Semi-conductive roller

A semi-conductive, low-hardness technology, used in circuits, electrical components, electrographics, etc., can solve problems such as difficult surface roughness, uneven thickness of the coating layer, and achieve the effect of avoiding scorch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] In order to further clarify the present invention, some embodiments of the present invention will be described. Of course, the details of these examples and the foregoing description do not limit the invention.

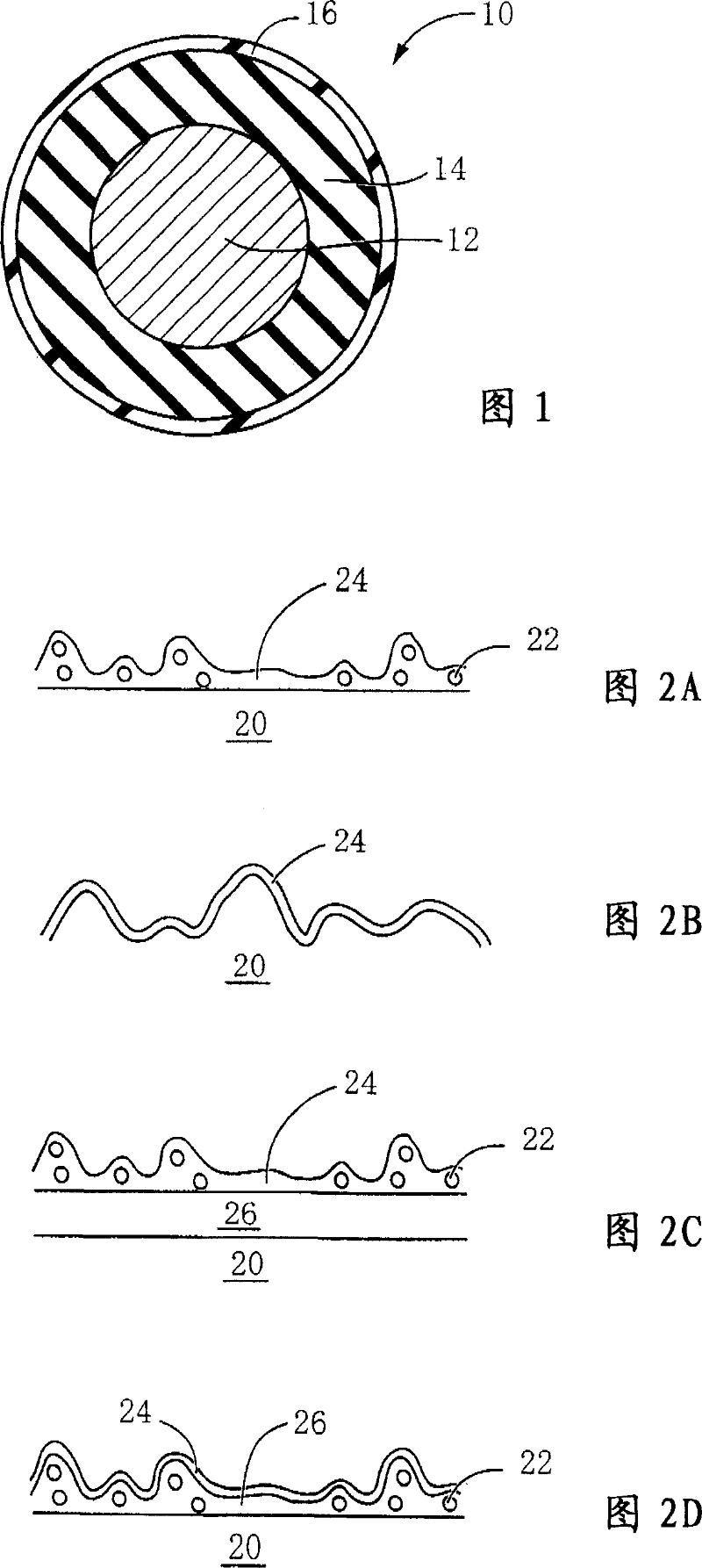

[0052] In order to obtain the semiconductive roller with the structure shown in Figure 1, prepare conductive silicone rubber (X34-264A / B, constructed from Shin-etsu Chemicals, Co., Ltd, Japan) as the material of low hardness base (14), and prepare The 13 kinds of materials forming each coating layer (16) respectively have the corresponding compositions listed in the following Tables 1-3 (ie Examples A-M). Each of these materials for the coating layer was dissolved in methyl ethyl ketone to provide respective coating liquids having predetermined viscosities (about 10 mPa·s).

[0053] Table 1

[0054] Example

A

B

C

D

E

contain

quantity

[

Heavy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com