Steel roof system

A technology of steel roof and steel roof truss, which is applied to roofs, joists, girders, etc., and can solve the problems of large steel consumption and small spans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

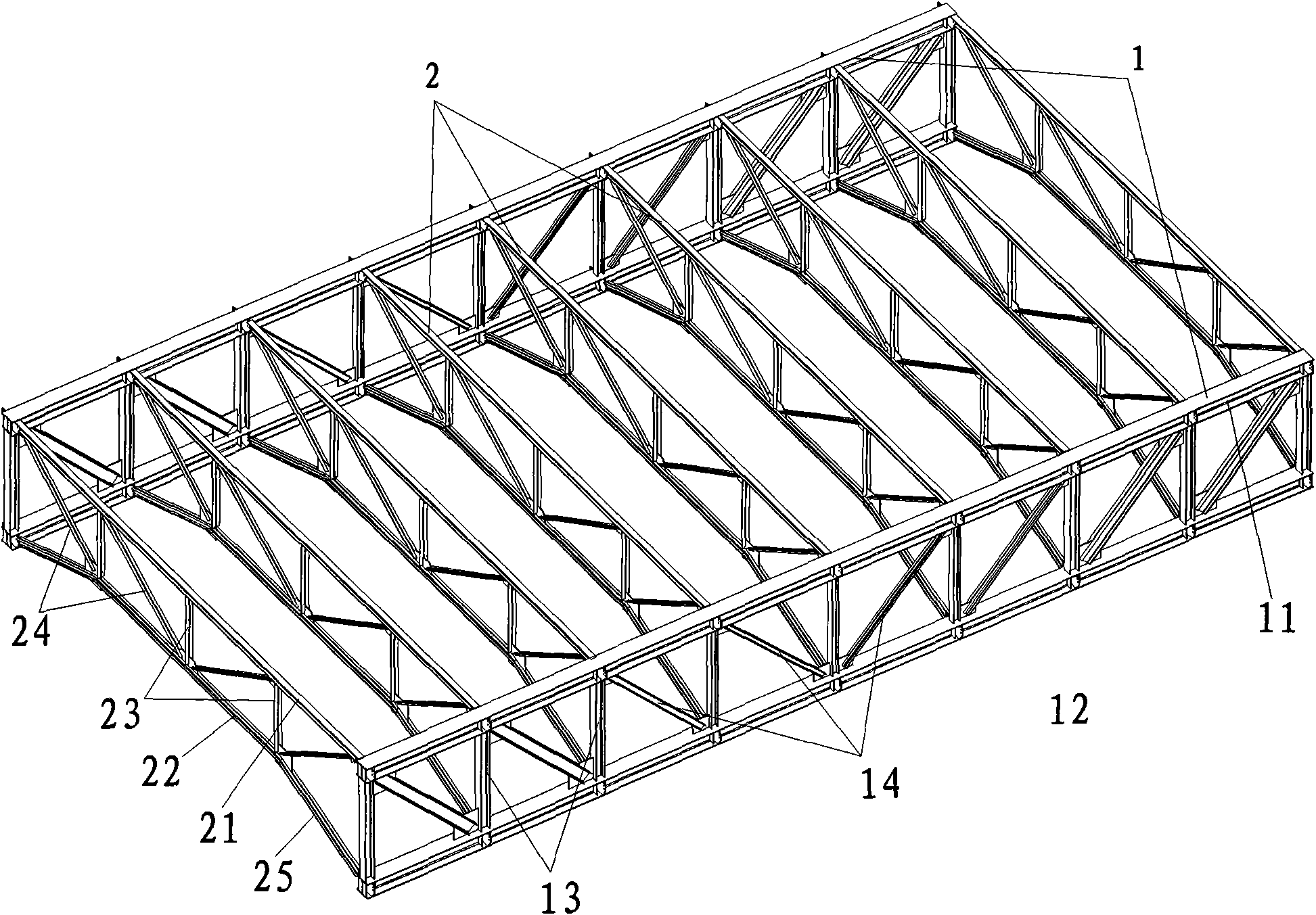

[0053] In order to solve the economic rationality of the amount of steel used in the steel roof system, realize the arbitrary arrangement of the lifting points and the unrestricted span design of the steel roof system, the embodiment of the present invention designs and provides a steel roof truss with parallel chords and parallel chords. Steel roof system made of trusses.

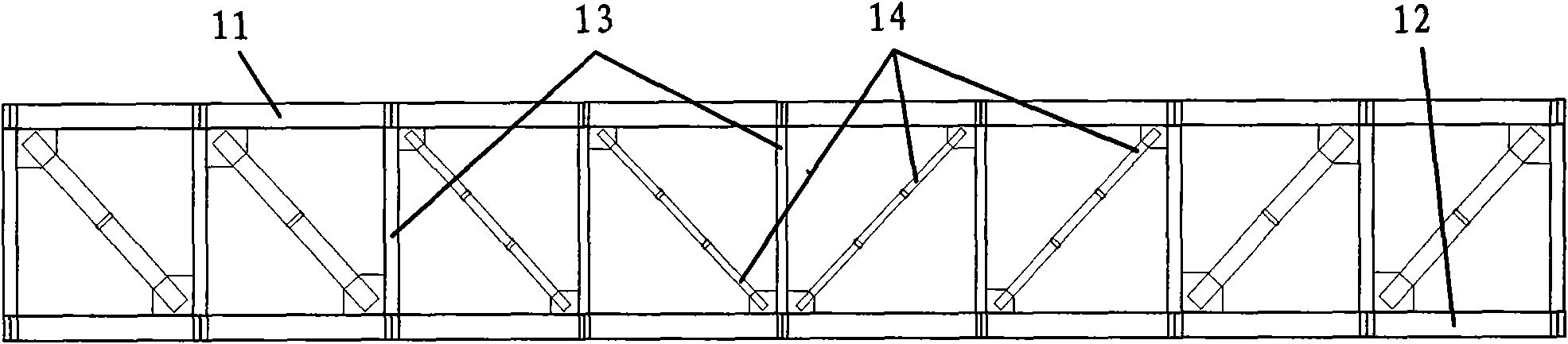

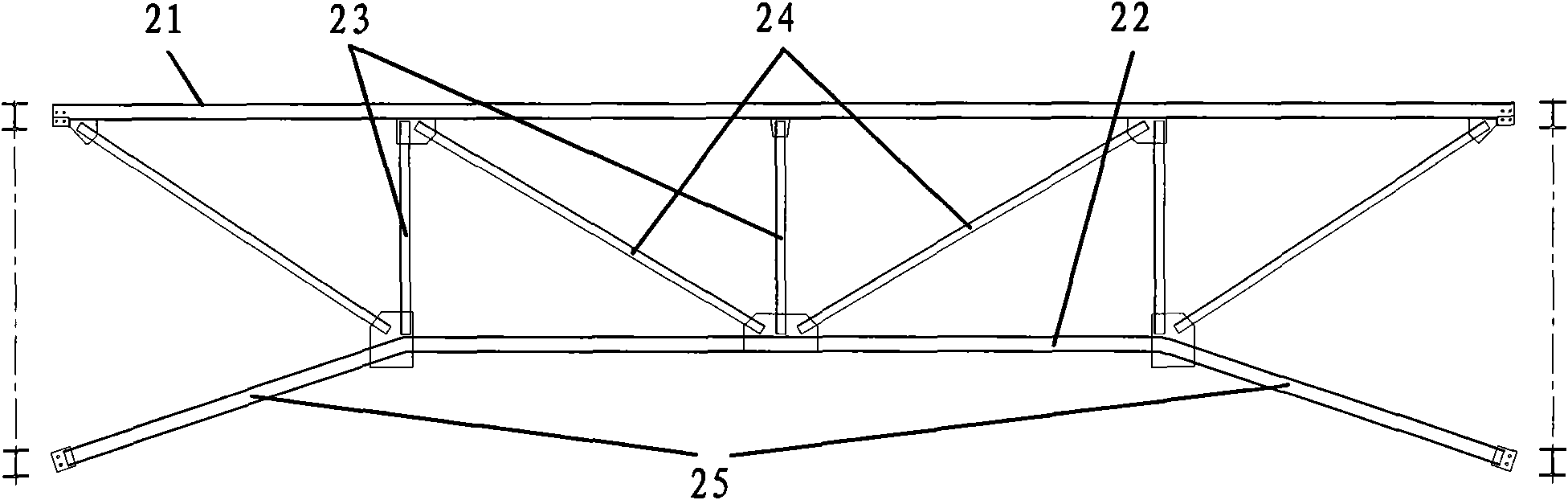

[0054] The steel roof system comprises: at least two parallel chord steel roof trusses and parallel chord trusses connecting adjacent two parallel chord steel roof trusses. The parallel chord truss is a steel truss with a parallel chord structure, which is used as the connection structure of the steel roof system, also known as the connection truss. Preferably, at least two parallel chord trusses are arranged between every two adjacent parallel chord steel roof trusses. For example: figure 1 The steel roof system shown in takes two parallel chord steel roof trusses 1 and several parallel chord trusses 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com