Device and system for preventing falling

A technology for anti-falling and equipment, applied in the direction of life-saving equipment, safety belts, etc., can solve problems such as repeated use that cannot be repeated, potential safety hazards for operators, physical injuries of operators, etc., to increase safety and work convenience, Improve safety and reliability, and protect workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

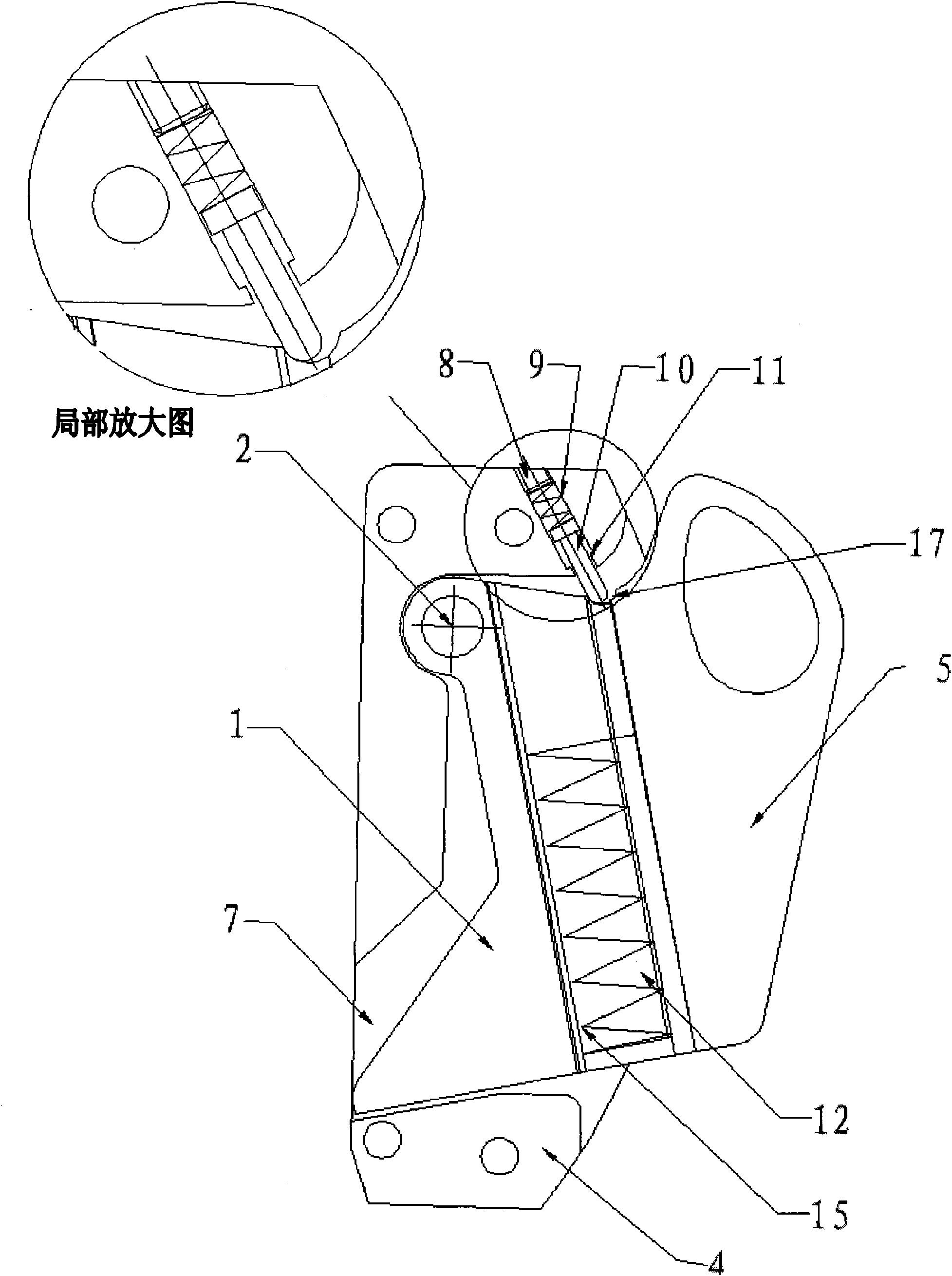

[0030] The principle of realizing the cushioning function and anti-dropping of the present invention will be described in detail below in conjunction with the accompanying drawings.

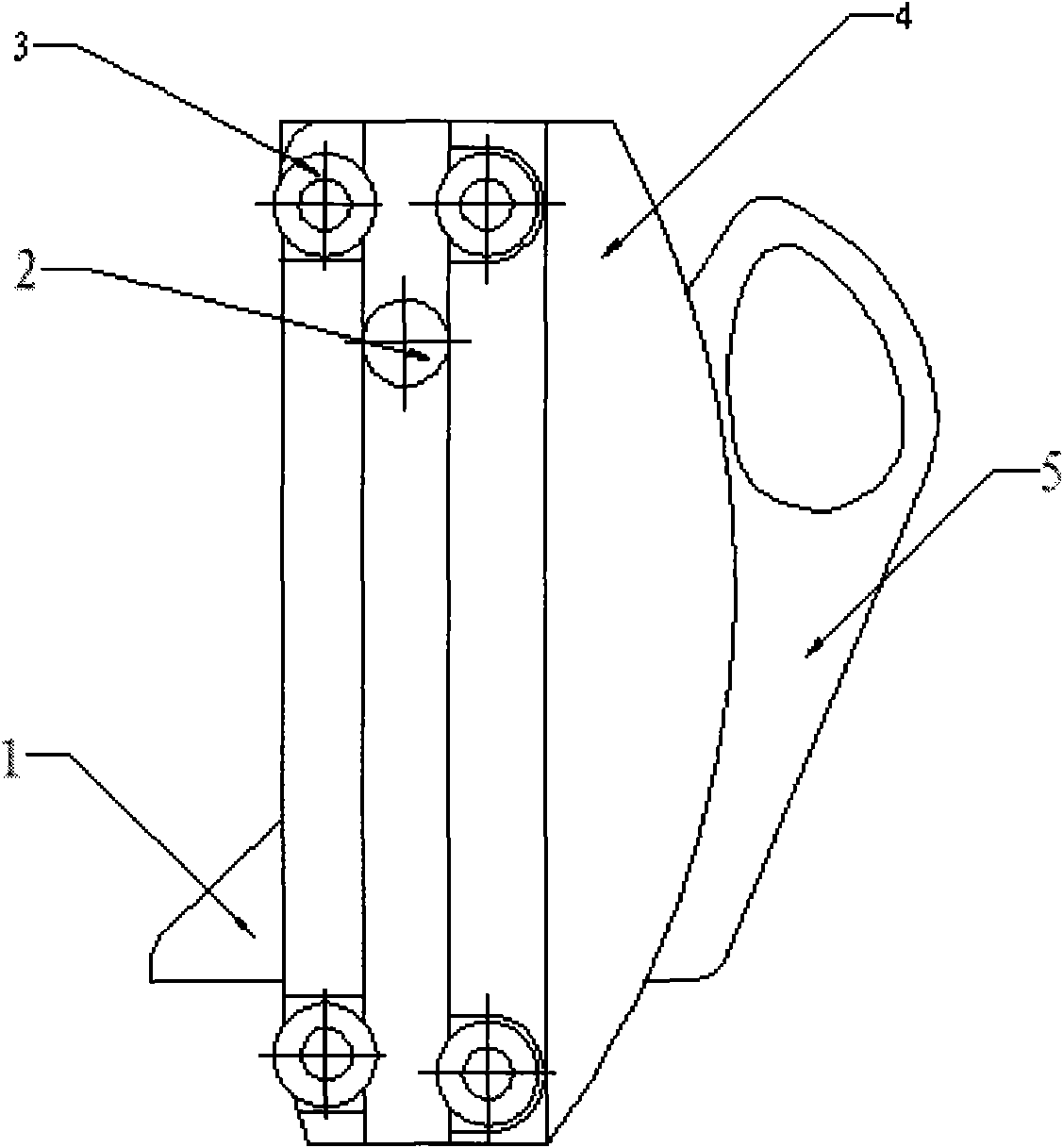

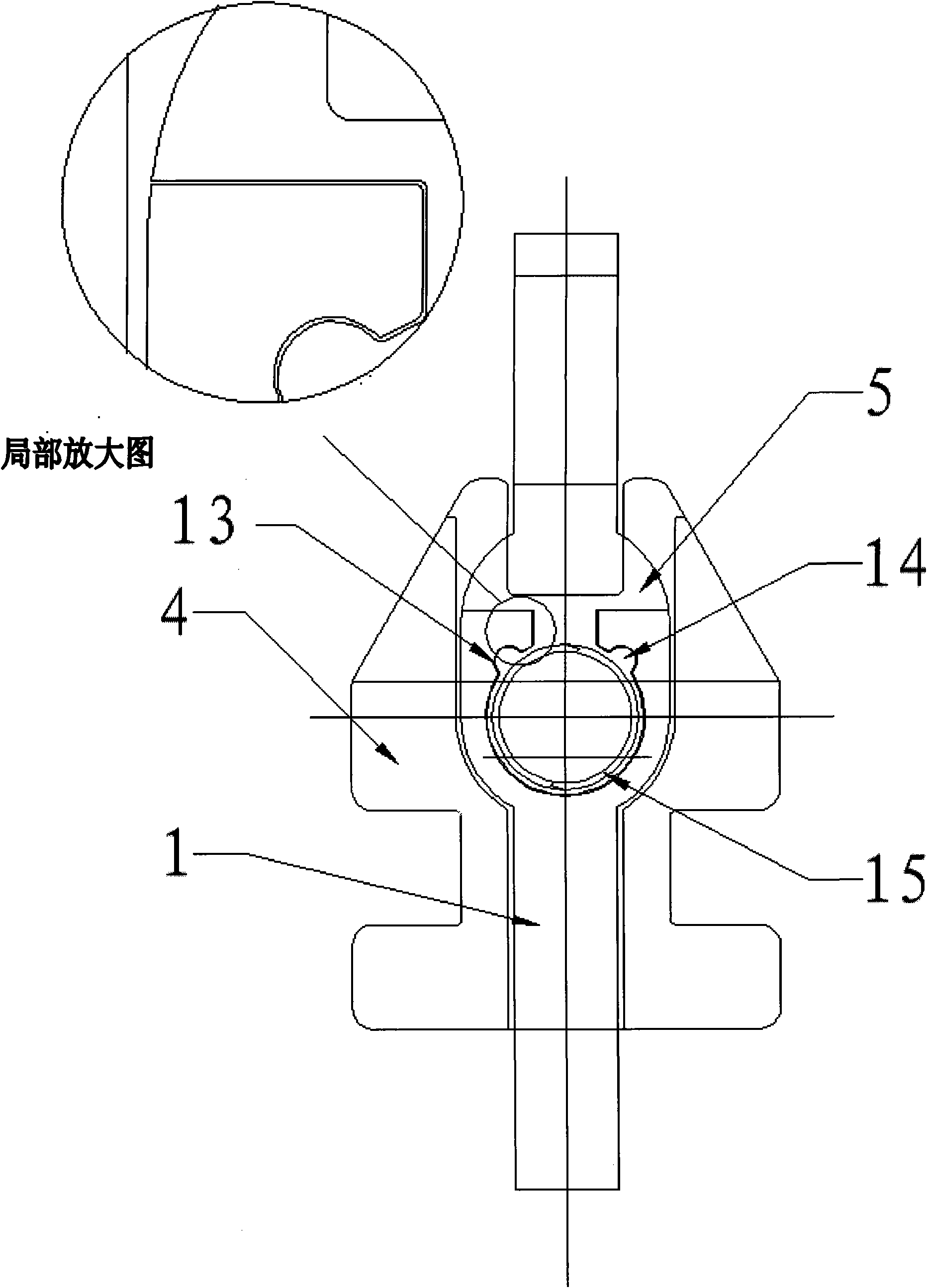

[0031] refer to Figure 1 to Figure 6 Shown, the present invention has the equipment (such as image 3 ) include:

[0032] The anti-fall buffer device composed of the rotating block 1, the sliding buffer block 5 and the buffer spring 15 can pass through the bottom of the housing 4, and its fixed end is inserted into the housing 4, and passes through the fixed shaft 2 It is movably connected with the housing 4 so that the anti-falling buffer device composed of the rotating block 1 , the sliding buffer block 5 and the buffer spring 15 can rotate in the housing 4 around the fixed shaft 2 . There is a gap running through the sliding buffer block 5 at one end of the sliding buffer block 5 pulled by the safety belt. A through hole 11 with a boss is opened on the upper part of the housing 4, and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com