Large traction screw propulsion micro-pipeline robot

A pipeline robot and screw propulsion technology, applied in the pipeline system, micro-manipulator, manipulator, etc., can solve the problems of poor traction ability of the robot, difficulty in reducing the structural size, and limited load capacity, etc., and achieve good adaptability to changing pipe diameters, Improve the driving traction and ensure the effect of normal movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

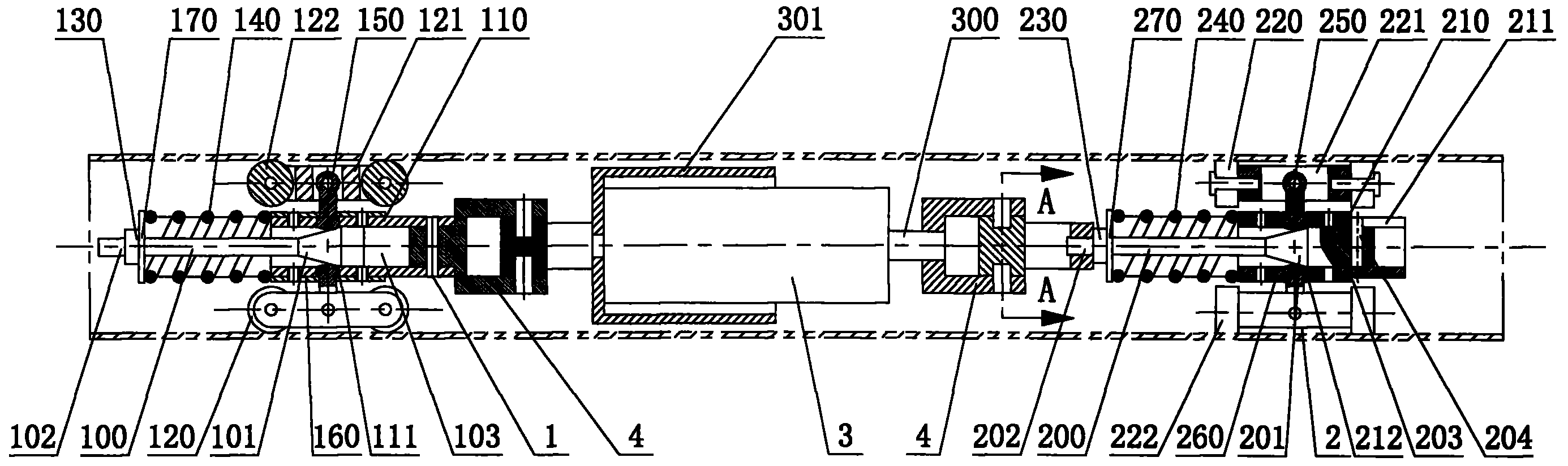

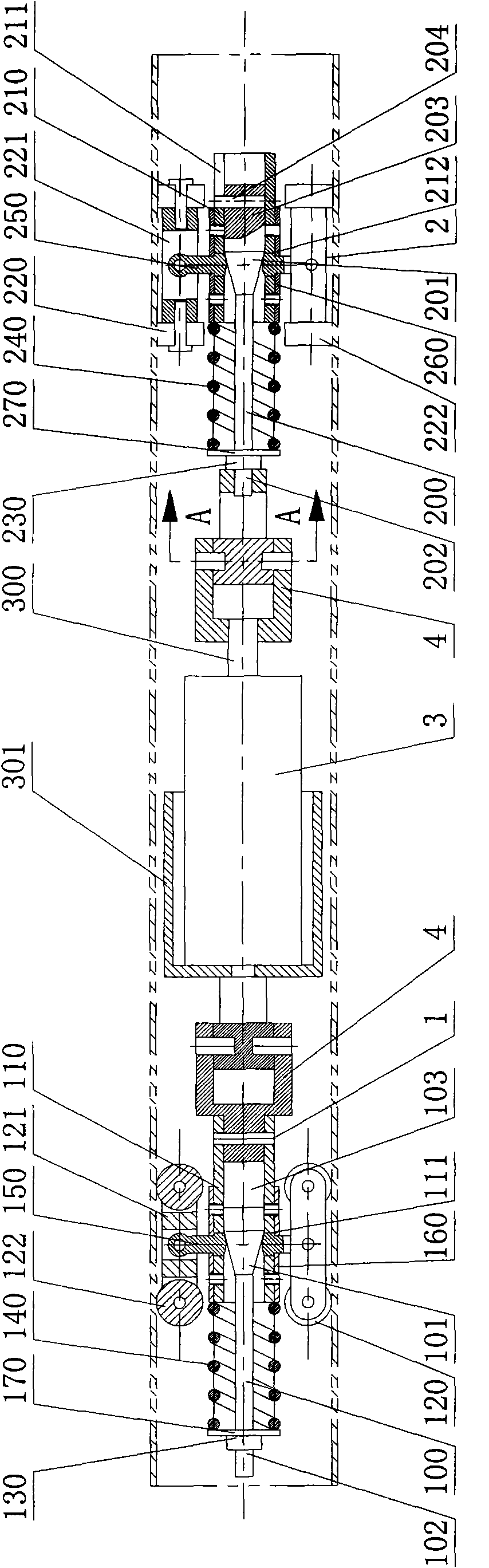

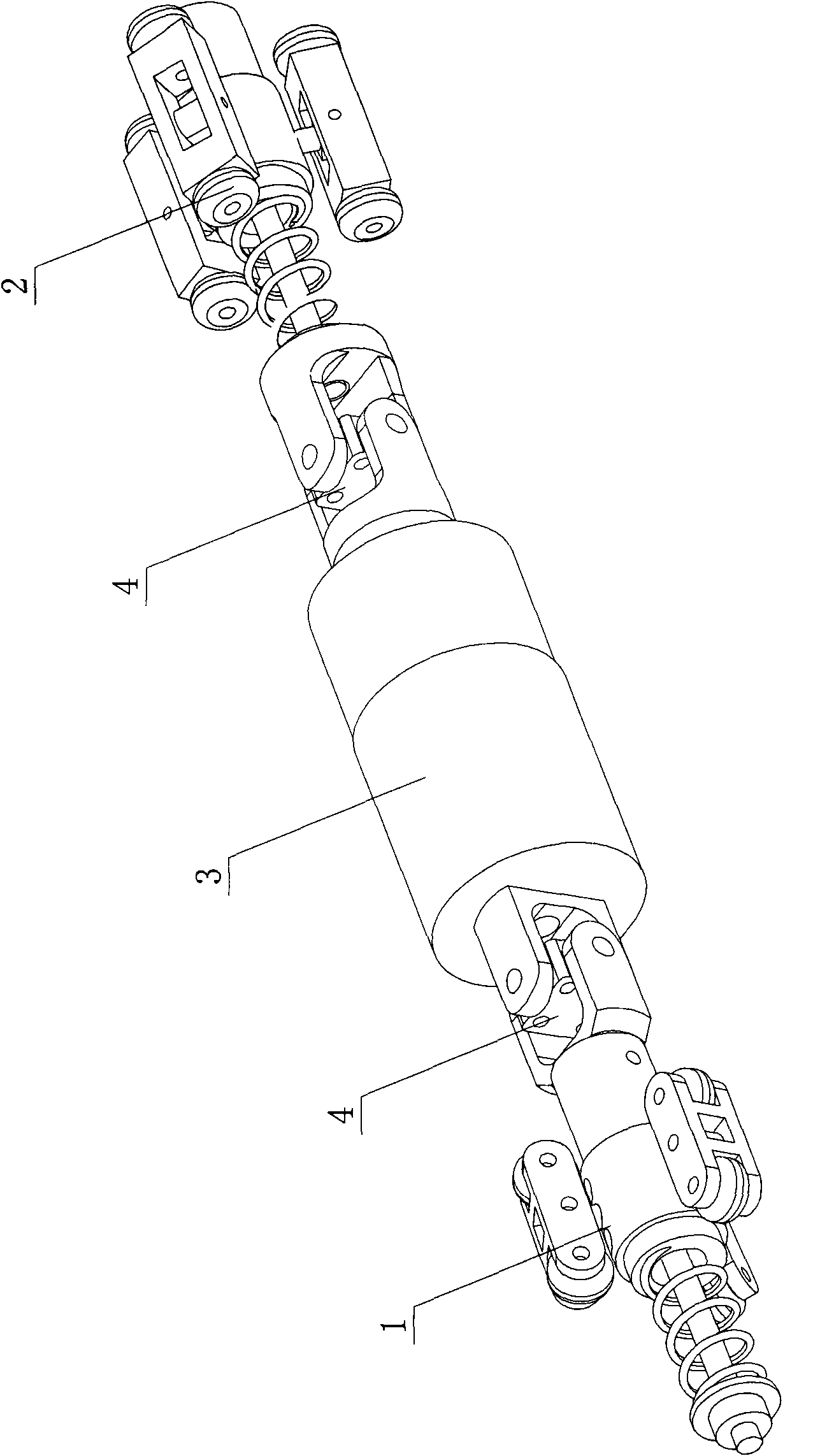

[0045] As shown in Fig. 1, Fig. 2 and Fig. 3, a kind of large traction force screw propulsion tiny pipe robot of the present invention comprises guide mechanism 1, screw propulsion mechanism 2 and rotary drive device 3, and rotary drive device 3 is located at guide mechanism 1 and Between the screw propulsion mechanism 2, in this embodiment, the guide mechanism 1 and the screw propulsion mechanism 2 are respectively connected to the rotary drive device 3 through a universal joint 4.

[0046] As shown in FIGS. 4 to 7 , the screw propulsion mechanism 2 includes a first tension rod 200 , a sleeve-shaped screw support 210 and at least three sets of screw wheels 220 uniformly arranged along the circumference of the screw support 210 . In this embodiment, three sets of spiral wheel sets 220 are provided. The spiral support 210 is provided with a chute 211 in the axial direction, and a first guide hole 212 corresponding to each spiral wheel set 220 is provided in the radial direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com