Calender

The technology of a calender and a frame is applied in the field of shoe machinery, which can solve the problems of poor heating effect of the heating plate, easy deformation and damage of the heating plate, poor adhesion effect of the shoe upper, etc., so as to improve the heating effect and facilitate installation and maintenance. , The effect of shoe upper pressing effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

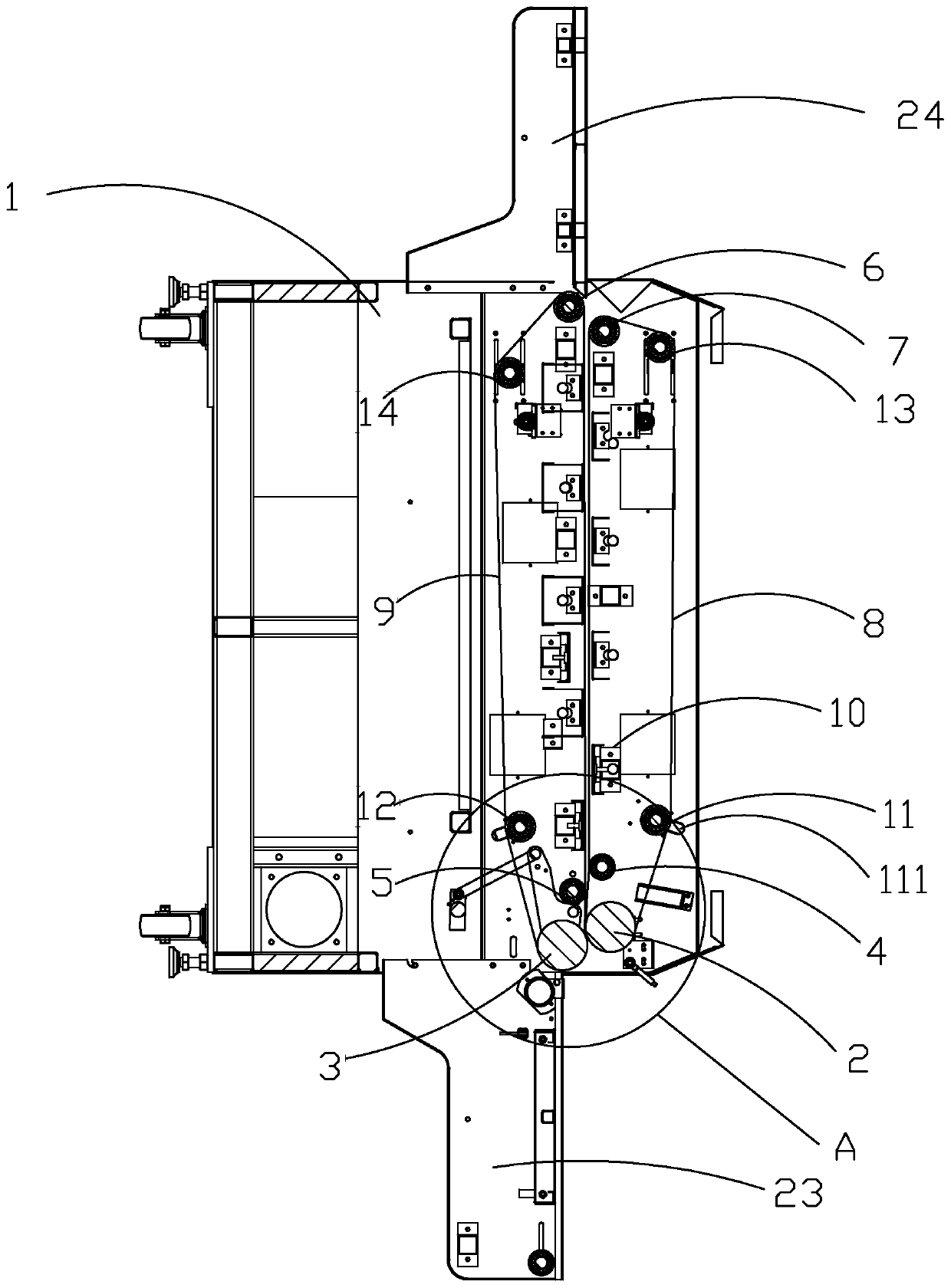

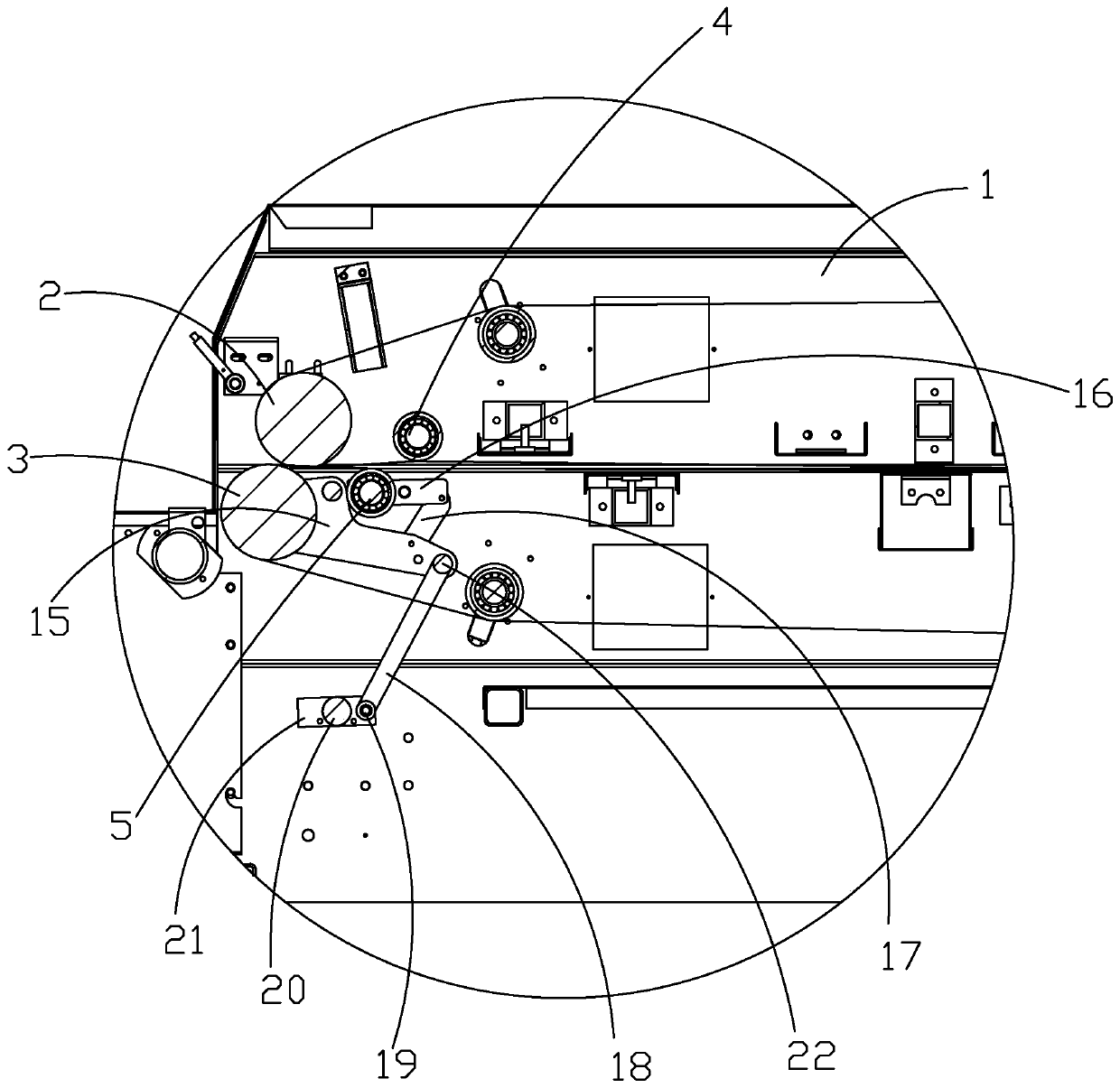

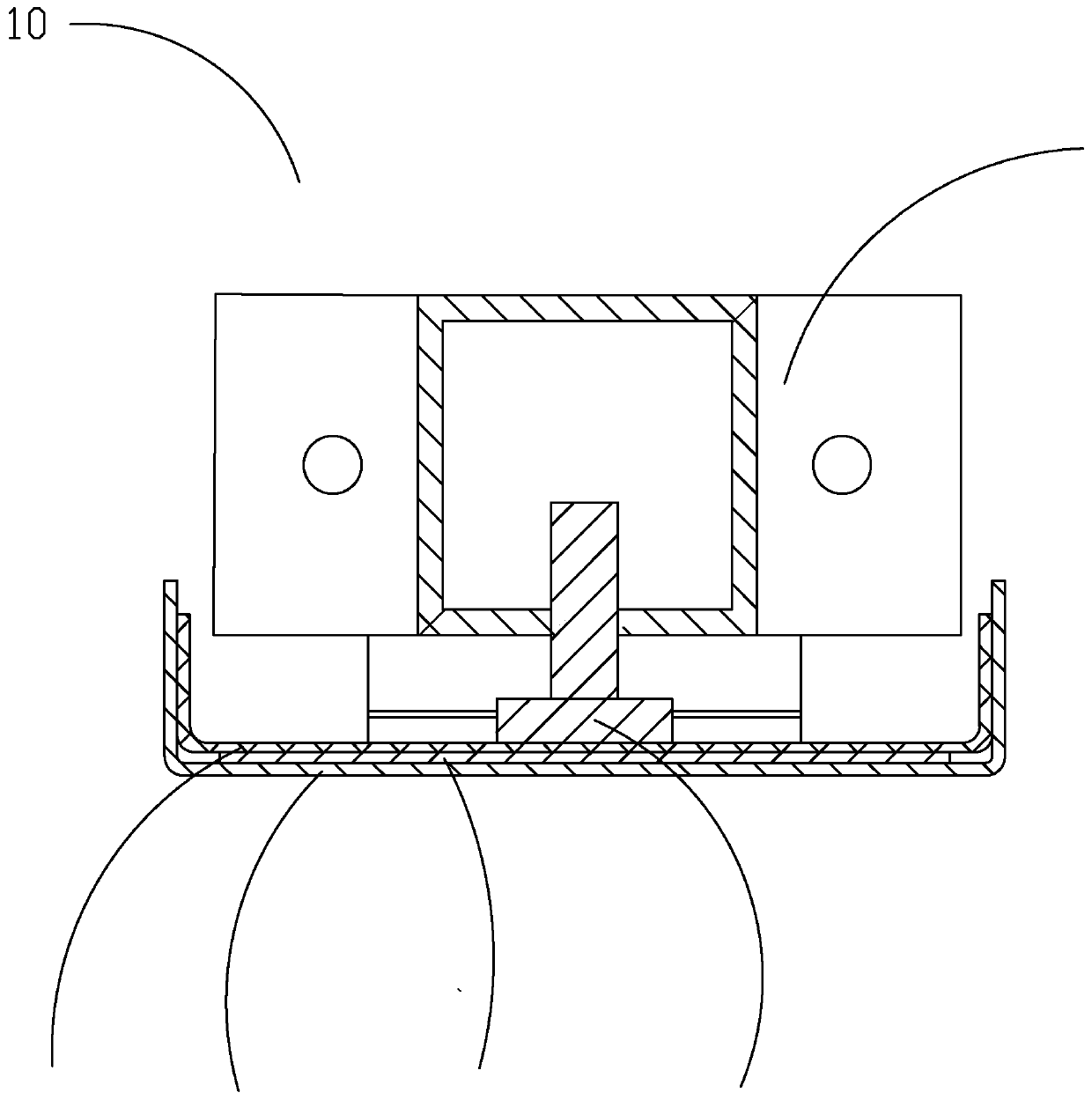

[0039] refer to Figure 1-Figure 8The embodiment of the present invention discloses a calender, which includes a frame 1, on which an upper pressing roller 2, an upper fabric guide roller 4 and an upper support roller 7 are rotatably arranged through bearings. The pressure roller 2, the upper cloth guide roller 4 and the upper supporting roller 7 are wound with an upper high-temperature endless belt 8, and the frame 1 is located below the upper high-temperature annular belt 8 and is rotatably provided with a lower pressure roller 3 and a lower guide roller 3 through bearings. The cloth roller 5 and the lower idler 6, the lower pressure roller 3, the lower cloth guide roller 5 and the lower idler 6 are wound with a lower high-temperature endless belt 9, and the output shaft 21 of the upper pressure roller 2 is fixed with a The first sprocket 114, the output shaft 31 of the lower pressure roller 3 is fixed with the second sprocket 113, the frame 1 is provided with a first drive ...

Embodiment 2

[0047] according to Figure 9 , based on the above solution, the second adjustment device in the present invention can also be: the second adjustment device includes an adjustment screw 3', an adjustment slot 2' is opened on the frame 1', and an adjustment groove 2' is opened on the frame 1'. There is also a mounting hole 4' that is connected to the adjustment groove 2' to facilitate the installation of the tension roller. One end of the adjustment screw 3' is fixed with a first fixed block 7', and the first fixed block 7' is respectively connected by screws 8'. Locked on the upper first tension roller 11' and the lower first tension roller (not shown in the figure), the frame 1' is fixed with a second fixed block 5', and the adjustment screw 3' The other end passes through the second fixing block 5' and passes through the second fixing block 5', the adjusting screw 3' is sleeved with a nut 6', and the nut 6' is connected to the second fixing block 5'. Block 5' resists. When...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap