Microwave leakage preventing device

An anti-leakage, microwave technology, applied in microwave heating, roads, road repair and other directions, can solve the problems of reduced anti-leakage effect, easy damage or aging of door seals, easy aging of silicone rubber, etc., and achieves good protective effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

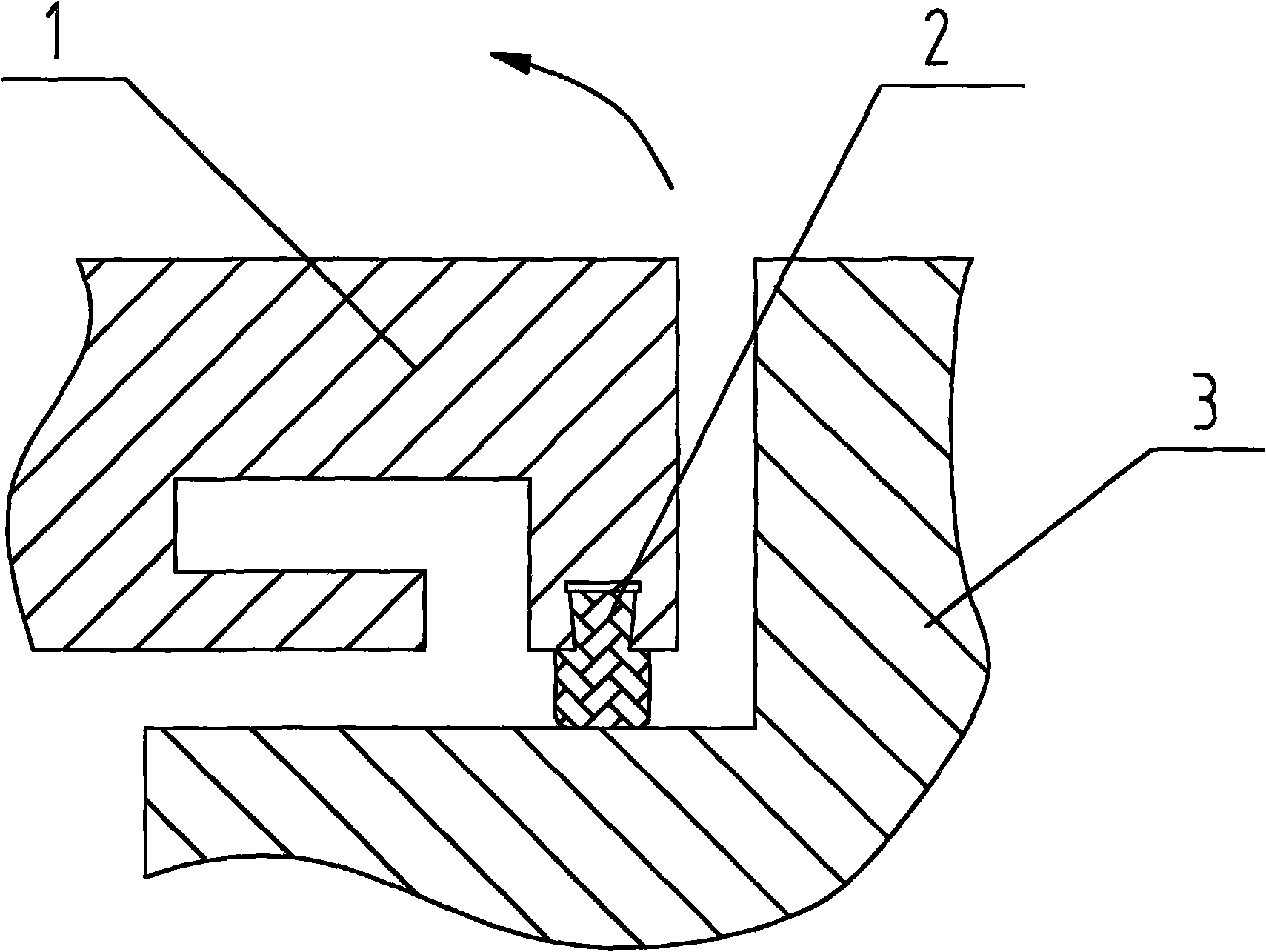

[0009] The machine-added anti-flow groove and rubber groove are used, and the purchased silicon rubber is assembled on the door. The anti-flow groove of the discharge furnace door is processed by a milling machine, and the silicone rubber is glued around the furnace door. The furnace door is driven by the cylinder through the connecting rod, and is opened by rotation. The microwave reaches the position of the furnace door, and the anti-flow groove reverses the microwave. , and resist each other to prevent leakage; at the same time, silicone rubber can absorb microwaves and play a better protective role.

[0010] Magnetron with higher power is used. In order to achieve better protection effect, the microwave anti-leakage device is formed by combining the protection method of anti-flow groove structure and silicon rubber seal.

[0011] The waveguide wall current that forms the microwave electromagnetic field is cut off by the gap or notch on the transmission path, and will becom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com