Electromagnetic shield door

An electromagnetic shielding door and shielding body technology, which is applied in the direction of defense against harmful radiation, etc., can solve the problems of high shielding efficiency, operator inconvenience, and increased insertion resistance, and achieve high shielding efficiency, easy opening and closing, and insertion resistance. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the electromagnetic shielding door according to the present invention will be described in detail below with reference to the accompanying drawings. In the following, "outer" and "inner" are relative to the shielding body, the part closer to the shielding body is called "inner", and vice versa is called "outer".

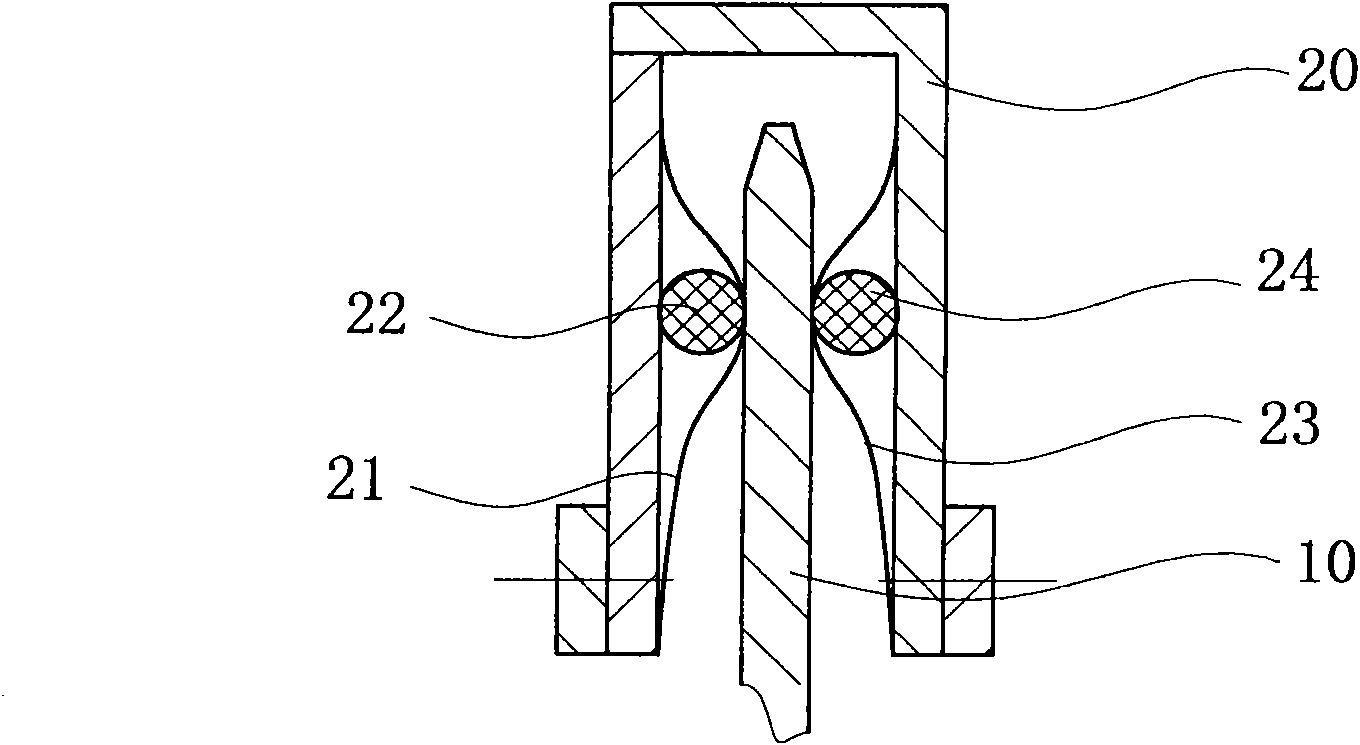

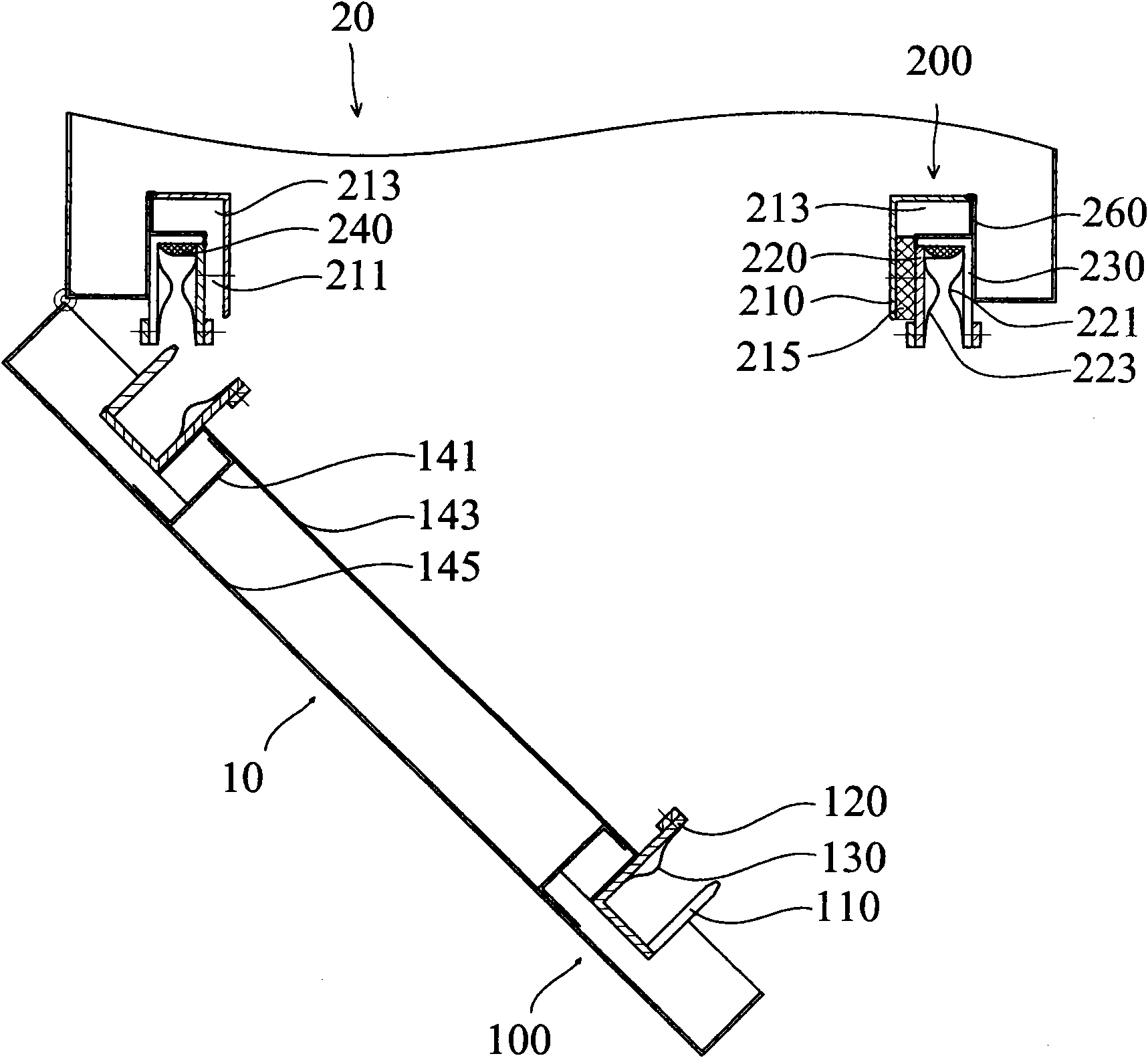

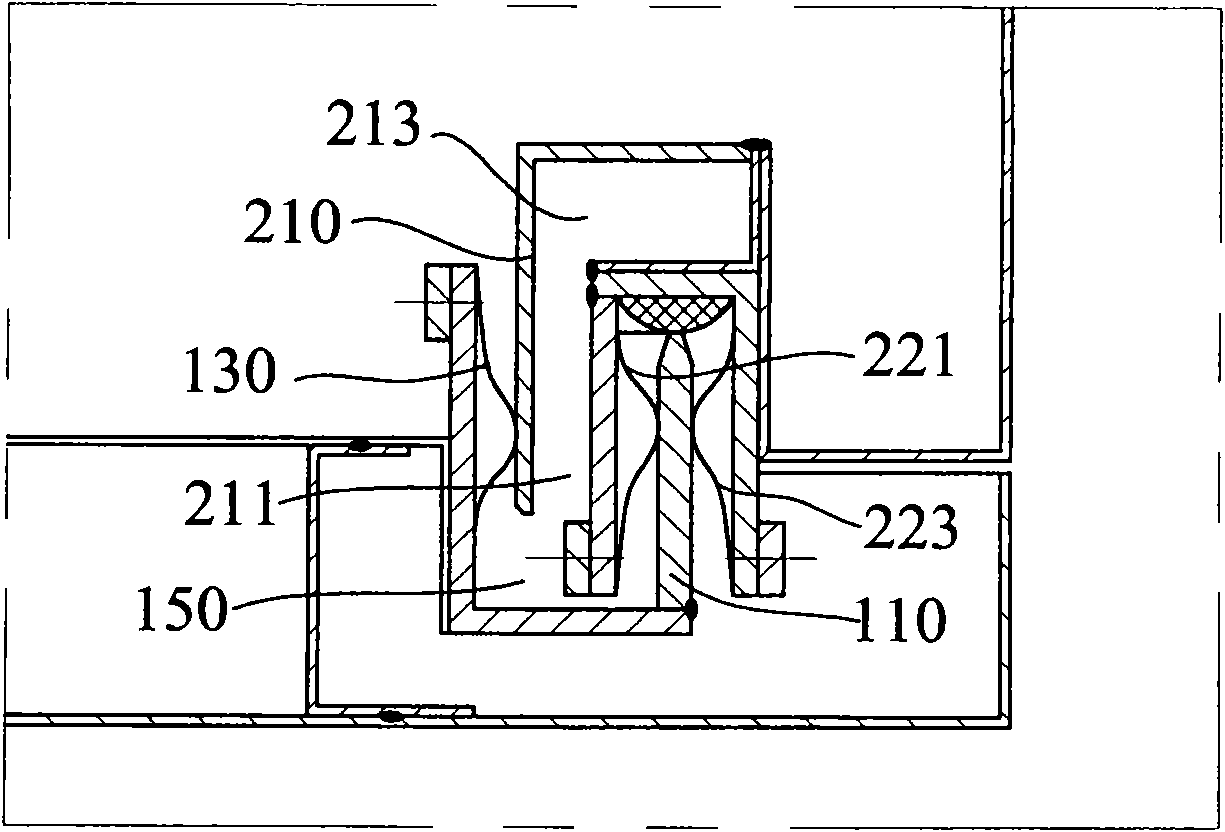

[0025] figure 2 is a schematic diagram of an electromagnetic shielding door according to an embodiment of the present invention, wherein the door is in an open state. In order to prevent the electromagnetic wave in the shield from leaking from the door gap, a plug-in 100 is arranged around the edge of the door body 10. Correspondingly, a socket 200 is provided at the edge of the shield 20. When the door is closed, the plug-in 100 is inserted into the socket 200, thereby Seal the door gap to achieve electromagnetic shielding effect. The structure of the plug-in 100 and the socket 200 will be described in detail below. Since the plug-in and soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com