Mechanical elastic large-angle slewing limit mechanism

A limit mechanism, large-angle technology, applied in the direction of mechanical equipment, position/direction control, non-electric variable control, etc., can solve problems such as limited range of rotation angle, equipment impact, affecting normal operation of equipment, etc., to achieve a wide range of applications, Avoid the effect of shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

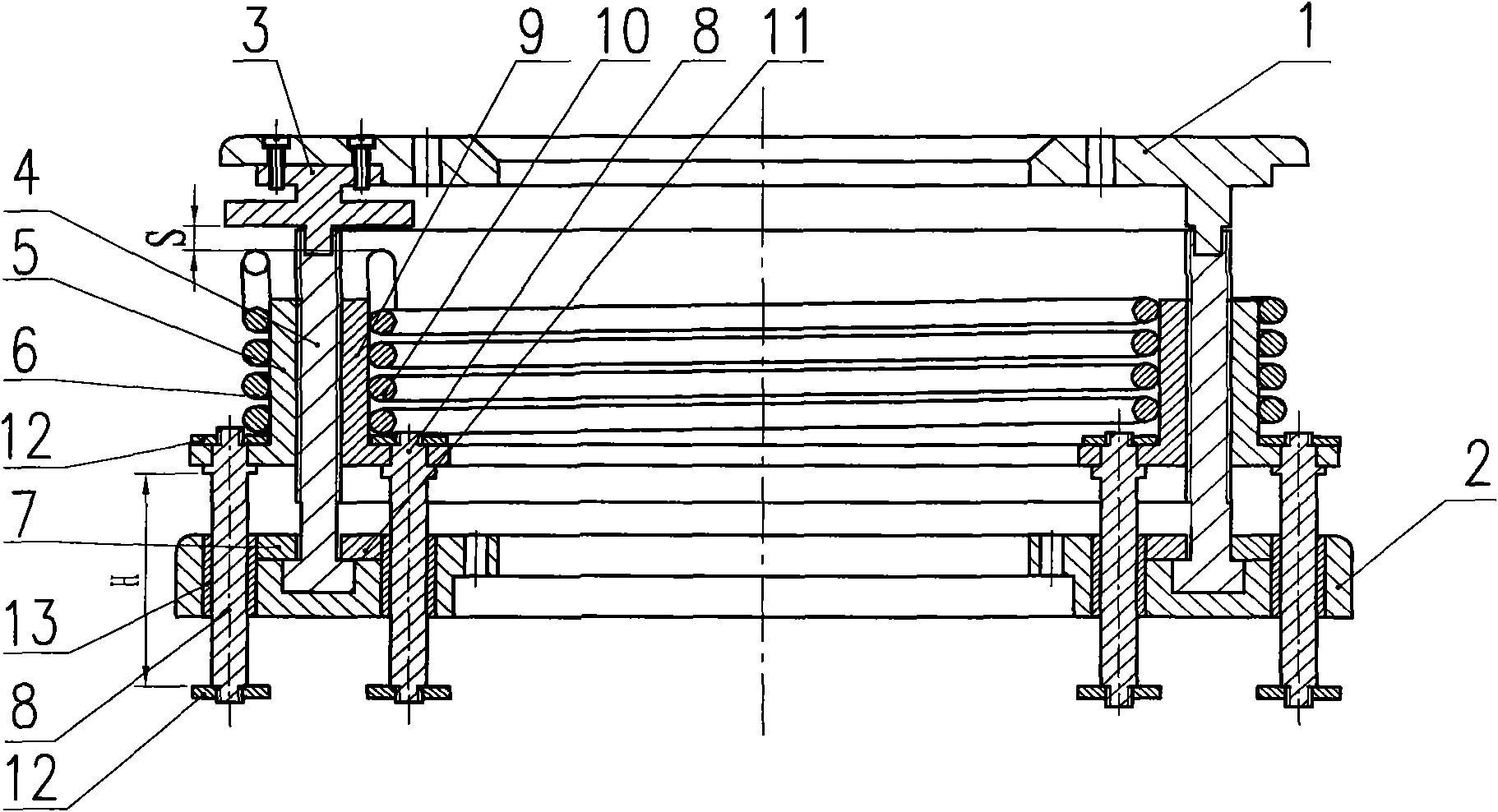

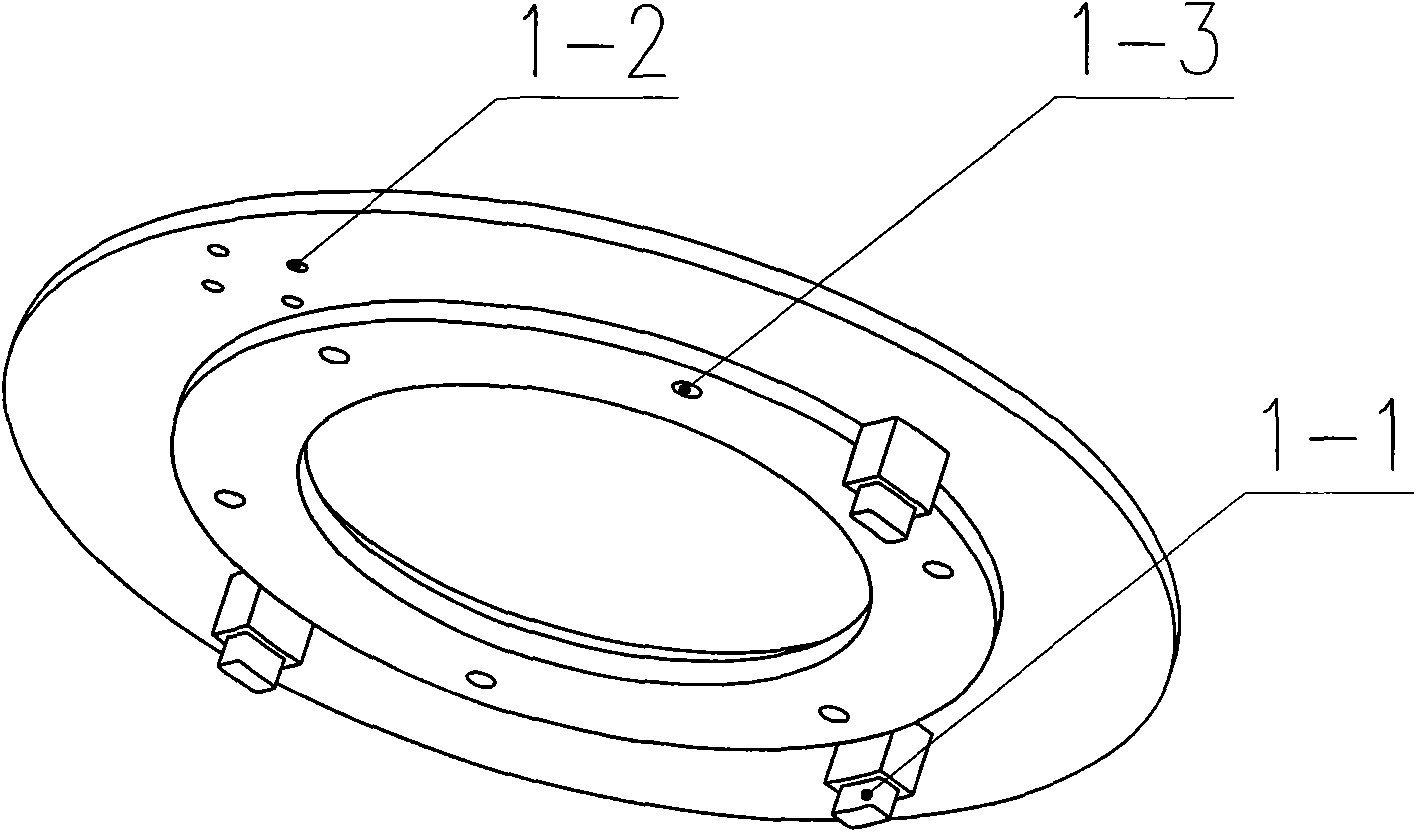

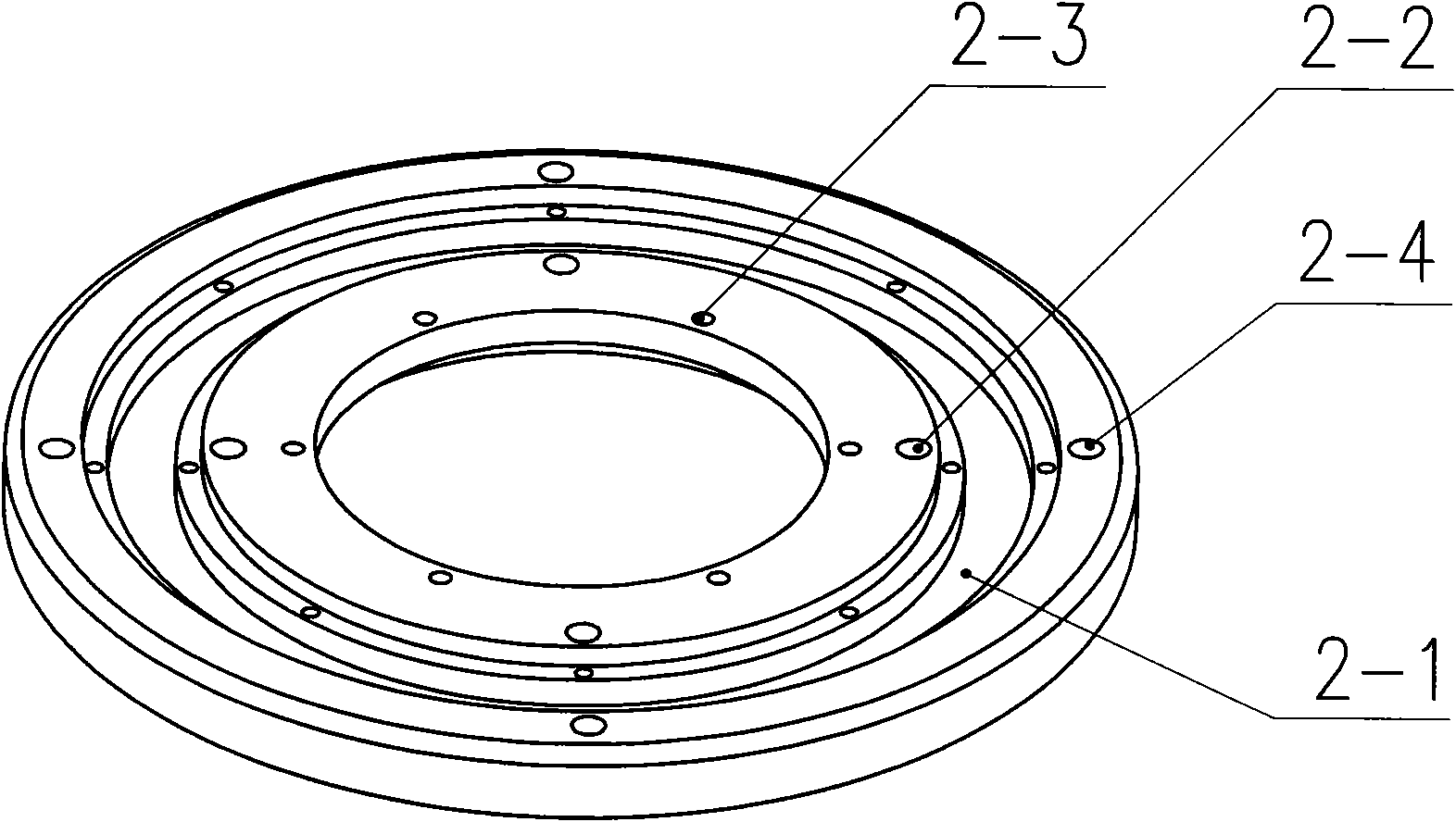

[0020] as figure 1 As shown, the large-angle rotation limit mechanism of the preferred embodiment of the present invention includes a rotary plate 1, a fixed seat 2, a limit block 3, a sliding ring 4, an outer guide cylinder 5, an outer limit spring 6, an outer pressure plate 7, and a guide rod 8. Inner guide cylinder 9, inner limit spring 10, inner pressure plate 11, pressure ring 12, sliding sleeve 13. Rotary disc 1 with central hole and stepped annular disc (see figure 2 ), its outer ring disc is provided with 3 linkage projections 1-1 and each is separated by 90°, and its other 90° position is provided with four first installation holes 1-2, and the protrusion on the rotary disc 1 The inner ring is provided with a group of second mounting holes 1-3 connected with the rotating parts of the equipment. The fixed seat 2 has a central hole and a stepped annular guide groove 2-1 (see image 3 ), the ring belt inside the stepped annular guide groove 2-1 is provided with four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com