Master-auxiliary vane pump and stator decompression method

A technology of vane and vane pumps, which is applied in the field of hydraulic pumps, can solve the problems of inconvenient maintenance, high working pressure and short service life of the vanes, and achieve the effects of convenient loading and unloading, low working pressure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

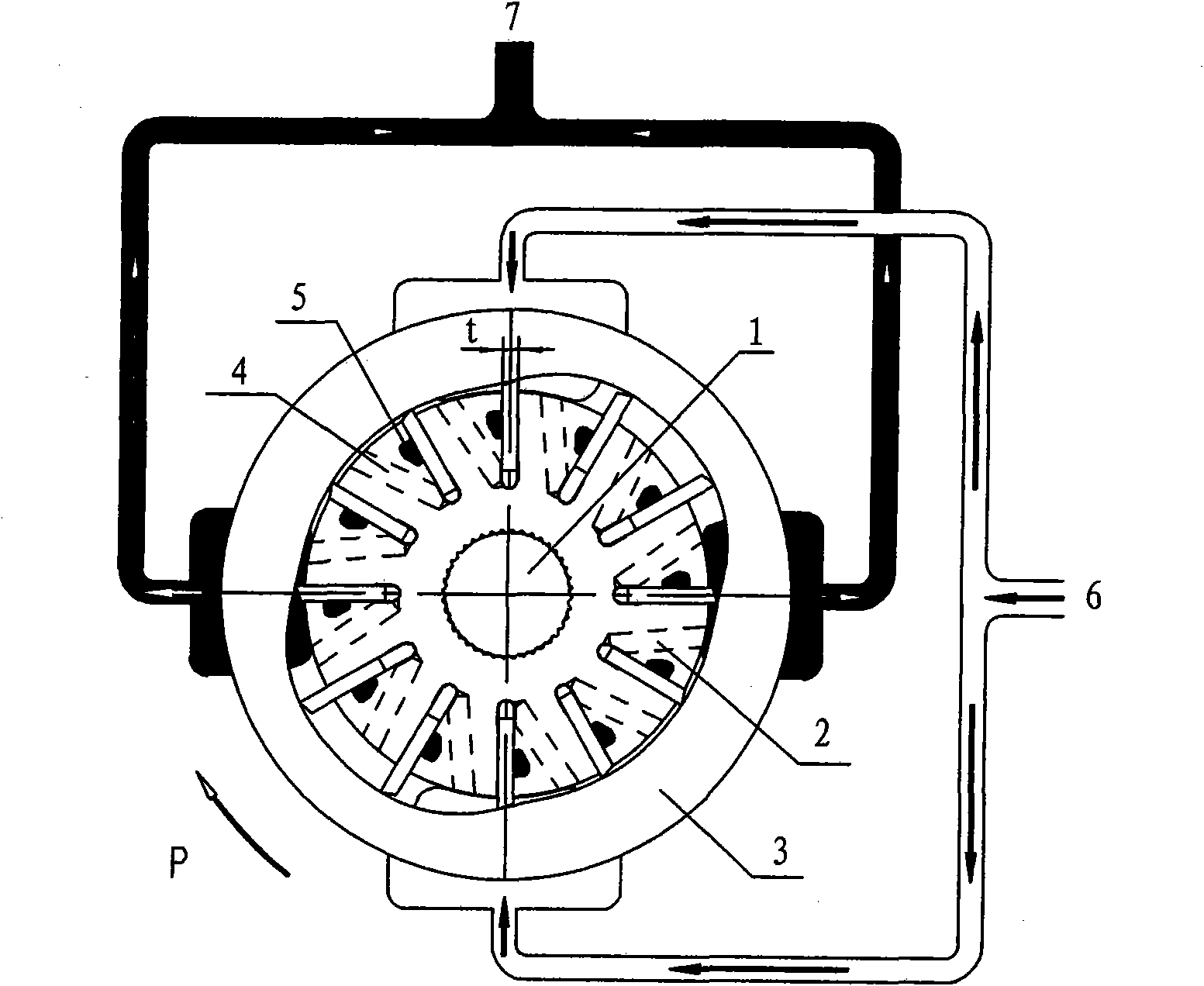

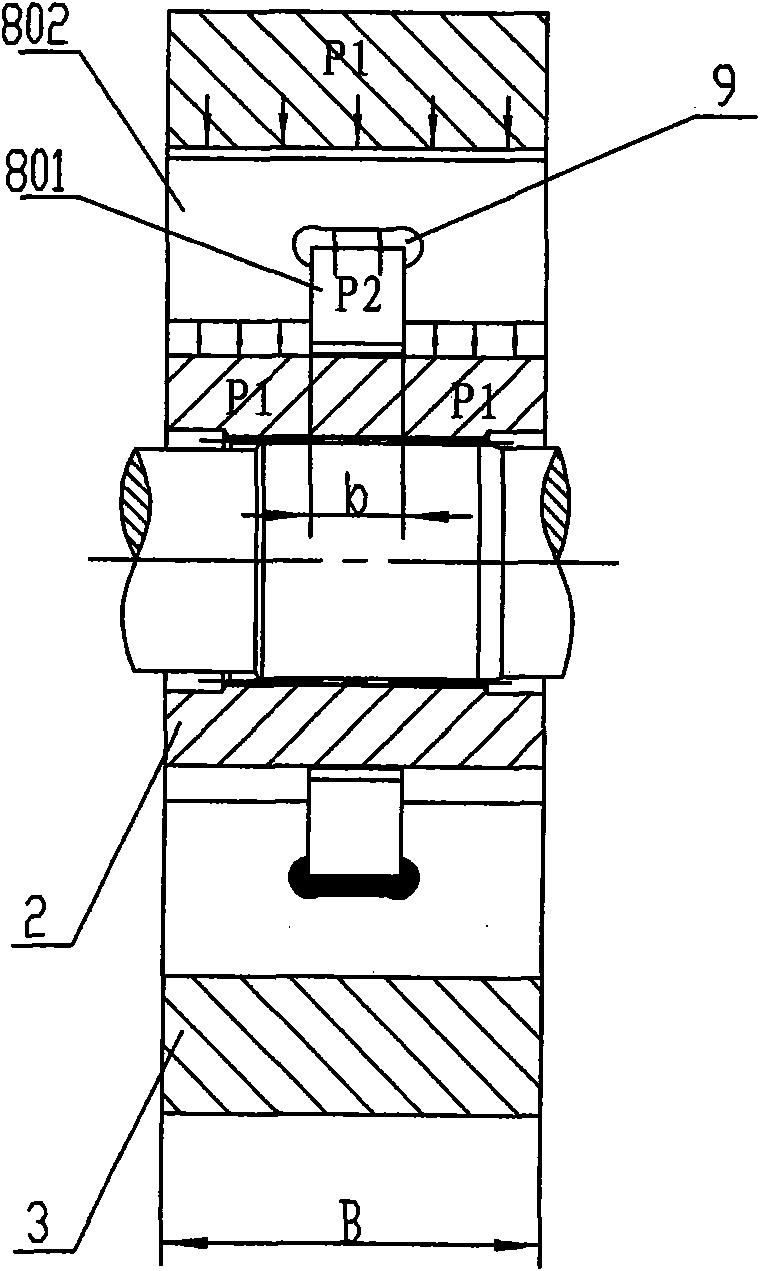

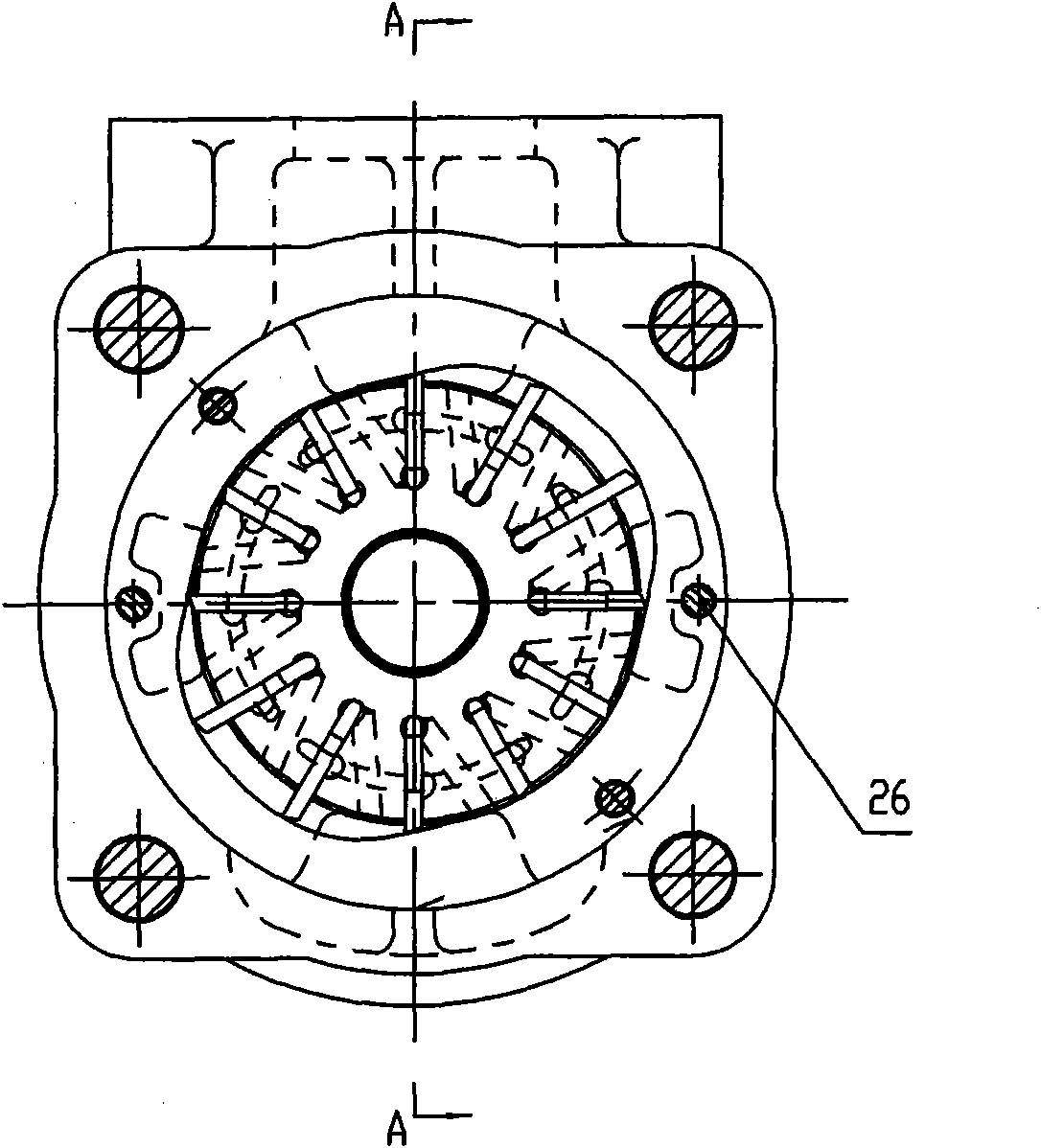

[0017] The embodiment takes the structure and working principle of the present invention as an example in conjunction with the drawings. Its structure is like image 3 , Figure 4 As shown, the front cover 16 and the rear cover 20 are connected to form a pump body, the front cover has a mounting flange surface connected to the oil pump support, and the front cover and the drive shaft are sealed with a skeleton oil seal 11. The rotor 2, the stator 3, and the daughter and mother blades 8 are clamped by screws 19 to form a pump core. The pump core and the front cover are plug-in structures, and the pump core is inserted into the pump through a pin 26. in vivo. The first PTFE retaining ring 14, the first O-ring 15, the second PTFE retaining ring 17, and the second O-ring 18 are respectively located between the front oil distribution pan and the front cover, and play a sealing role. The high and low pressure oil chambers in the pump body are separated. The transmission shaft is supporte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap