New method for regulating angle of stinger and device thereof

A stinger, a new method of technology, applied in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., can solve problems such as complex operations, avoid excessive bending moments, enhance independence, and reduce material requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention provides a new method and equipment for adjusting the angle of the stinger, and its specific operation method includes the following steps:

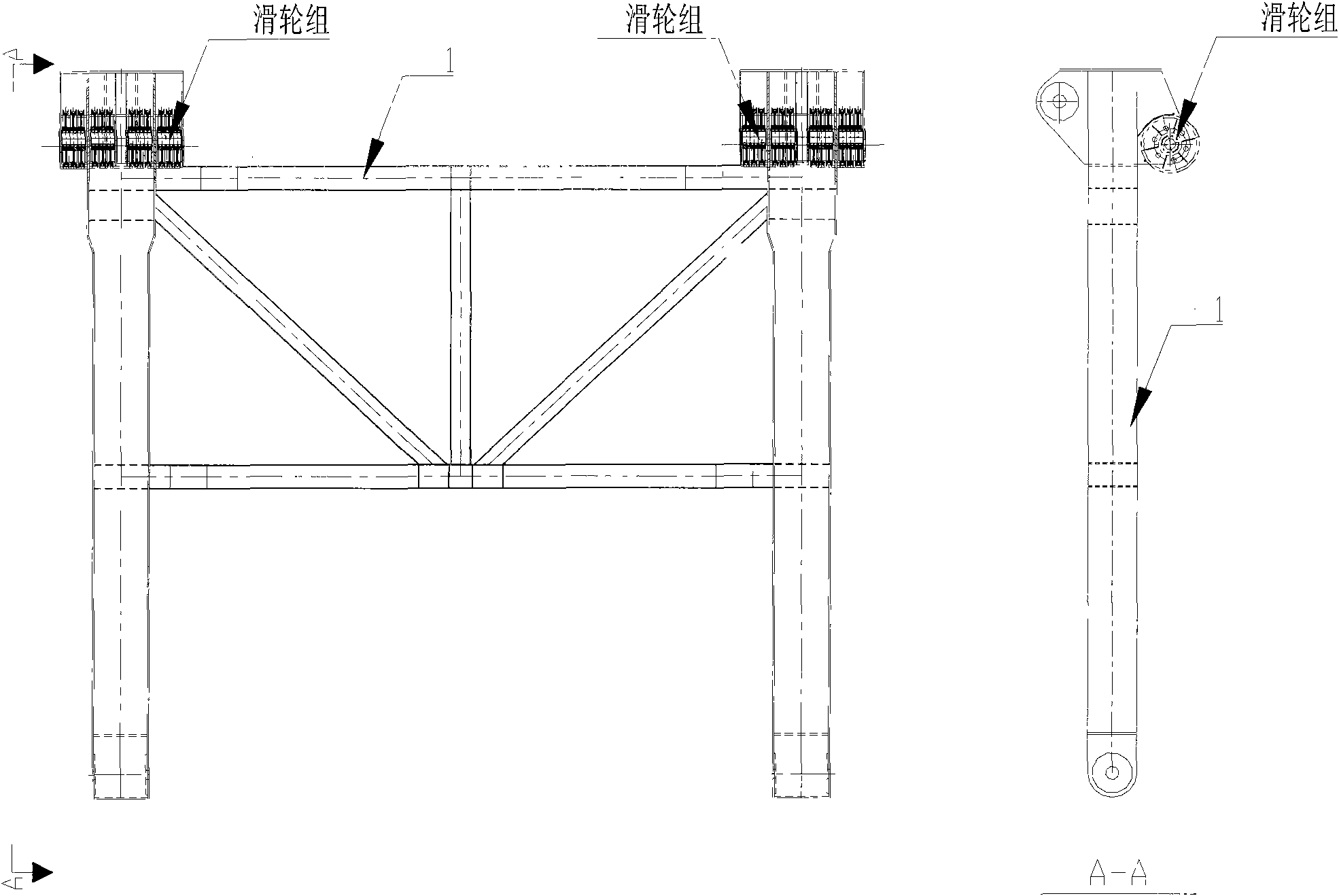

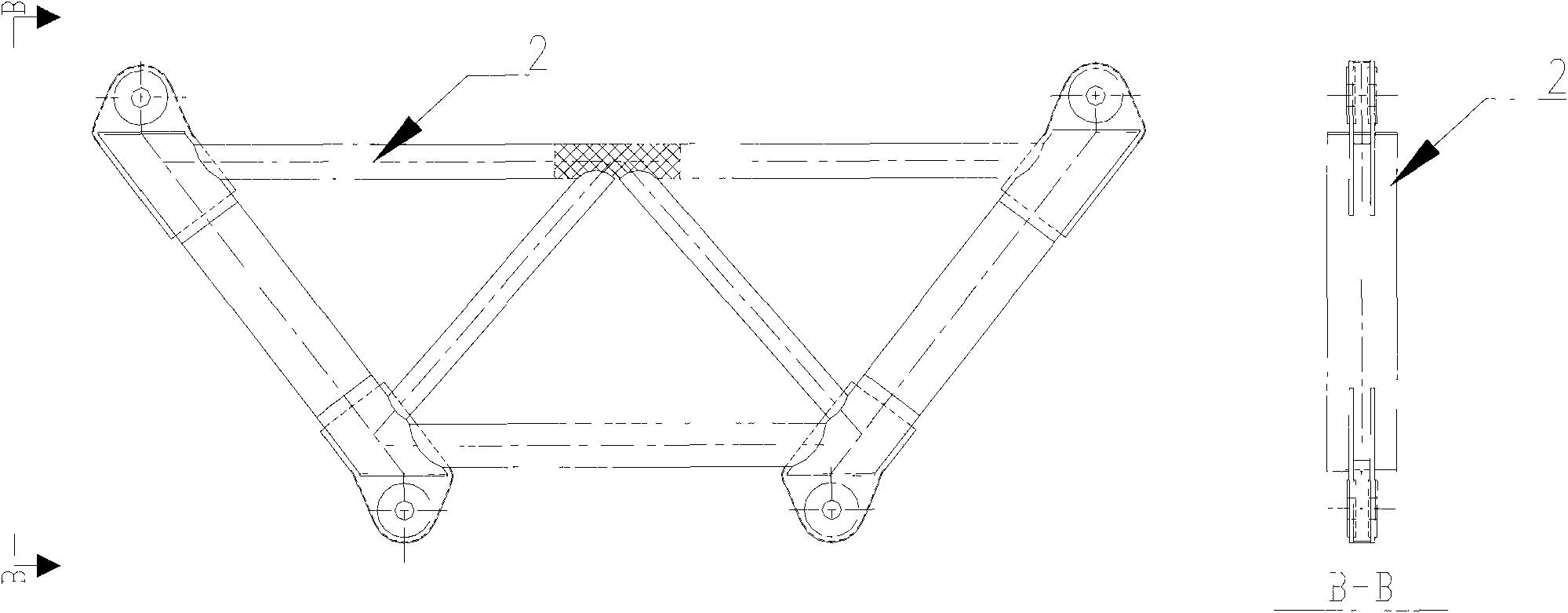

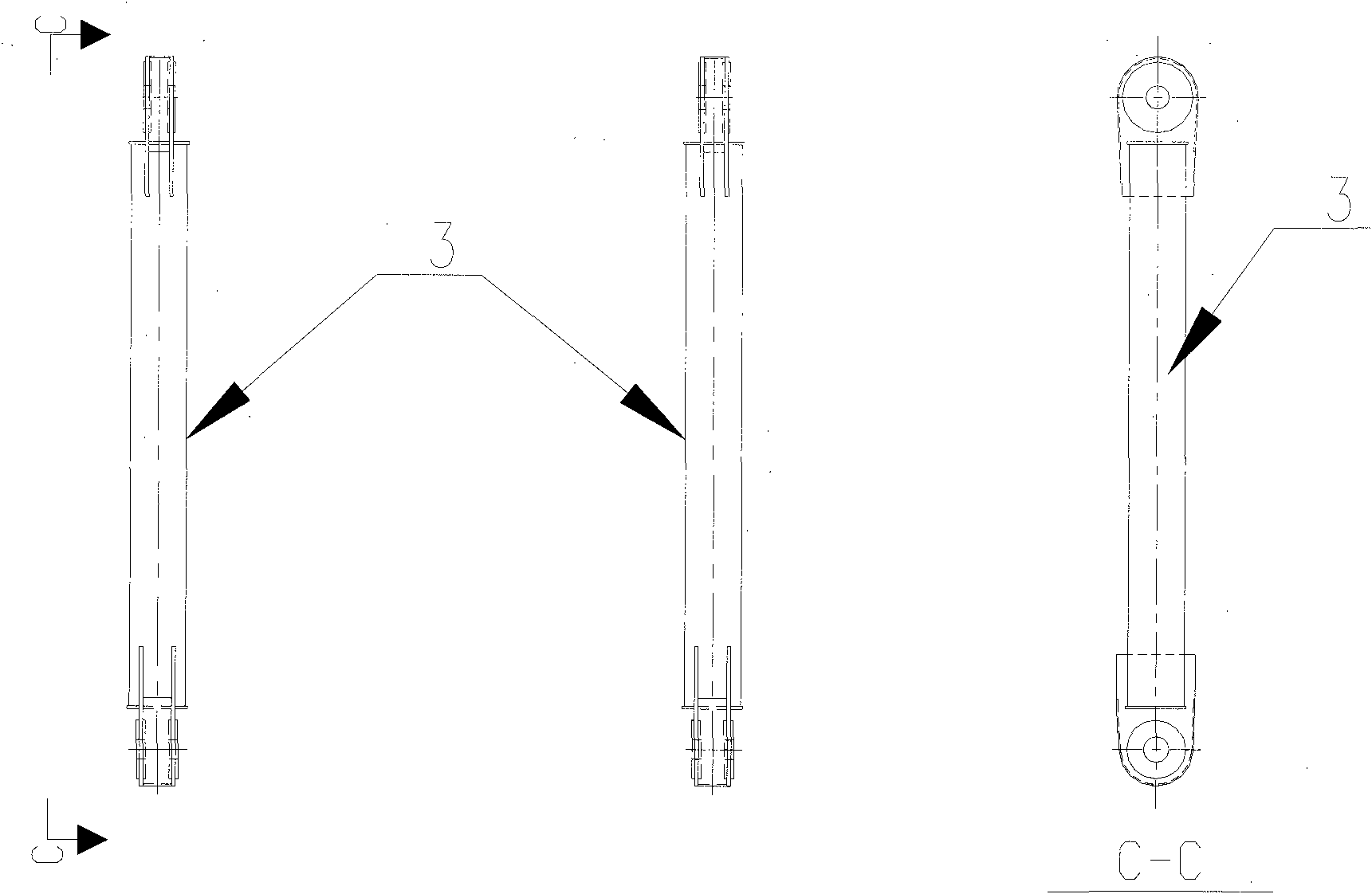

[0029] (1) Connect the reinforced structure equipped with pulley blocks, the truss structure and the connecting rod structure with lifting points that can rotate in both directions. see Figure 1-Figure 5 .

[0030] (2) Fix the structural hinge installed in (1) to the stern (bow). see Image 6 .

[0031] (3) Connect the reinforced structure equipped with the pulley block with the pulley block of the support structure at the end of the hull with cables, see Image 6 .

[0032] (4) Hoist the stinger and fix the stinger to the stern (bow). Connect the connecting rod structure with the working lifting point on the stinger. see Figure 7 .

[0033] (5) After the connection of the entire structure is completed, according to the needs of the pipe laying operation, the cables between the pulley blocks can be loosene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com