Warp knitting machine

A technology of warp knitting machine and frame, which is applied in the field of warp knitting machine and can solve the problems of high cost and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

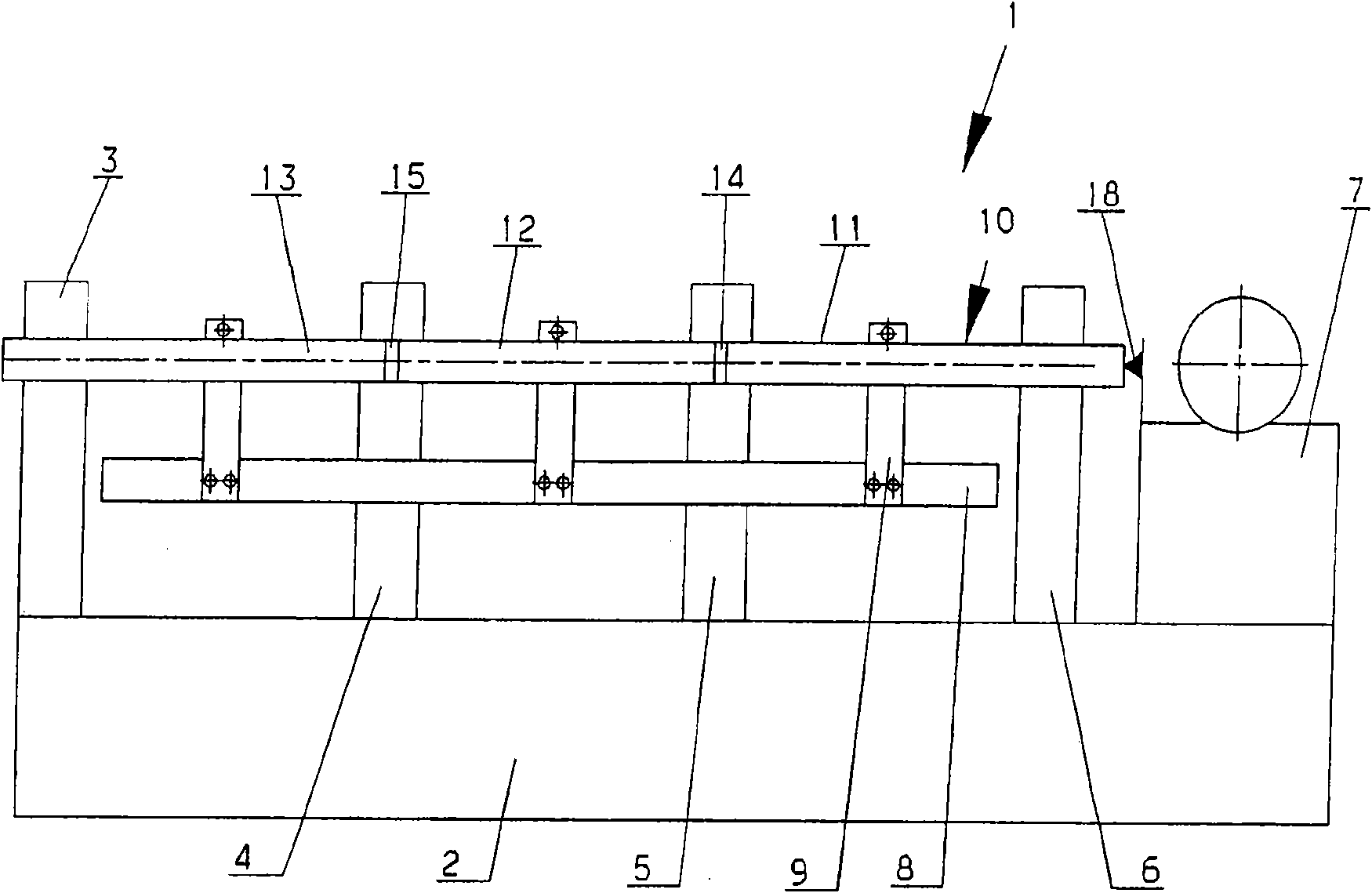

[0027] figure 1 A warp knitting machine 1 is shown very schematically, comprising a frame 2 with a plurality of supports 3-6. Here, the support plates 3 , 6 form the end-side end walls, and the support plates 4 , 5 form the intermediate plate. One end of the frame is provided with a jacquard drive 7 which is only schematically indicated.

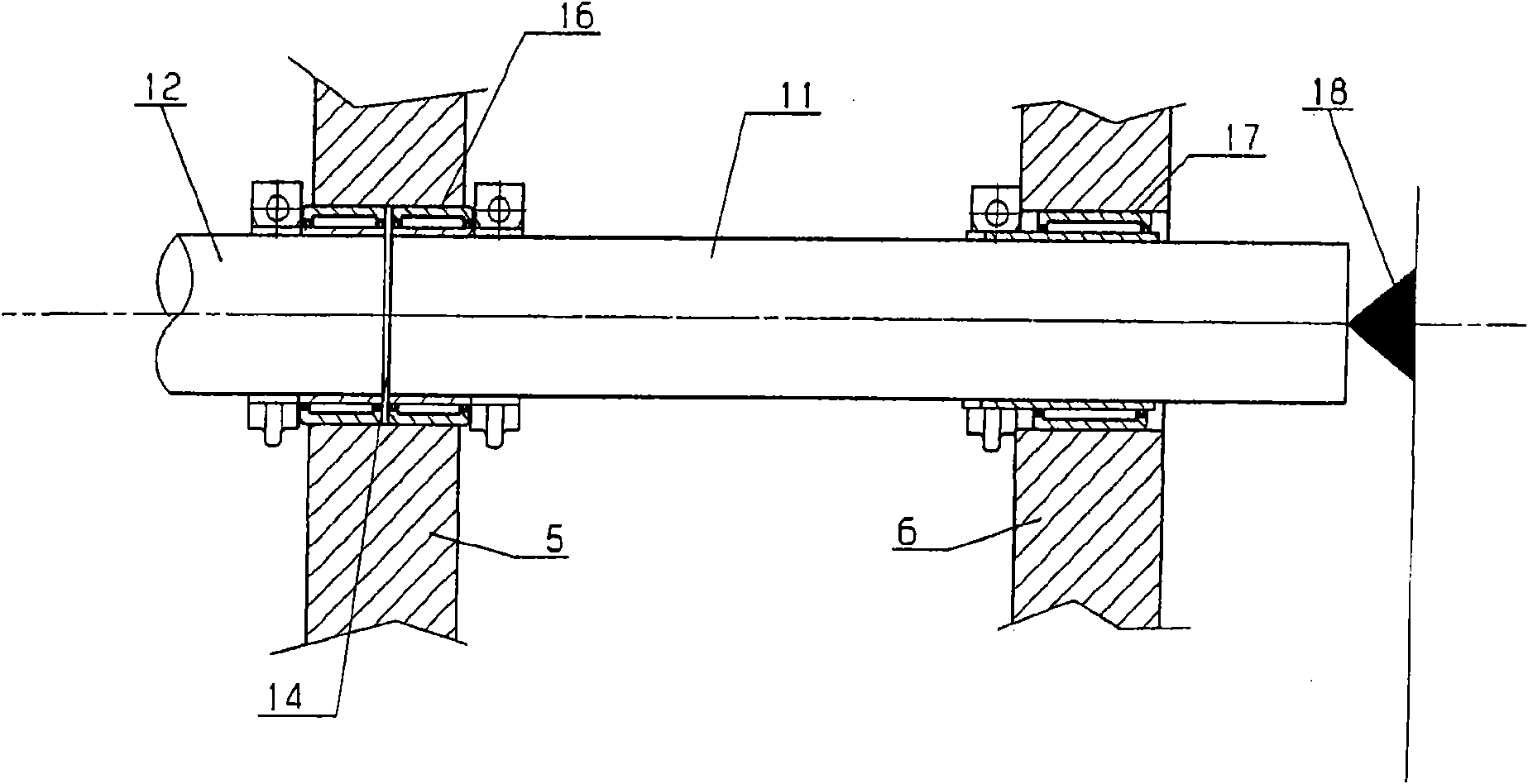

[0028] For example, the knitting tool bar 8 with guide needles, crochet needles, compound needles or other knitting tools is fixed on the support shaft 10 by the guide support rod 9 . If the support shaft 10 is rotated (a drive not shown in the figure is provided for this purpose), the guide support rod 9 is rotated and thus the looping tool bar 8 is moved in a reciprocating oscillating motion. If the looping tool bar 8 is designed as a bar, for example, the guide needles are guided through the interneedle gaps between the crochet needles during the described reciprocating oscillating movement. For this purpose, the guide rod 9 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com