Method for precisely positioning large member

A large-scale component and precise positioning technology, which is applied to metal processing machinery parts, measuring devices, instruments, etc., can solve problems such as improvement, difficulty in component processing, and increased machine tool costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

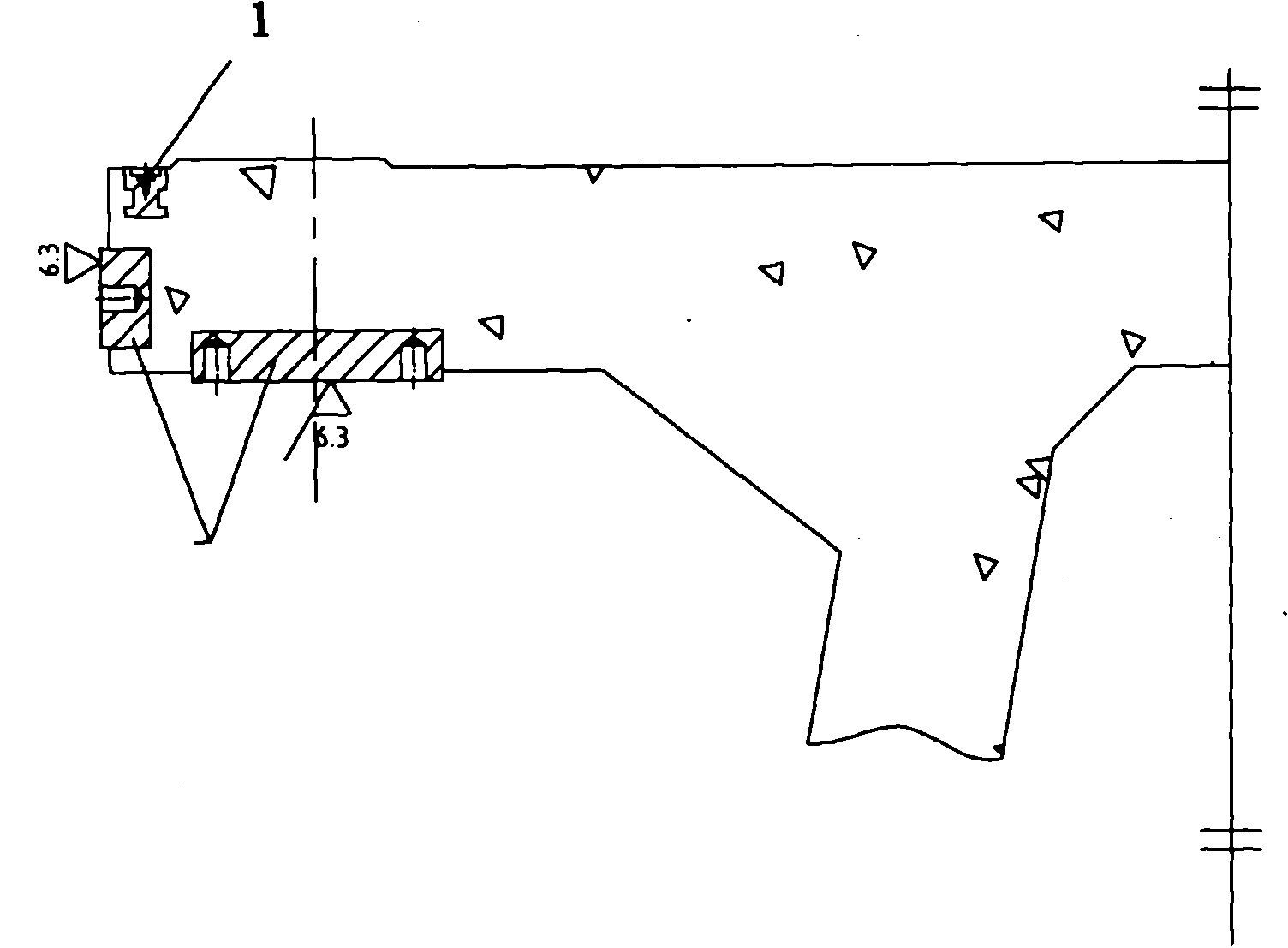

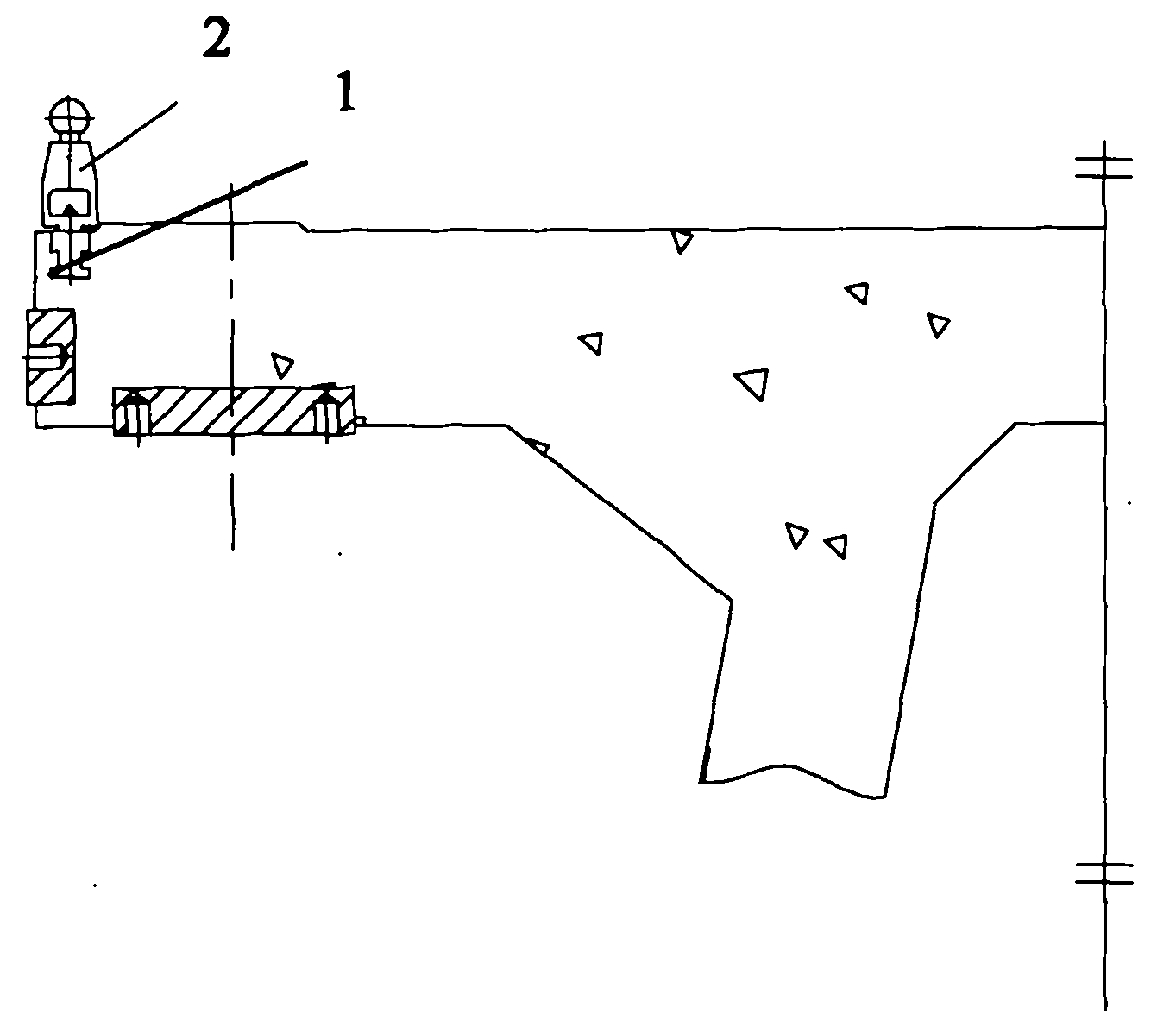

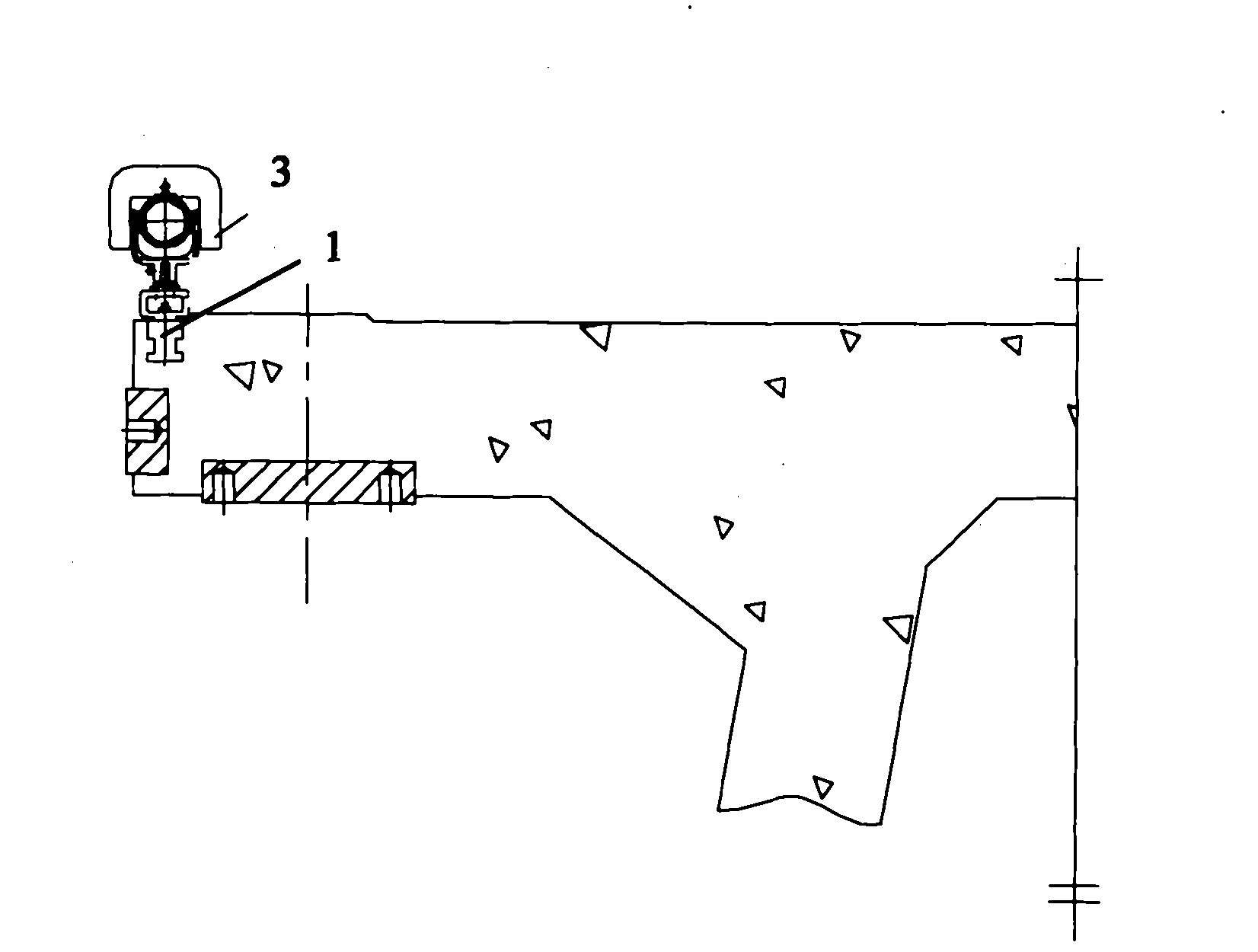

[0016] like Figure 1~3 As shown, the present invention is realized by using a measurement reference point device 1 and a measurement positioning device connected to the reference point device 1 . The measuring and positioning device described in this embodiment includes a measuring ball device 2 and a prism positioning device 3 . The measuring ball device 2 includes a measuring ball support and a sphere arranged in sequence. The prism positioning device includes a connected prism holder and a prism.

[0017] The method for the precise positioning of large components of the present invention comprises the following steps:

[0018] Step 1. Install and embed the measurement reference point device 1 on the large component. like figure 1 As shown, the installation position of the measurement reference point device 1 should be convenient for installing the measurement positioning device used later, and it should be convenient for measurement and observation. The structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com