Method for gluing and chip loading on lead frame of integrated circuit or discrete device

A lead frame and discrete device technology is applied in the field of electronic component packaging and chip mounting technology to achieve the effects of improving utilization, reducing development costs, and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 is the method for gluing on the lead frame of integrated circuit or discrete device, and the method comprises the following process steps:

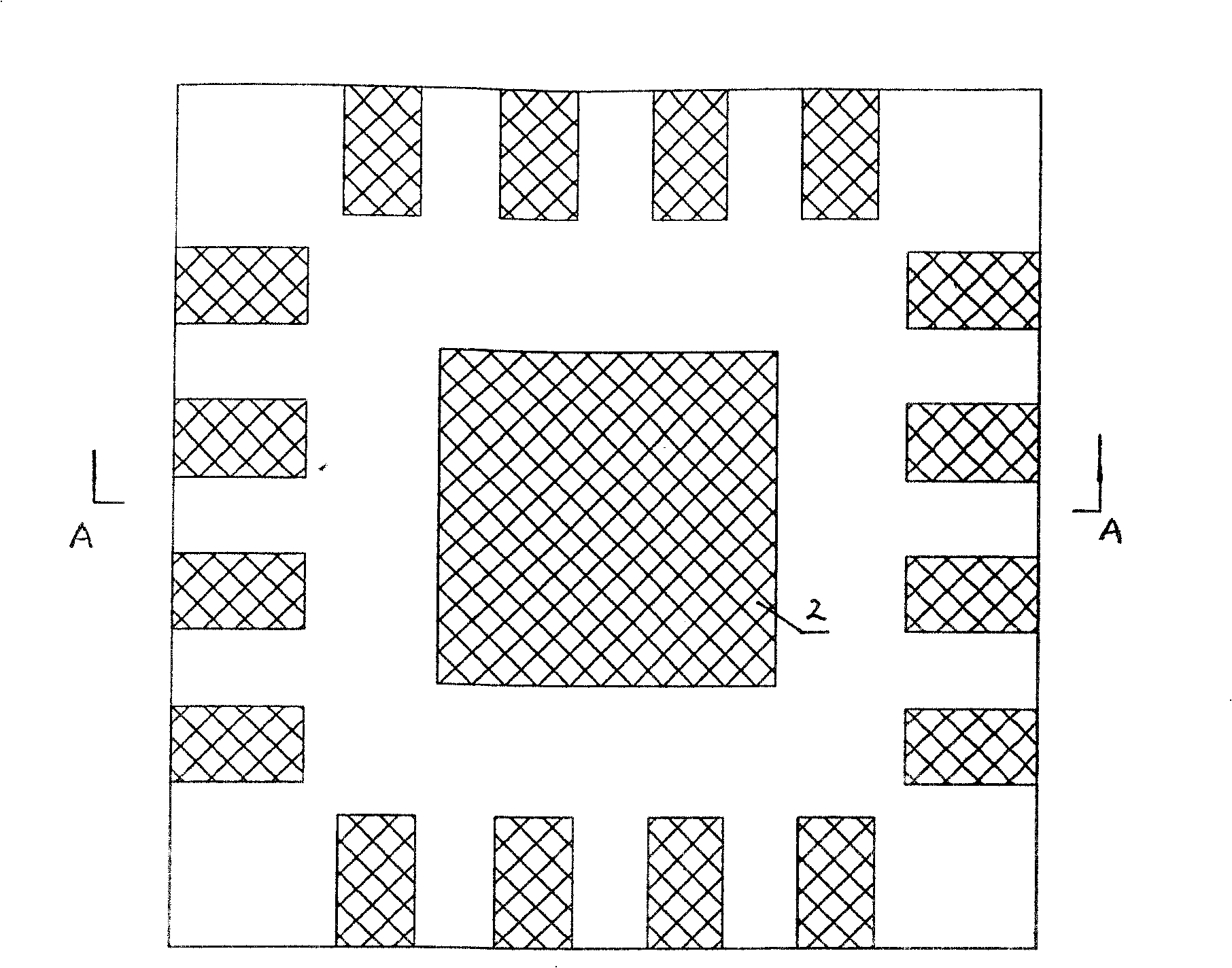

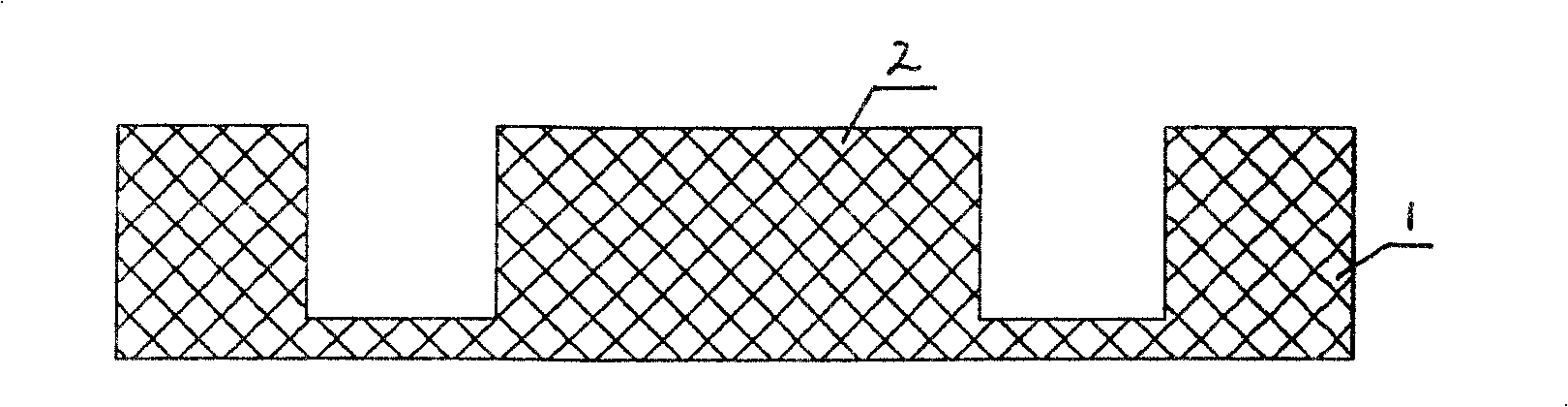

[0043] 1) Take the lead frame - take a piece of lead frame 1, such as figure 1 , 2 ;

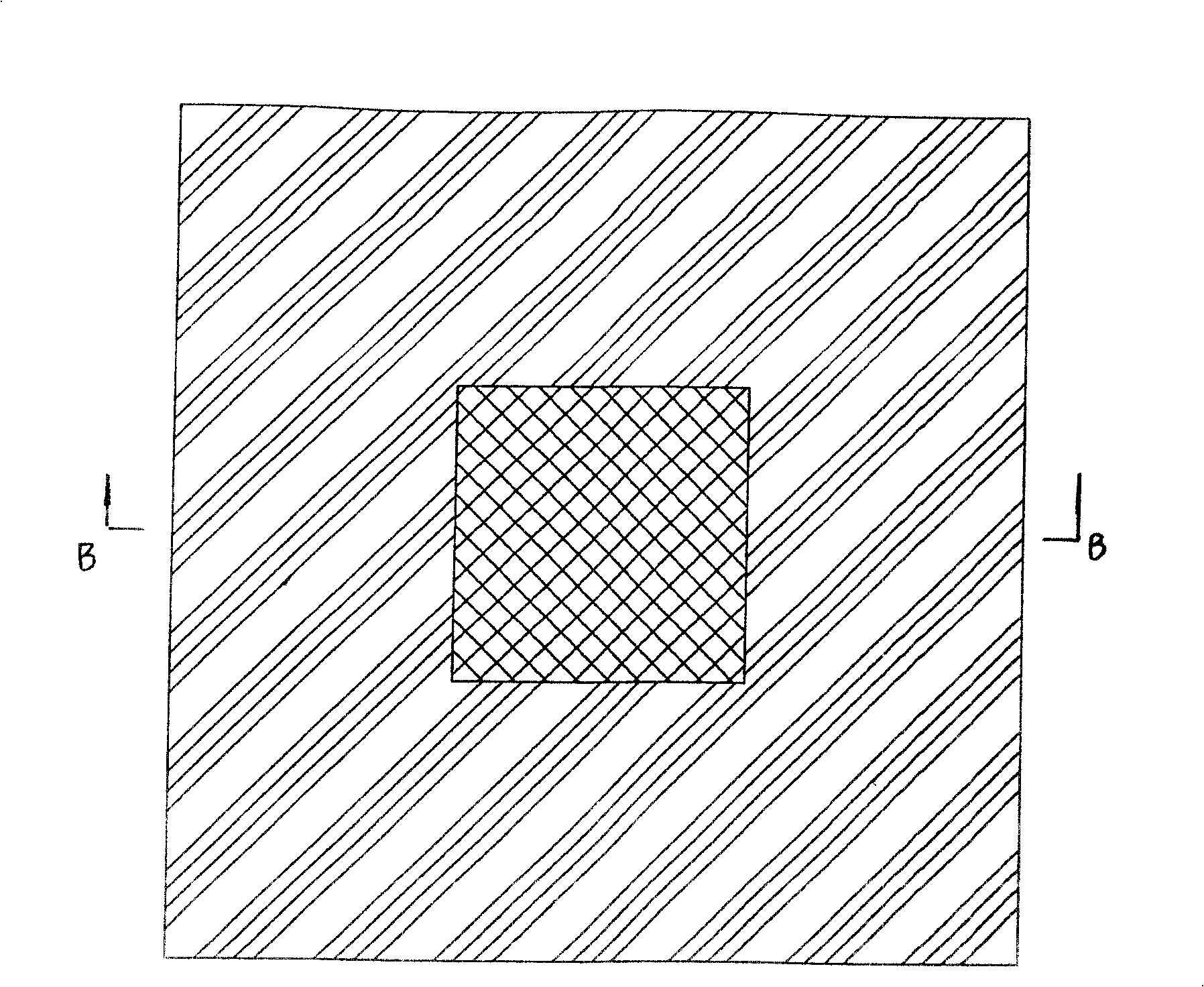

[0044] 2) Attaching the mask—cover the area of the lead frame 1 that does not need to be loaded with the mask 3, and leave the area 4 on the base island 2 that needs to be loaded, such as image 3 , 4 ;

[0045] 3) Glue coating operation—use the glue coating method to apply glue 5 to the area 4 on the vacated base island of the lead frame 1 that needs to be loaded, such as Figure 5 , 6 ;

[0046] 4) Removing the mask - Remove the mask 3 covering the lead frame, such as Figure 7 , 8 ;

[0047] 5) Baking operation—baking the semi-finished lead frame that has been coated with glue 5 on the base island 4 for the first time;

[0048] 6) Softening glue operation - before loading, heat the semi-finished lead frame that has bee...

Embodiment 2

[0052] In the above steps, after the mask is removed in step 4, step 5 and step 6 can be skipped and chip loading 6 can be directly performed on it, and then baked and strengthened.

[0053] In each of the above embodiments, the chip loading, wherein the chip installed may refer to a chip chip, and may also be a chip resistor, a chip capacitor, a chip inductor, etc.; the chip mounting on the base island is not limited to Since it is only installed on the base island, it can also be mounted on the front or back of the lead frame other than the base island.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com