Two transmission shaft and four roller cross adjustable universal rolling mill and universal continuous rolling mill set formed by same

A universal rolling mill and transmission shaft technology, applied in metal rolling mill stands, driving devices for metal rolling mills, metal rolling stands, etc., can solve the problems of high rolling energy consumption, increased metal deformation resistance, and large width expansion and other issues to achieve the effect of structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

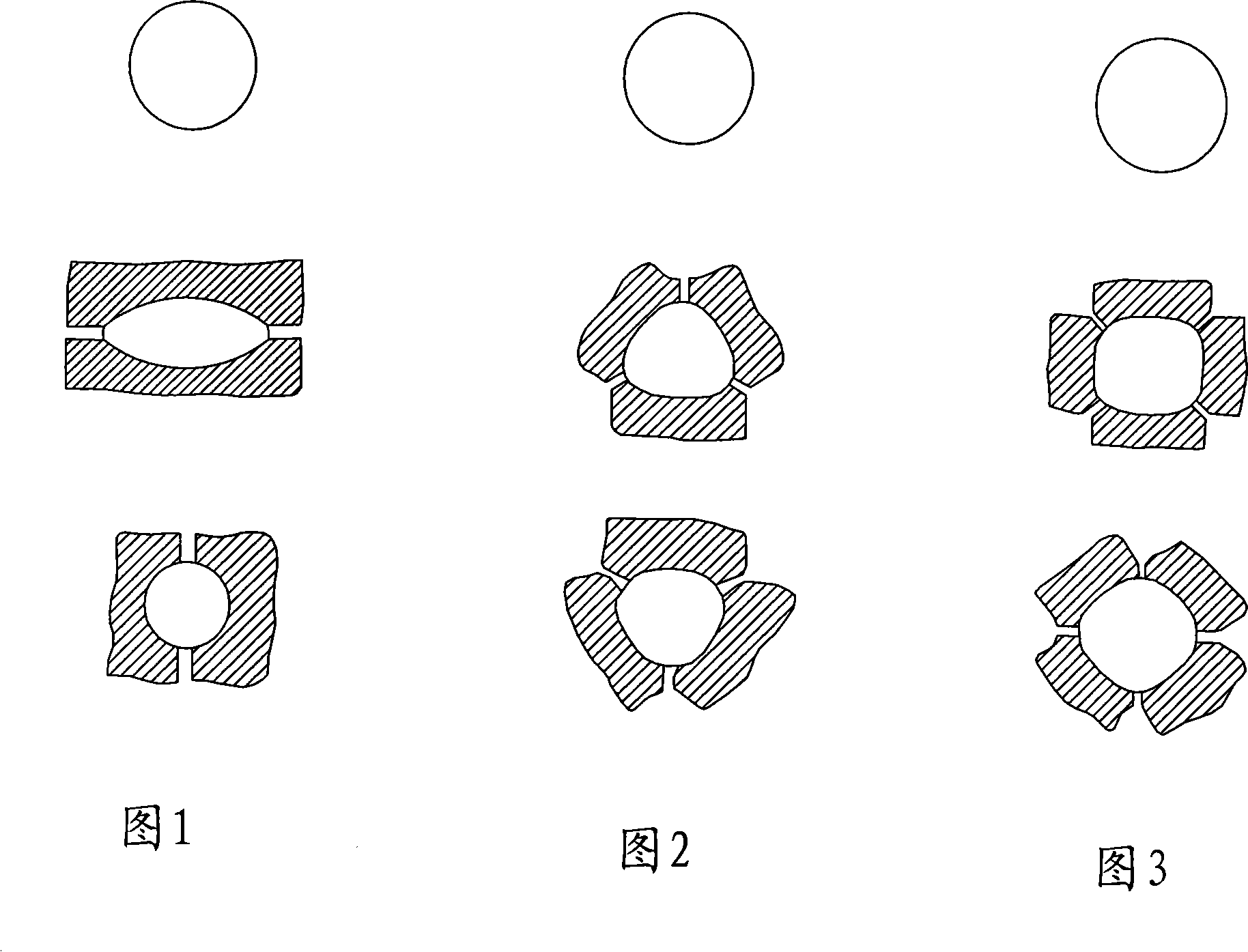

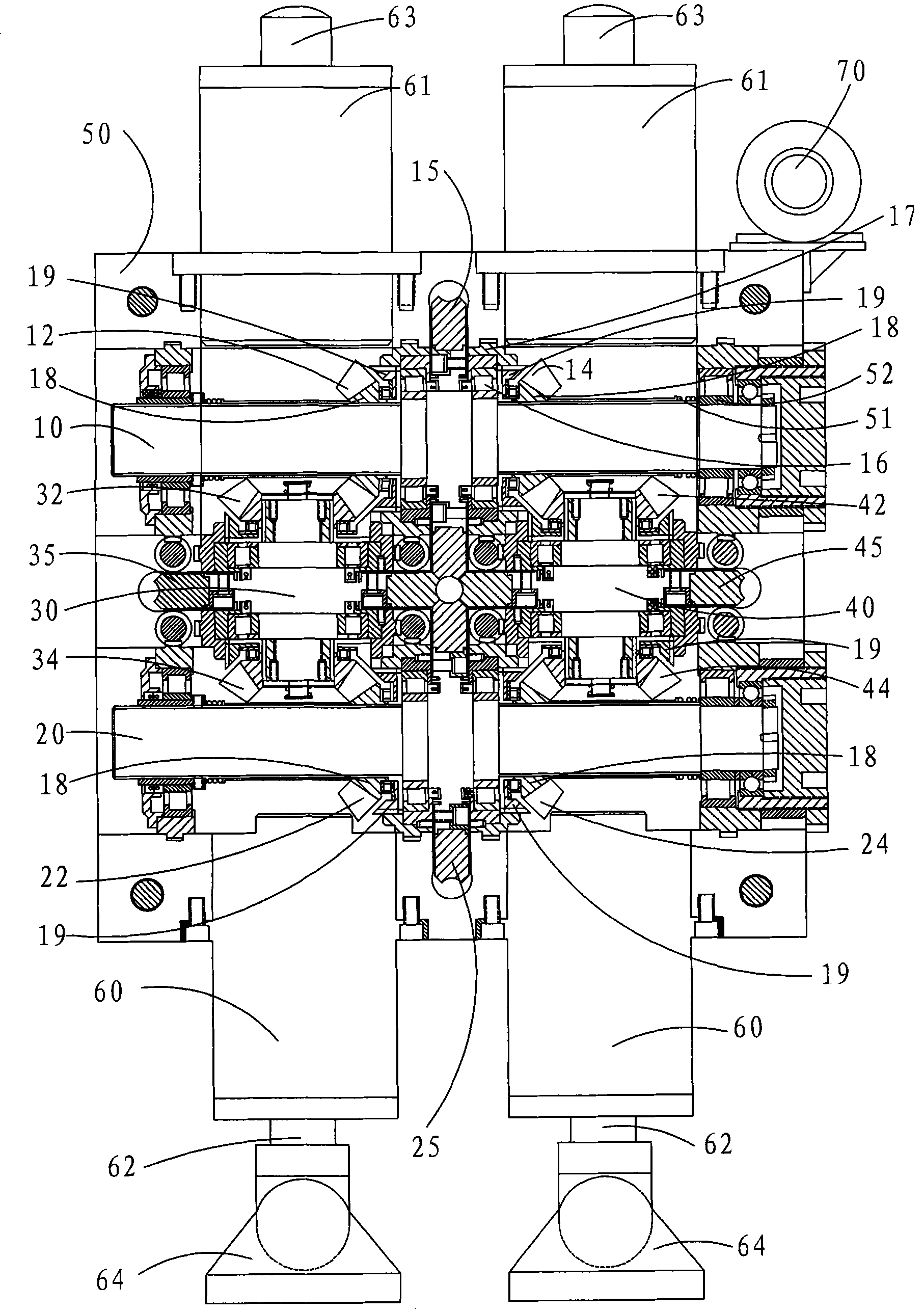

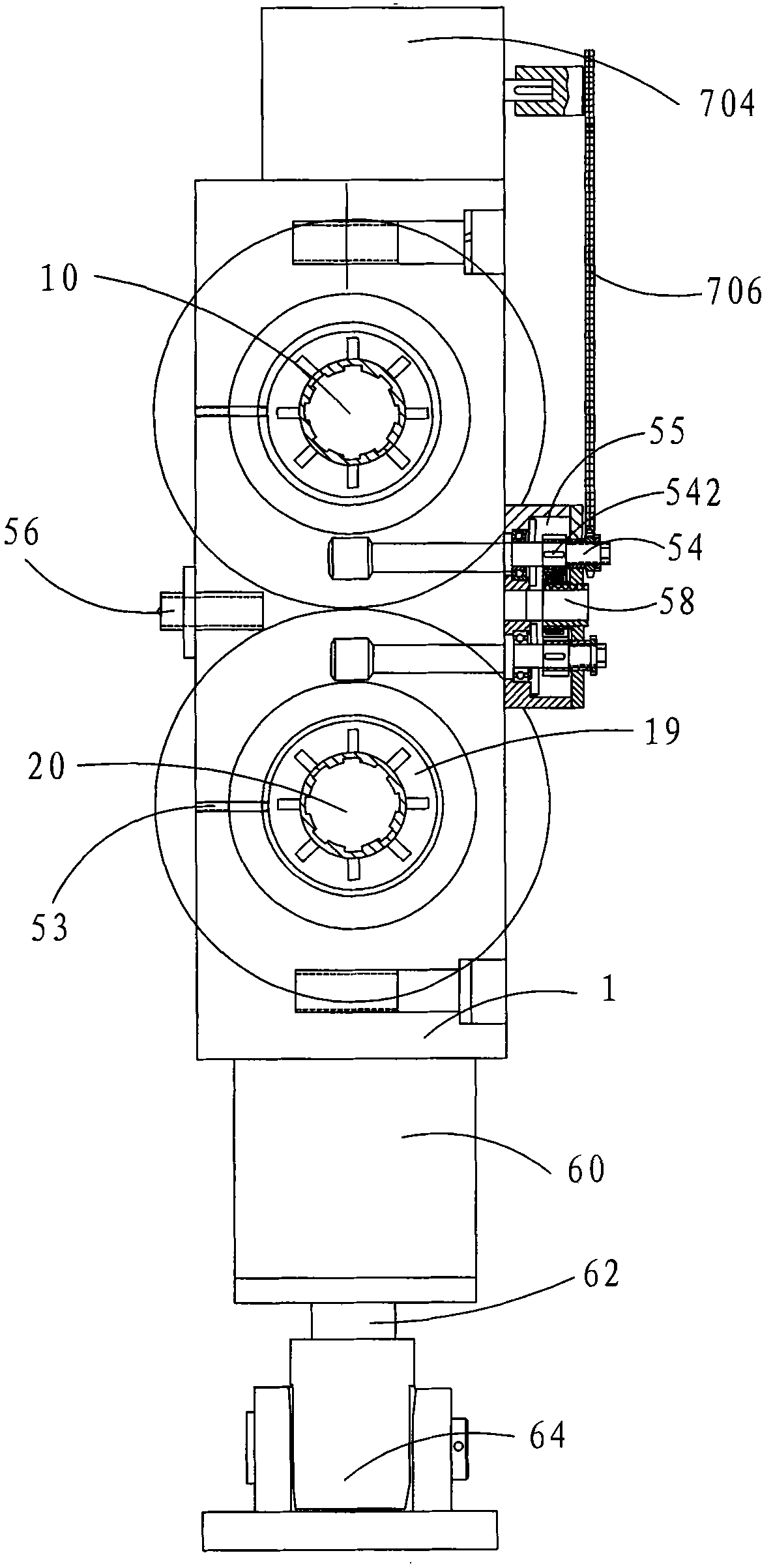

[0047] Please also see Figure 4 and Figure 5 , is the front view and the side view of the first embodiment of the double transmission shaft four-high cross type adjustable universal rolling mill of the present invention. The four-roller cross-type adjustable universal rolling mill with double transmission shafts comprises an upper transmission shaft 10, a lower transmission shaft 20, a left vertical roll shaft 30, a right vertical roll shaft 40, a frame 50, a lifting hydraulic cylinder 60, a stepping motor 70, and Roll gap synchronous adjustment device.

[0048] Left bevel gear 12 and right bevel gear 14 are respectively housed on the upper drive shaft 10, left bevel gear 22 and right bevel gear 24 are respectively housed on the lower drive shaft 20, upper bevel gear 32 is housed on the left vertical roller shaft 30 And lower bevel gear 34, upper bevel gear 42 and lower bevel gear 44 are housed on this right vertical roller shaft 40.

[0049] The left bevel gear 12 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com