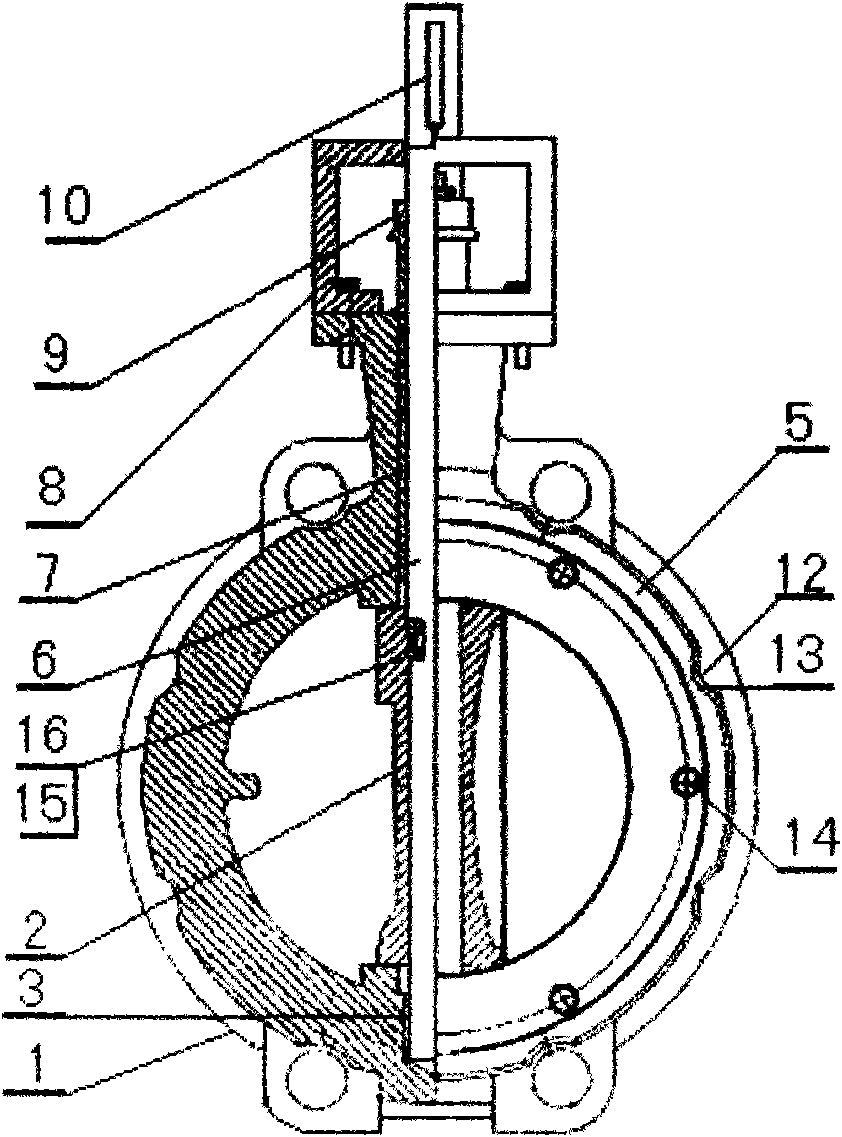

Double eccentric high-sealing butterfly valve

A high sealing, double eccentric technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of small applicable medium range, low service life, large torque, etc., to achieve superior sealing performance, prolong service life, load force-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

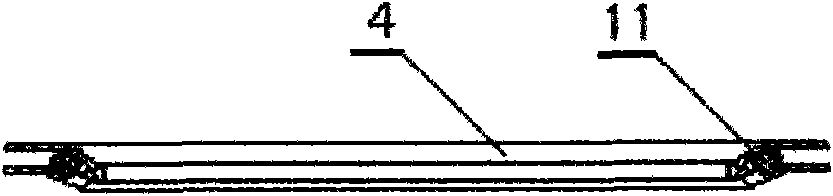

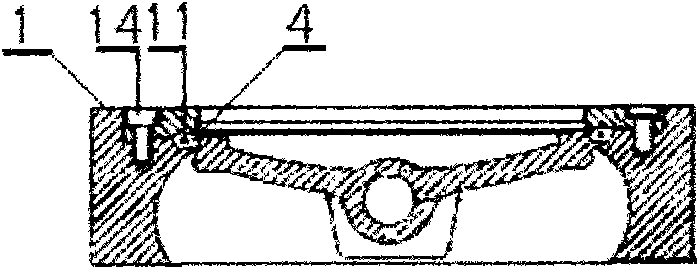

[0011] Referring to the accompanying drawings, the technical solution of the present invention will be further described. The present invention includes a valve body 1, a valve plate 2, a bearing sleeve 3, a valve seat 4, a valve seat gland 5, a valve shaft 6, a V-shaped sealing ring 7, and a bracket 8. The pressure flange 9 and the key 10 are characterized in that the valve seat 4 is a combined type, that is, an elastic O-ring 11 is wrapped in the valve seat 4, the valve seat 4 is made of polytetrafluoroethylene material, and the elastic O-ring 11 Made of fluorine rubber, the valve seat 4 is provided with a valve seat gland 5, and the valve body 1 and the valve seat gland 5 are respectively provided with valve body positioning teeth 12 and valve seat gland positioning grooves 13, and the valve body positioning teeth 12 and the positioning groove 13 of the valve seat gland are engaged with each other to ensure the firm and accurate positioning of the valve seat 4. The valve se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com