Honeycomb structure

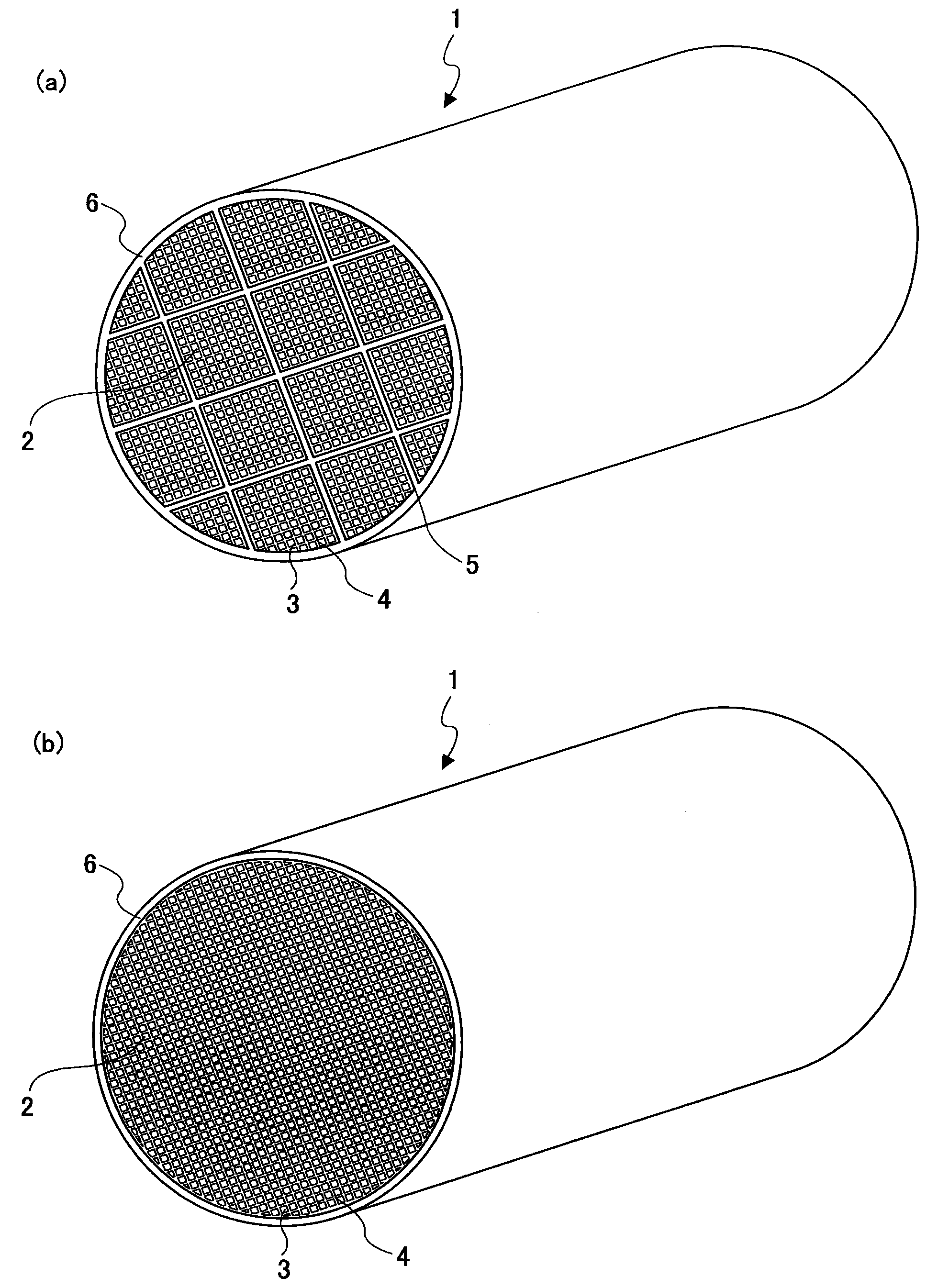

A honeycomb structure, honeycomb technology, applied in gas treatment, filtration and separation, household appliances, etc., can solve the problems of low strength of honeycomb units and inability to maintain functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] (production of honeycomb unit)

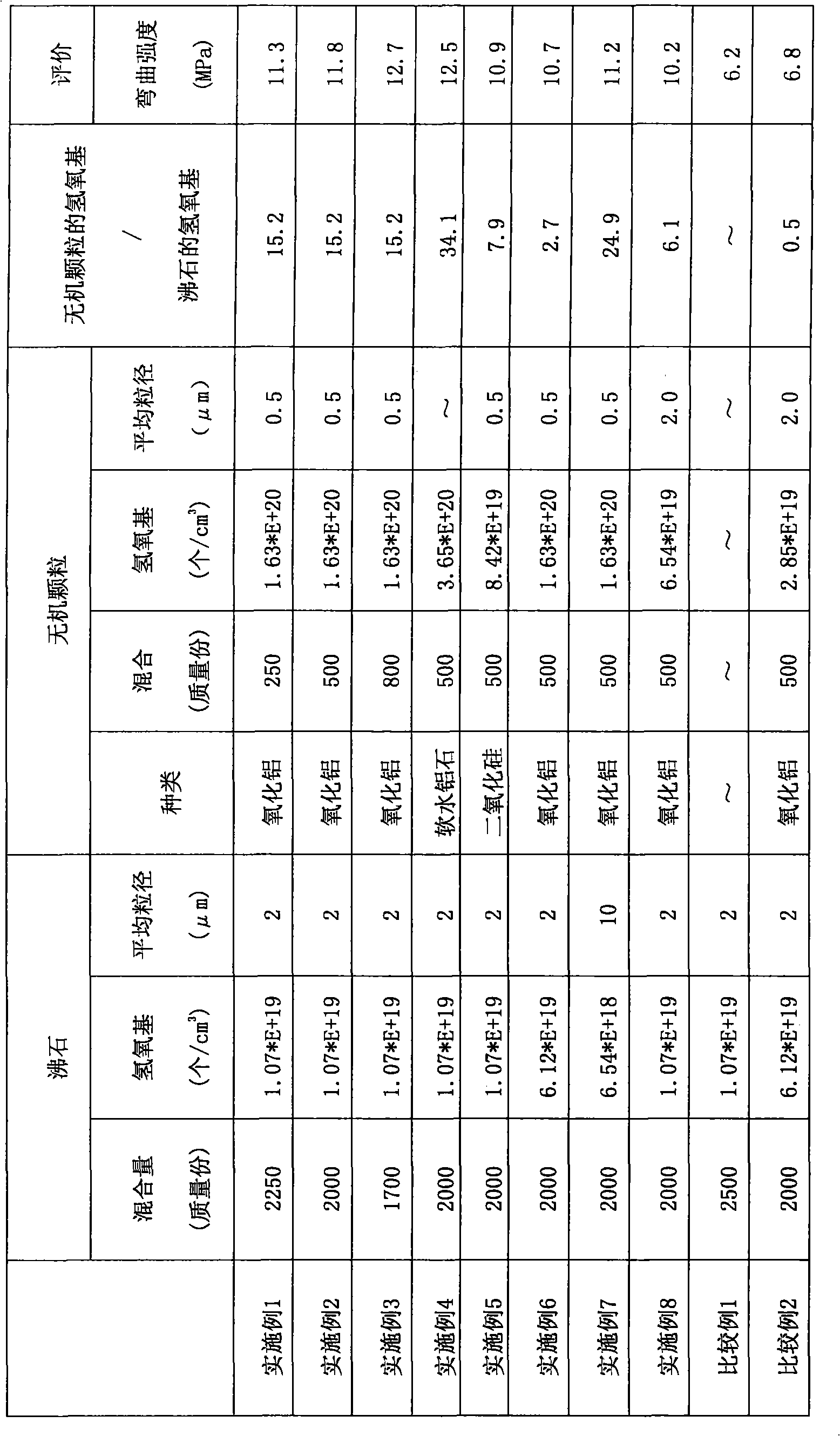

[0082] First, add and mix 2250 parts by mass of zeolite particles (with a hydroxyl content of 1.07×10 19 piece / cm 3 , an average particle diameter of 2 μm (the average particle diameter is the average particle diameter of secondary particles, the same below)), 250 parts by mass of γ-alumina particles (the content of hydroxyl groups is 1.63×10 20 piece / cm 3 , average particle diameter is 0.5 μm), 680 mass parts of alumina fibers (average fiber diameter is 6 μm, average fiber length is 100 μm), 2600 mass parts of alumina colloid solution (solid concentration is 30 mass %), 320 mass parts organic binder (methylcellulose). Then, add a small amount of plasticizer, surfactant and lubricant, and mix and knead while adding water to adjust the viscosity of the slurry to obtain a mixed composition for molding. Next, the mixed composition was extruded using an extrusion molding machine to obtain a green honeycomb molded body.

[0083] The obta...

Embodiment 2~8、 comparative example 1~2

[0092] (production of honeycomb unit)

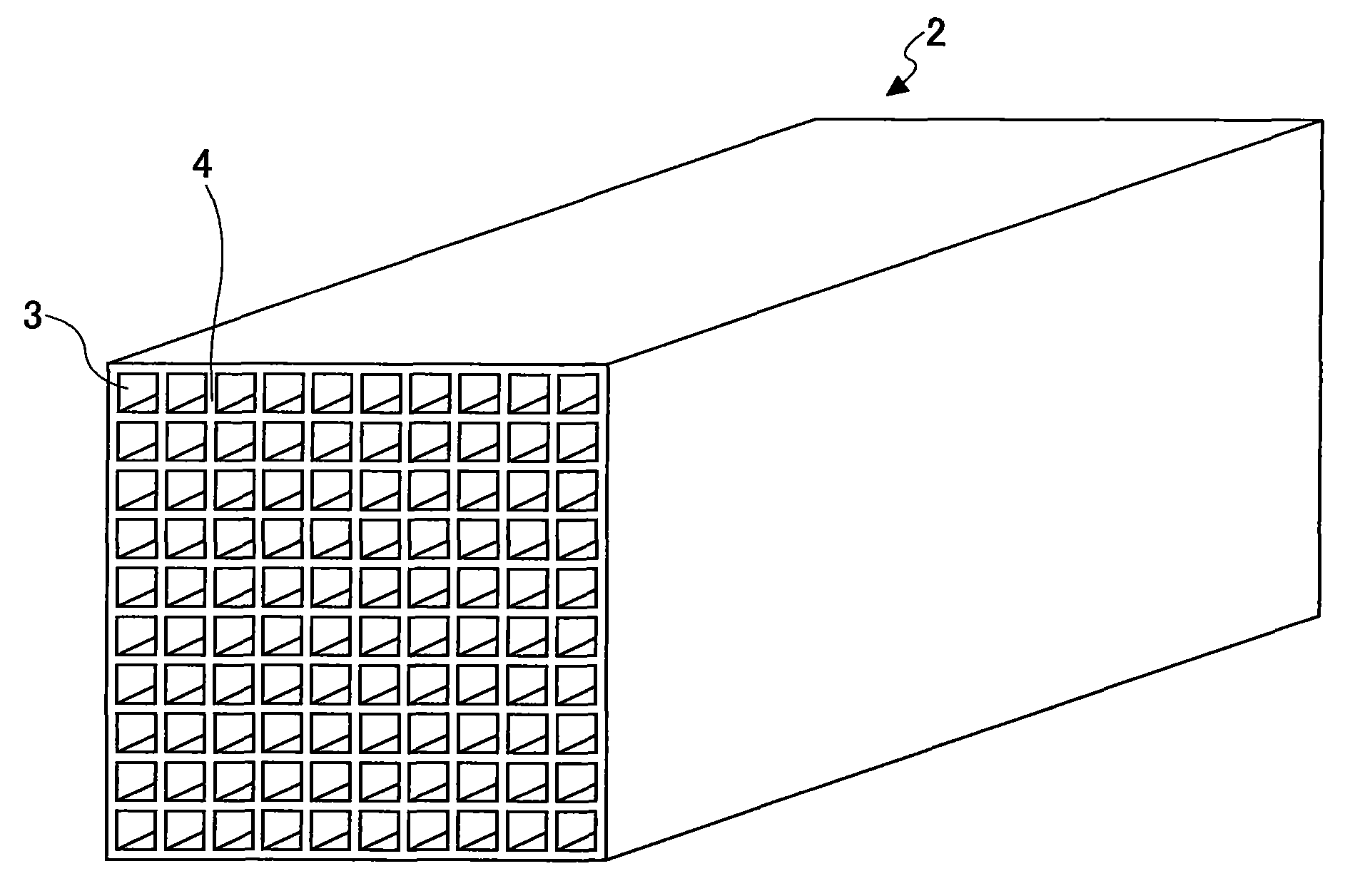

[0093] The same method as in Example 1 was used except that the mixing amount of the raw material zeolite particles and alumina particles (inorganic particles) in Example 1, and the content of hydroxyl groups and the average particle diameter were changed as shown in Table 1. Method The honeycomb units of Examples 2-8 and Comparative Examples 1-2 were produced. In addition, it should be noted that Comparative Example 1 is an example in which a honeycomb unit is produced without using inorganic particles. Measure each honeycomb unit that makes in the same way as embodiment 1 (as figure 2 The bending strength of the shape shown), and the results are listed in Table 1.

[0094] (Evaluation results)

[0095] As can be seen from the results shown in Table 1, the 3-point bending strength of the honeycomb unit as the basic unit of the honeycomb structure of Examples 1 to 8 exceeds 10 MPa, so the honeycomb structure of the present invention ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com