Line thermal printer

A thermal printer and line-type technology, applied in printing devices, printing, etc., can solve the problem of recording quality degradation and achieve the effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

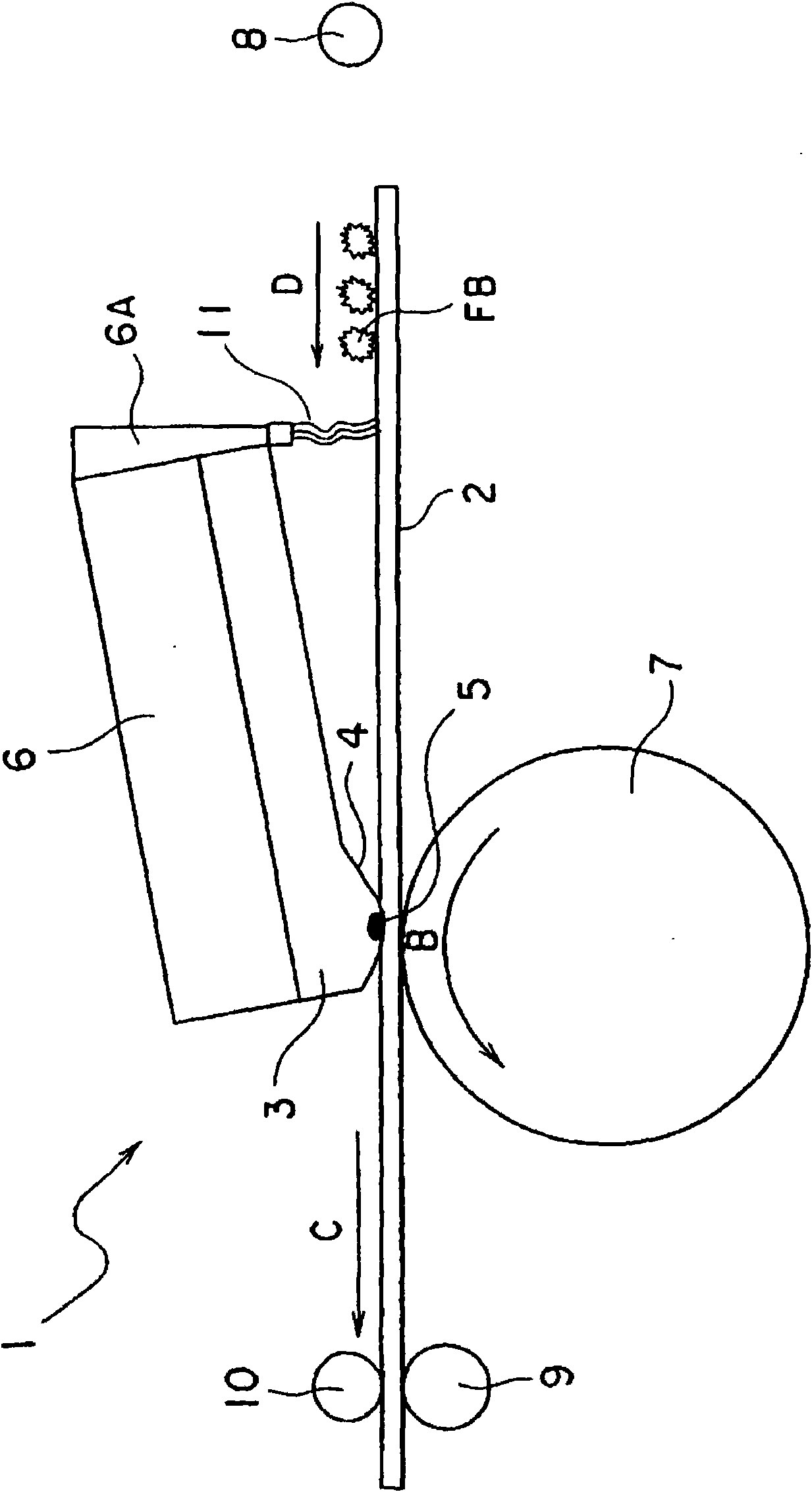

[0028] figure 1 Shows the main parts of the line thermal printer according to the present invention. A line thermal printer 1 according to the present invention has a line thermal head 3 that performs printing by selectively heating a plurality of heating elements that are driven by a recording paper 2 that is fed to the left in the figure. The entire area in the width direction is arranged so as to face each other, and heat can be selectively generated. On the line thermal head 3 is formed a protruding portion 4 protruding downward, and on the protruding portion 4 are arranged a plurality of heat generating elements 5, 5, . . . In addition, the recording paper in this embodiment is heat-sensitive recording paper.

[0029] Above-mentioned line type thermal head 3 is supported on the thermal head installation platform 6, line type thermal head 3 and thermal head installation platform 6 are centered on the rotation axis not shown in the figure by cam (not shown in the figure)...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap