Array substrate and repairing method

A technology of array substrates and common electrode lines, applied in optics, instruments, electrical components, etc., can solve the problem of frequent laser welding times, reduce the times of laser welding and laser cutting, improve repair rhythm, and save man-hours. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

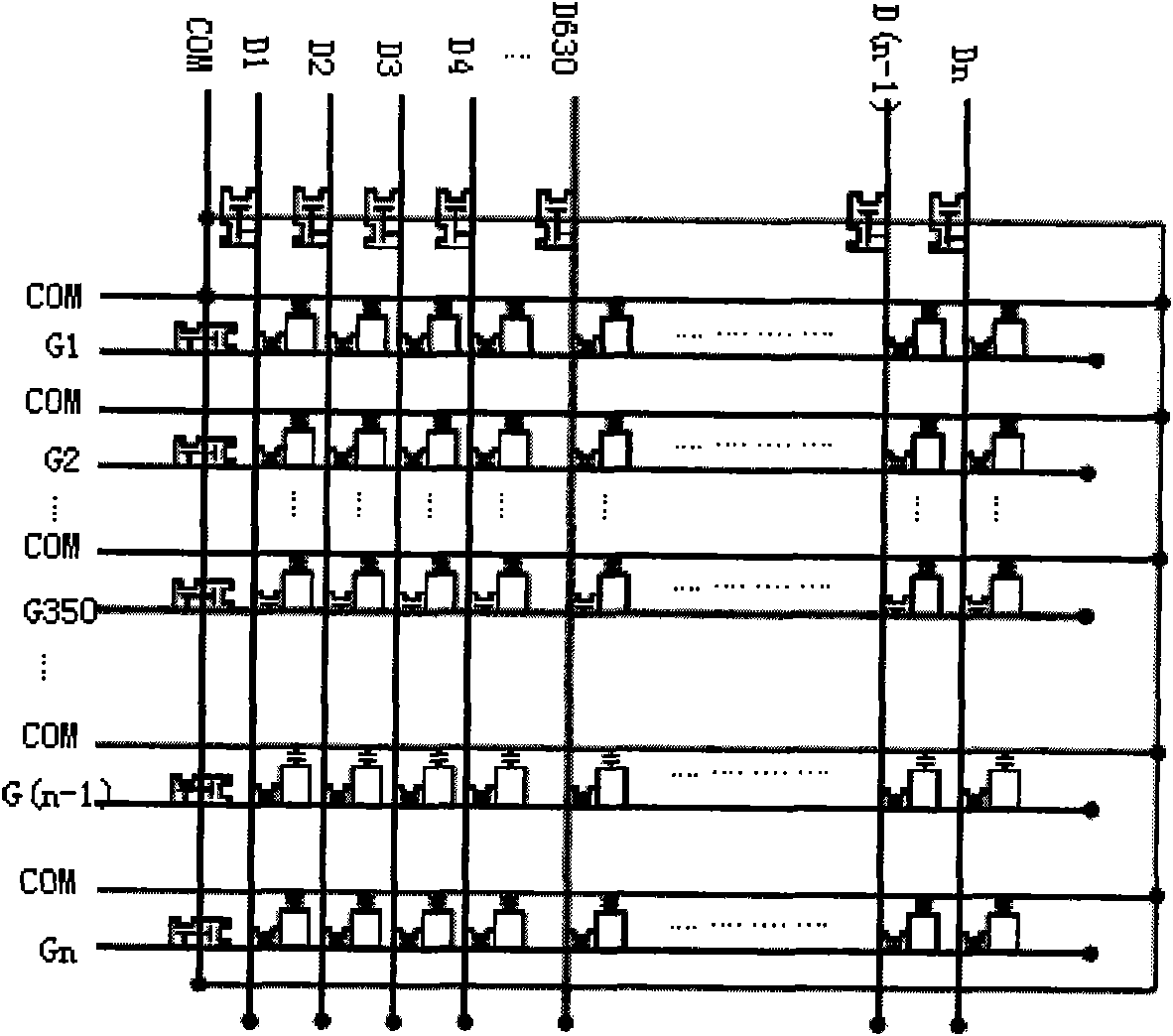

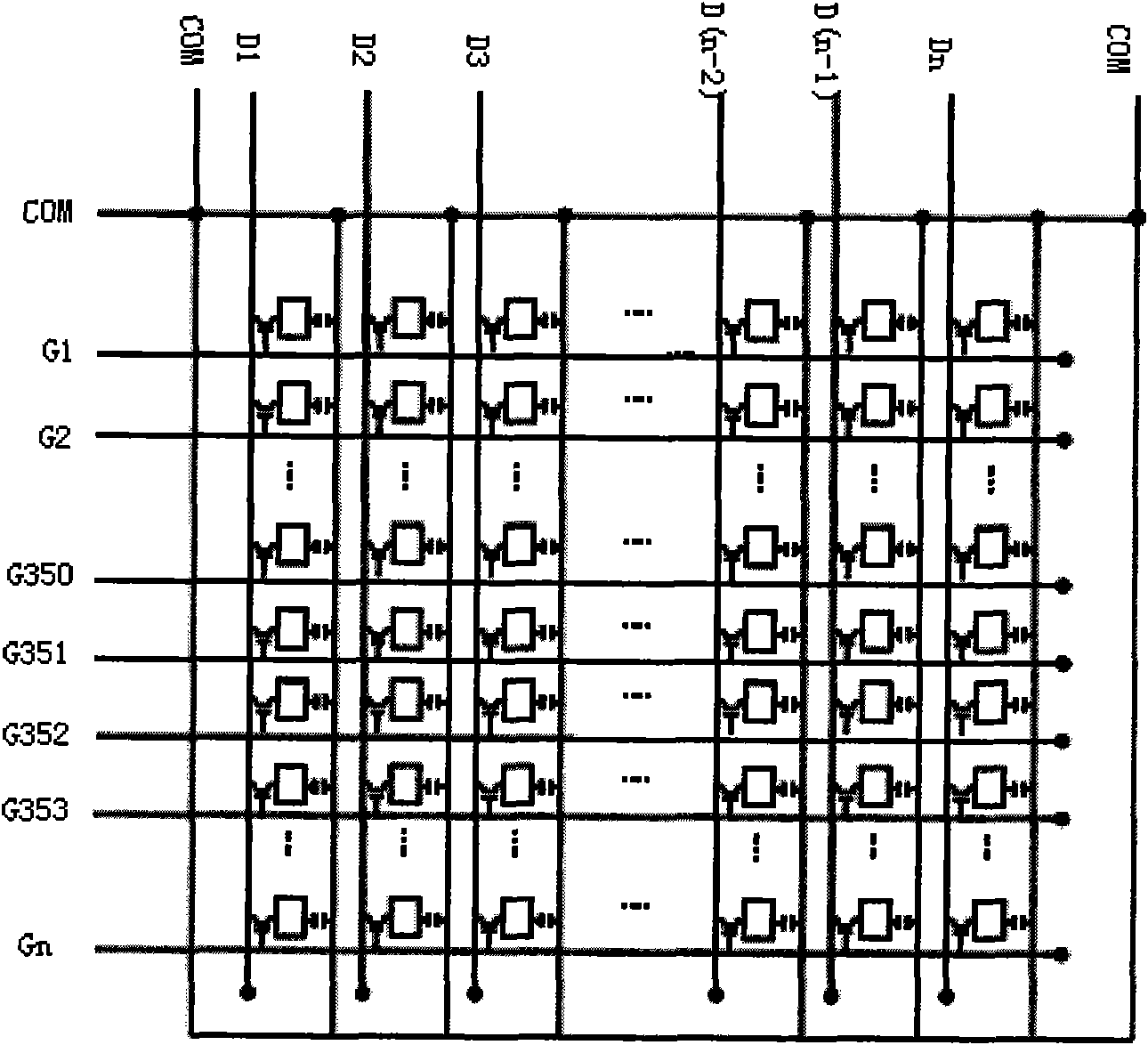

[0030] In order to solve the above defects in the prior art, the present invention provides an array substrate, in which each data line corresponds to a first common electrode line, and each first common electrode line is provided with a The second common electrode lines that are connected to each other, and all the common electrode lines and data lines are made of the same layer of metal, and the second common electrode lines are used as repair lines through laser welding and laser cutting, which can repair the corresponding broken lines. The data line is repaired, and at the same time, it can avoid the display failure caused by the existing cutting or passing through the surrounding common electrode pattern.

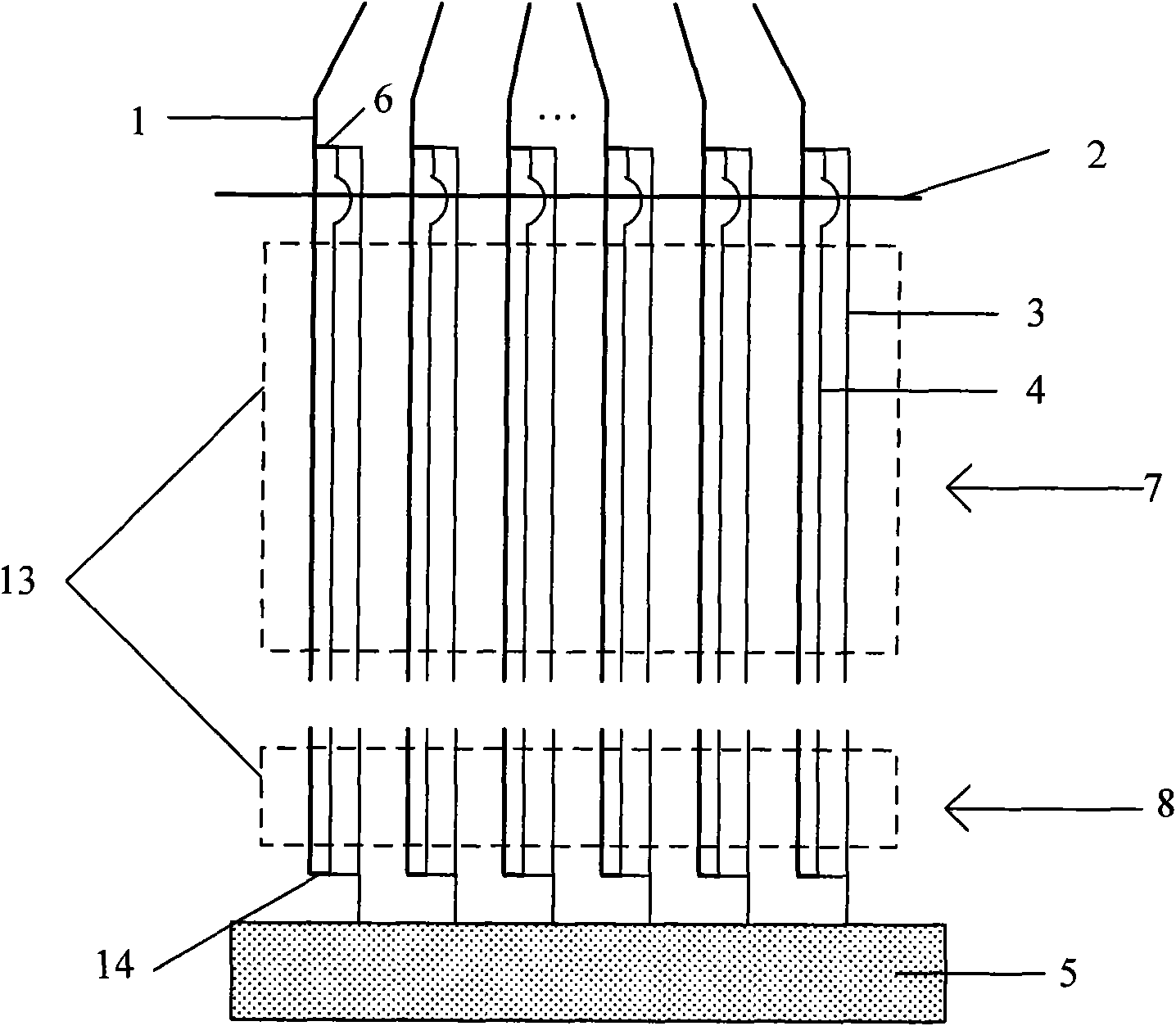

[0031] Such as image 3 As shown, the data lines 1 , the first common elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com