Composite process, tool block and device for uniformly coating composite brazing filler metal on ceramic surface

A composite brazing filler metal and ceramic surface technology, which is applied to the device and coating of the surface coating liquid, can solve the problems such as difficult to control the thickness of the coating, and achieve the effects of improving precision, saving manufacturing costs, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In the first aspect, a process for evenly coating composite solder on a ceramic surface, the process flow includes a coating process and a heating process, and the coating process includes:

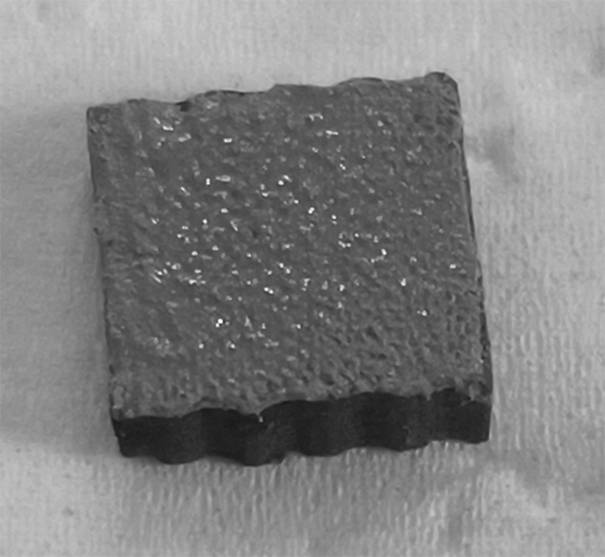

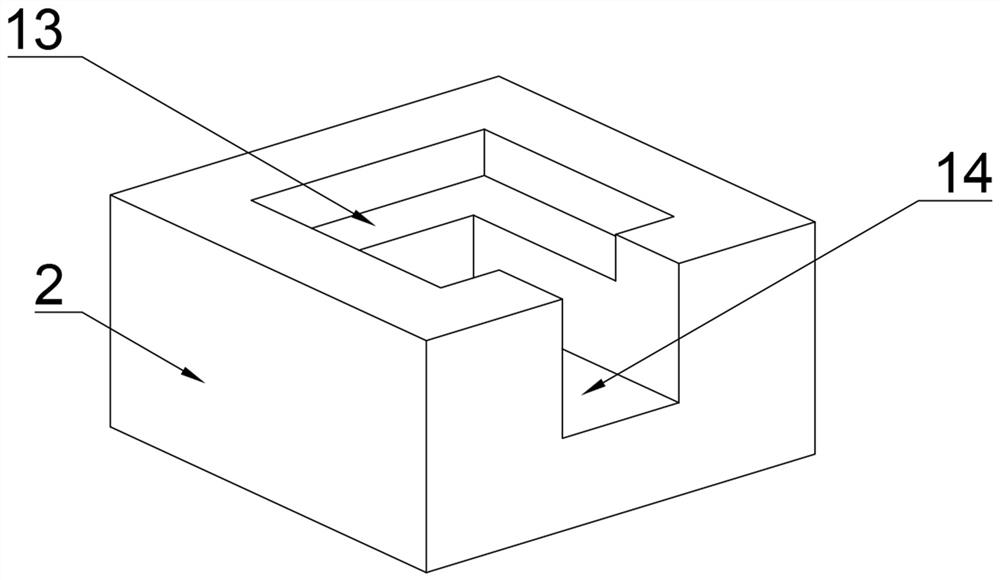

[0044] S1: Put the ceramic sample block 1 into a specific tooling block 2 for fixing, and the height of the top surface of the ceramic sample block 1 after fixing is greater than the height of the top surface of the tooling block 2;

[0045] S2: Position the silk screen grid 3 directly above the ceramic sample block 1;

[0046] S3: apply the composite solder on the area where the top of the silk screen grid 3 is directly above the ceramic sample block 1;

[0047] S4: Use the brush plate 4 to evenly spread the composite brazing material applied on the top of the silk screen grid 3, so that the composite brazing material can be completely covered and uniformly applied on the top surface of the ceramic sample block 1 to form a composite brazing material coating 27 with uniform thickne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap