Measuring method and instrument used for assembling and installing locomotive gear cases

A measurement method and gearbox technology, applied in the direction of mechanical thickness measurement, mechanical clearance measurement, etc., can solve the problems of deformation stress on the inner side of the gearbox, uneven force on the side of the gearbox, affecting the service life of the gearbox, etc., to meet the design requirements requirements, avoid additional stress, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

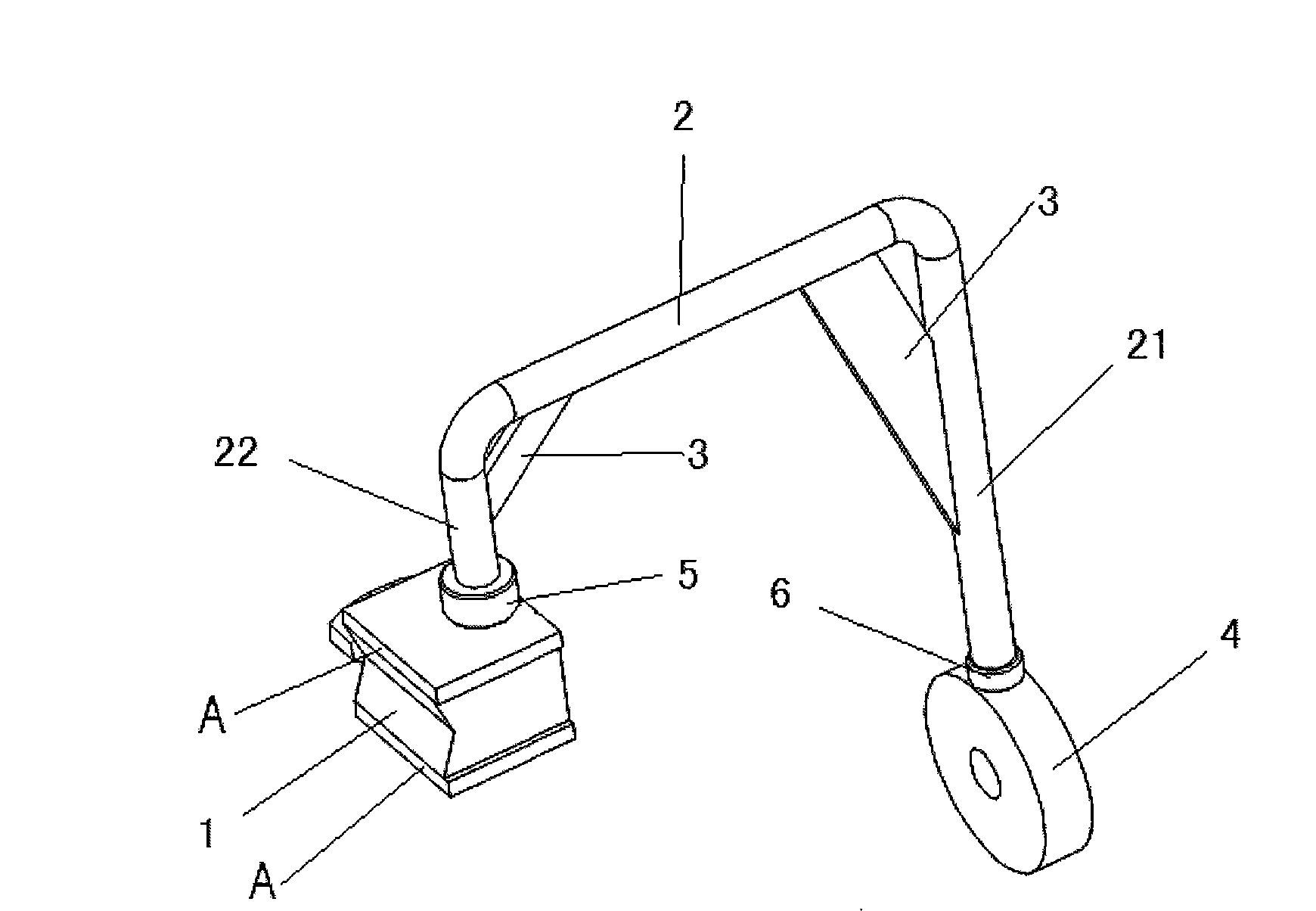

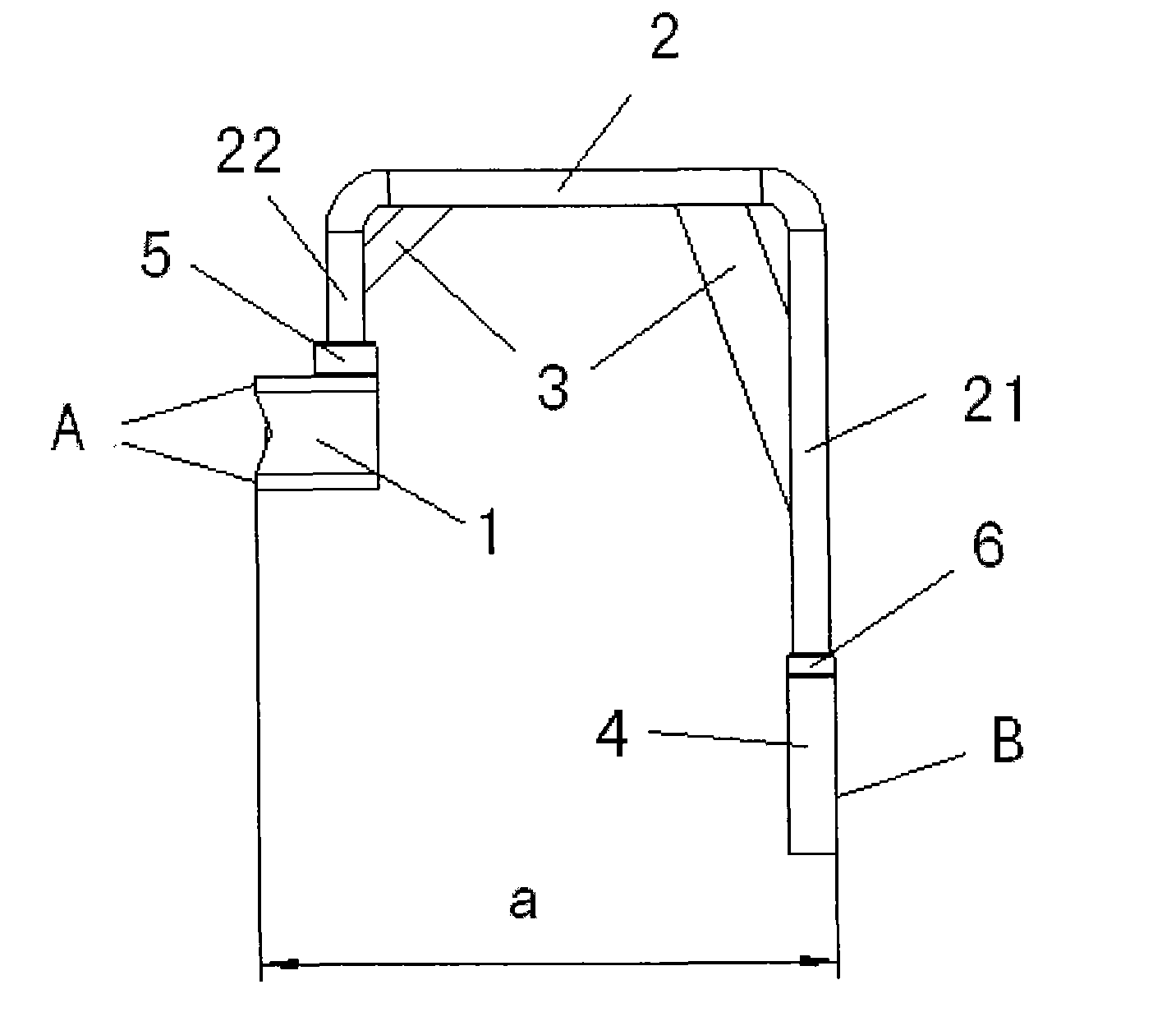

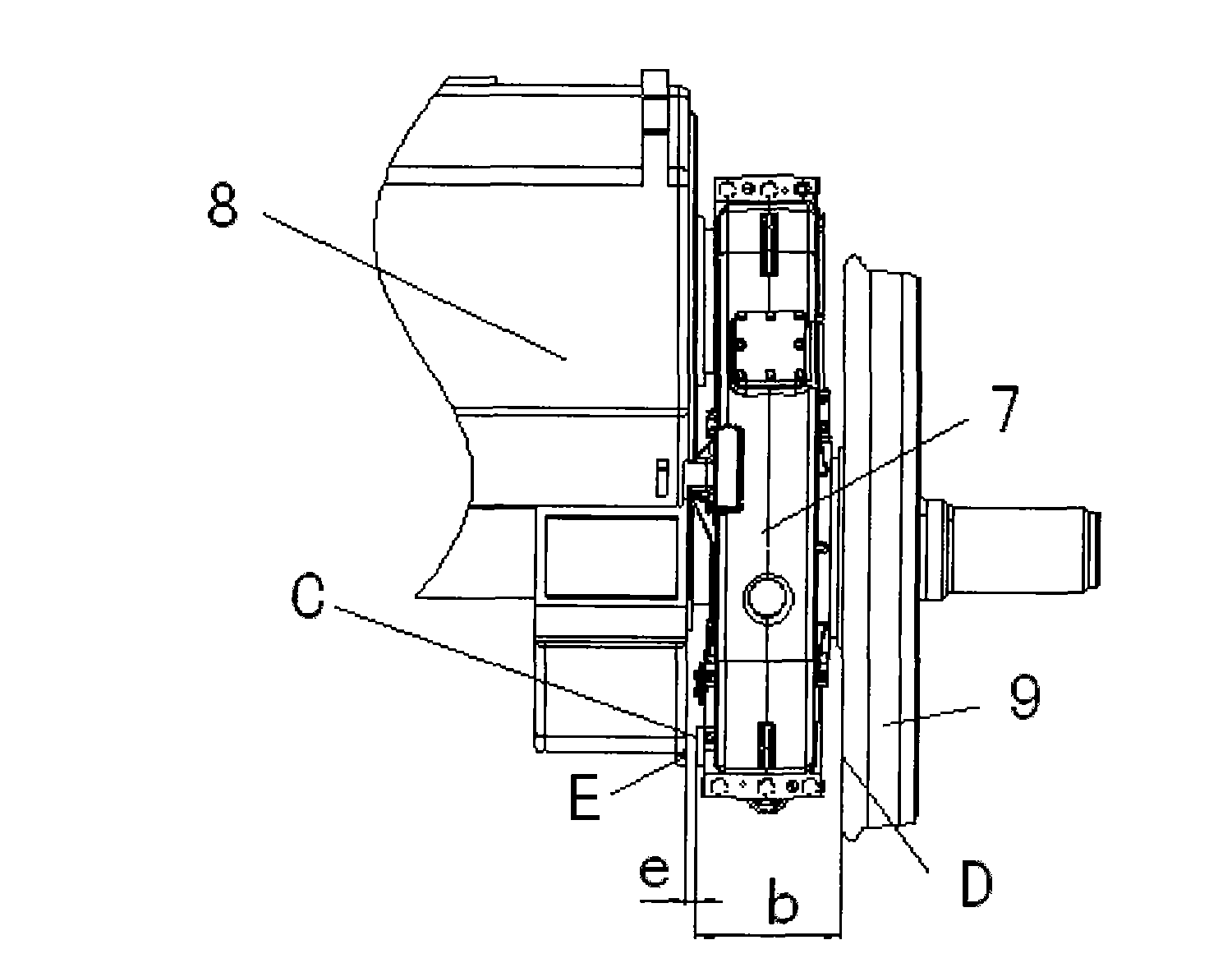

[0018] Such as figure 1 As shown, the method of the present invention is based on the following understandings: because the locomotive gear box and the axis of the axle are vertical in theory; and the inner surface of the locomotive wheel is to ensure that it is perpendicular to the axis of the axle, generally after the wheels of the locomotive are assembled on the axle. The inside of the wheel is machined. Therefore, in the actual measurement process, the inner surface of the wheel can be taken as a measurement reference, the magnetic meter seat of the present invention is adsorbed on the inner surface of the wheel, and the distance between the outer surface of the measuring steel ring of the present invention and the plane connecting the gear box of the motor is directly measured. , to indirectly obtain the distance from the four planes where the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com