Method for operating a printing press

A technology for printing presses and printing devices, applied in printing presses, general parts of printing machinery, printing, etc., can solve problems such as unavailability and danger, avoid downtime, avoid machine downtime, and avoid restart-waste page effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

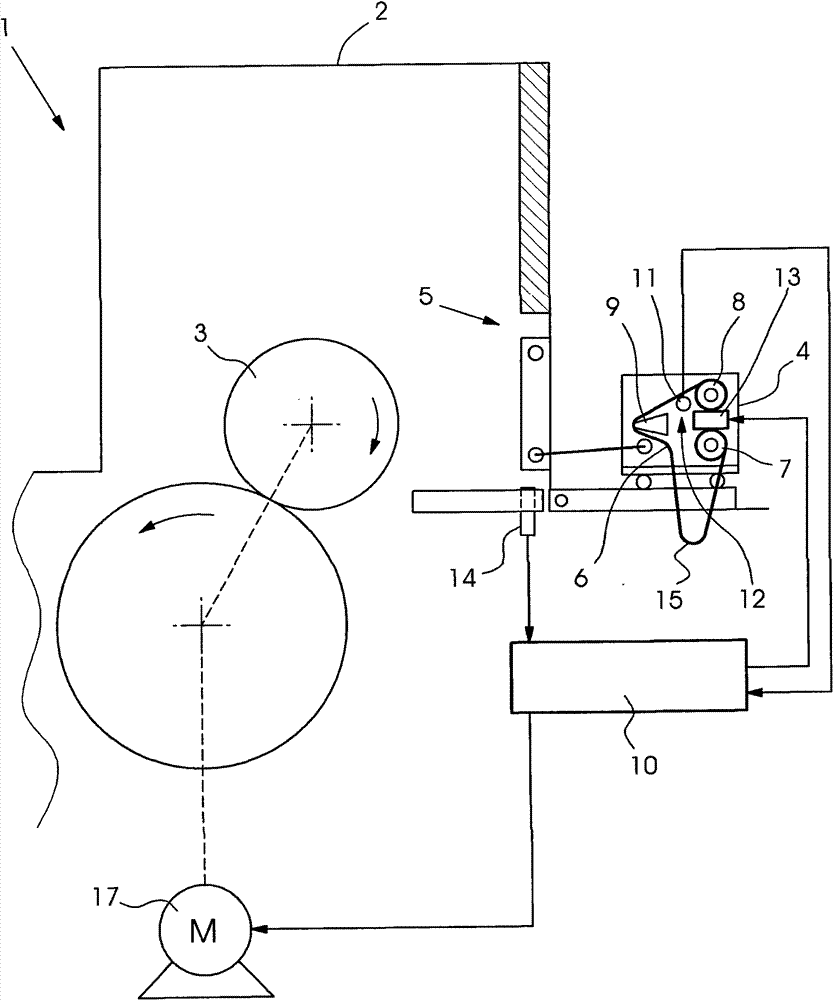

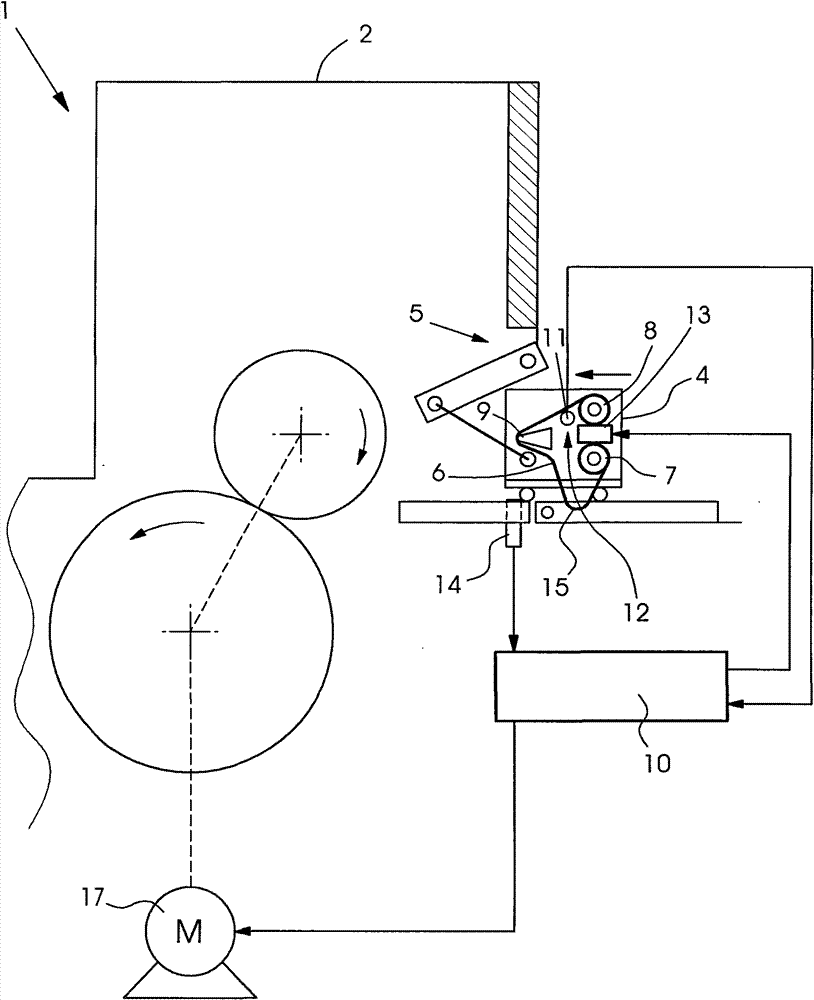

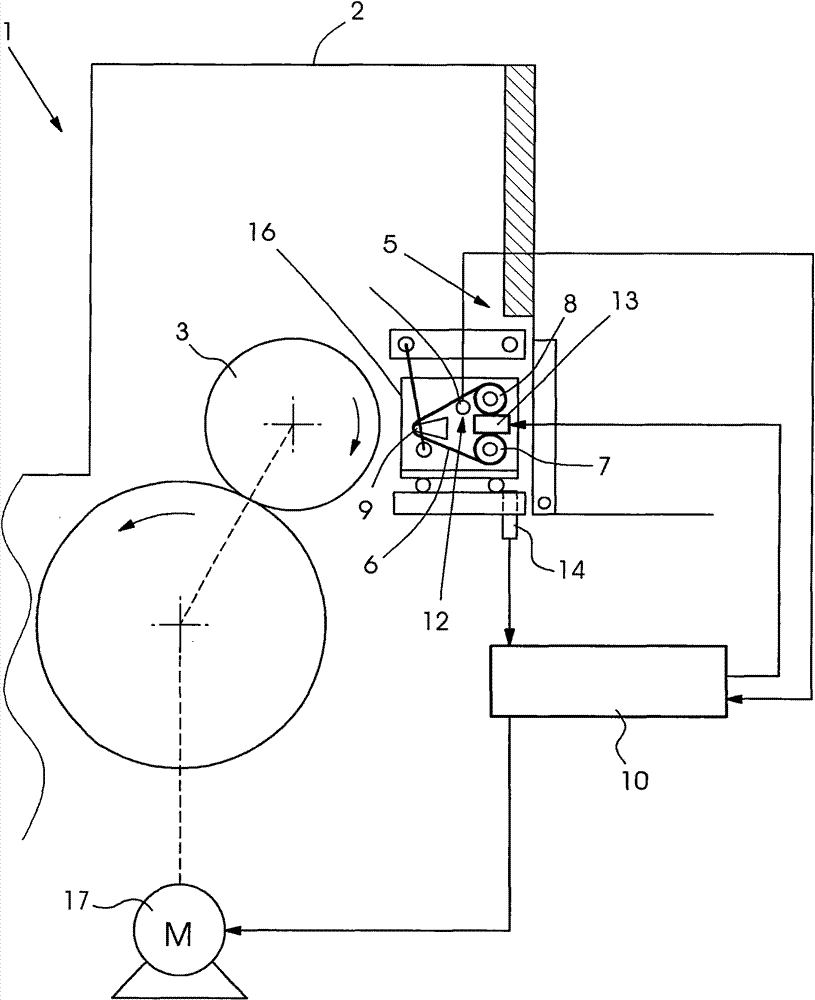

[0024] figure 1 A printing press 1 for printing sheets is shown. The printing press 1 comprises a plurality of printing units arranged in series for offset printing, of which one printing unit 2 is present. The printing unit 2 includes a cylinder 3 which is a blanket cylinder. Furthermore, the printing unit 2 includes a printing form cylinder and an impression cylinder, which cooperate with the cylinder 3 . The printing press 1 is assigned a cleaning device 4 which is used to clean the cylinder 3 from time to time, for example between successive printing jobs. In a wall of the printing unit 2 parallel to the axis of rotation of the cylinder 3 there is an opening 5 through which the cleaning device 4 can be moved into the printing unit 2 .

[0025] The cleaning device 4 includes a cleaning cloth 6 which can be unwound on a clean cloth spindle 7 and can be wound onto a dirty cloth spindle 8 . The cleaning cloth 6 runs over a pressing element 9 which serves to press the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com