Vertical type vibratory molding process for concrete tube of lining type prestressed steel cylinder

A technology of vertical vibration forming and prestressed steel, which is applied in strengthening forming, ceramic forming machines, manufacturing tools, etc. It can solve the problems of high labor intensity, low work efficiency, long time for concrete feeding and centrifugal forming, and achieve labor intensity Small size, high production efficiency, and the effect of shortening the compacting molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

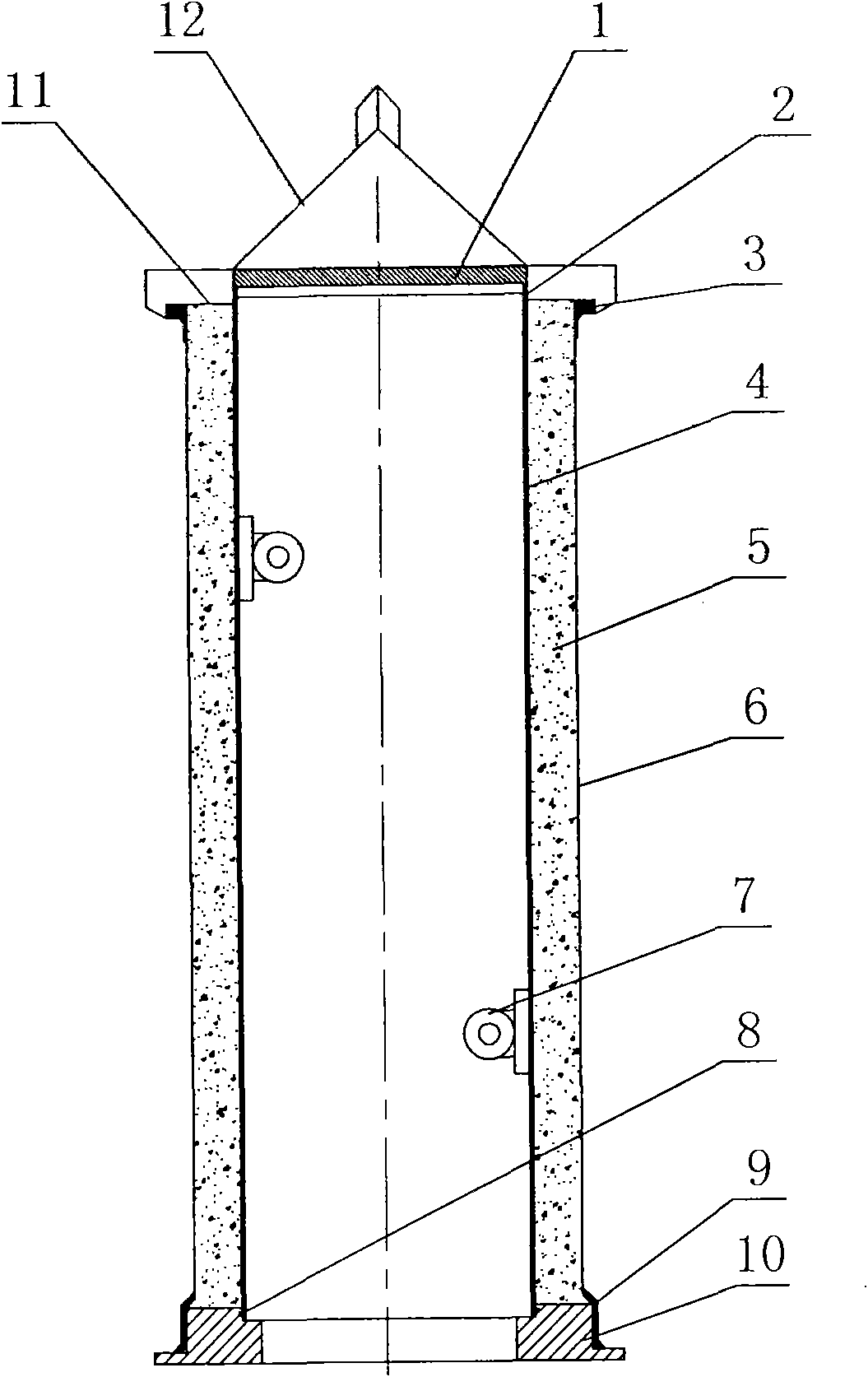

[0016] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

[0017] As shown in the figure, the vertical vibration molding process of the lined prestressed steel cylinder concrete upper pipe according to the present invention uses a vertical mold to pour and vibrate to form. The vertical mold consists of a bottom mold 10, a cylindrical core mold 4 and a top mold. Module 1 constitutes. The outer diameter of the mandrel 4 is 1000mm, the bottom mold 10 and the top mold 1 are respectively provided with a mandrel holder 8 and a mandrel snap ring 2, and the mandrel 4 is assembled on the mandrel holder 8 and the mandrel snap ring 2 , the outer side of the core mold snap ring 2 on the top mold 1 is provided with a steel cylinder socket snap ring 3, and a blanking port 11 is provided between the mandrel snap ring 2 and the steel tube socket snap ring 3, and the top mold 1 corresponds to the blanking port 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com