Device and method for producing adhesive tape with air holes

A production device and ventilation hole technology, which can be applied to devices for coating liquid on the surface, adhesives, film/sheet-like adhesives, etc. and other problems, to achieve the effect of saving dosage, good air permeability and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

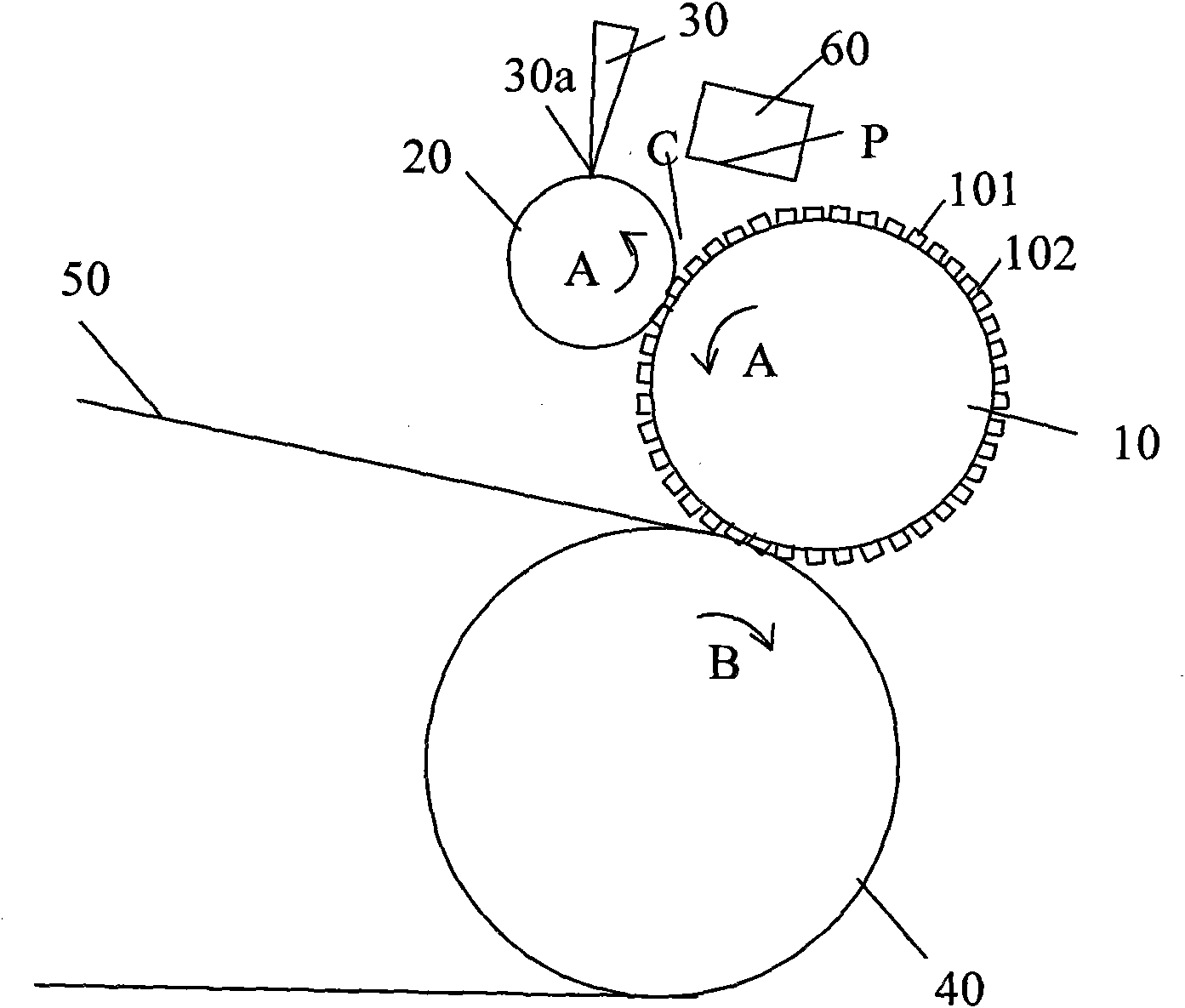

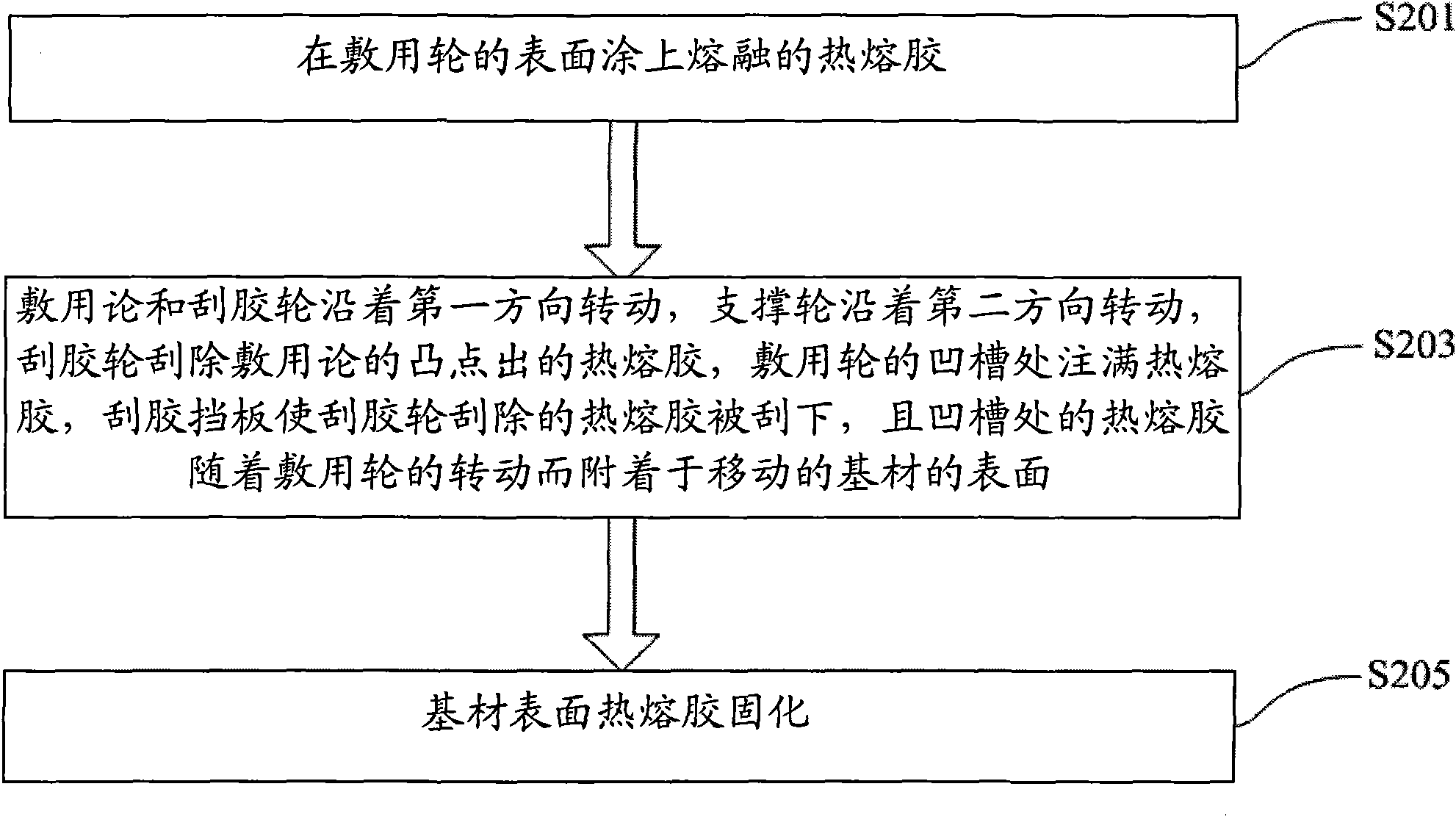

[0013] figure 1 It is a structural schematic diagram of a production device for an adhesive tape with ventilation holes according to an embodiment of the present invention. The production device of the adhesive tape with air holes includes an application wheel 10 , a squeegee wheel 20 , a squeegee baffle 30 and a support wheel 40 . The application wheel 10 rotates along a first direction A, and has bumps 101 on the surface, and grooves 102 are formed between the bumps 101 . The squeegee wheel 20 is tangent to the surface of the convex point 101 of the application wheel 10 and rotates along the first direction A, and a glue injection point C is formed between the application wheel 10 and the squeegee wheel 20 . One end surface 30 a of the squeegee baffle 30 is in close conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com