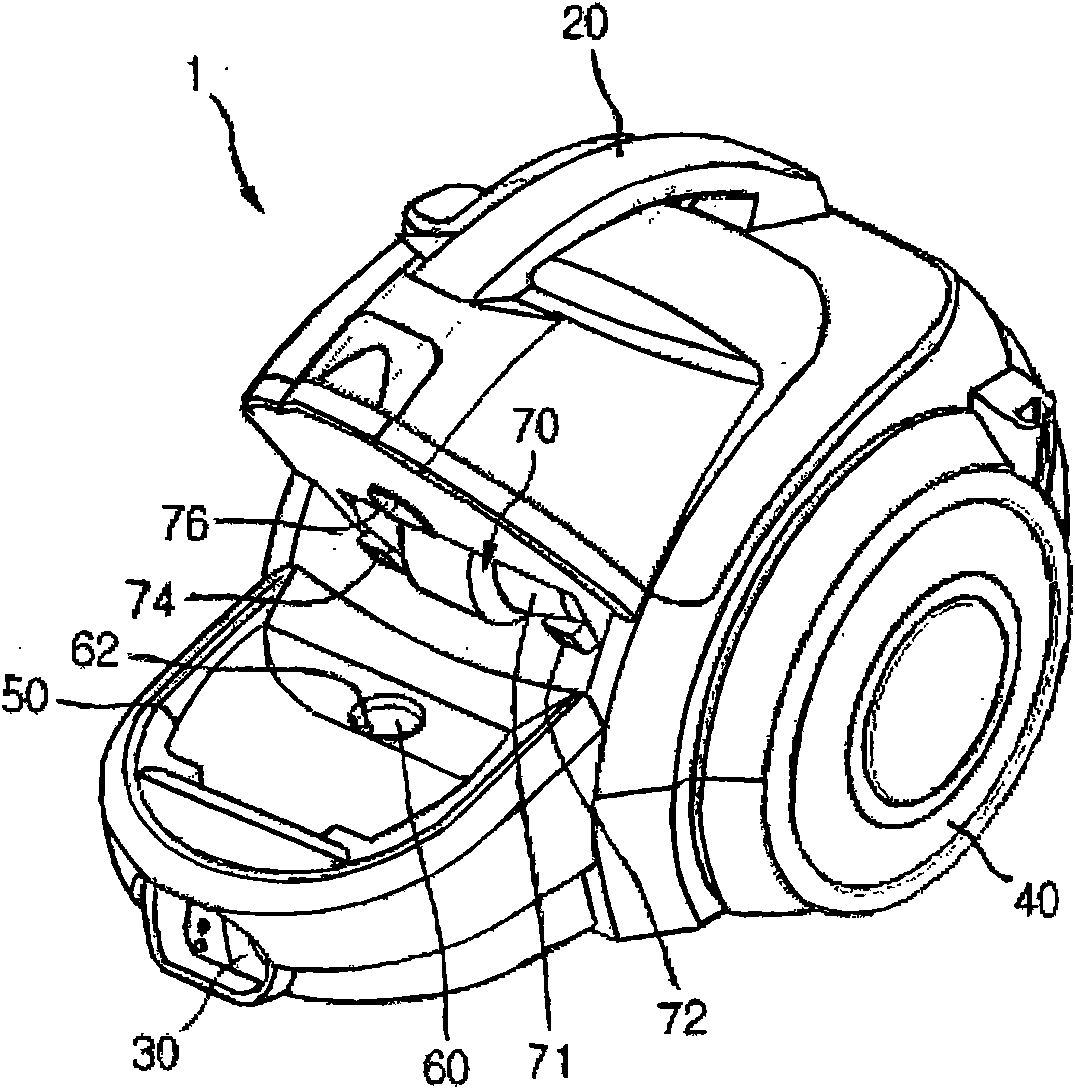

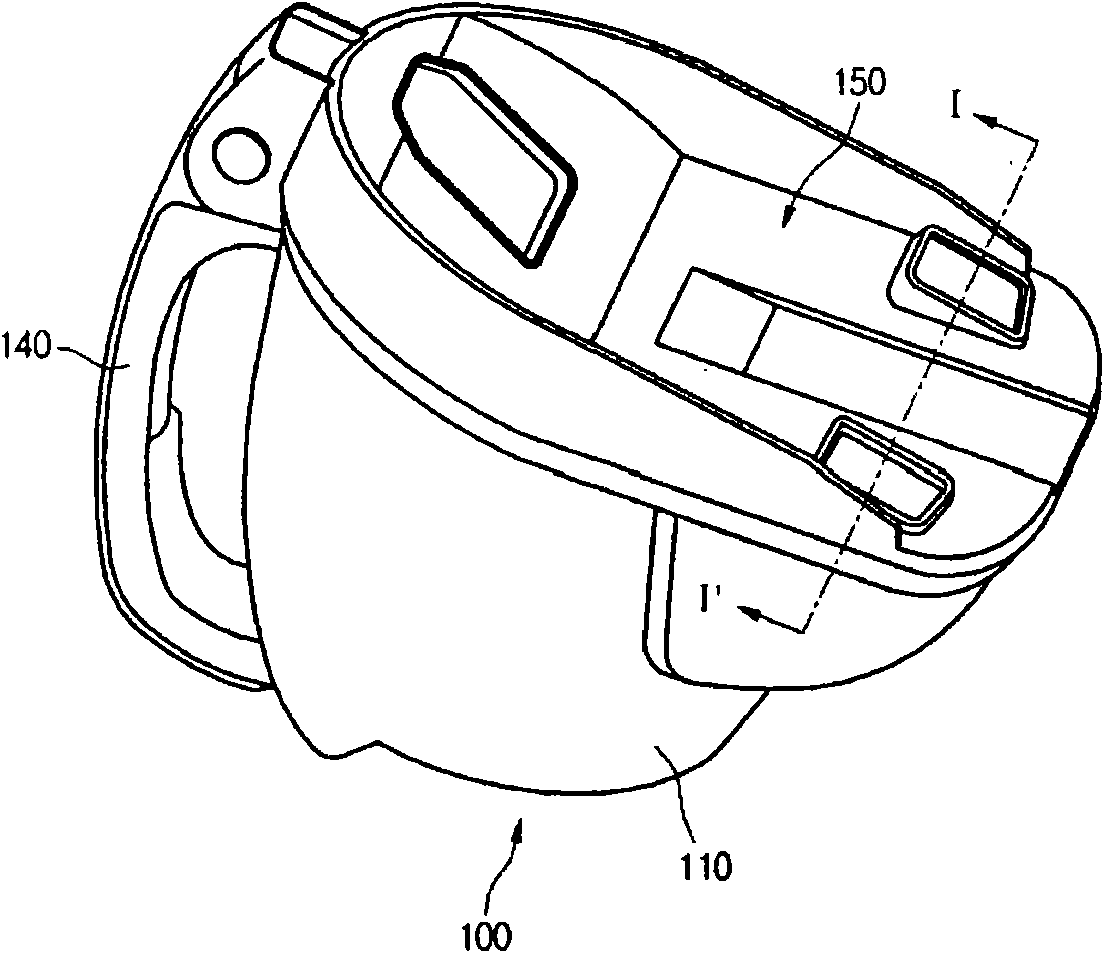

[0024] figure 1 It is an oblique view of the vacuum cleaner with the structure of the present invention; figure 2 It is a perspective view of the vacuum cleaner with the dust collecting device separated.

[0025] refer to figure 1 and figure 2 According to an embodiment of the present invention, the vacuum cleaner 1 includes a vacuum cleaner main body 10 constituting the appearance of the vacuum cleaner;

[0026] The dust separating device includes: a dust separating part 70 provided on the main body 10 of the vacuum cleaner;

[0027] The main body 10 of the vacuum cleaner includes: an air inflow part 30 that sucks air from the space to be cleaned and flows into the main body 10 of the vacuum cleaner; moving wheels 40 that can make the movement of the vacuum cleaner 1 more flexible; 20.

[0028] In addition, although not shown in the figure, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com