Steam mop

A mop and steam technology, applied in the field of steam mop, can solve the problems of high product price, complex structure, water cut-off or uneven steam, etc., and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

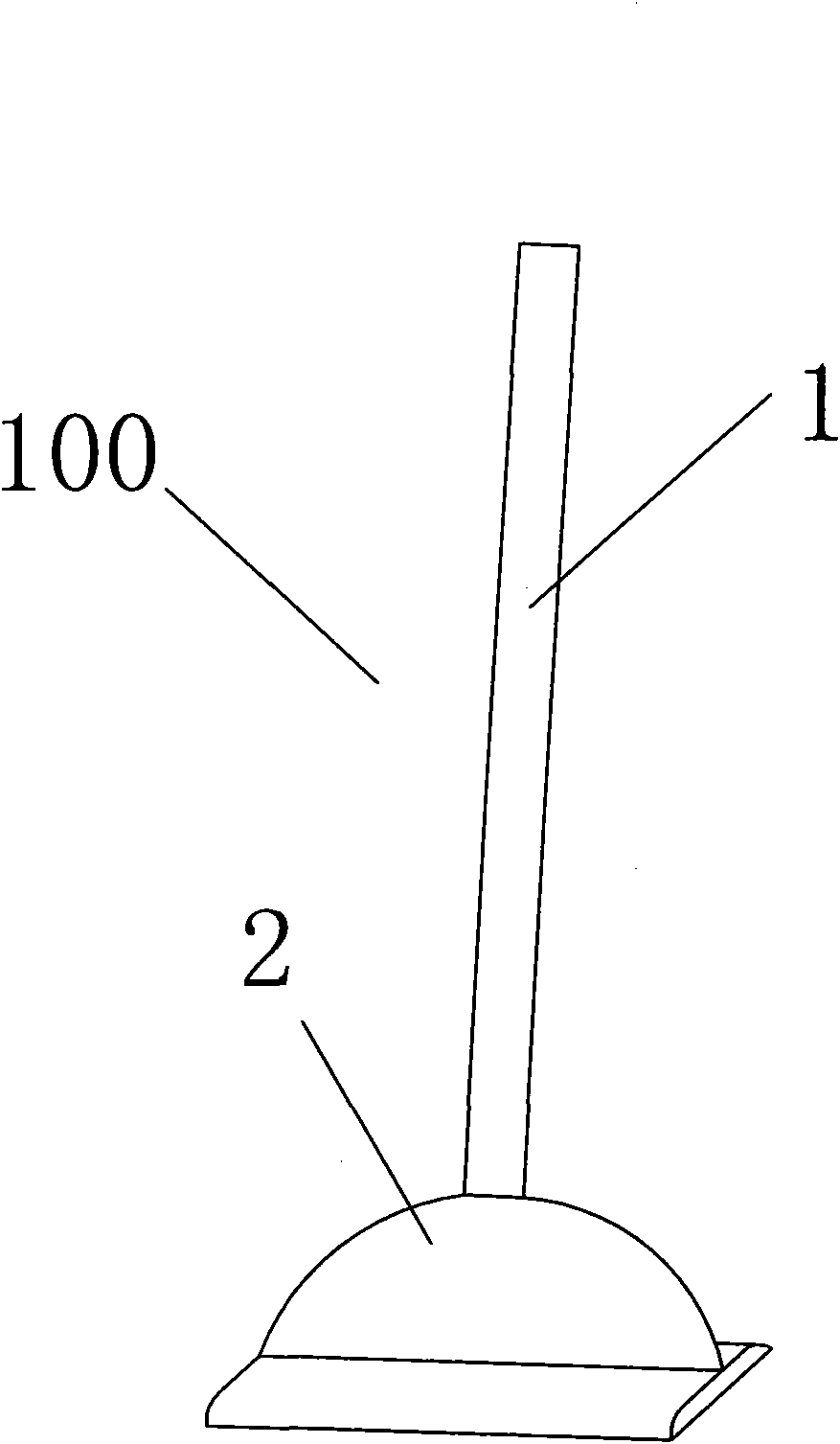

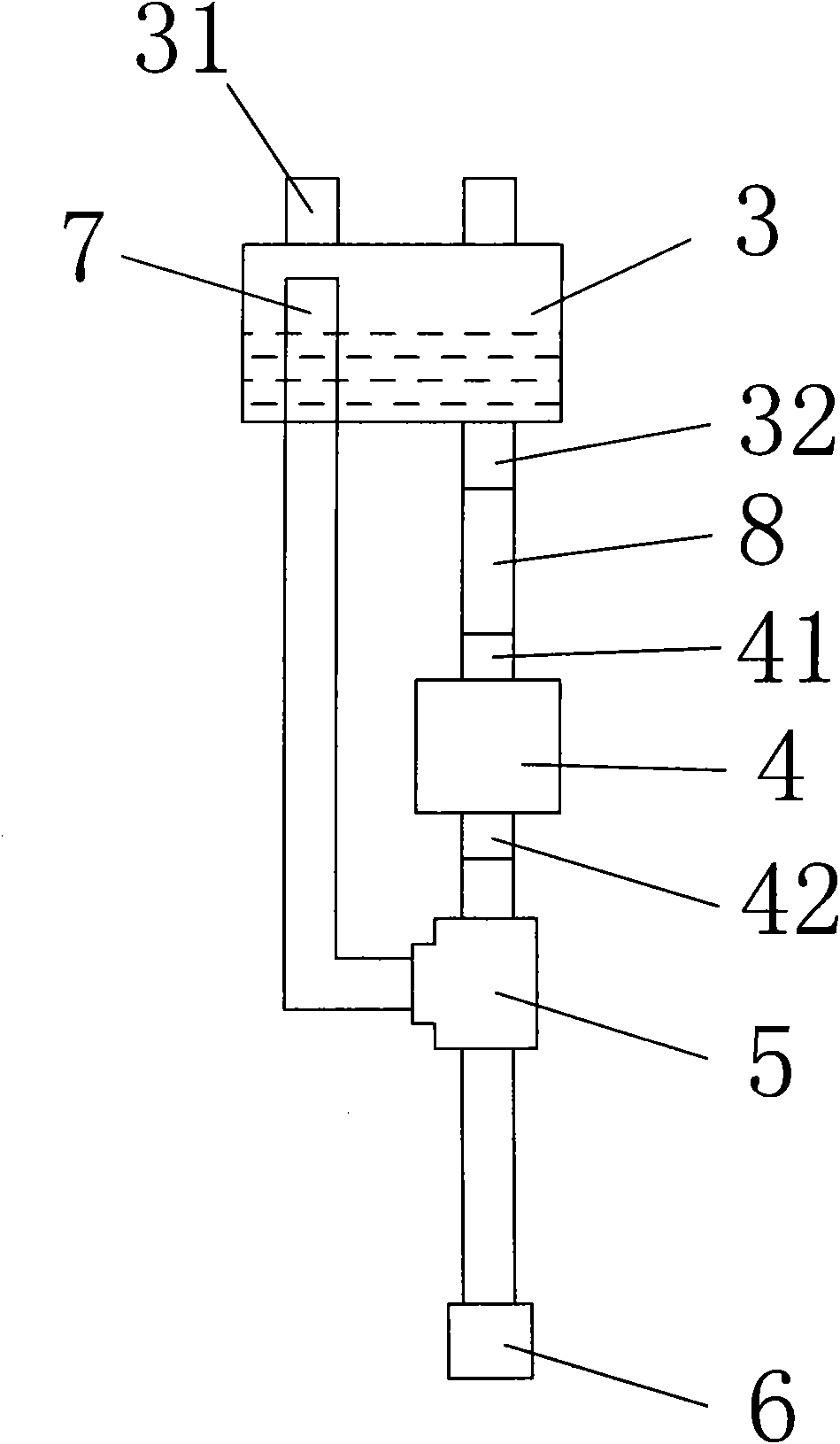

[0012] Such as figure 1 , figure 2 As shown, the steam mop 100 has a handle 1, the handle 1 is connected with the mop body 2, and the body 2 is provided with a steam outlet (not shown in the figure). The body 2 is provided with a water tank 3 and a steam generator 4 , and the water outlet 32 of the water tank 3 communicates with the water inlet 41 of the steam generator 4 through a pipe 8 . A decompression device is connected to the steam outlet 42 of the steam generator 4 , and the decompression device used in this embodiment is a three-way pipe body 5 . The three-way pipe body 5 has two steam outlets 6 , 7 , wherein the steam outlet 7 is located in the water tank 3 and at the top of the water tank 3 , and the steam outlet 6 communicates with the steam outlet on the body 2 .

[0013] When using the mop 100, water is injected into the wat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap