Heat-sealing mechanism of flat-plate-type blister packaging machine

A blister packaging machine, flat-panel technology, applied in packaging sealing/fastening, packaging, transportation packaging, etc., to achieve the effect of saving costs and reducing the weight of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

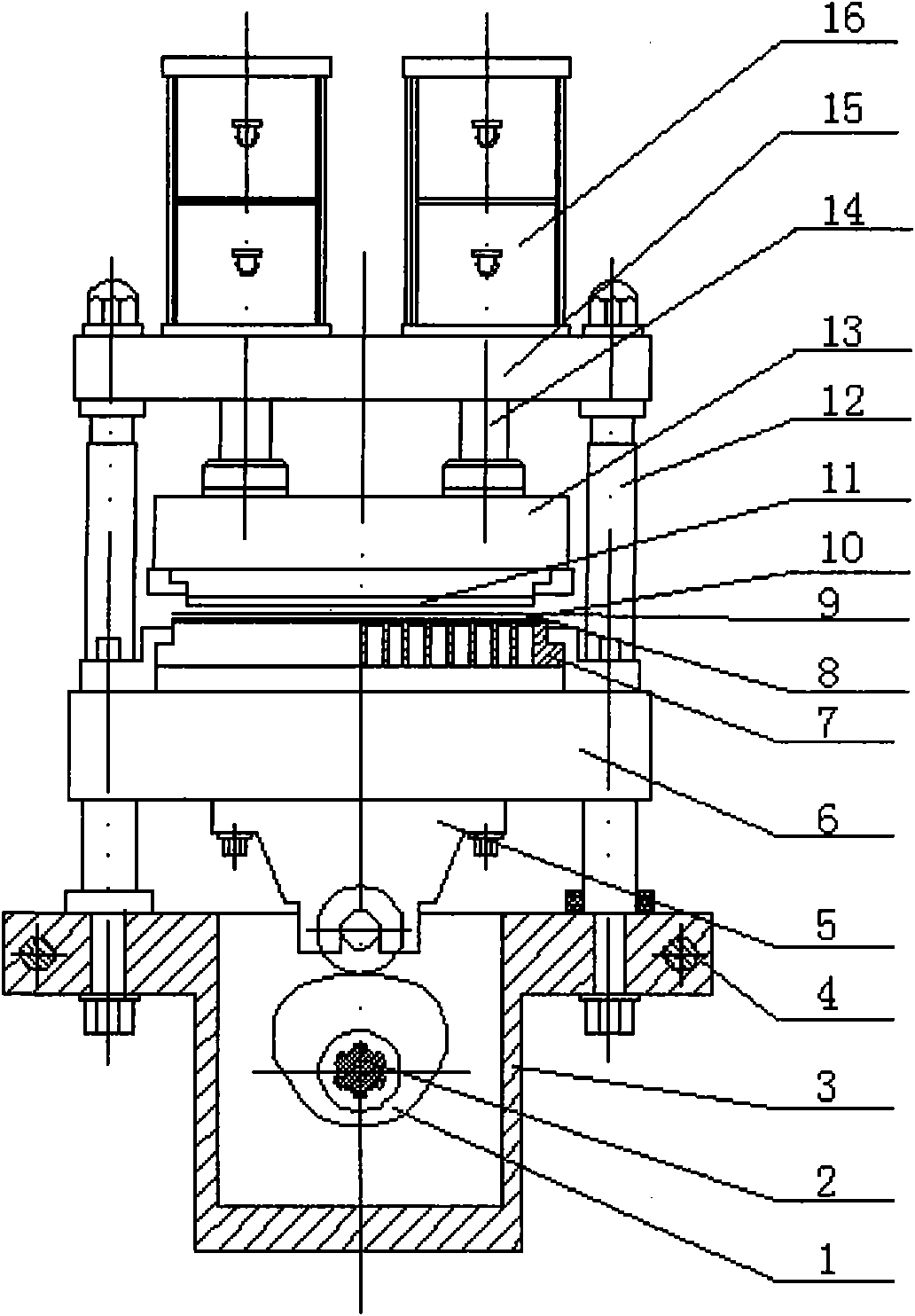

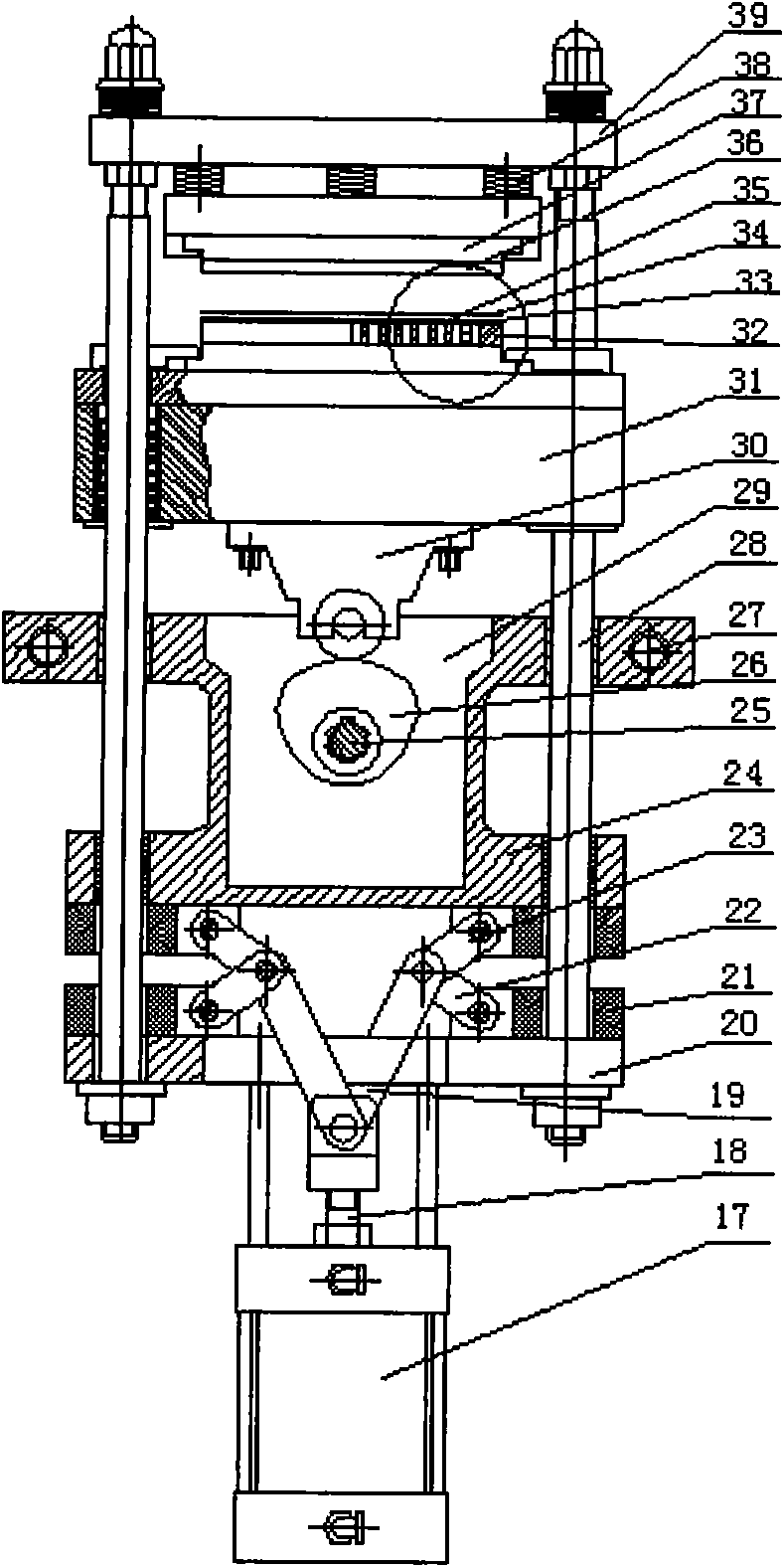

[0013] Depend on figure 2 It can be seen that the present invention includes: heat sealing cam 27, spline spindle 26, cam box 25, cam box guide rod 28, roller seat 30, lower die guide plate 31, heat sealing lower die 32, forming material PVC33, heat sealing aluminum foil 34, The blister 35 filled with medicine, the heat-sealing upper mold (anilox plate) 36, and the heat-sealing heating plate 37; also include: an up and down movement mechanism arranged at the bottom end of the cam box 25; The upper end of the lower motion mechanism is connected at the junction of a cylinder piston 18 and a pair of long connecting rods 19; the other ends of the long connecting rods 19 are respectively connected with one end of the lower connecting rod 22 and the upper connecting rod 24; The other end is fixed with a lower link seat 21 connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com