Seed dibbler

A technology for seeding machines and seeds, which is applied in the directions of sowing seeders and seeder parts, etc., can solve the problems of inappropriateness, high labor intensity, and large amount of seeds used, and achieves adjustable row spacing and plant spacing, convenient and reliable use, and accurate seeding amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

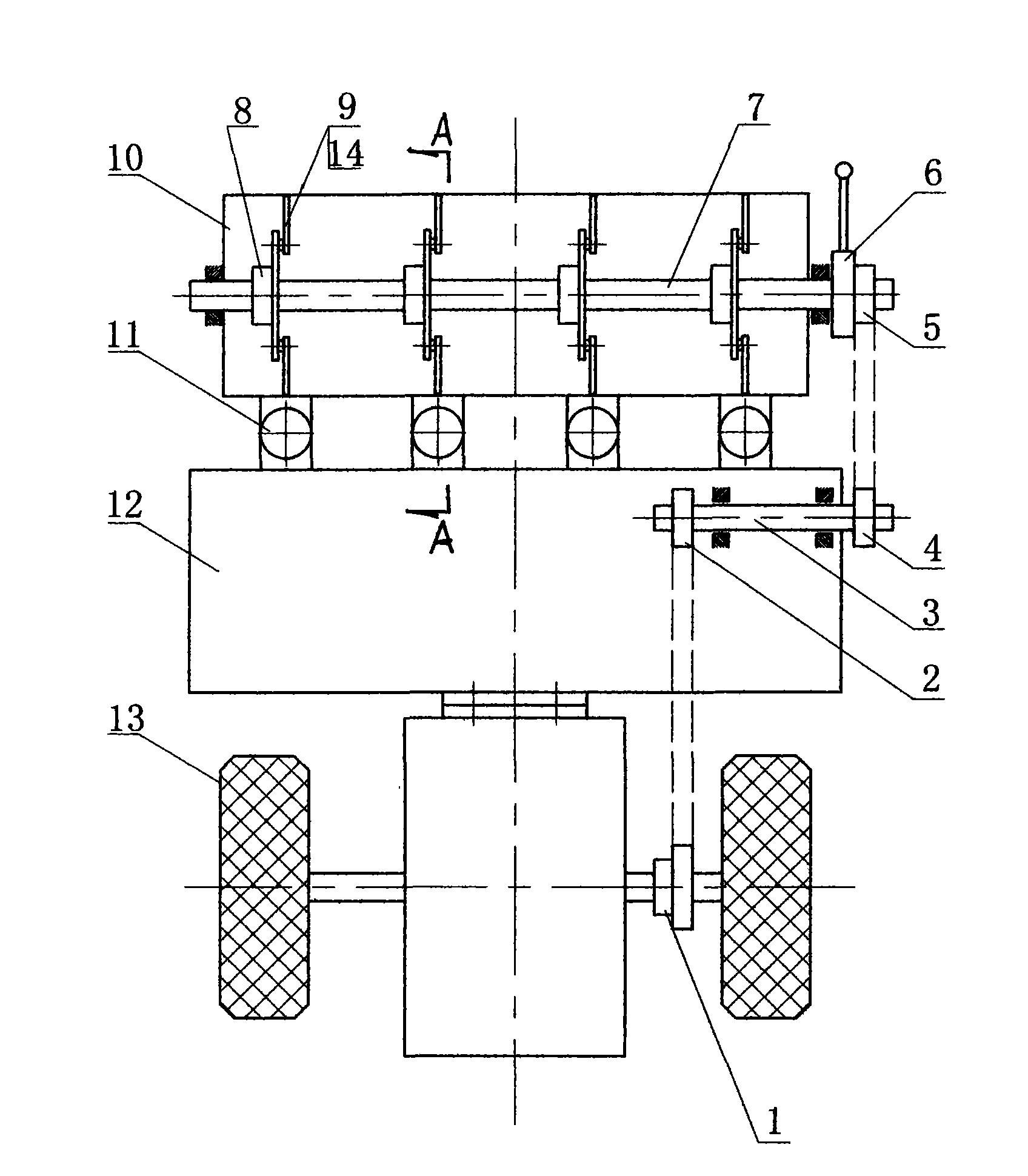

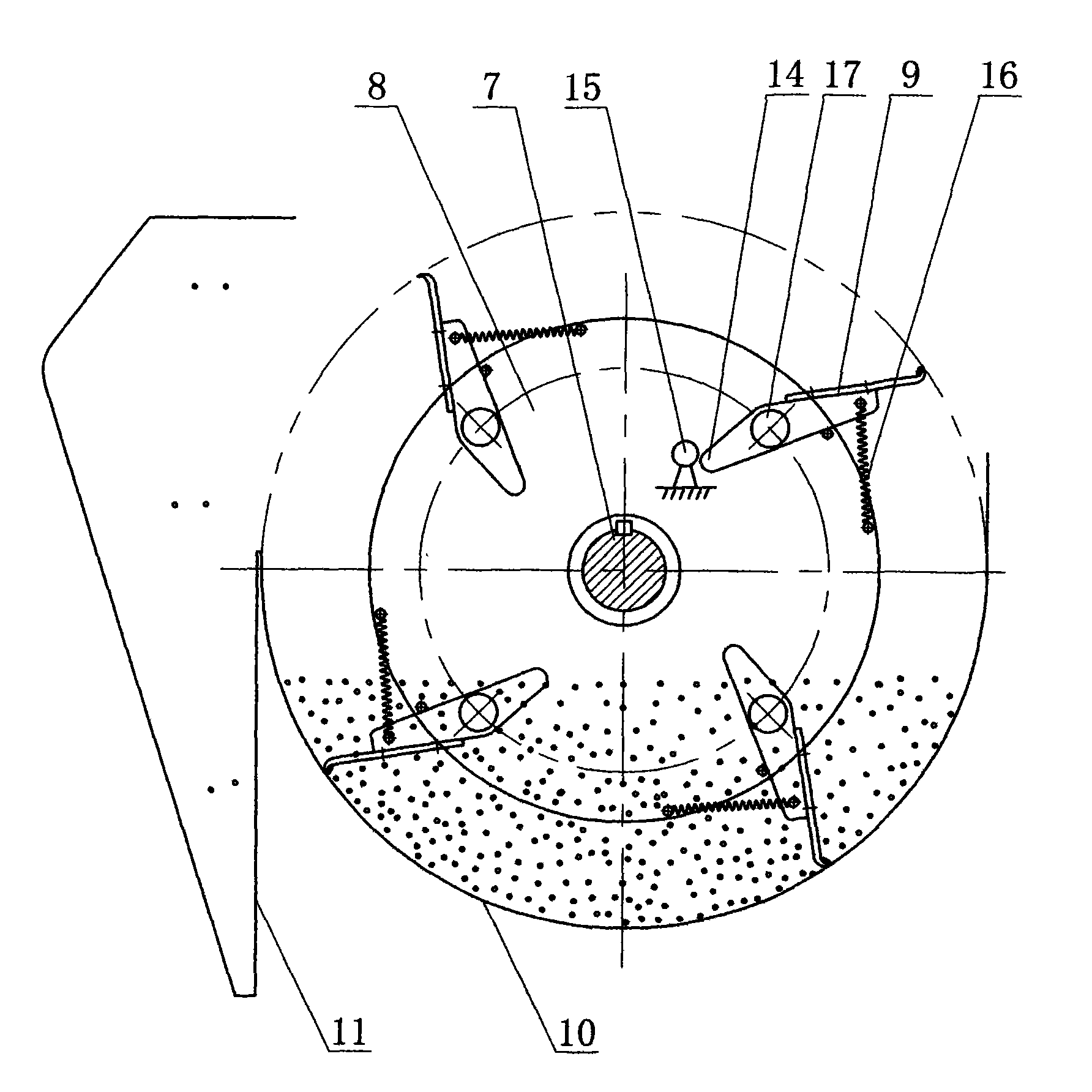

[0009] exist figure 1 , figure 2 Among them, the driving sprocket 1 is installed on the wheel shaft of the walking tractor. When the tractor moves forward, the wheel shaft rotates and drives the driven sprocket 2 on the intermediate transmission shaft 3 to rotate through the chain; the sprocket 4 installed on the other end of the intermediate transmission shaft 3 also follows The rotation; the sprocket 4 drives the sowing shaft sprocket 5 to rotate through the chain. 4 to 6 sowing discs 8 are housed on the sowing shaft, lever 14 is housed on the sowing disc 8, and a detachable sowing scoop 9 is housed on each lever (see figure 2 ), a set of clutch 6 is also housed on the sowing shaft 7, and when the clutch is pulled to the combined position, the sowing disc 8, the lever 14, and the seed throwing spoon 9 also rotate at a uniform speed with the sowing shaft 7, and when the short arm of the lever 14 and the bumper are turned to When the wheels 15 collided, the seed throwing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com