Automobile cardan joint transmission shaft packaging paper box

A universal joint drive shaft, automobile technology, applied in the directions of packaging, transportation and packaging, rigid containers, etc., can solve the problems of increasing the support strength, low support strength, and easy damage of the automobile universal joint drive shaft, and reduce the movable support. , The structure is simple, the effect of increasing the support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

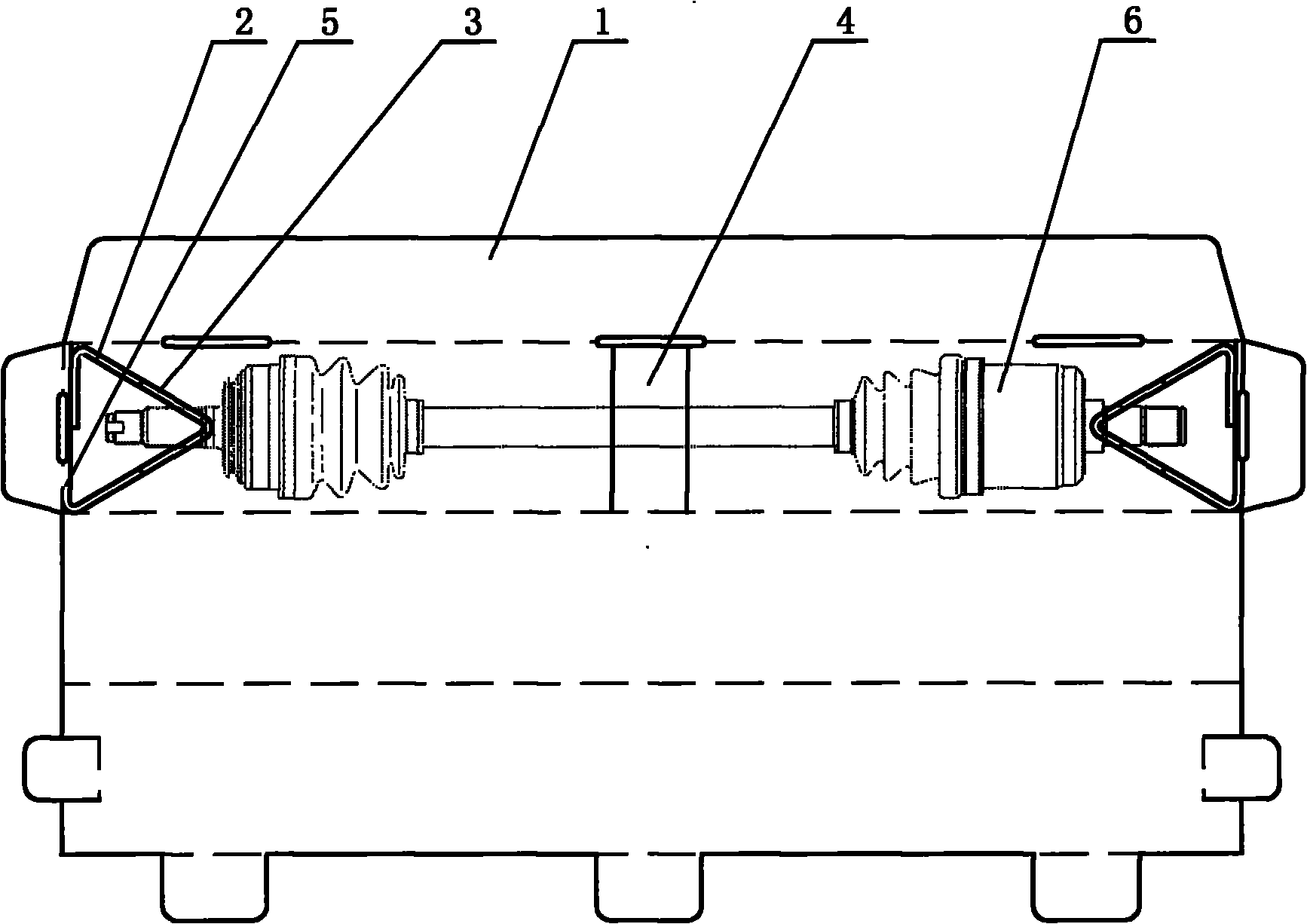

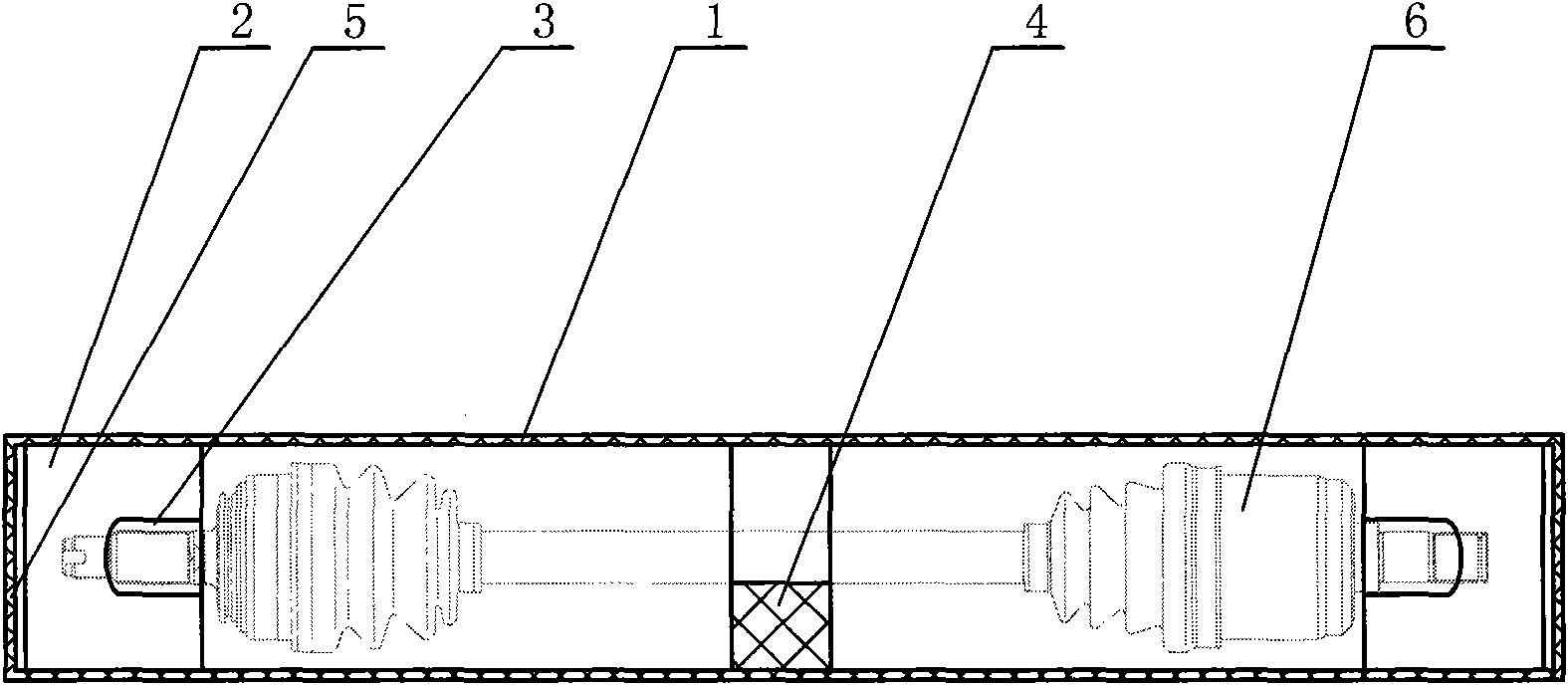

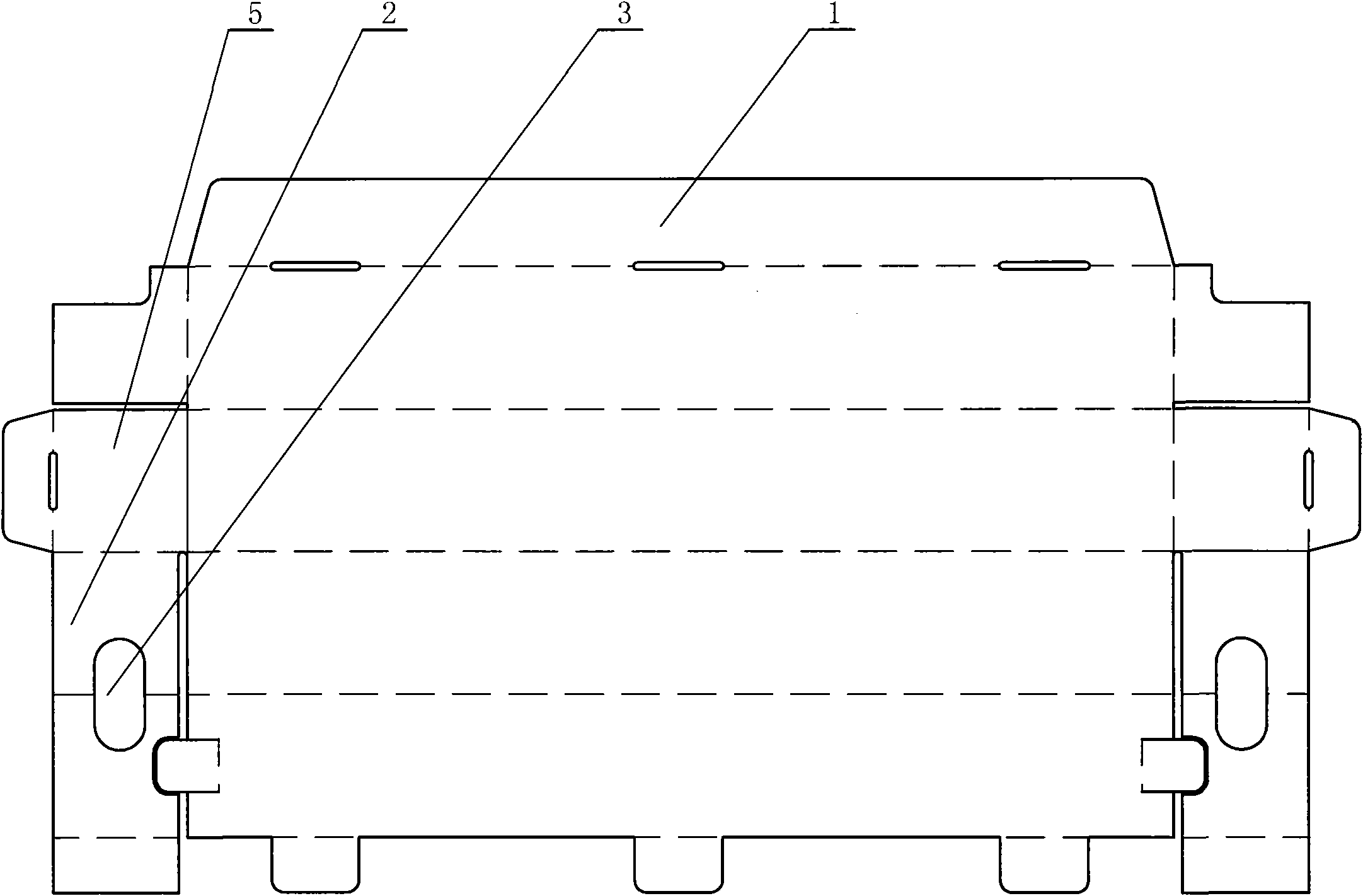

[0014] Depend on figure 1 combine figure 2 and image 3 As shown, the packaging carton for the transmission shaft of the automobile universal joint includes a box body 1. The box body 1 is folded from a whole cardboard. The dotted line in the figure is the folding line. There is a through hole 3 in the middle of the cardboard 2, and the support cardboard 2 is folded to form a triangle with the end surface 5 of the box body 1, and the end of the support cardboard 2 is folded back to be in close contact with the end surface 5 of the box body 1. The through hole 3 is a strip-shaped hole and is symmetrical along the folding line opposite to the end face after being folded on the support cardboard 2. After the support cardboard 2 is folded, the through hole 3 coincides with the end of the automobile universal joint drive shaft 6 . After the through hole 3 opened by the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com