Walnut shell and meat separator

A technology for separating shells and kernels and walnuts, which is applied in the fields of shelling, pod removal, and food science, and can solve problems such as low efficiency, unhygienic, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

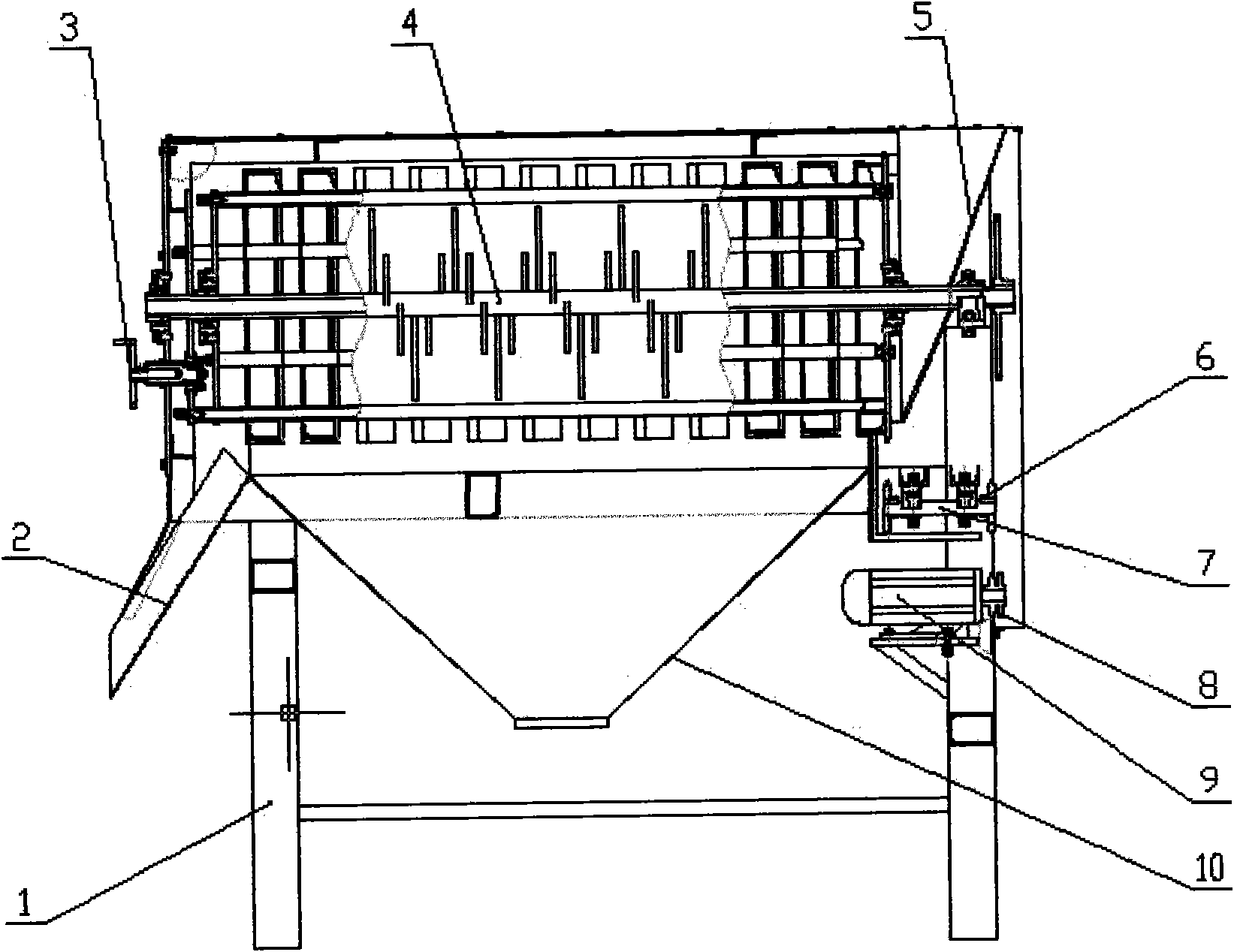

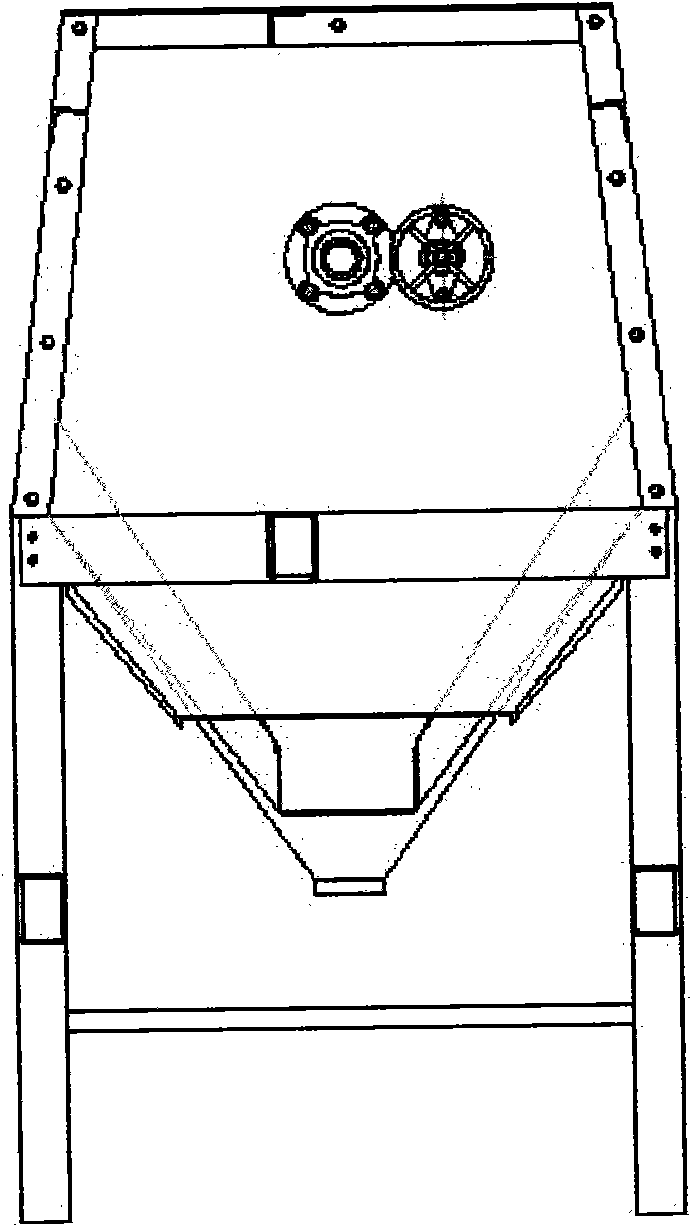

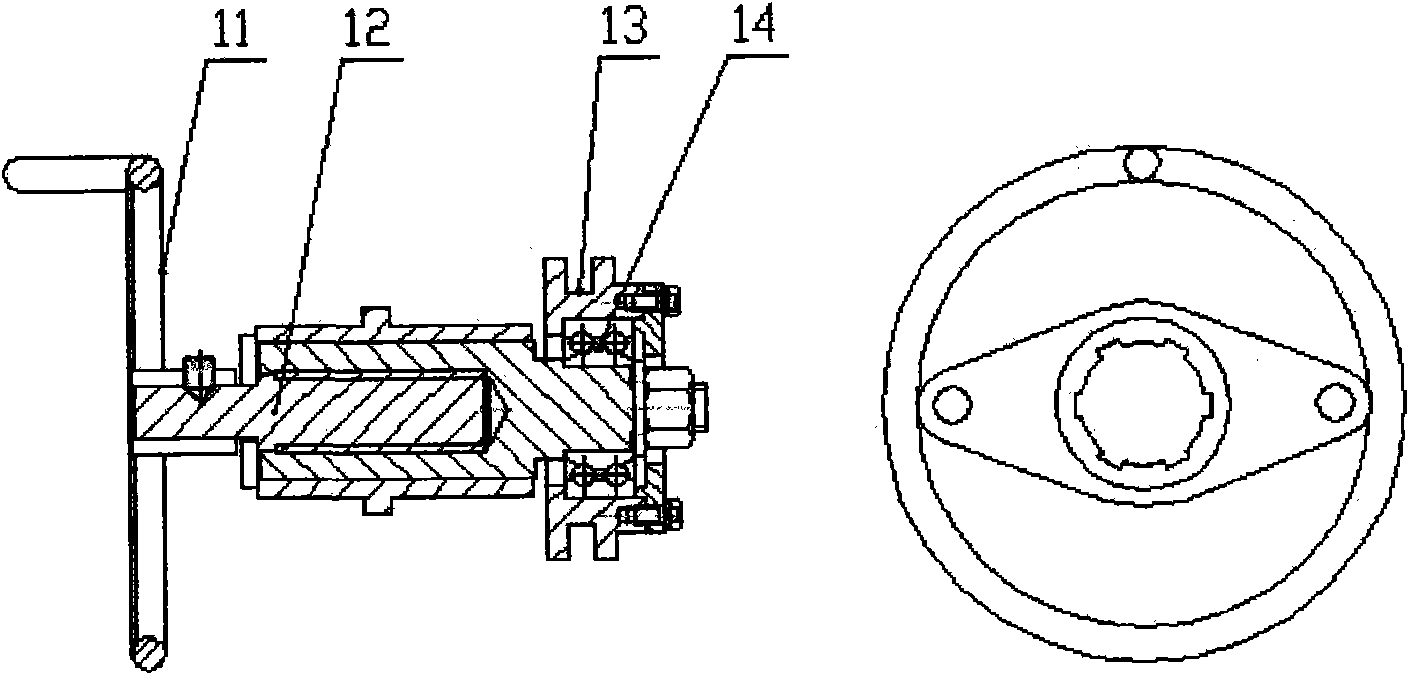

[0011] Example: such as figure 1 , figure 2 The shown walnut shell and kernel separator consists of a frame (1), a large shell discharge hopper (2), a lead screw distance adjuster (3), a shell and kernel separating ring body (4), a feed hopper (5), an intermediate shaft ( 6), intermediate sprocket (7), motor sprocket (8), motor (9), collecting hopper (10), hand wheel (11), threaded shaft (12), bearing housing (13), thrust ball bearing ( 14), mounting plate (15), mounting bearing (16), ring body support bearing (17), circular ring (18), ring body support plate (19), central shaft (20), nail teeth (21), shaft Cover (22), fixed shaft (23), moving separation ring (24), fixed separation ring (25), small sprocket wheel (26), large sprocket wheel (27), moving shaft (28) form.

[0012] The right end of the frame (1) is provided with a feed hopper (5), the left end is provided with a large shell discharge hopper (2), and the bottom is a collection hopper for kernels and small shells...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com