Fourth axle device for processor

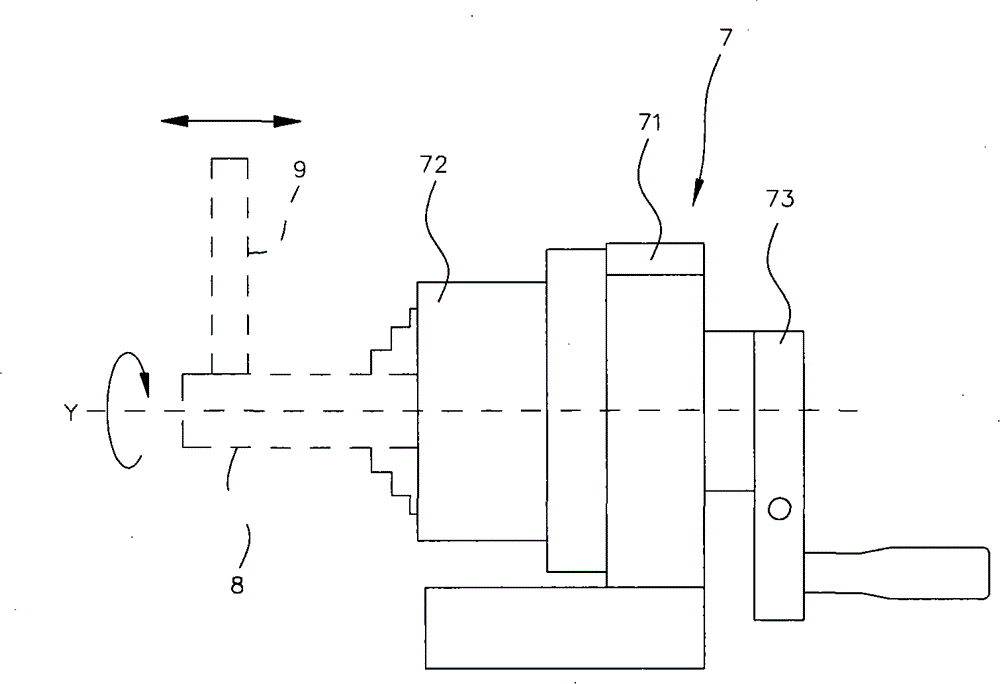

A shaft device and processing machine technology, applied in the direction of the work carrier, etc., can solve the problems of increased time cost, a large number of processing obstacles, the inability to automate the operation of the punch forming grinder 7, etc., and achieve the effect of rapid angle positioning and reduction of processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

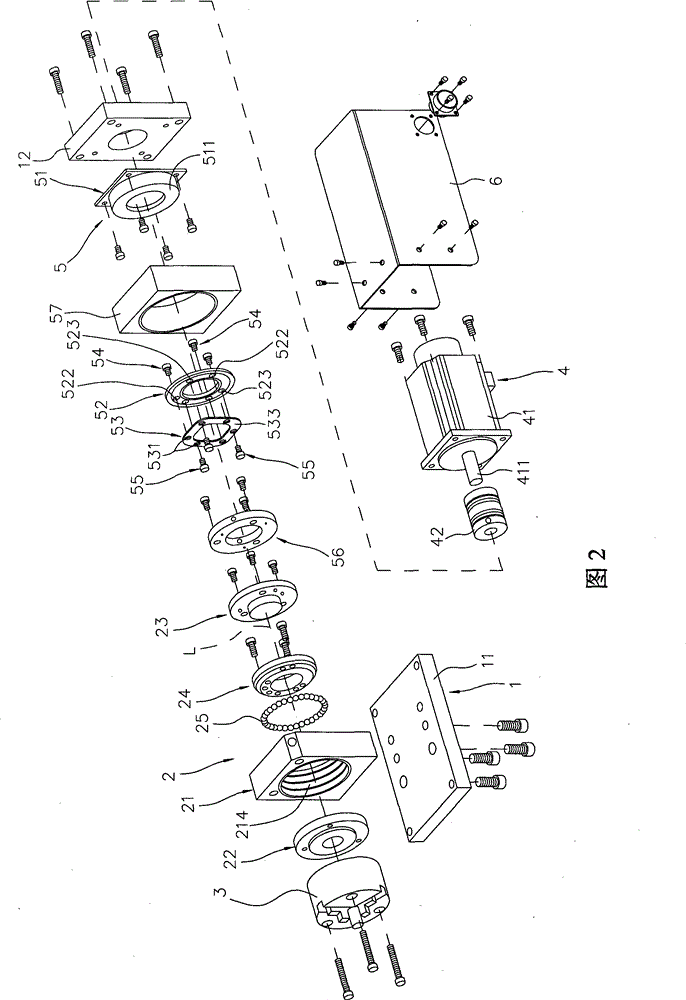

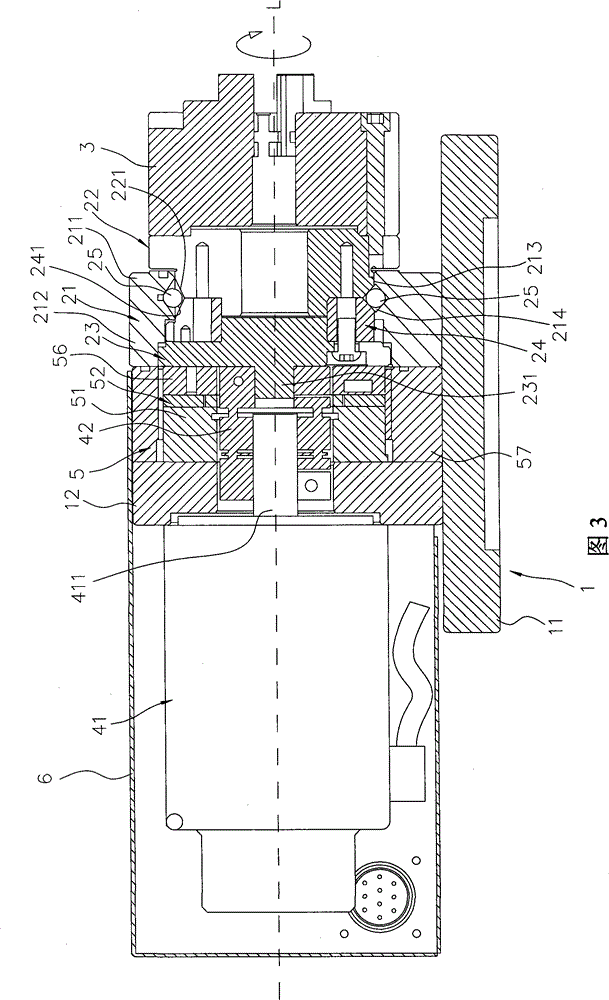

[0039] see now figure 2 and image 3 , figure 2 is a three-dimensional exploded view of the components of the embodiment of the present invention, image 3 It is a schematic cross-sectional view of the connection relationship of various components in the embodiment of the present invention. As shown in the figure, the fixing unit 1 includes a base plate 11 and a fixing base 12 disposed on the base plate 11 and between the bearing unit 2 and the driving motor 41 . The bearing unit 2 includes a hollow body 21 disposed on the base plate 11, a first face plate 22 connected to the fixture 3, and a first face plate 22 spaced apart from the first face plate 22 along an axis L direction. The second face plate 23 , a spacer plate 24 sandwiched between the face plates 22 , 23 and connected to the face plates 22 , 23 , and a plurality of rolling elements 25 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com