Patents

Literature

35results about How to "No change in dimensions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

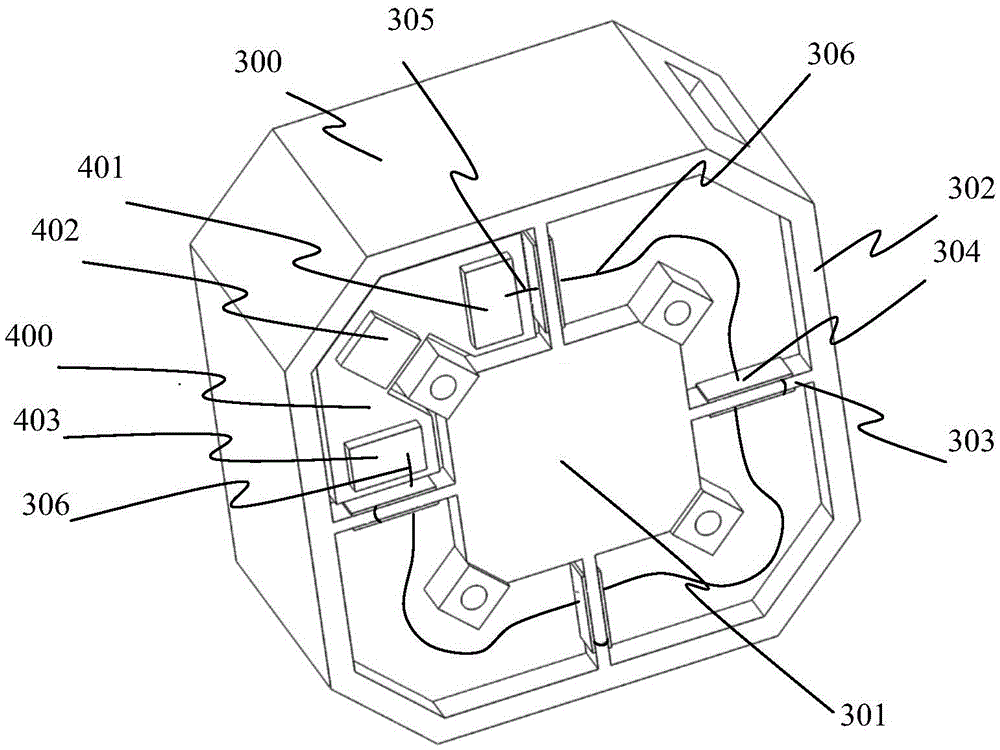

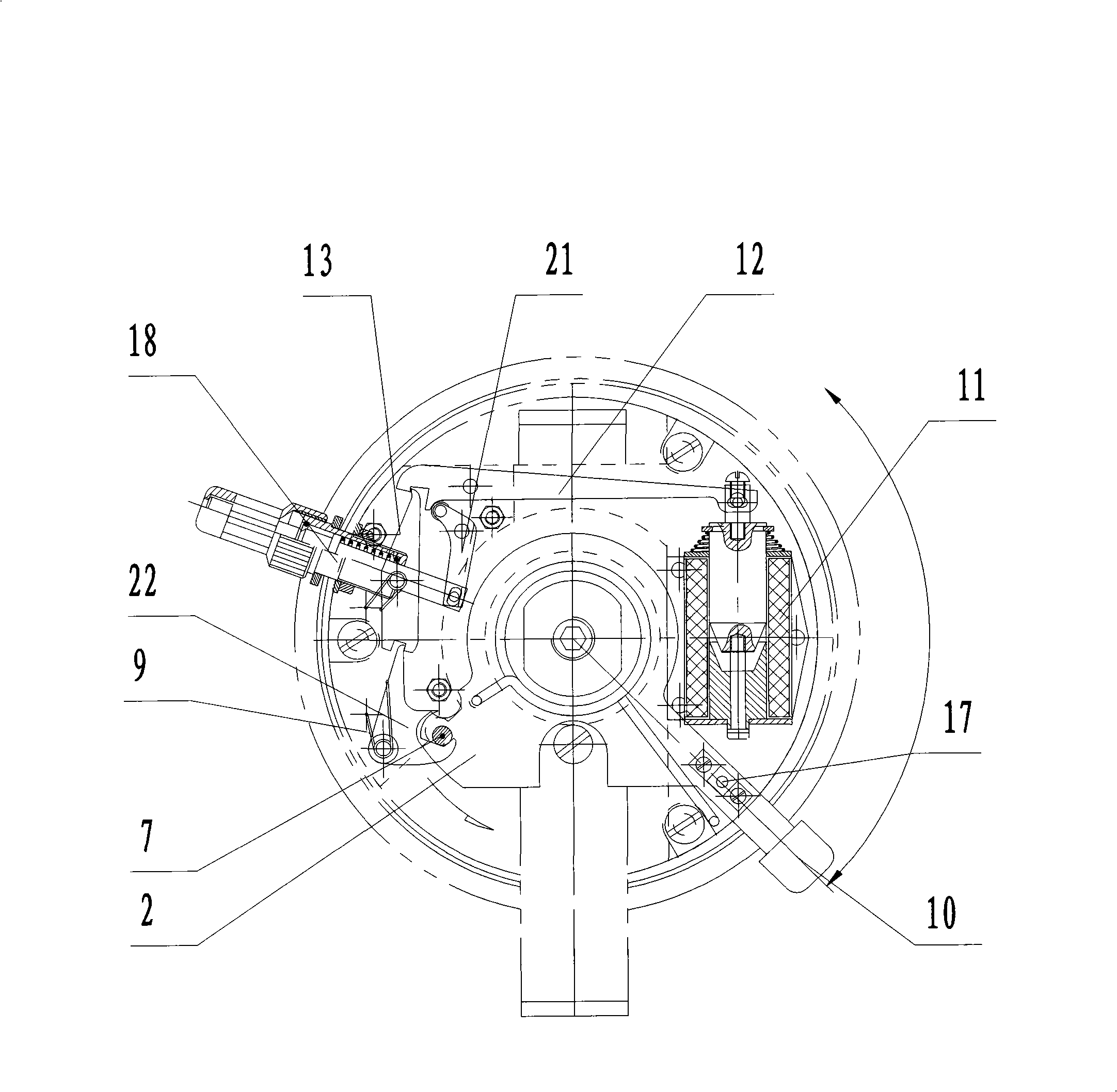

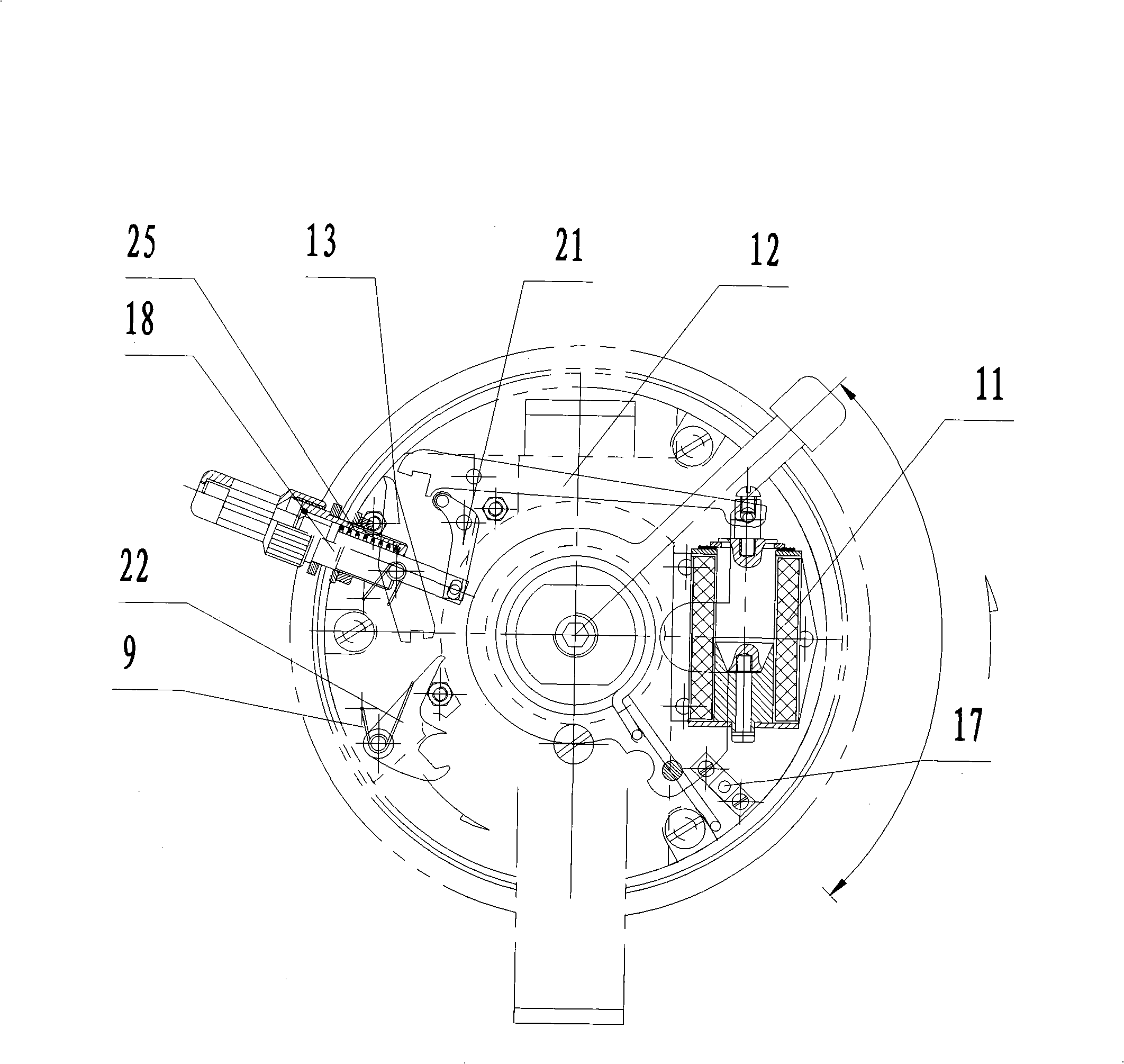

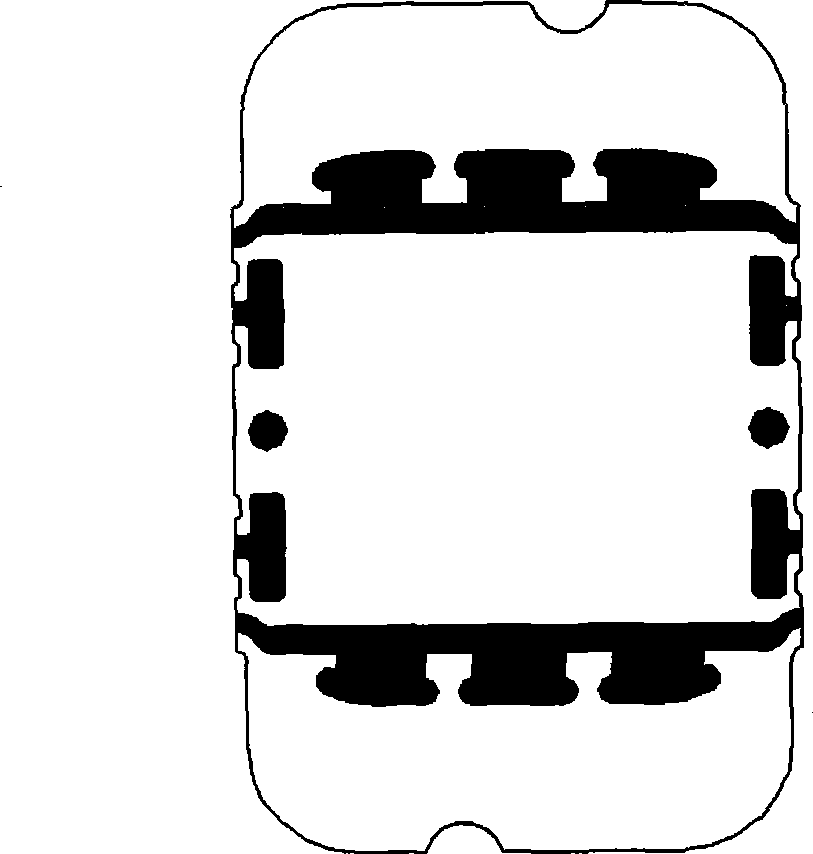

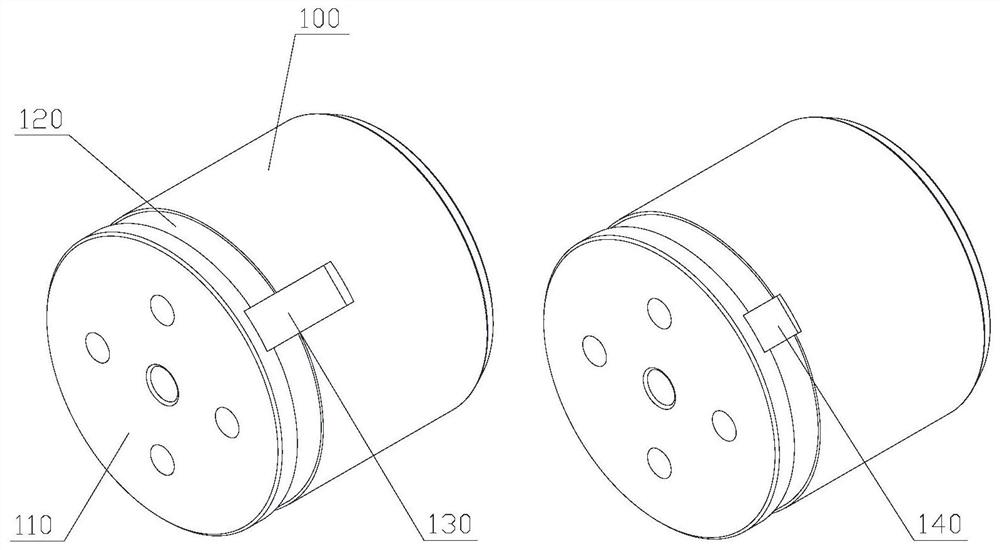

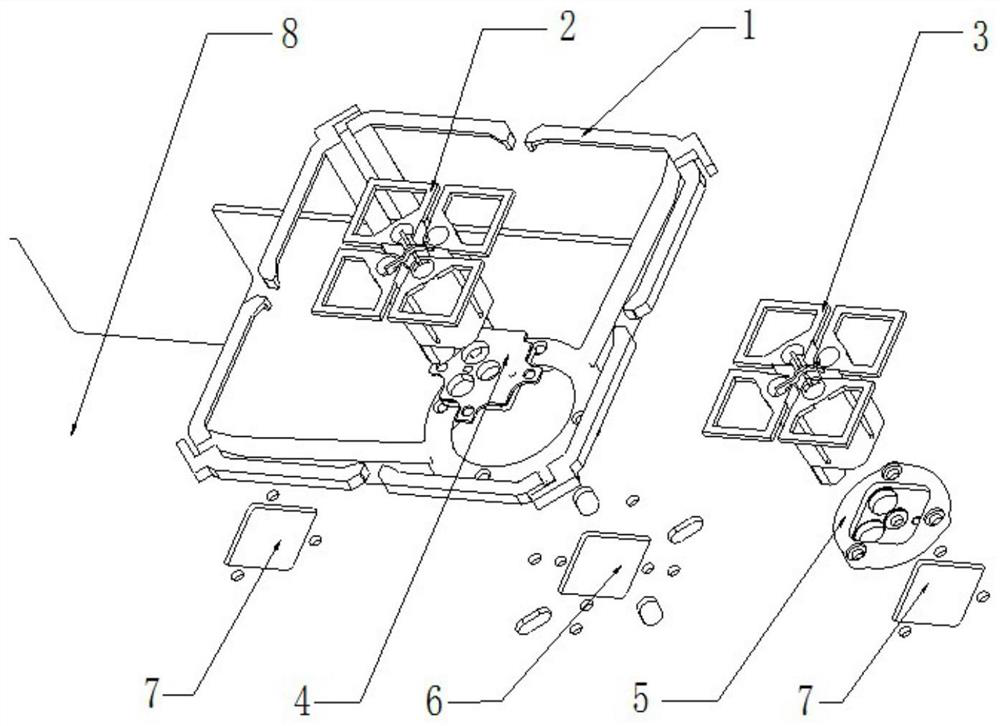

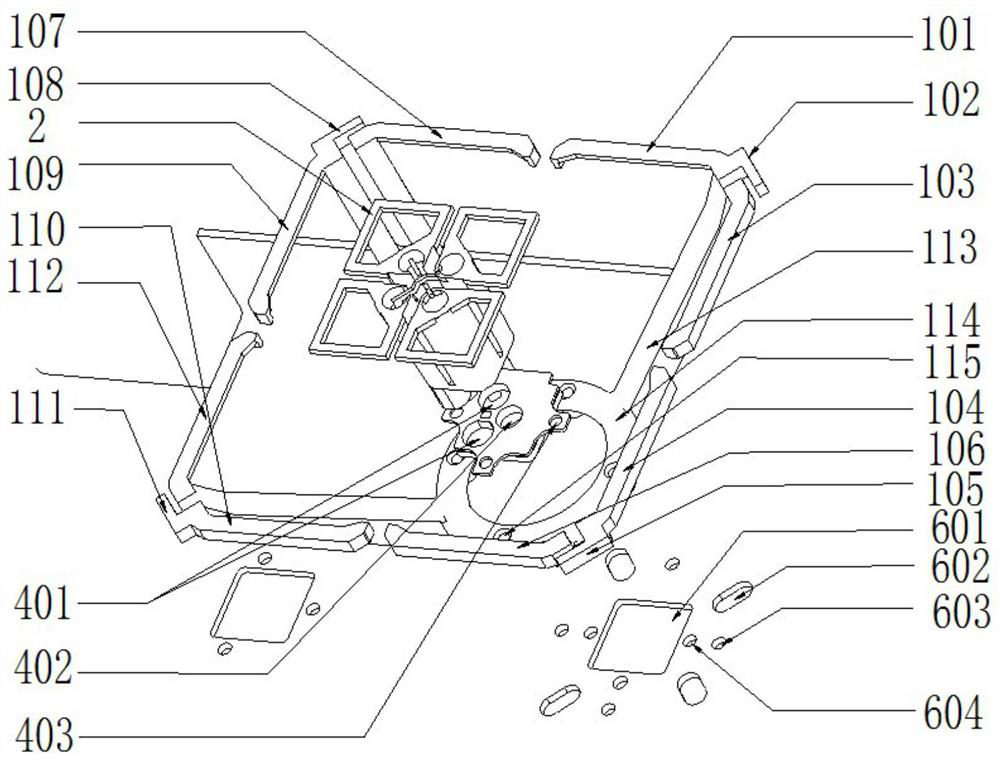

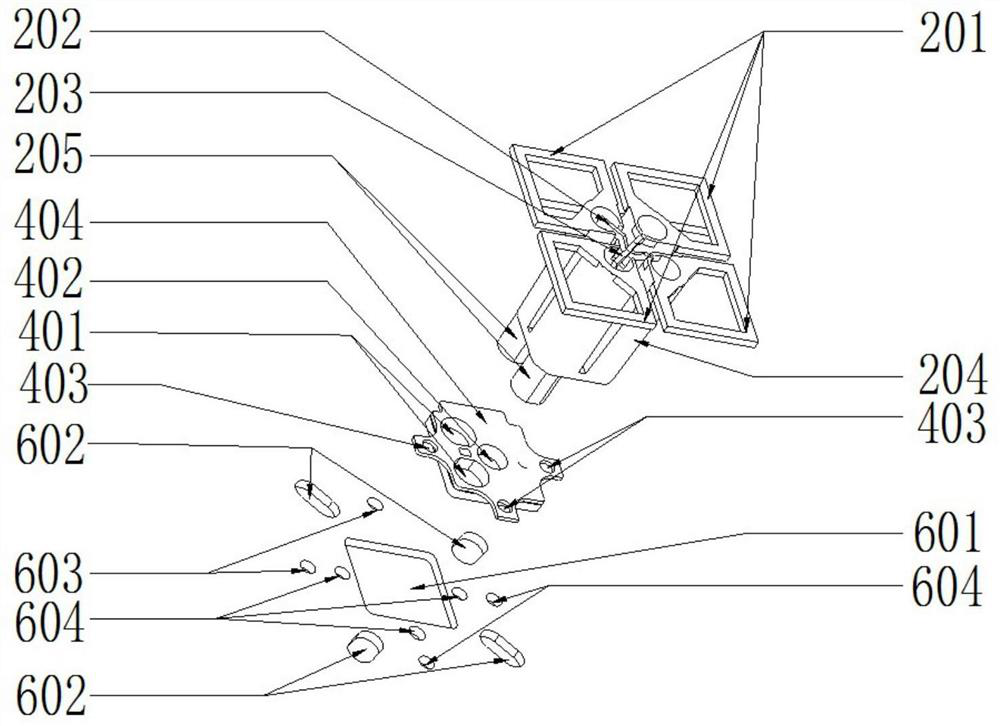

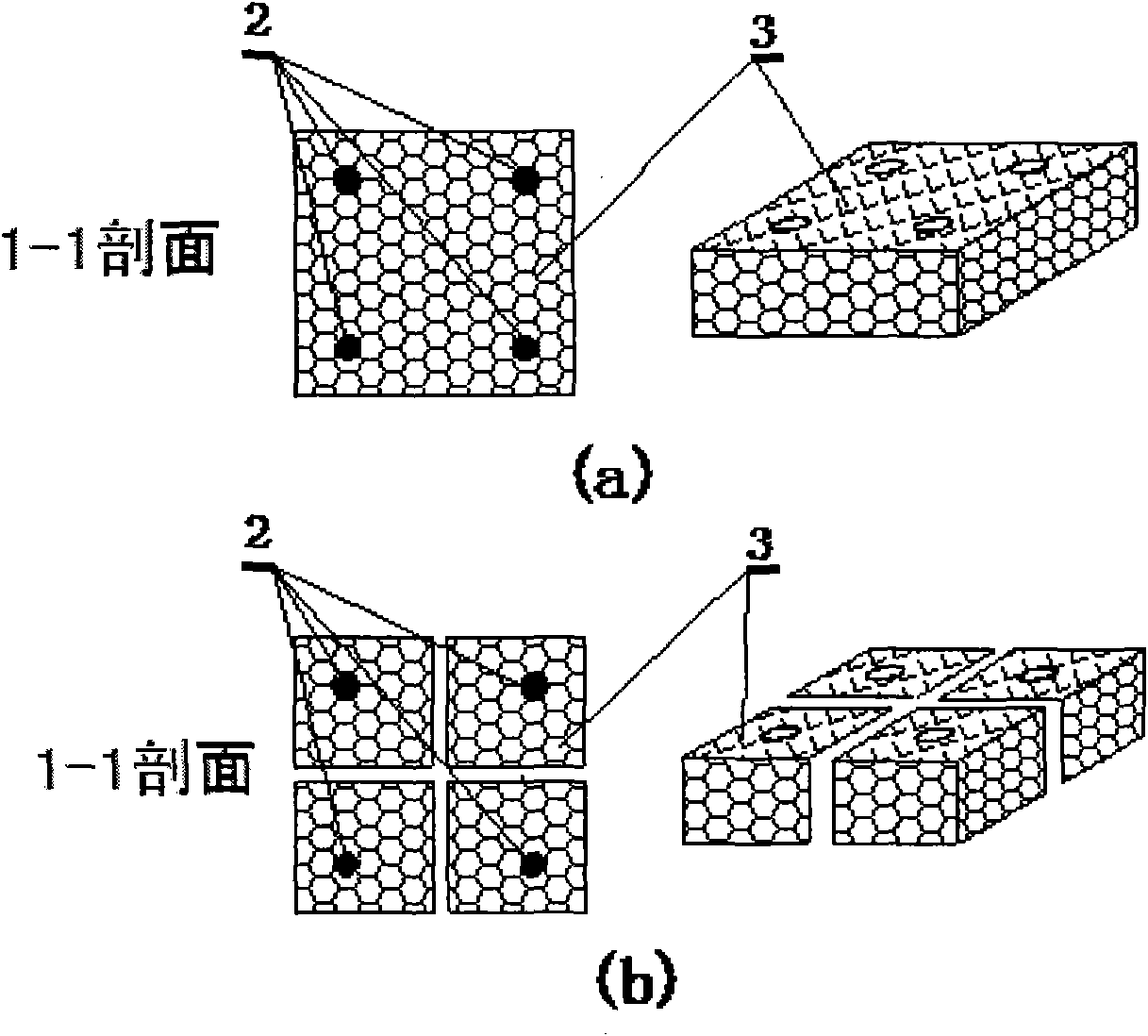

Cavity filter

InactiveCN106025465ANo change in dimensionsReduce processing difficultyWaveguide type devicesResonant cavityHigh volume manufacturing

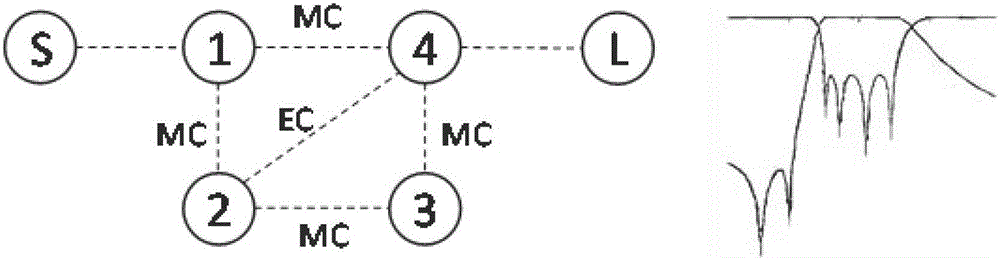

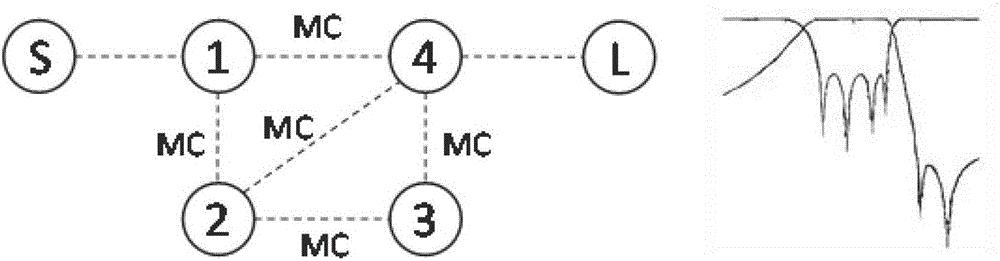

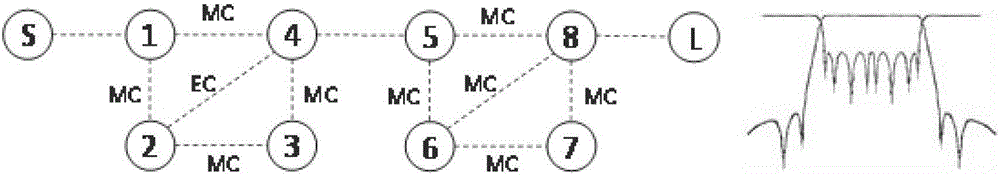

The invention discloses a cavity filter. The cavity filer comprises a metal cavity and a metal cover plate which is positioned on the metal cavity, wherein the metal cavity comprises at least eight resonance cavities which are coupled in sequence; a resonance rod is arranged in each resonance cavity; and the resonance rods in the first and the last resonance cavities are connected with an input signal connector and an output signal connector respectively. The coupling between the adjacent resonance cavities is magnetic coupling; coupling windows and coupling rods are arranged between the corresponding resonance cavities on the left and right sides of a passband; four places of crossed coupling is introduced, so that two transmission zero points can be generated on the left and right sides of the passband respectively, and higher out-of-band rejection can be achieved; the outline dimension of the overall filter cavity is not changed; the order of the filter is not increased, and the size of the filter is not enlarged; meanwhile, the cavity filter is easy to process and debug, and low in cost; and the large-batch production of the cavity filter can be achieved.

Owner:36TH RES INST OF CETC

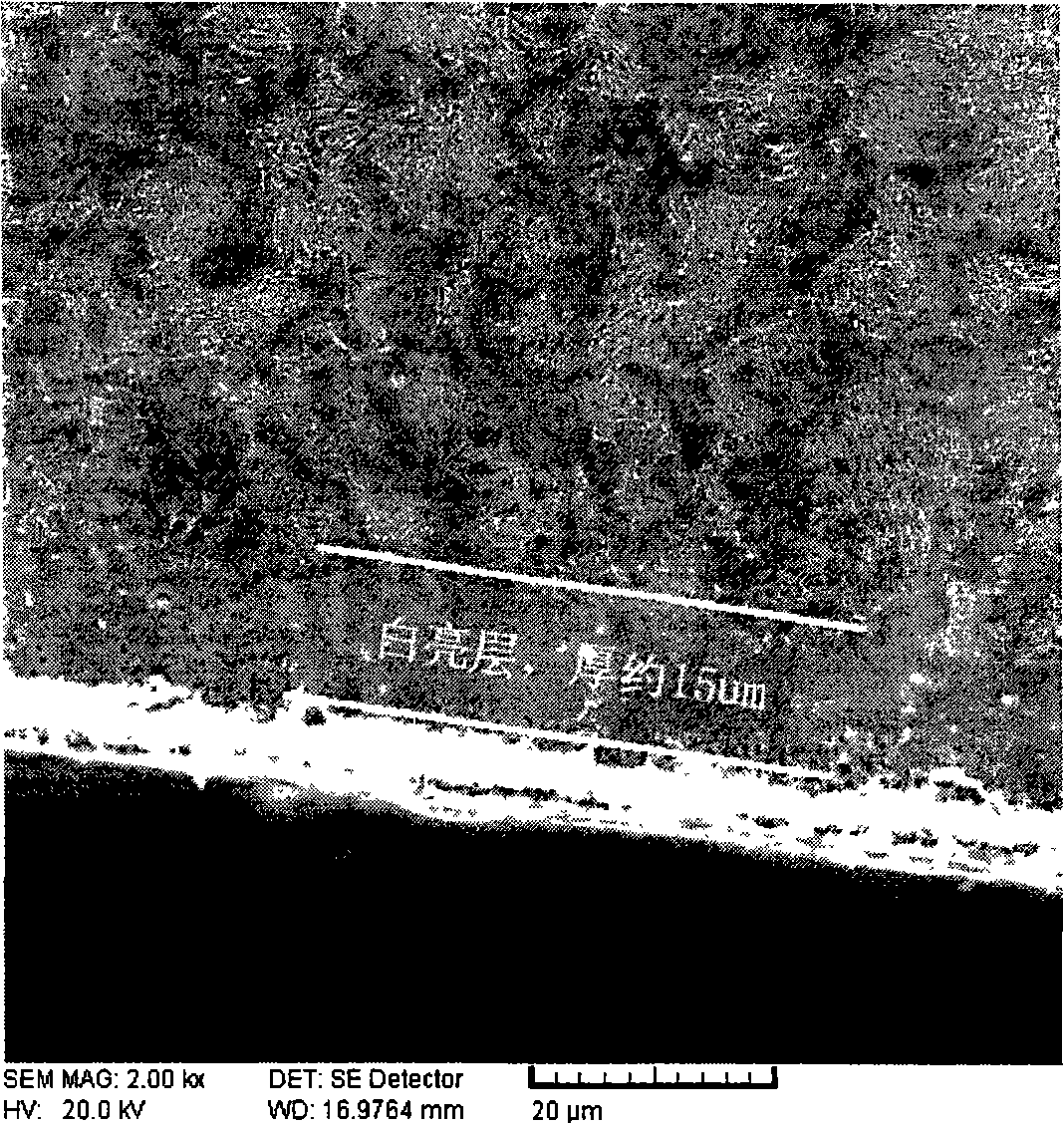

Anti-corrosion and heat tinting composite surface treating method for steel

InactiveCN101353801AImprove wear resistanceImprove corrosion resistancePolishing machinesSolid state diffusion coatingComposite filmSodium nitrite

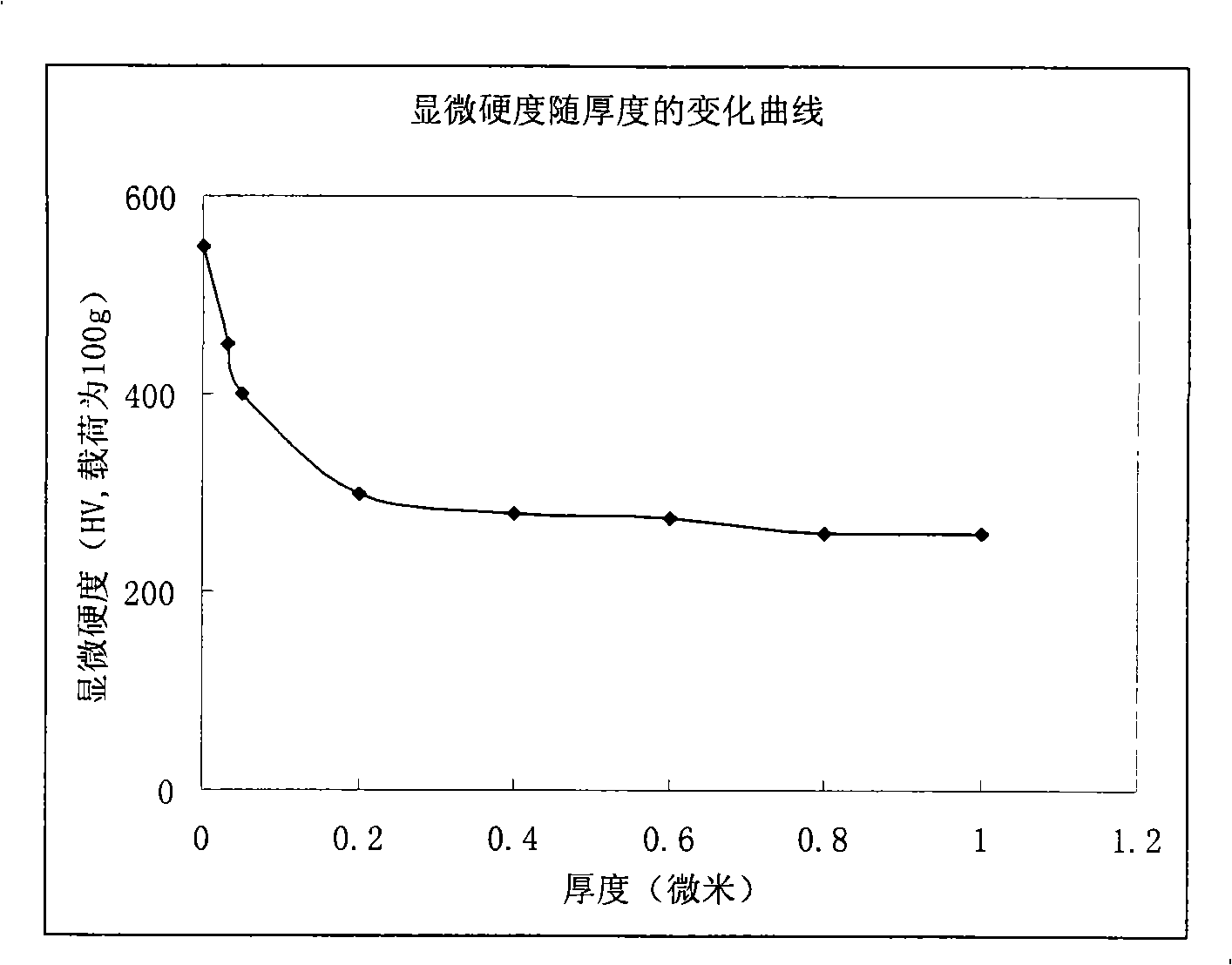

The invention relates to a method for treating the anti-corrosion and oxidized and colored composite surface of steel, and pertains to the metal material surface treatment technical field. Derusting and polishing are first carried out to a steel material so as to lead the roughness degree of the material surface to reach the requirement, and pre-oxidation is carried out to the treated blank; the pre-oxidated blank is put into a salt bath furnace to react and then a carburizing salt residual on the surface is washed off, or the pre-heated blank is put into an atmosphere of ammonia and ethanol to react, the blank for carburizing treatment is vibrantly polished, and polishing wax or grease residual on the surface is cleaned; the polished blank is put into tempering atmosphere for coloring, or immersed in the water solution of sodium hydroxide and sodium nitrite to be colored, and finally, sealing treatment is carried out. The method of the invention can cause that the colored composite film of the steel surface has the excellent performances of wear resistance and anti-corrosion, and the products prepared by the steel material of the invention have good ornamental performance. The method of the invention has simple technology process, low product cost, and no environmental pollution, does not change external dimension of the products, and can be used for coloring treatment of various carbon steels and alloy steels.

Owner:余煌

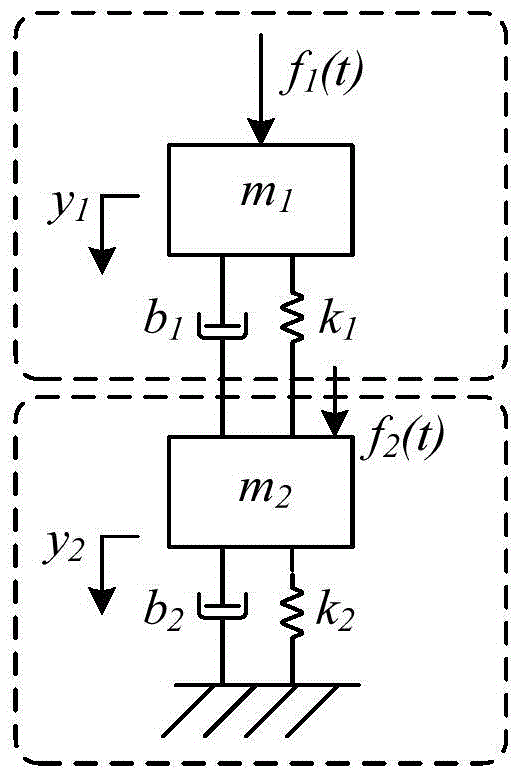

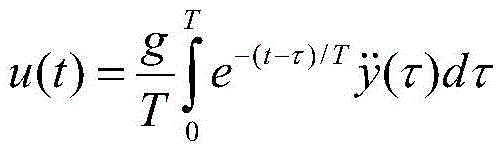

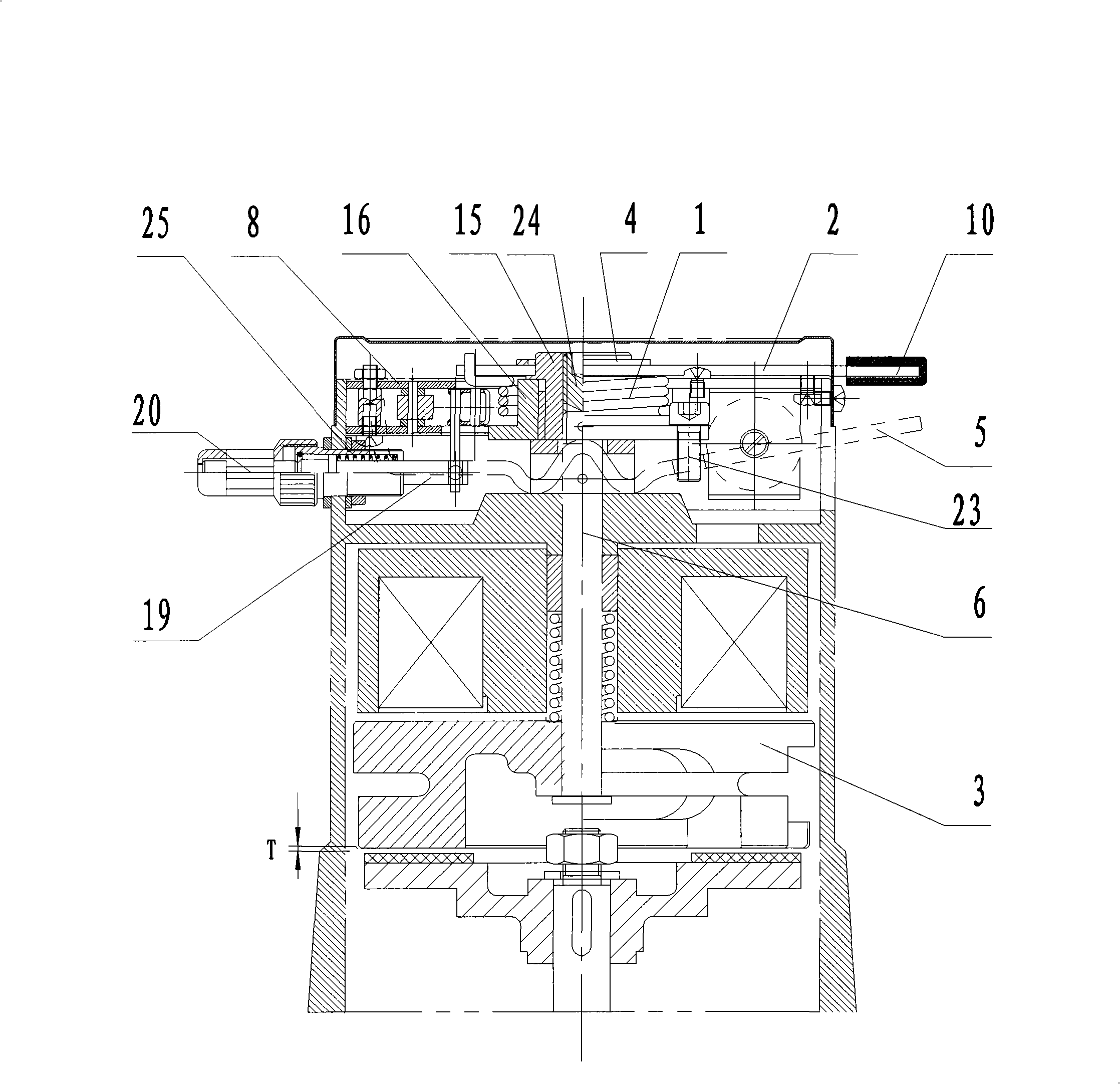

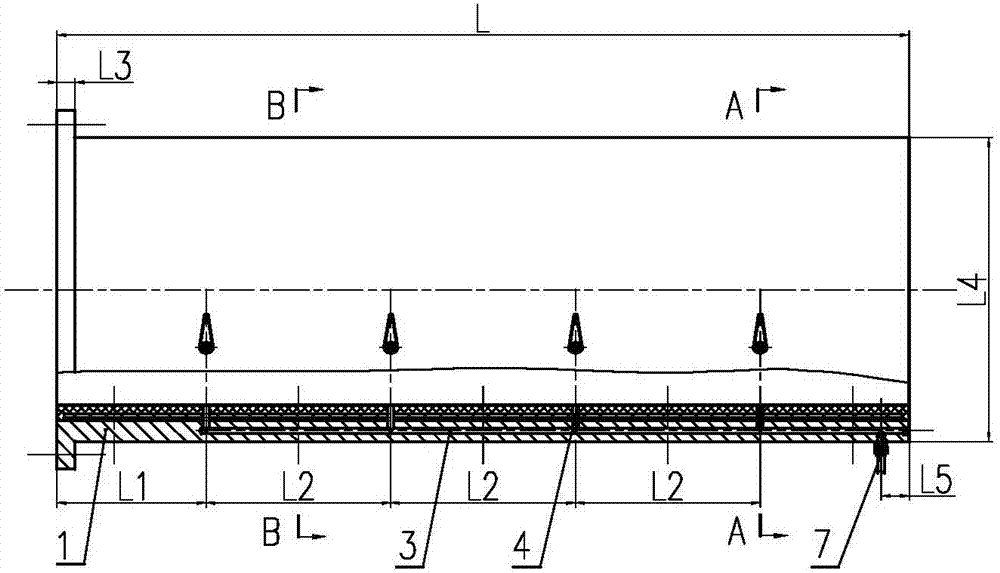

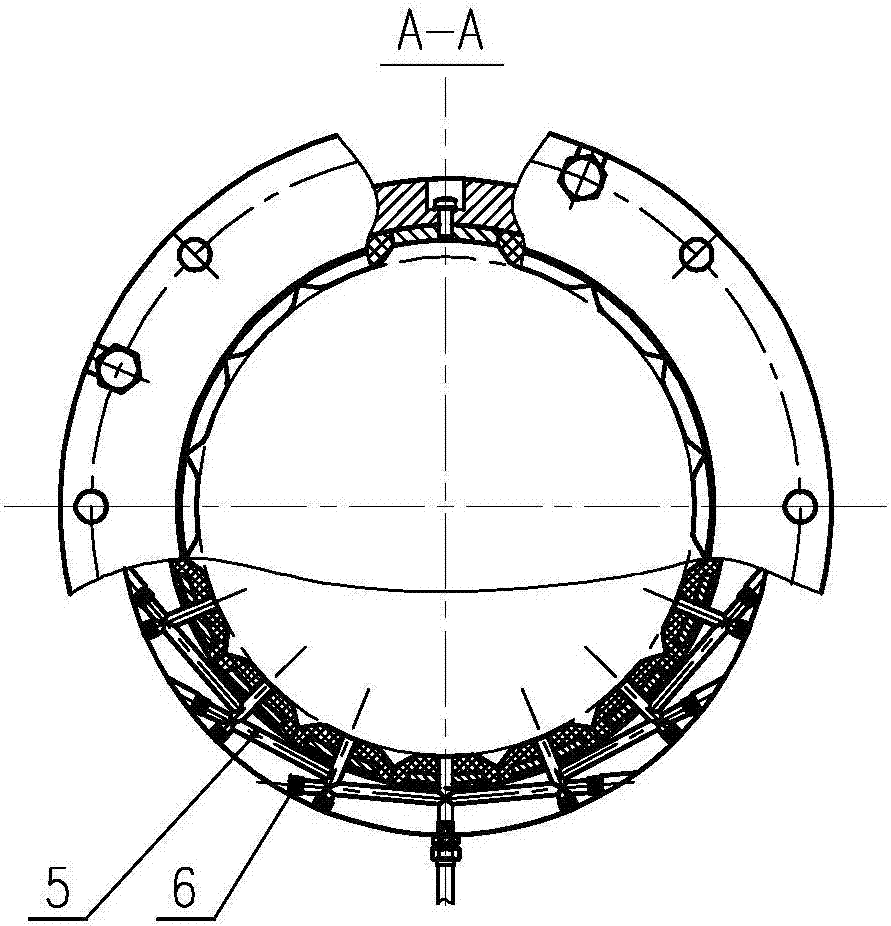

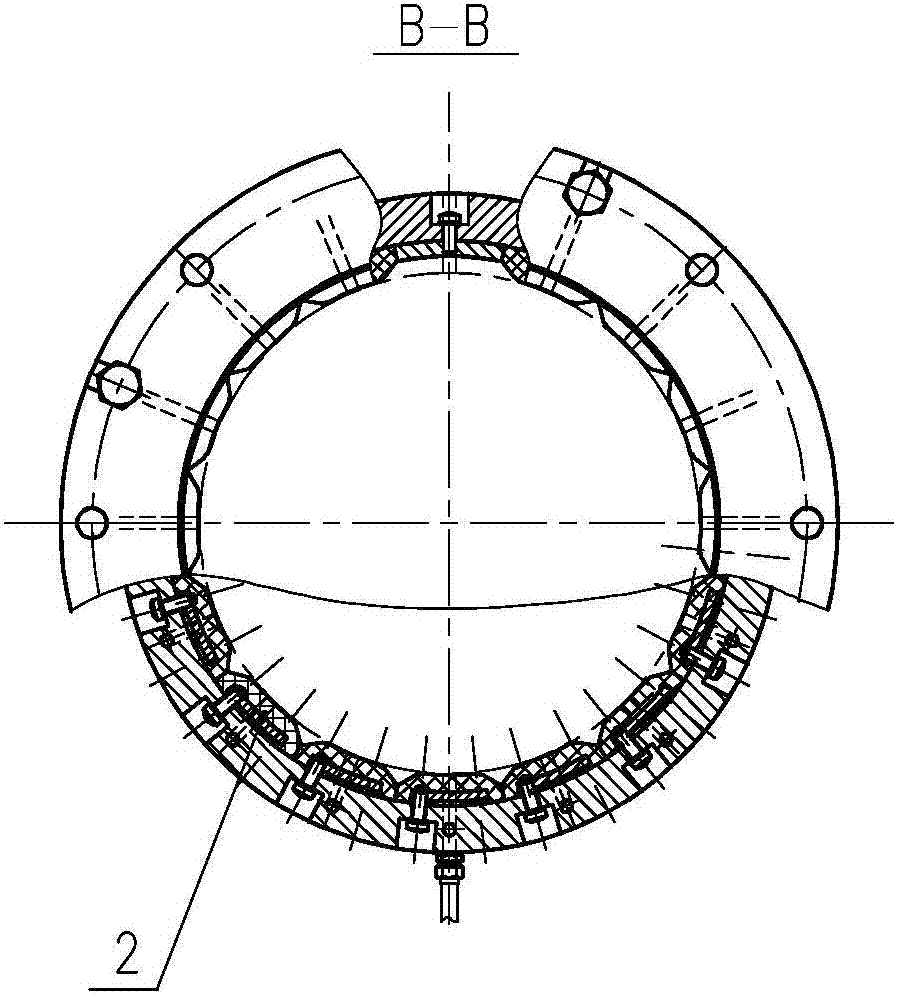

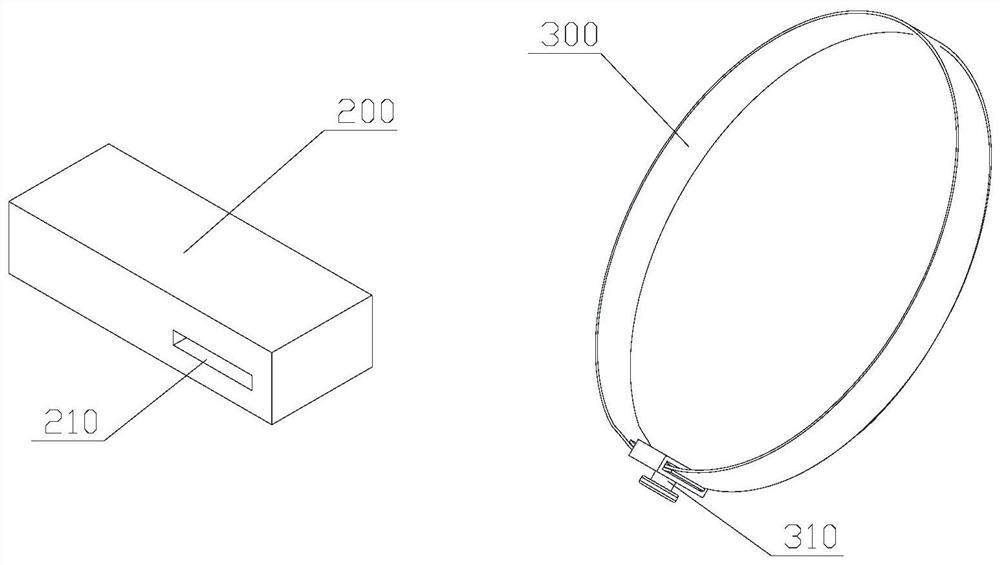

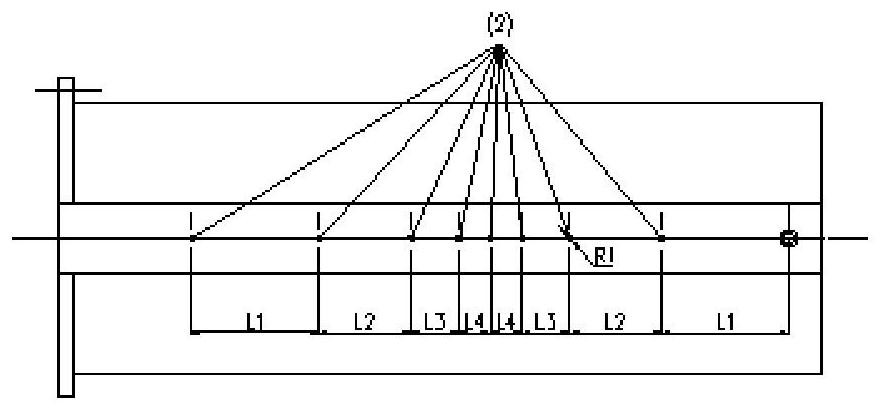

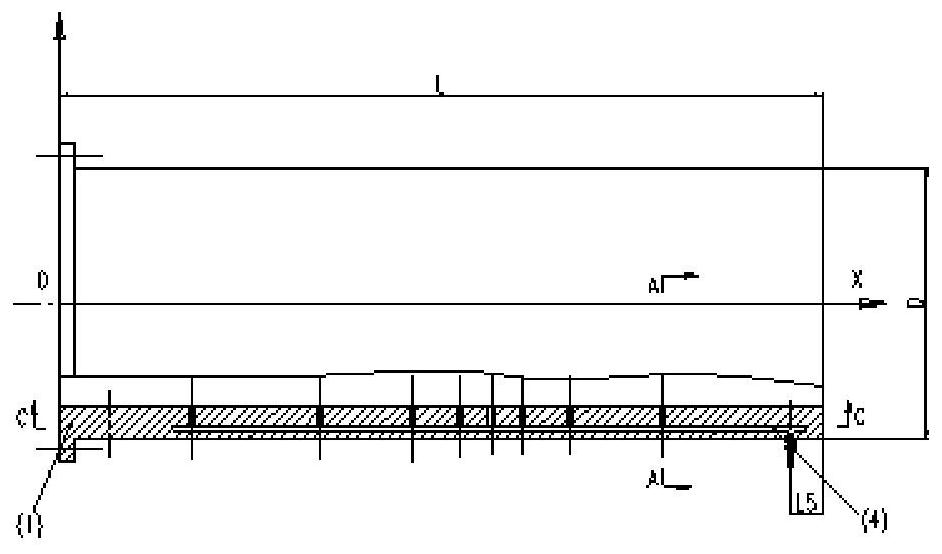

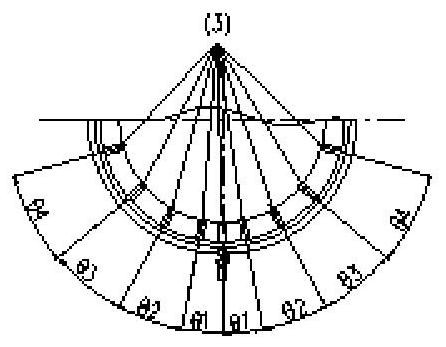

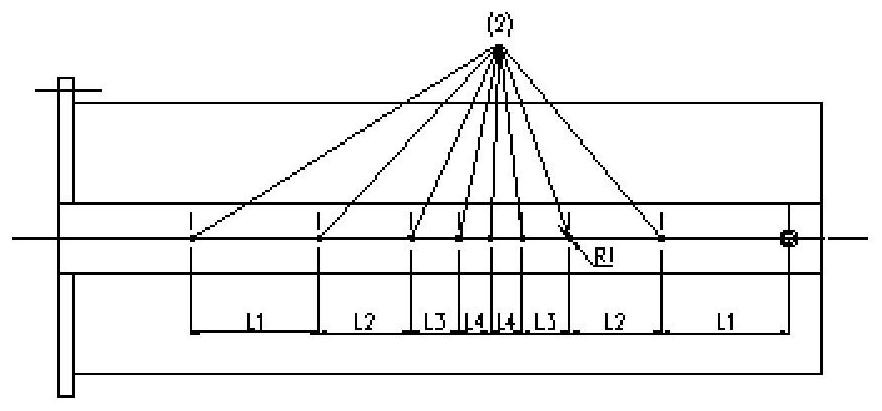

Active vibration damping control method for mechanically dithered ring laser gyroscope

InactiveCN105547274ANo change in dimensionsSeamless replacementSagnac effect gyrometersElectricityRing laser gyroscope

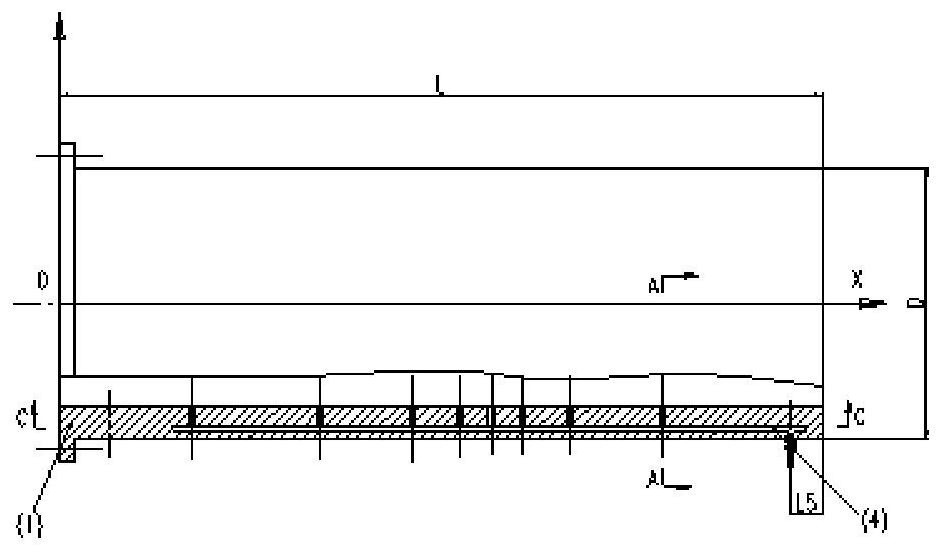

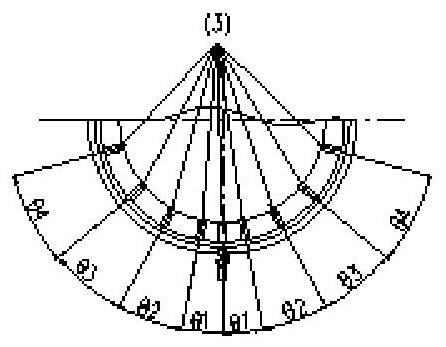

The invention relates to an active vibration damping control method for a mechanically dithered ring laser gyroscope. In the bottom space of an installation housing provided with a mechanically dithered ring laser gyroscope, N equally spaced damping weight spokes are arranged between a central base and an external wall of the installation housing, and the N weight spokes are in rotational symmetry about the center of the central base; both sides of each vibration damping weight spoke are provided with piezoelectric ceramic sheets, wherein one is used for detecting a dither signal generated by a mechanical dither device of the mechanically dithered ring laser gyroscope and then inputting the signal to a processor; and the processor outputs an active damping driving signal voltage and loads the voltage onto the remaining 2N-1 piezoelectric ceramics. The method simplifies the complex process of actual parameter adjustment, shortens the setup time of active vibration damping and improves the control precision.

Owner:NAT UNIV OF DEFENSE TECH

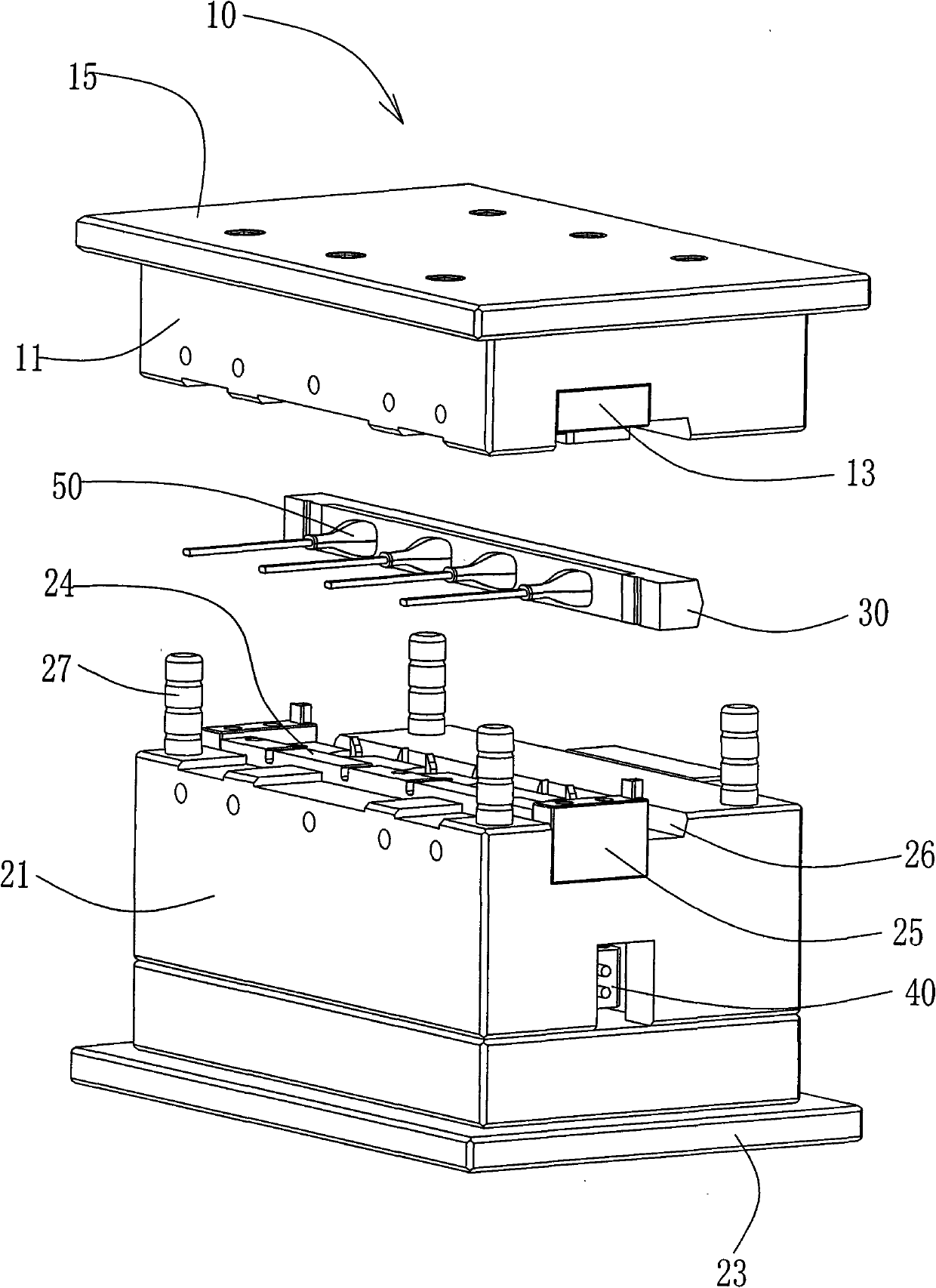

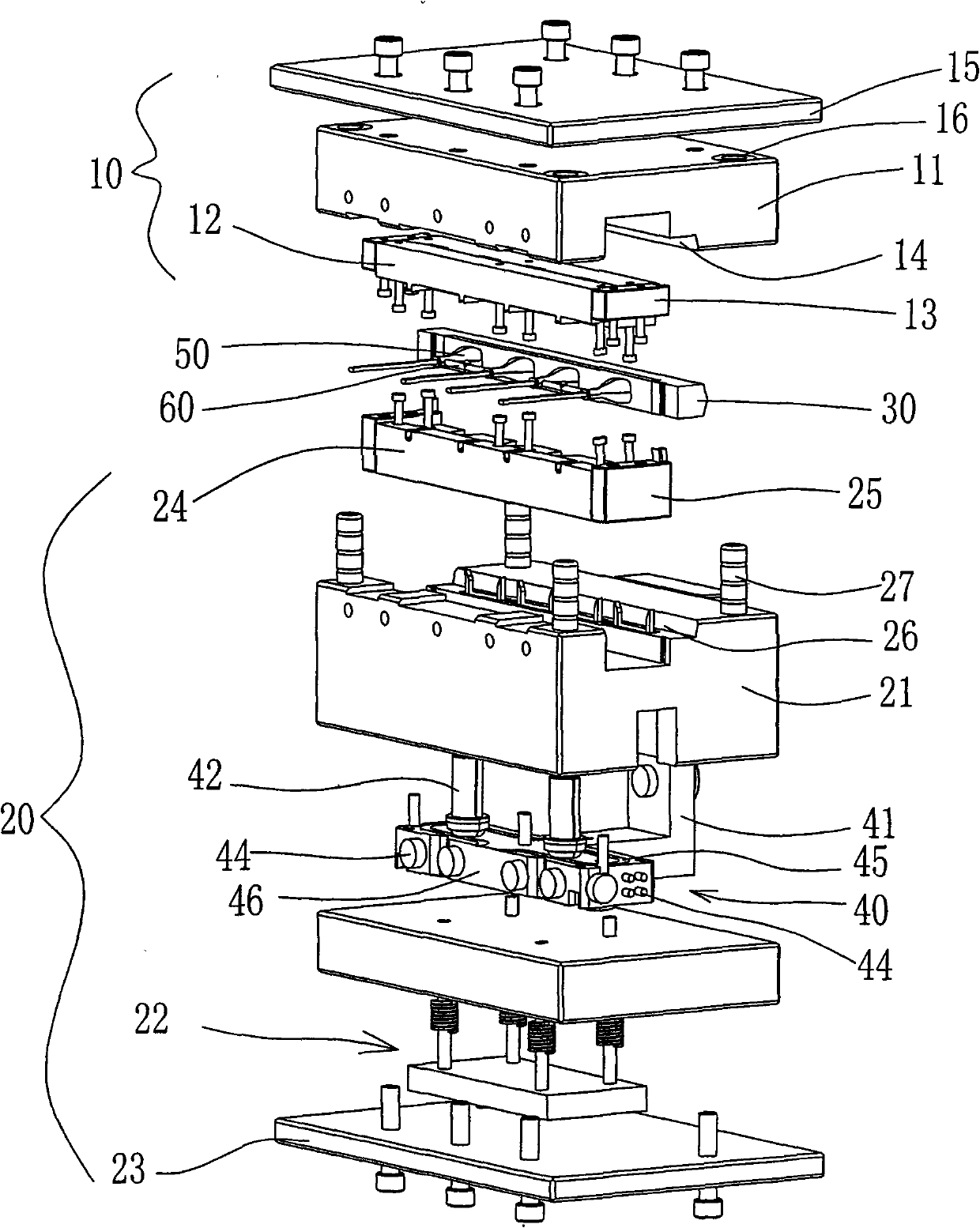

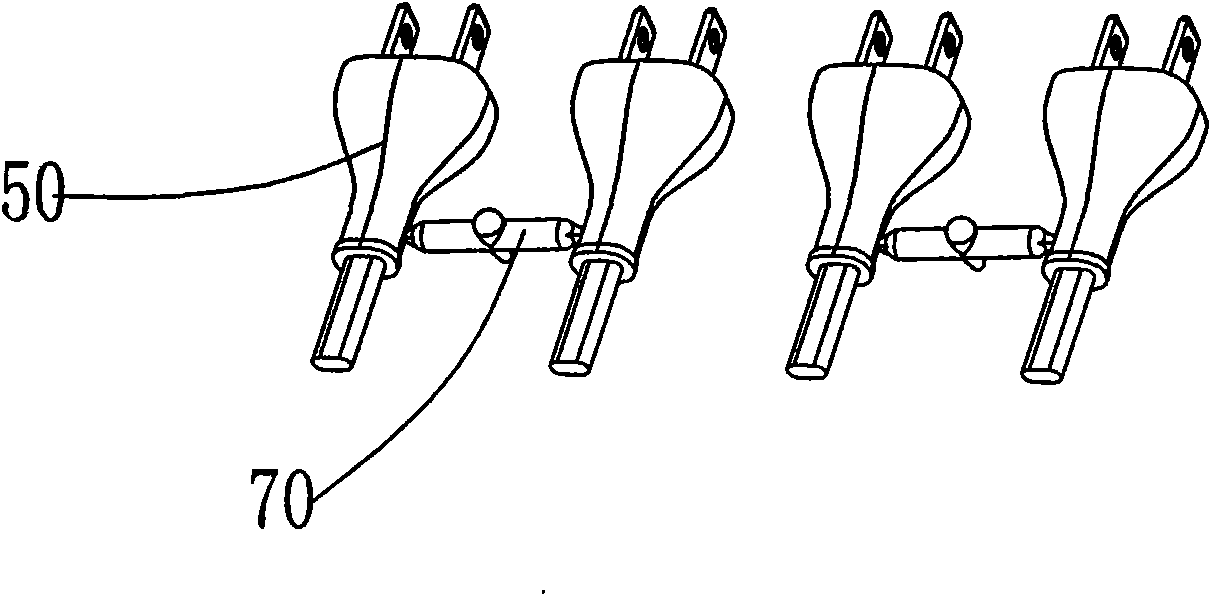

Vertical-type injection mold of improved plug

The invention relates to a vertical-type injection mold of an improved plug, comprising a movable die, a fixed die and a die strip. The fixed die comprises a fixed template; a thimble mechanism is arranged below the fixed template; the upper bottom side of the fixed template is sequentially provided with a lower slot, a lower mold cavity and a lower die strip slot for placing the die strip; a lower bottom plate is arranged below the thimble mechanism; the movable die comprises a movable template; an upper slot, an upper mode cavity and an upper die strip slot are arranged on the lower bottom side of the movable template; an upper bottom plate is arranged above the movable template; the movable die and the fixed die are positioning through a guide post and a guide sleeve; the fixed template is internally provided with a holding cavity; a hot runner device is arranged on four sides of the holding cavity in a suspending and positioning way; an inlet of the hot runner device is arranged on a nozzle plate; an outlet of the hot runner device is provided with a hot runner electric heat nozzle; a nozzle of the hot runner electric heat nozzle is arranged near the cavity of the lower die cavity and is communicated with the cavity; or the nozzle of the hot runner electric heat nozzle is directly communicated with the lower die cavity. The mold has the advantage that less or no injection waste is produced without changing the overall dimension of the existing vertical-type injection mold.

Owner:陈功明

Quick release device for rolling screen door

InactiveCN101285370ALong-term useUnlimited by blackout timeDoor/window protective devicesFireproof doorsEngineeringElectric control

The invention provides a fast pulling-down device for roller shutter doors, comprising a drive plate, a hoisting mechanism and an electronic control starting mechanism, wherein the hoisting mechanism comprises a rotating rod and a positioning sleeve kept fixed; one end of the rotating rod is fixed with the top end of a brake rod, and the other end of the drive plate; the rotating rod and the positioning sleeve are in threaded fit connection; the drive plate drives the rotating rod to rotate under the drive of the electronic control starting mechanism and drives the brake rod to move up and down by utilizing the thread lead angle between the drive plate and the positioning sleeve. The invention provides the fast pulling-down device for roller shutter doors, which is simple and compact in structure, low in cost, high in control precision and wide in application range.

Owner:石峥嵘

Metal carrier band for packaging noncontact module with large size

InactiveCN101447465AAvoid encapsulation processChange sizeSemiconductor/solid-state device detailsSolid-state devicesChip sizeShell molding

The invention provides a metal carrier band for packaging a noncontact module with large size which is characterized in that the metal carrier band comprises a chip bearing region which can bear a chip of 3.9*4.5mm. The chip which is 1.5 times of the area of a common chip can be bear and packaged, and a module product with the same mechanical size is obtained. By the improvement of the metal carrier band and under the premise of the increased size of the packaged chip, the combining force of a mould body with the metal carrier band is improved to the maximum extent after the mould packaging, therefore, the mechanical force resistance of internal devices is improved greatly. The carrier band is packaged in a reeling way. Under the premise of not adding the investment, the present conventional packaging process and the existing equipment can be used for producing products with better quality, therefore, the application of high-end chips, such as noncontact intelligent electronic passport, EMV band card, and the like in the intelligent card field is expanded.

Owner:SHANGHAI CHANGFENG SMART CARD

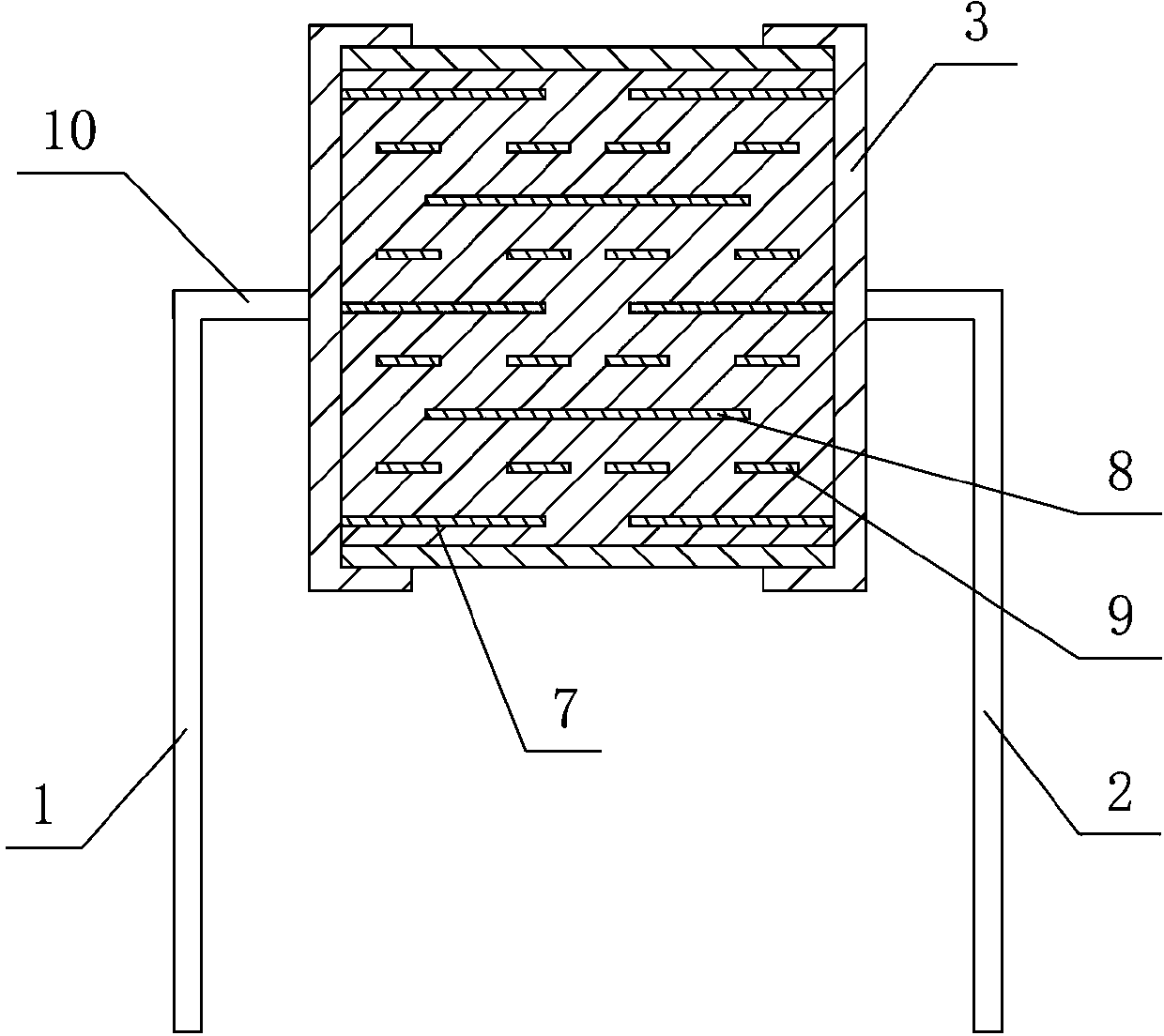

Rubber bearing for low-speed heavy-load environment

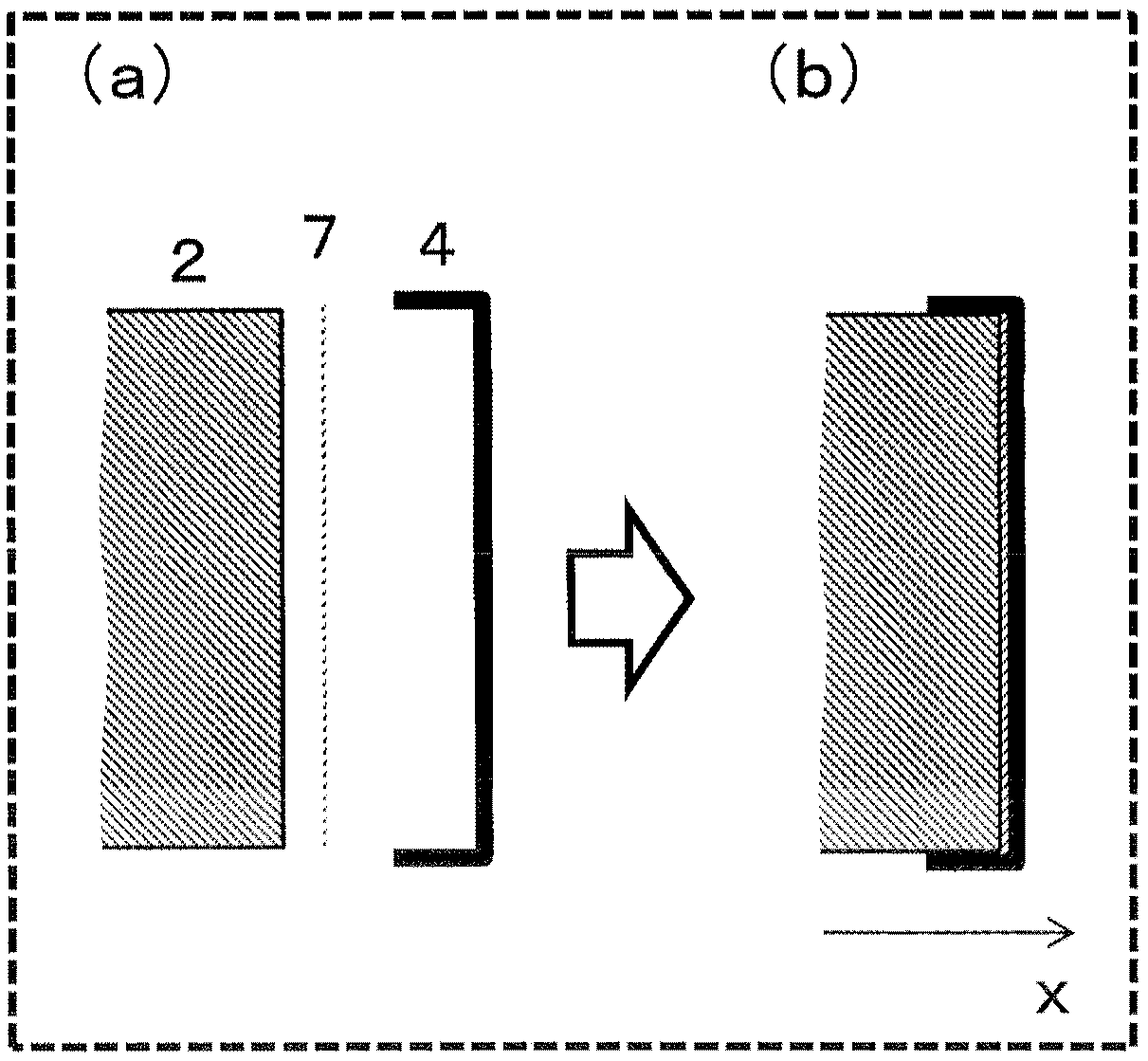

PendingCN106979223ANo change in dimensionsGood effectBearing componentsSliding contact bearingsLow speedRadial position

The object of the present invention is to provide a rubber bearing for low-speed and heavy-duty environments, including a bearing housing, a control valve, and a pump. The inner wall of the bearing housing is provided with slats, and the slats are fixed to the bearing housing by bolts. Axial flow holes are set in the axial direction, radial flow holes are set in the radial direction of the bearing shell, tangential flow holes are set in the position tangent to the inner wall of the bearing shell inside the bearing shell, and a main pipe is set on the outer wall of the bearing shell. The control valve and the pump are connected in sequence through the pipeline. The radial flow hole, tangential flow hole and axial flow hole are all connected. The end of the axial flow hole is connected to the main pipe. Corresponding to the position of the water hole. The invention directly injects water with a certain pressure into the gap between the shaft and the bearing through the water hole to form an effective dynamic pressure lubrication method; the opening position of the water hole can be arranged in a targeted manner according to the actual load state of different ship bearings, So as to achieve better results.

Owner:HARBIN ENG UNIV

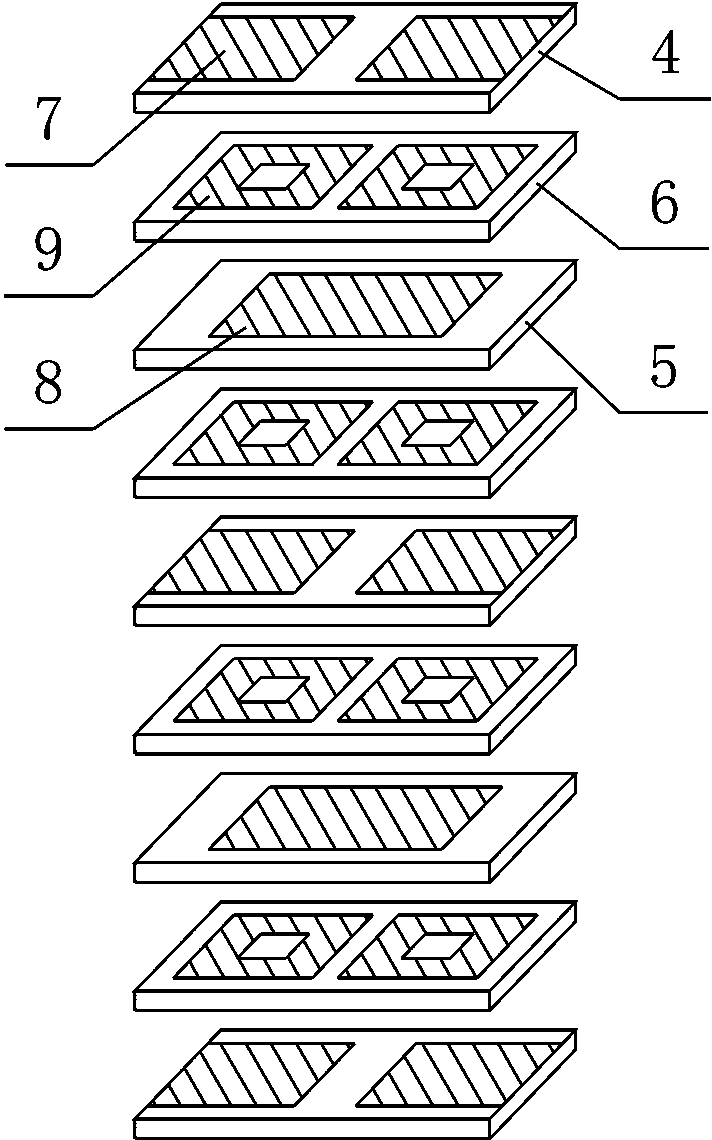

Multi-layer ceramic laminar capacitor

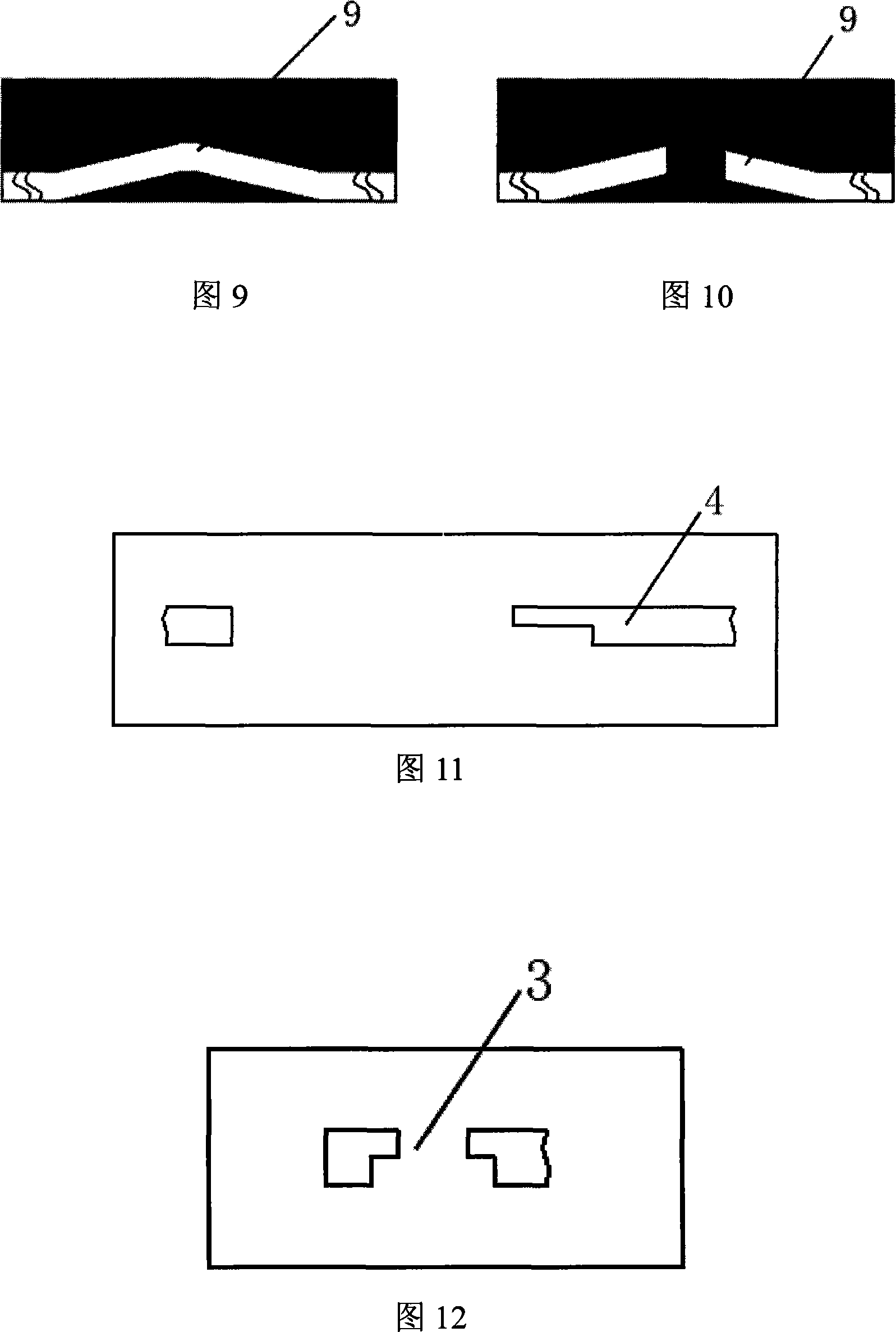

InactiveCN103811182ASmall physical areaThere will be no problem of separation from each otherFixed capacitor electrodesStacked capacitorsPuncture resistanceHigh pressure

The invention discloses a multi-layer ceramic laminar capacitor. The multi-layer ceramic laminar capacitor comprises a laminar main body, a first lead and a second lead, wherein the laminar main body comprises two outer electrodes, and a first medium layer, a second medium layer and a third medium layer which are positioned between the two outer electrodes; the first medium layer is provided with two inner electrodes a which are distributed at a certain interval and are in the forms of small rectangles, and the two inner electrodes a are connected with the two outer electrodes respectively; the second medium layer is provided with two inner electrodes b which correspond to the positions of the two inner electrodes a and are in the forms of large rectangles; the third medium layer is provided with two inner electrodes c which correspond to the positions of the inner electrodes a and the inner electrodes b and are in the forms of frame-type quadrangles; the third medium layer is positioned between the first medium layer and the second medium layer, and the three medium layers are overlapped in sequence; the first lead and the second lead are arranged outside the outer electrodes respectively, and transverse epitaxial segments are arranged on portions connected with the outer electrodes. By adopting the multi-layer ceramic laminar capacitor, the high-voltage puncture resistance can be improved greatly under the condition of not basically increasing the overall dimensions.

Owner:CHENGDU RONGHUA ELECTRONICS

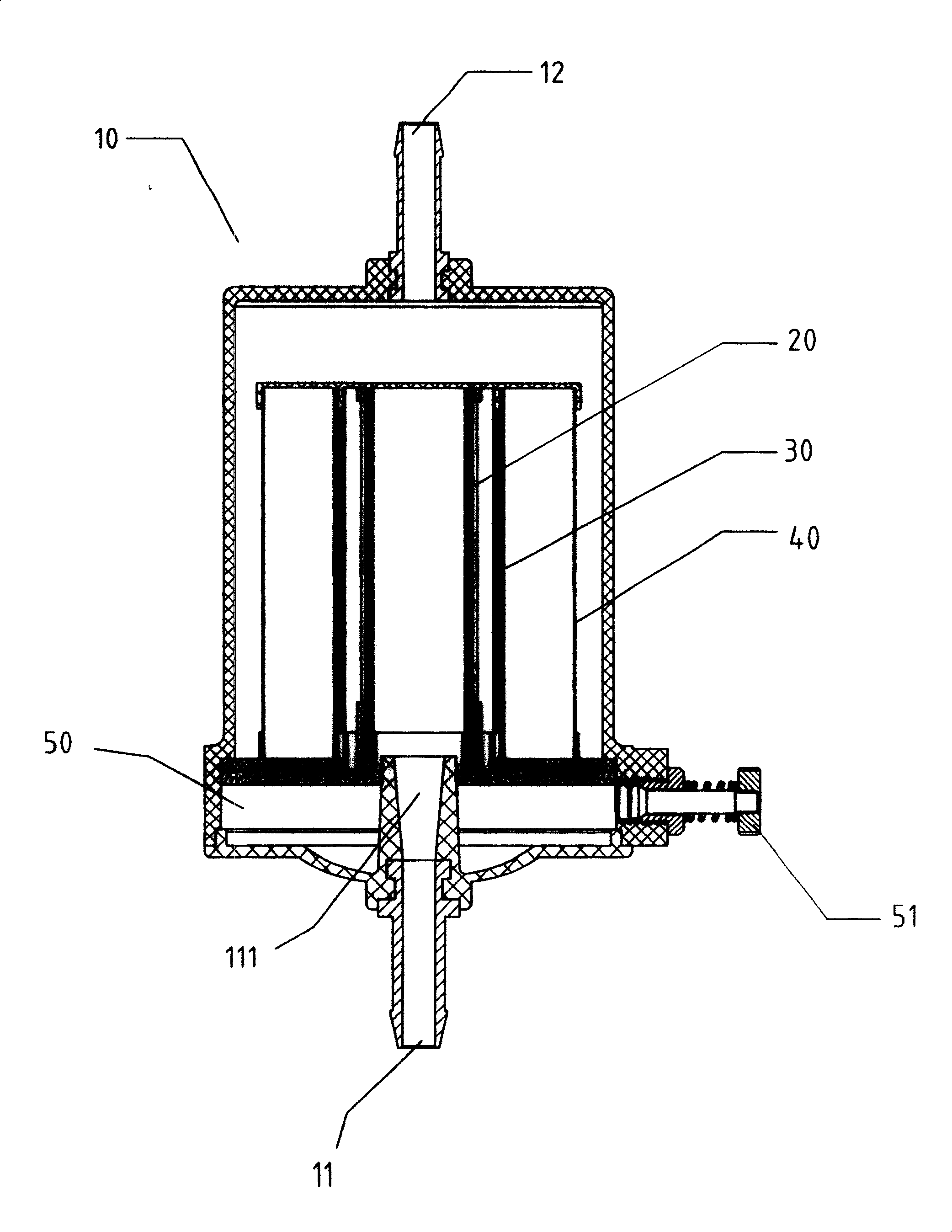

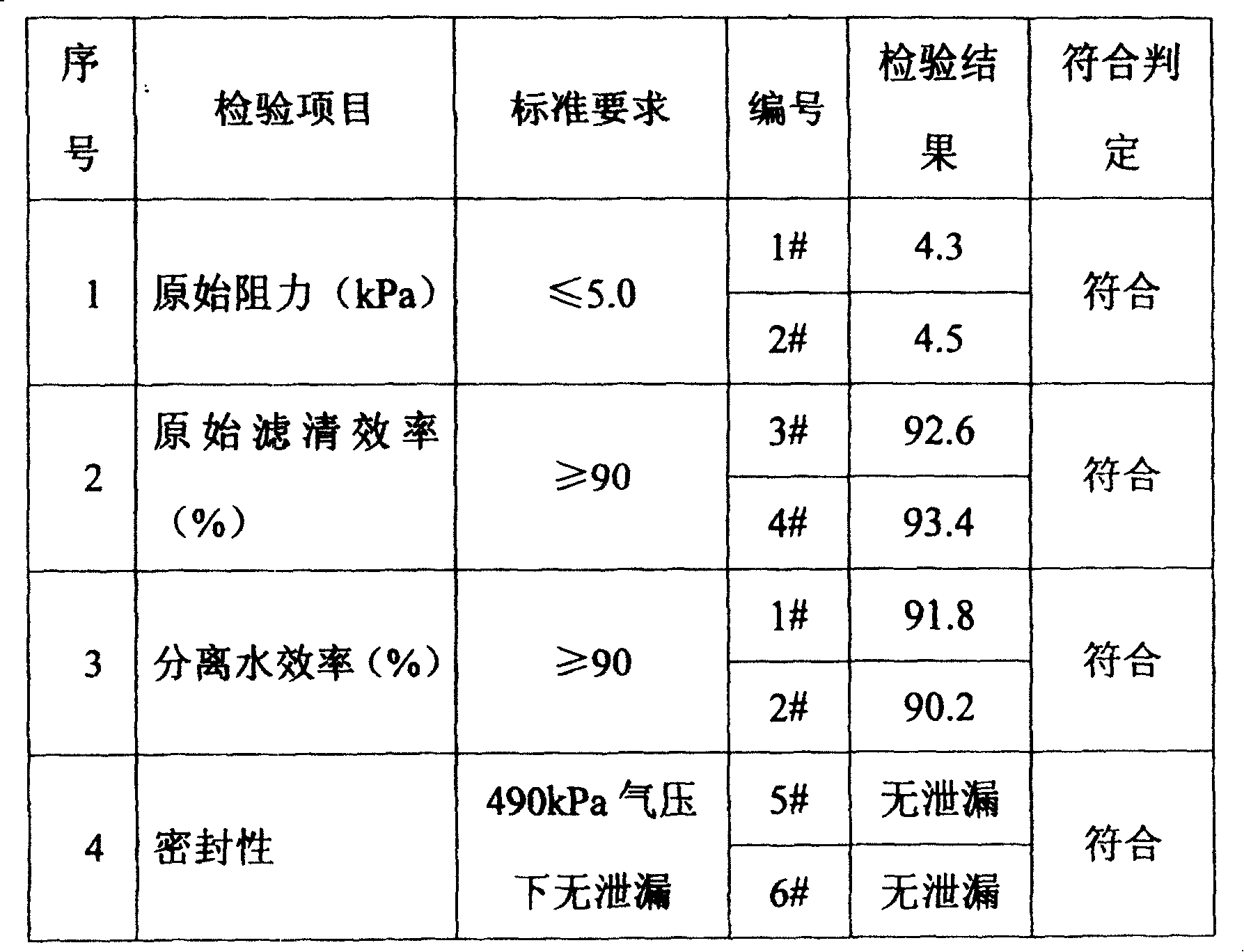

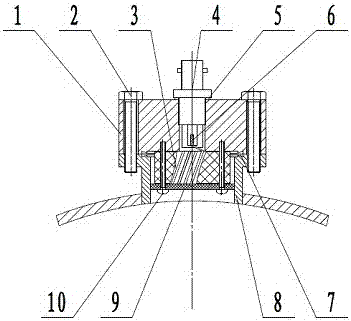

Fuel oil filter for oil water separation, precise filtration

InactiveCN100394016CEasy to separateNo change in dimensionsCombustion-air/fuel-air treatmentMachines/enginesFiltrationFuel filter

Owner:DONGGUAN UNICLEAR NEW MATERIAL

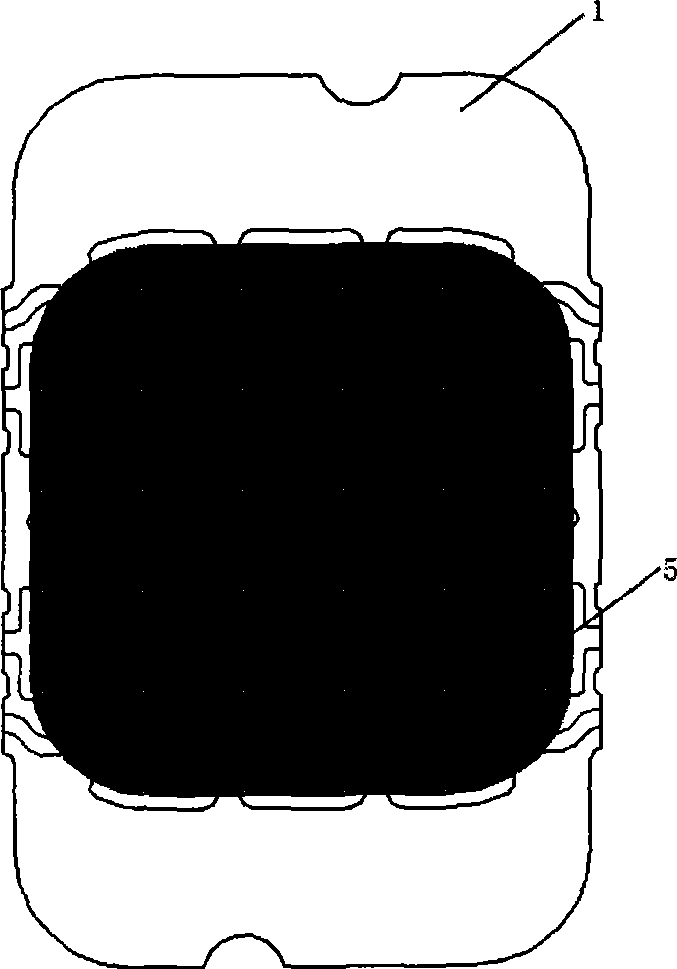

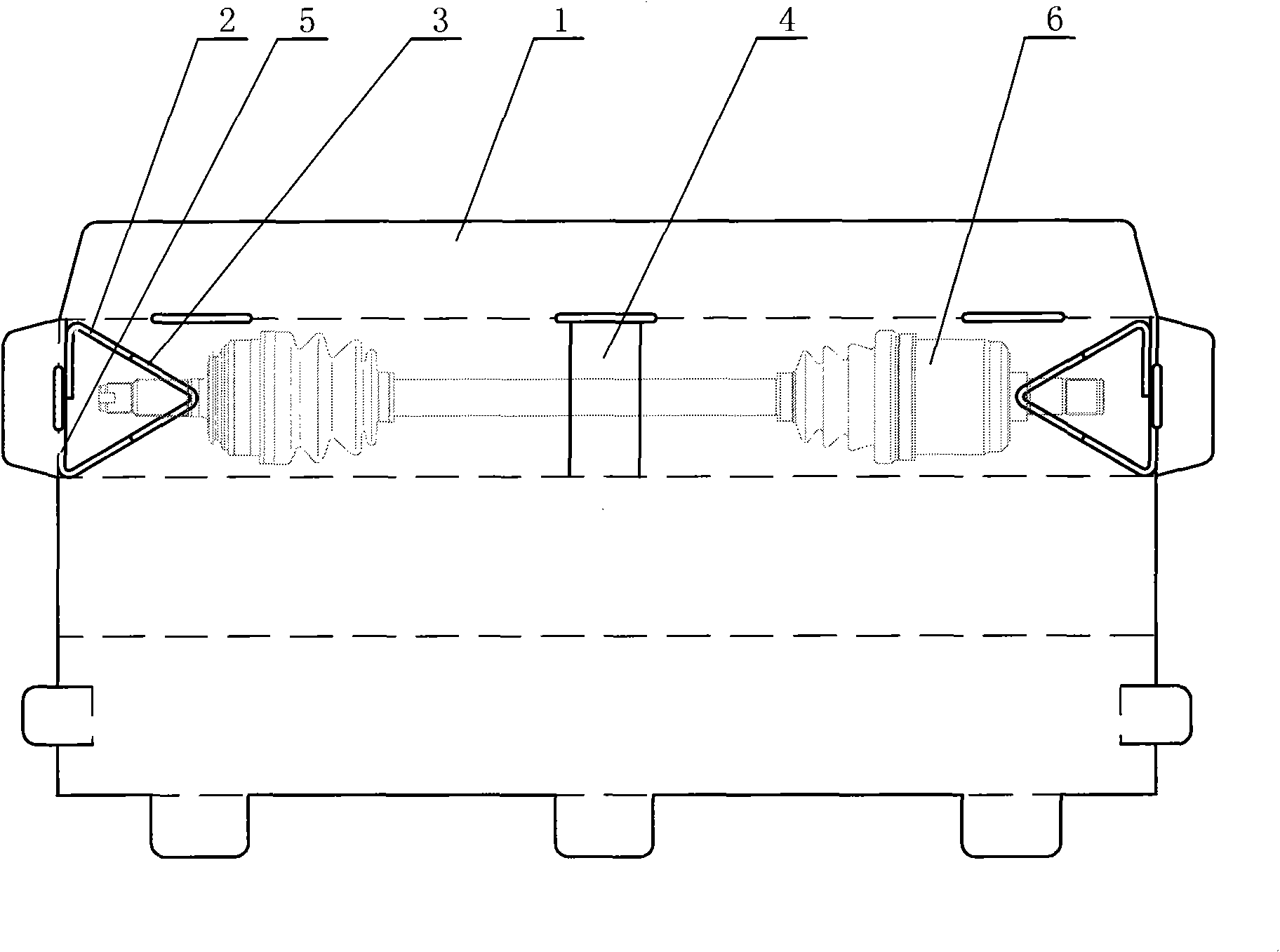

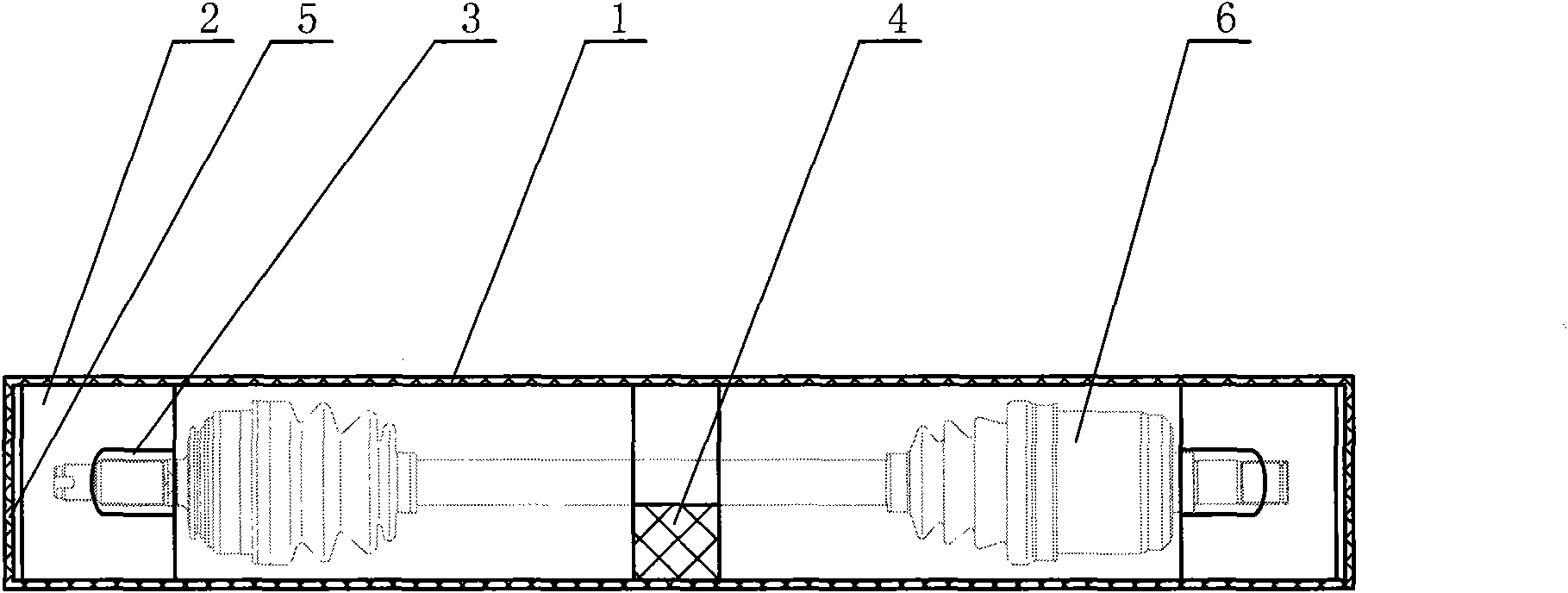

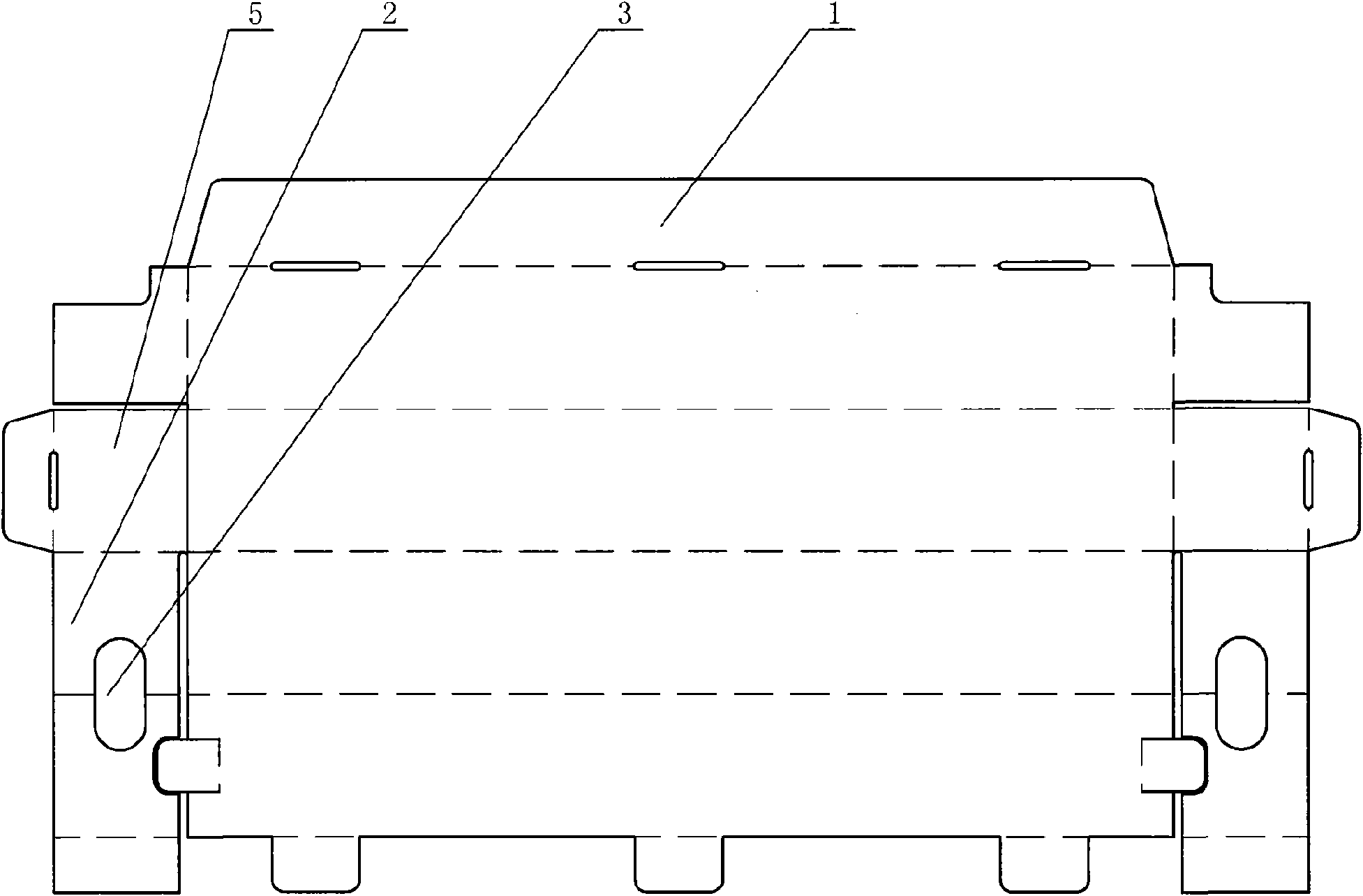

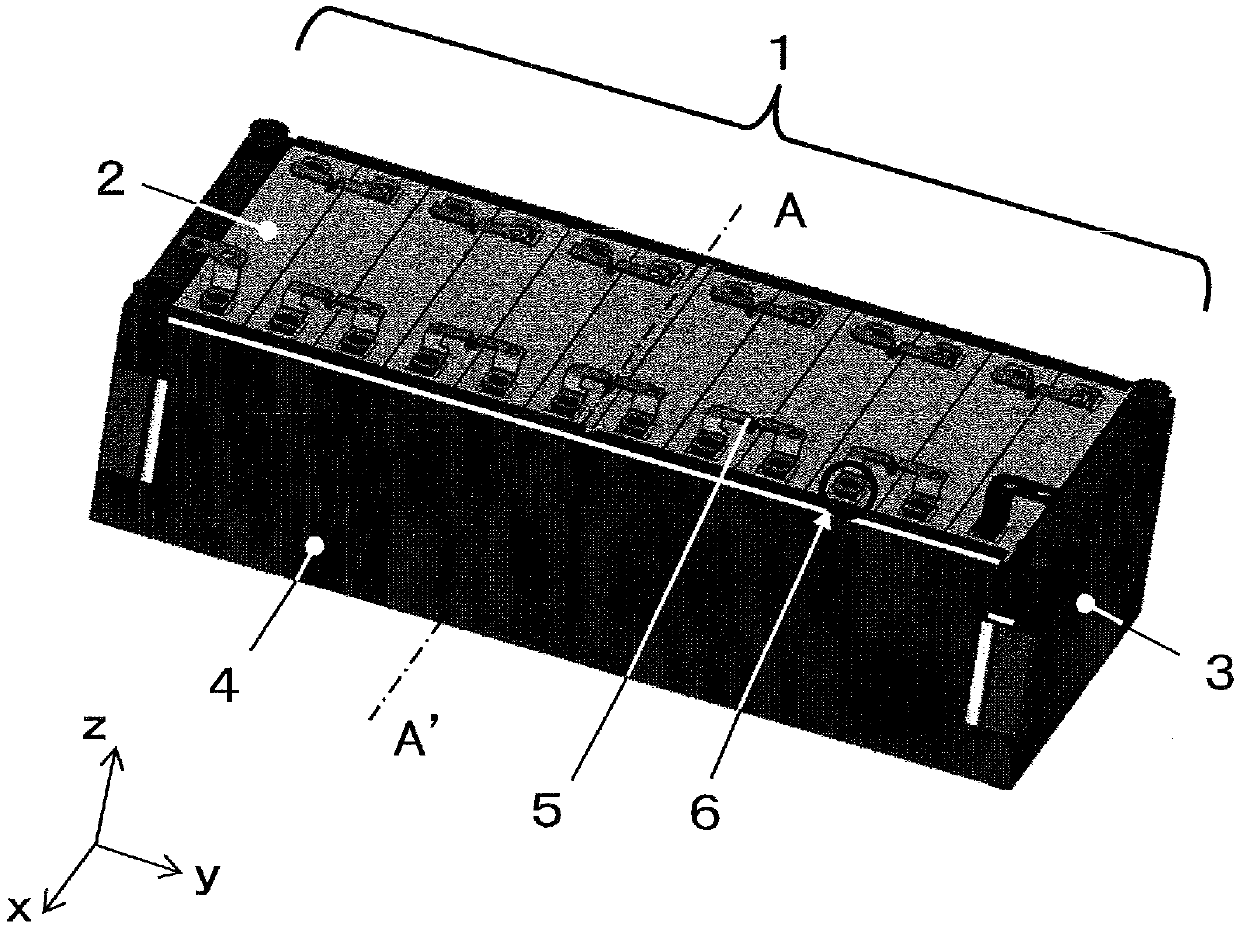

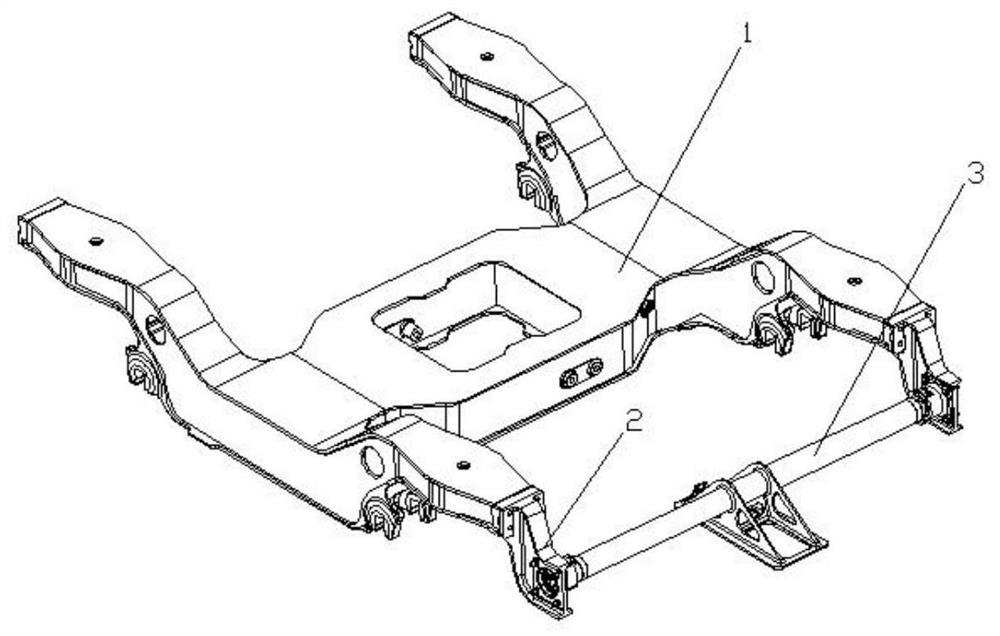

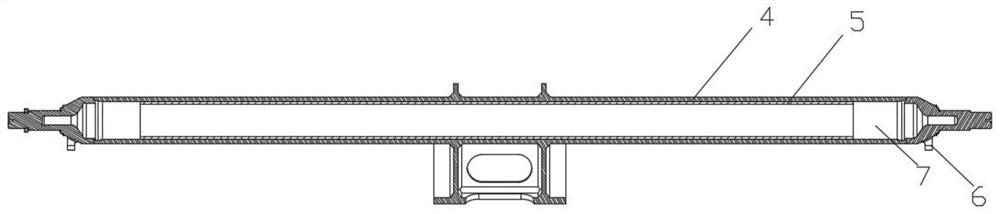

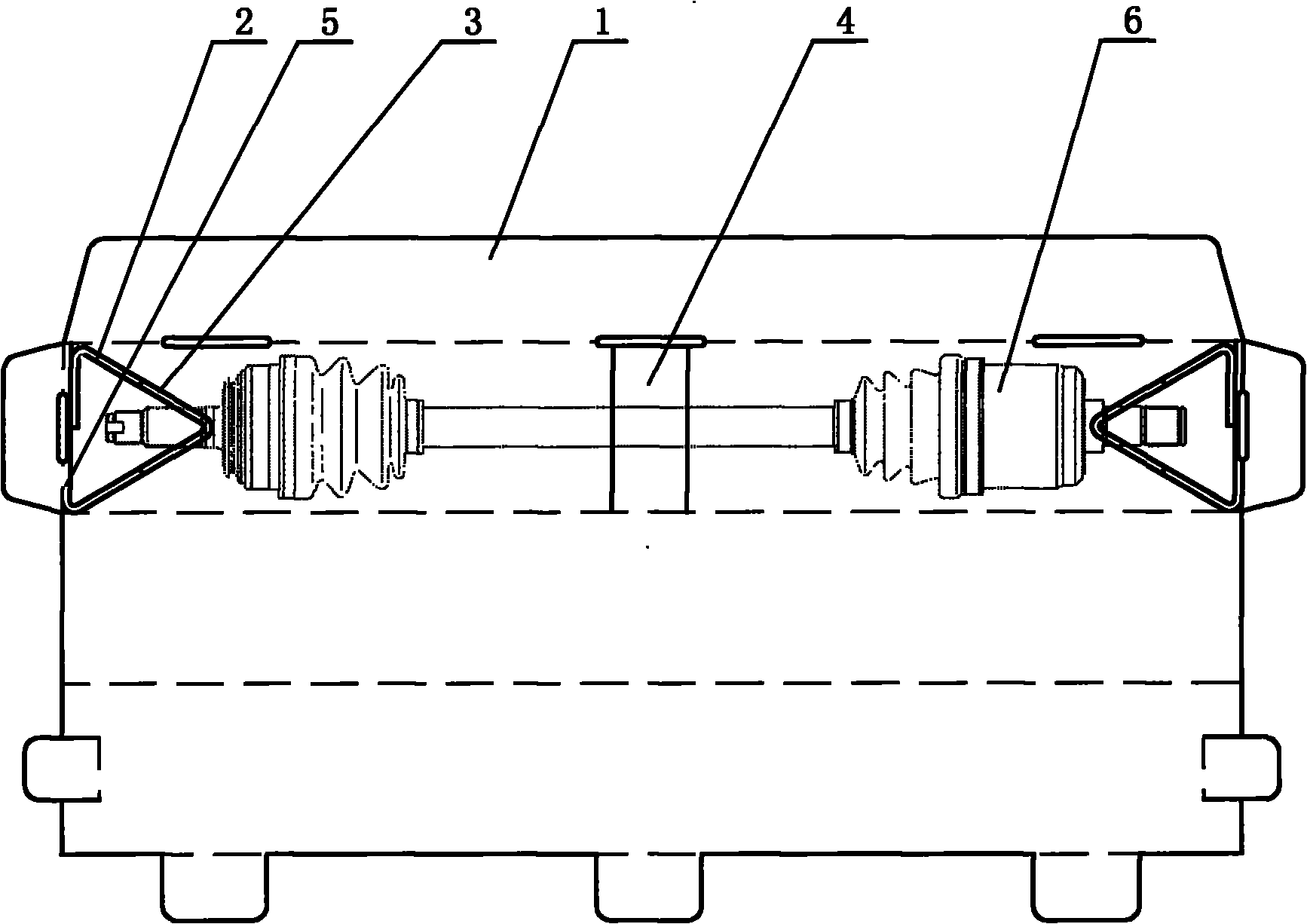

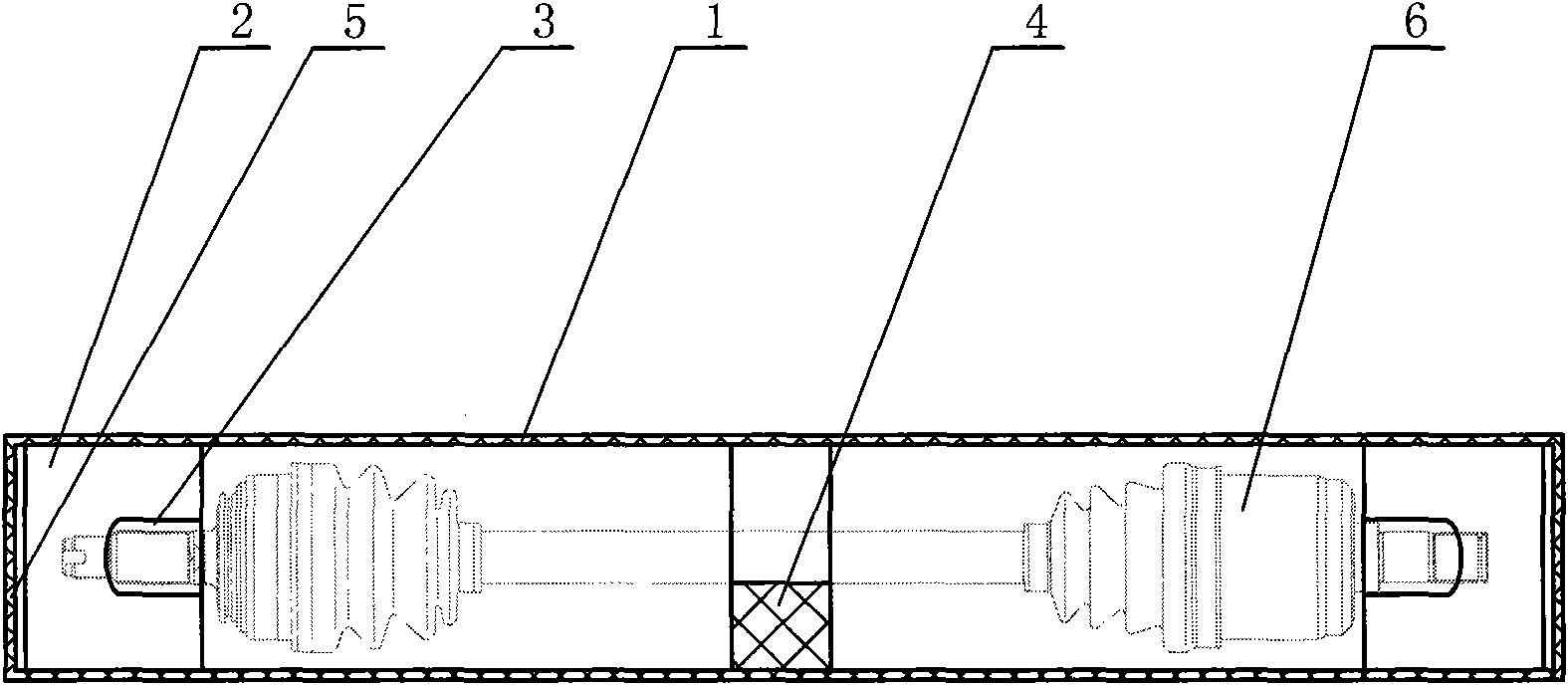

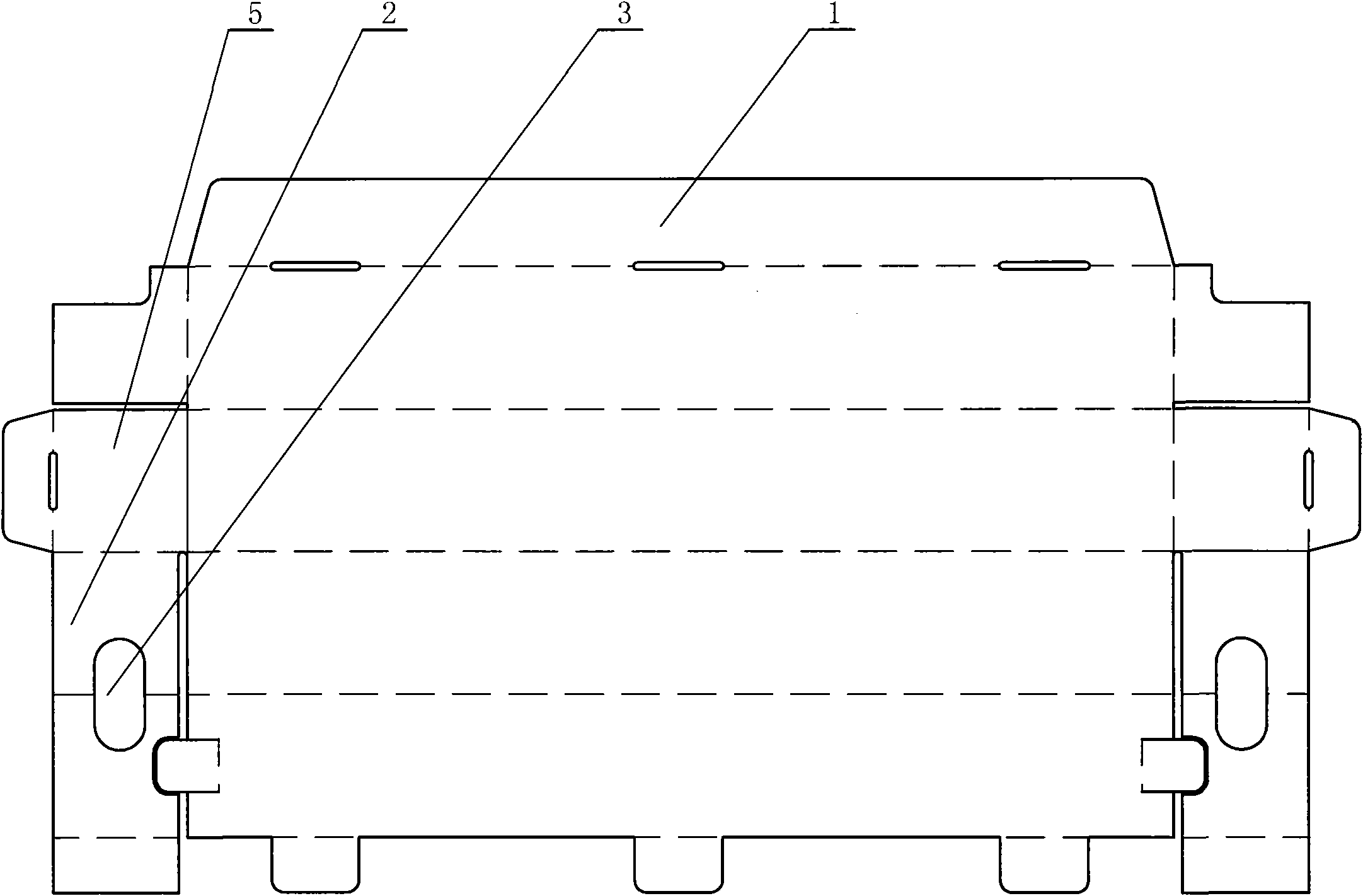

Automobile cardan joint transmission shaft packaging paper box

The invention relates an automobile cardan joint transmission shaft packaging paper box,which mainly solves the problem of easy damage owing to the low supporting strength of the existing ball cage assembly packaging paper box. The packaging paper box is characterized in that both ends of a box body (1) with a supporting paperboard (2), the middle which is provided with a through hole (3); the supporting paperboard (2) is folded, and then forms a triangulate with the end surface (5) of the box body (1); after the supporting paperboard (2) is folded, the through hole is caused to be matched with an end socket of the ball cage assembly. The cardan joint transmission shaft changes supporting form of two end sockets in the box body, adds supporting strength of the paper box on the ball cage assembly while not adding the cost of the paper box, does not change outline size of the original box body, and is characterized by convenient assembly, simple structure, low cost and being difficult to damage.

Owner:GSP AUTOMOTIVE GRP WENZHOU

Battery pack

ActiveCN109920945ANo change in dimensionsReduce displacementFinal product manufactureSecondary cellsMechanical engineeringBattery cell

The present invention provides a battery pack that suppresses breakage at a junction between a bus bar and an electrode. The battery pack includes: a plurality of battery cells in a line arranged in one direction as an arrangement direction; a pair of end plates configured to sandwich the plurality of battery cells in the line from both ends in the arrangement direction of the plurality of batterycells; a pair of binding bars configured to sandwich the plurality of battery cells from a direction perpendicular to the arrangement direction and to fasten the pair of end plates at both ends in the arrangement direction; and an insulator sandwiched in a gap between each of the binding bars and the battery cells, wherein the insulator having an initial thickness larger than a thickness of the gap before insertion into the gap is in a compressed state.

Owner:PANASONIC INTPROP MANAGEMENT CO LTD

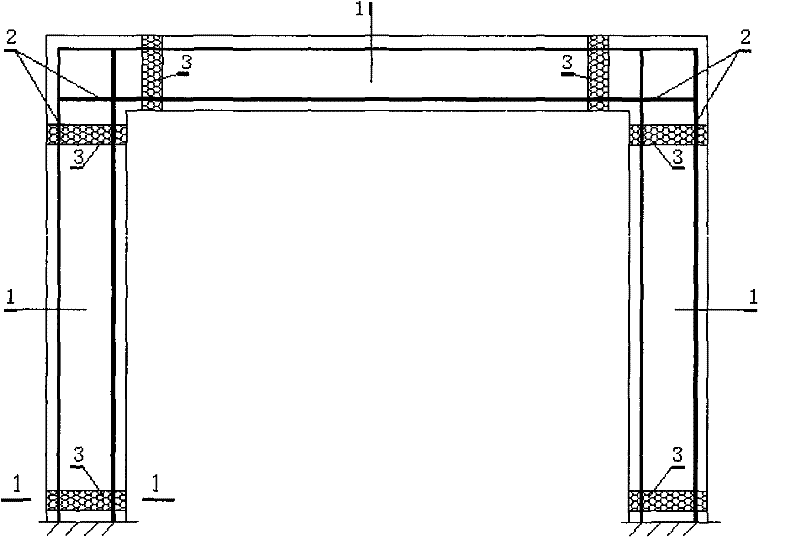

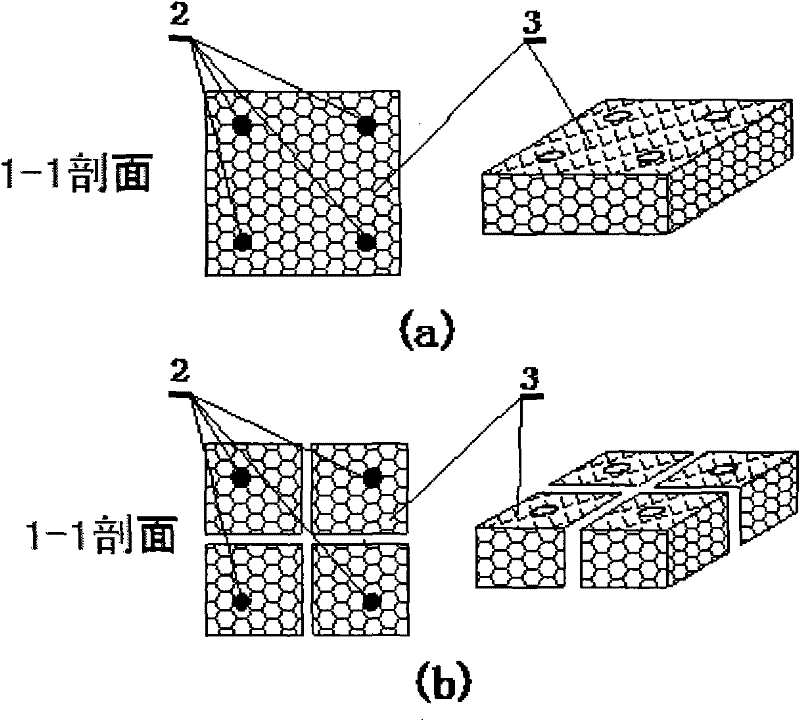

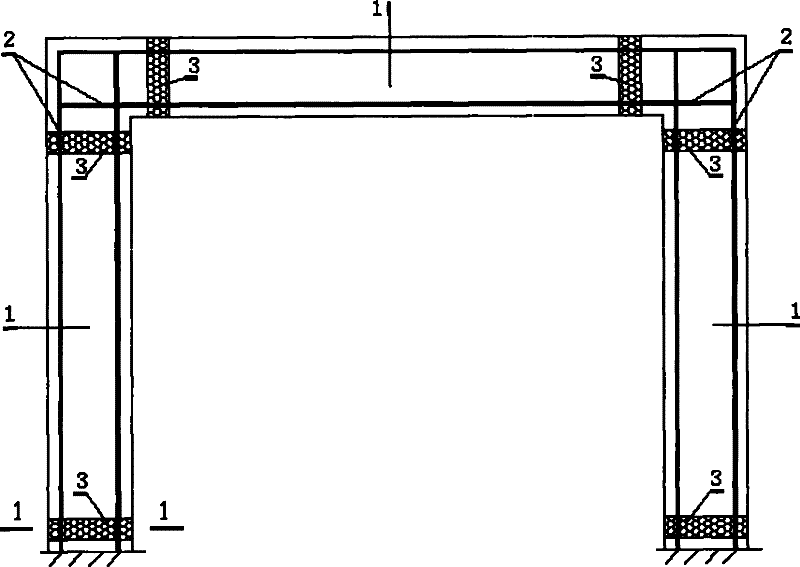

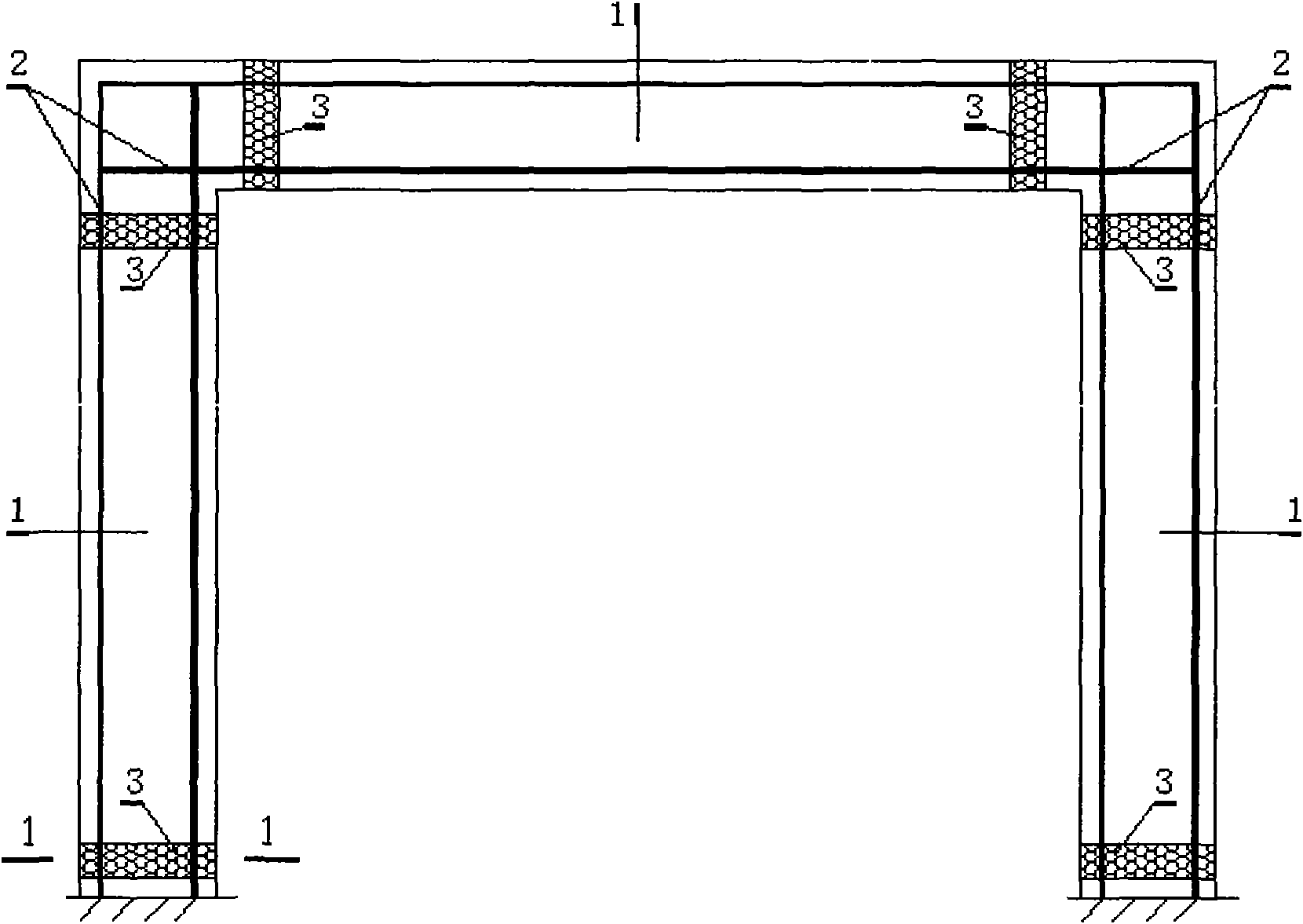

Method for improving continuous earthquake disaster resistance of reinforced concrete structure

InactiveCN106759875AImprove seismic performanceNo change in dimensionsProtective buildings/sheltersShock proofingEarthquake disasterRebar

A method for improving continuous earthquake disaster resistance of a reinforced concrete structure comprises the following steps that a, an SMA plastic hinge connector is made, an SMA connection rod is connected between two rebars, the rebars and the SMA connection rod are connected head to tail through a stainless steel sleeve, the stainless steel sleeve and one ends of the rebars are connected through taper threads, and the stainless steel sleeve and one end of the SMA connection rod are connected through a bolt fixedly in a compressed mode; b, the SMA plastic hinge connector is placed in a plastic hinge area of the reinforced concrete structure, and the plastic hinge area is determined through structural antiseismic calculation; and c, the SMA plastic hinge connector is fixed, then concrete is poured, and the reinforced concrete structure provided with the SMA plastic hinge connector in a embedded mode is constructed. Through the method, the antiseismic performance of the reinforced concrete structure under continuous earthquake disasters is improved.

Owner:UNIV OF JINAN

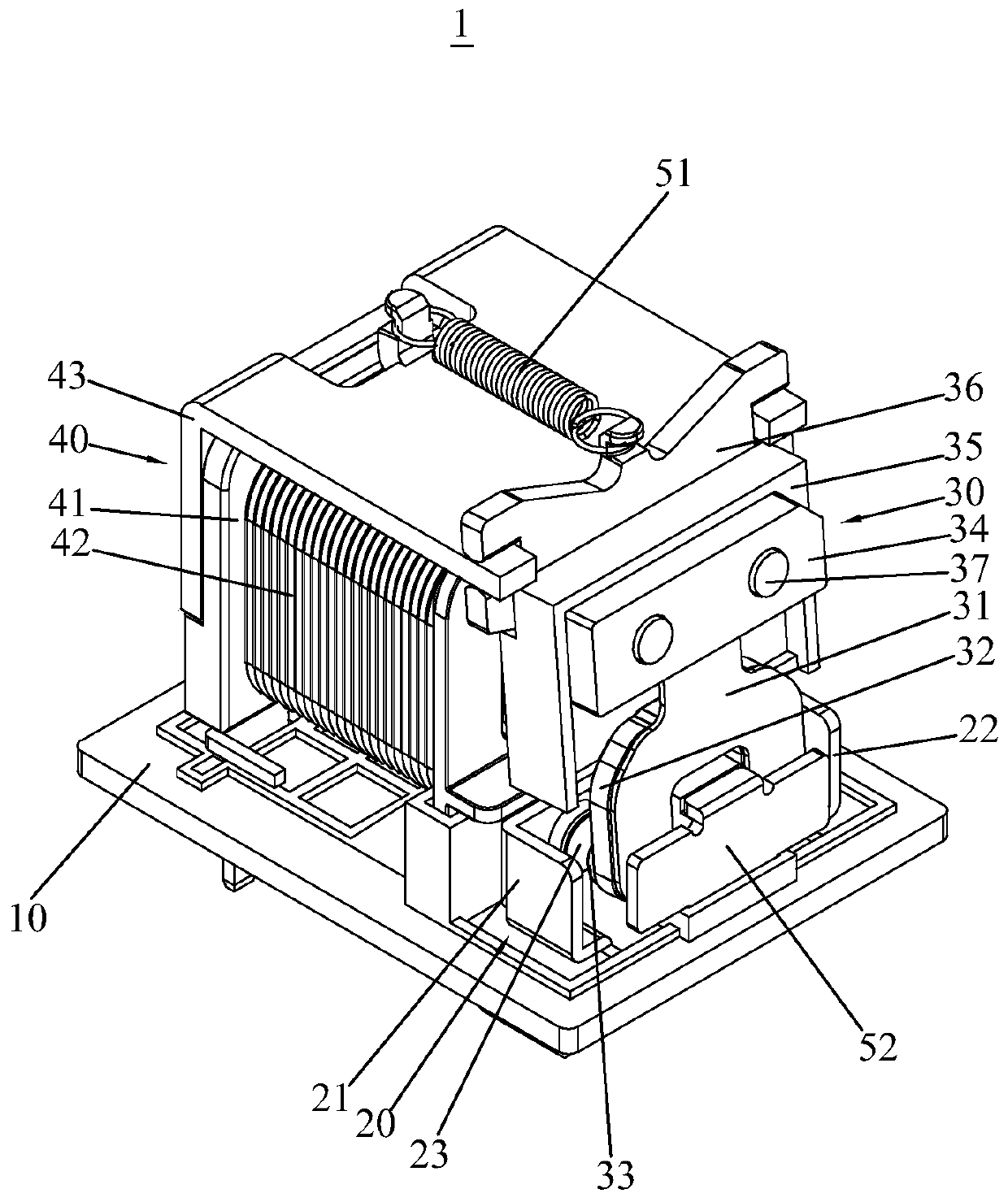

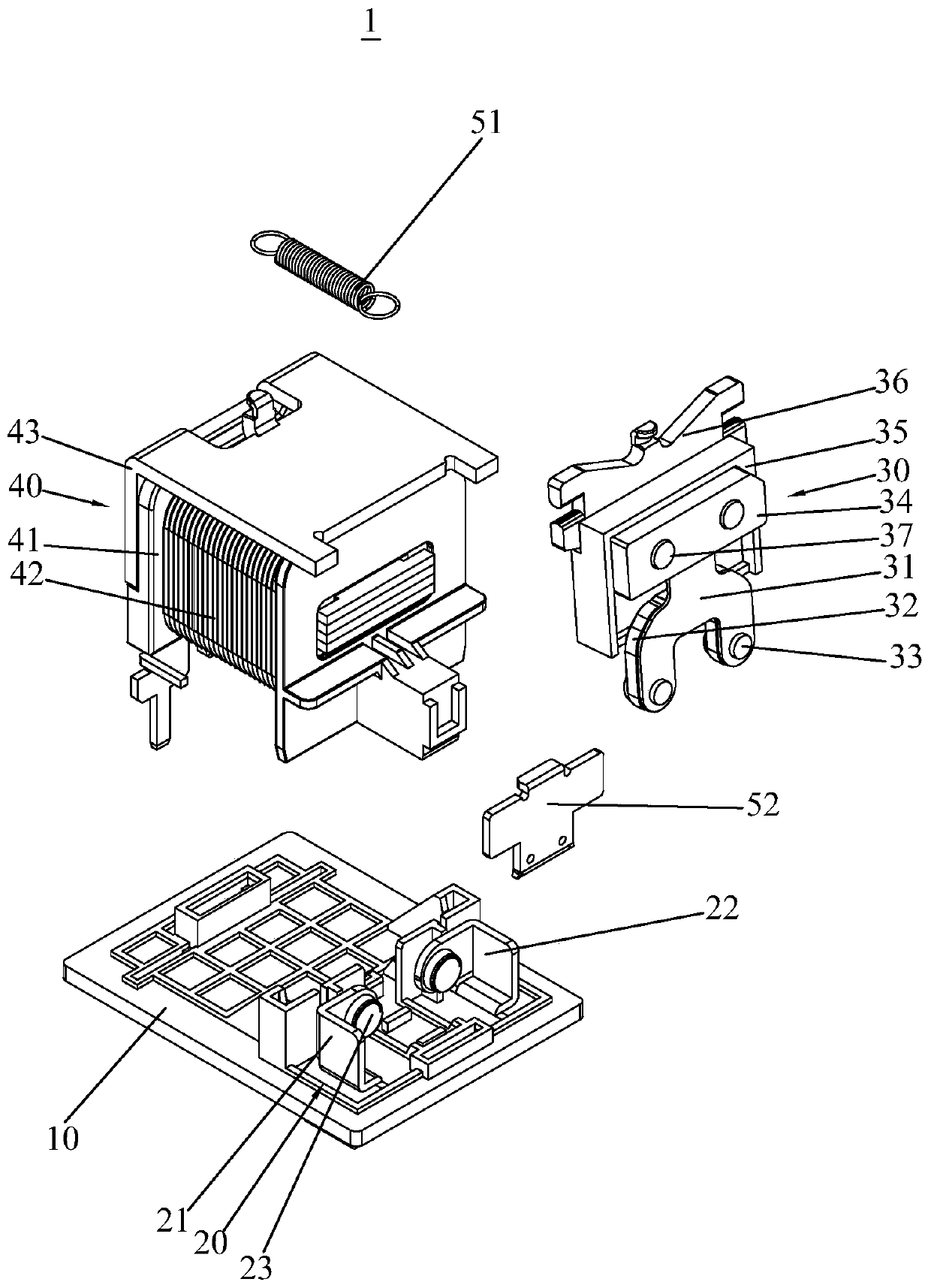

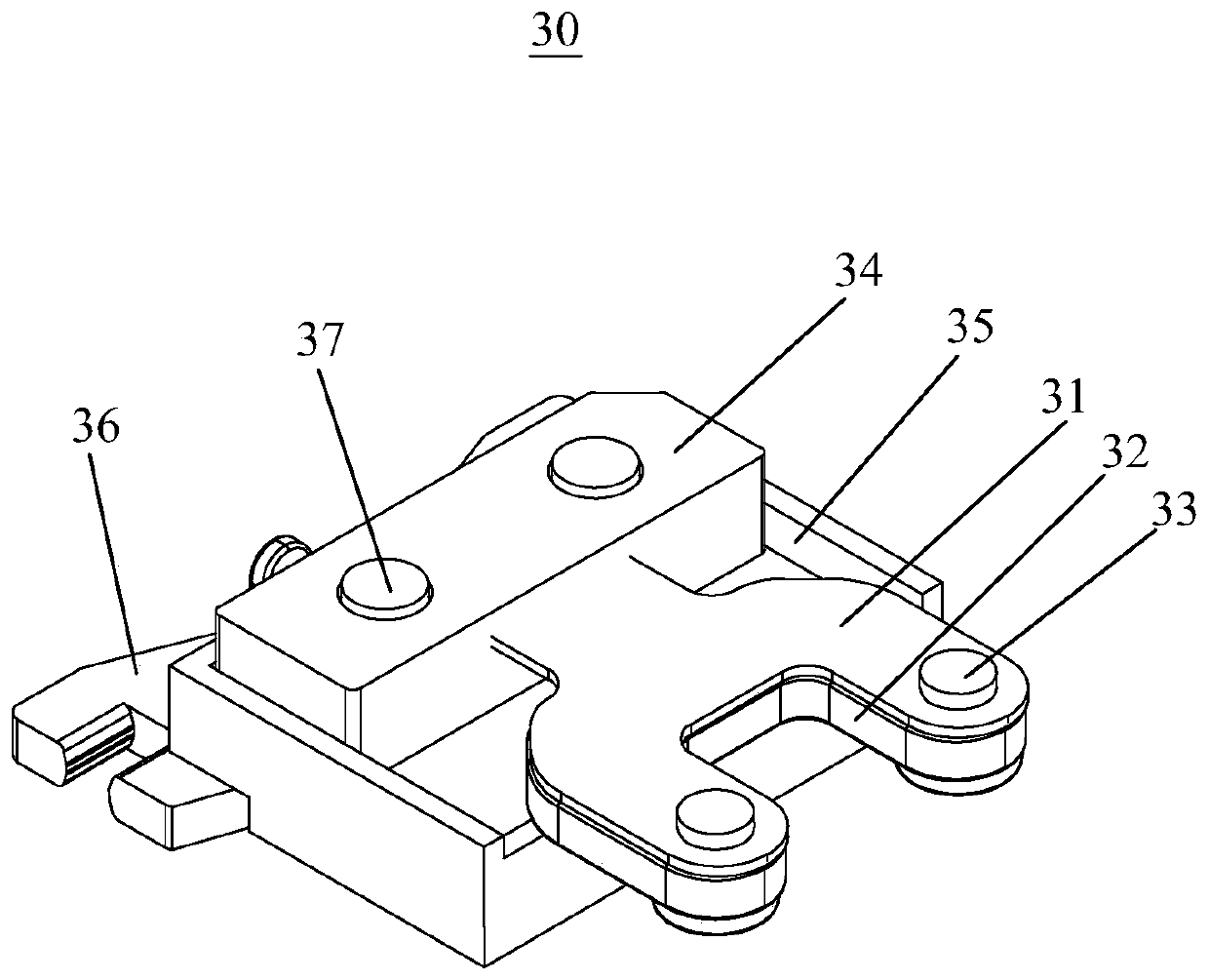

Small electromagnetic relay of large current

PendingCN109741993ANo change in dimensionsDoes not affect basic movement performanceElectromagnetic relay detailsContact pressureElectric current

The invention discloses a small electromagnetic relay of large current. The small electromagnetic relay of large current comprises a movable spring part, the movable spring part comprises a movable reed, a contact bridge and two movable contacts; one end of the movable reed is a U-shaped structure, the contact bridge is presented as a U-shaped structure matched with one end of the movable reed; two tail ends of the U-shaped structure are respectively riveted with the contact; the movable contact is fixedly connected with the movable reed and the contact bridge. An appearance size cannot changed when adding one contact bridge; when the relay is in work, the movable reed is used for providing the movable contact pressure, the basic action performance cannot be influenced; the contact bridgeis used for providing the cross section required by current carrying, and larger current can pass the contact bridge.

Owner:DONGGUAN ZHONGHUI RUIDE ELECTRONICS

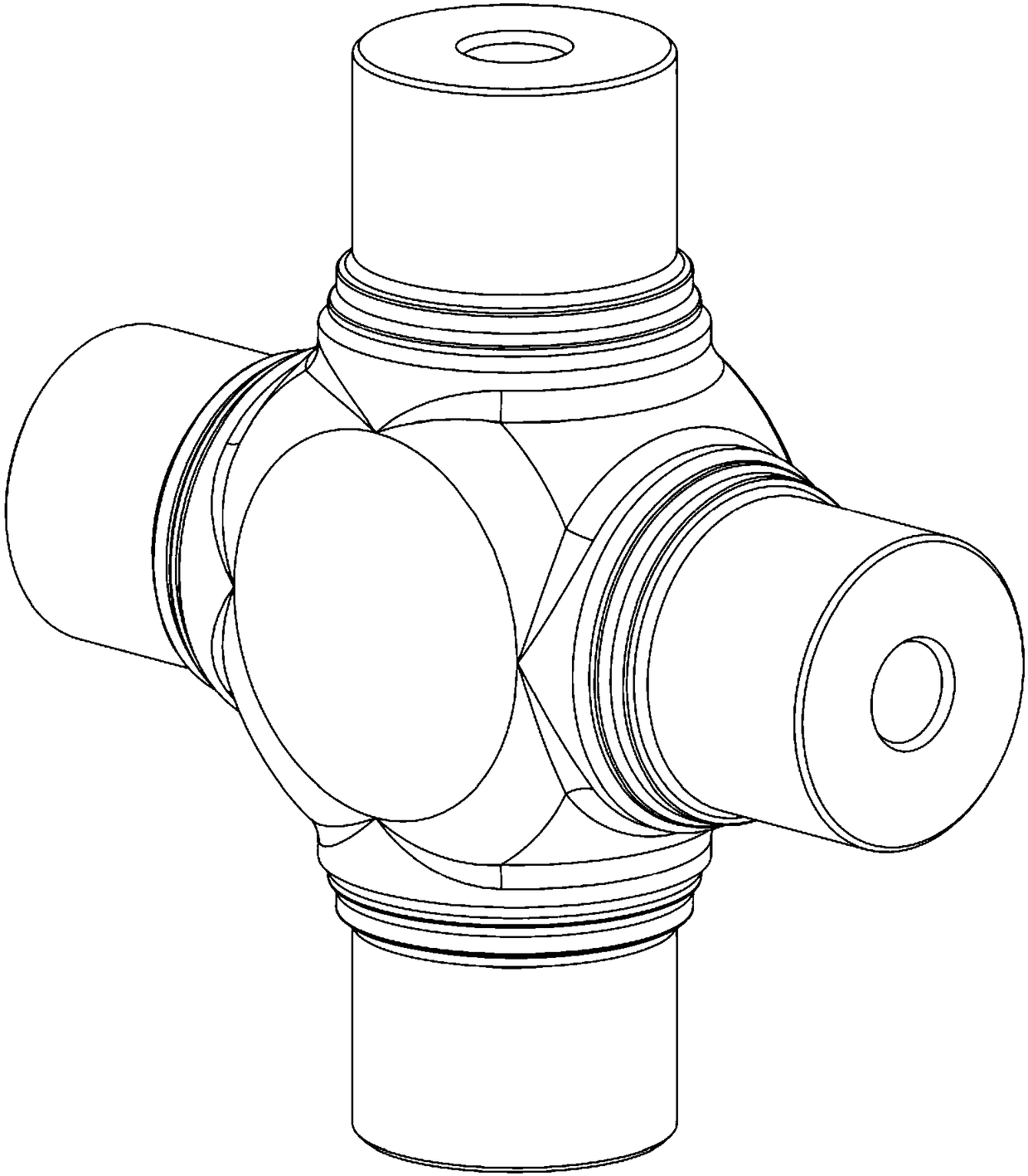

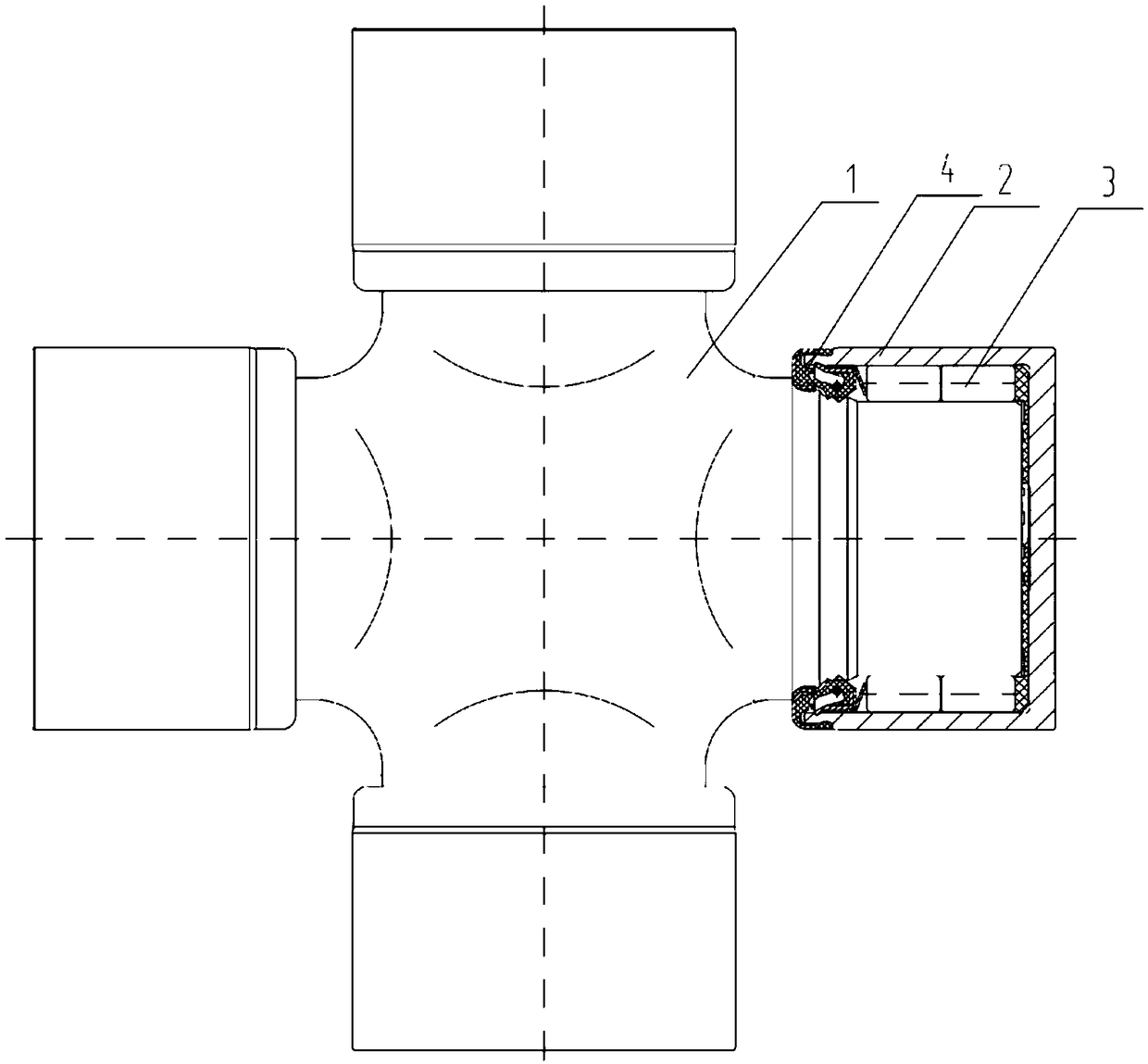

High-bearing and long-life cross-shaft universal joint

PendingCN109322934ANo change in dimensionsIncrease the life of the universal jointYielding couplingUniversal jointEngineering

The invention discloses a high-bearing and long-life cross-shaft universal joint. The high-bearing and long-life cross-shaft universal joint comprises a cross shaft, outer rings, roller pins, sealingrings and u-shaped grooves. The u-shaped grooves are formed in four shaft journals of the cross shaft. The roller pins are installed in the u-shaped grooves. The roller pins are sleeved with the outerrings, and the sealing rings are installed between the outer rings and the shaft journals of the cross shaft to seal the roller pins. By means of the high-bearing and long-life cross-shaft universaljoint, due to the design of the u-shaped grooves, the contact area between the roller pins and the journal shafts of the cross shaft is effectively enlarged, the oil storage capacity of the surfaces of the journal shafts is improved, the contact stress of the roller pins and the shaft journals of the cross shaft is reduced by 20% or higher, and the fatigue life of a bearing is prolonged by 15% orhigher.

Owner:WANXIANGQIANCHAO CO LTD +1

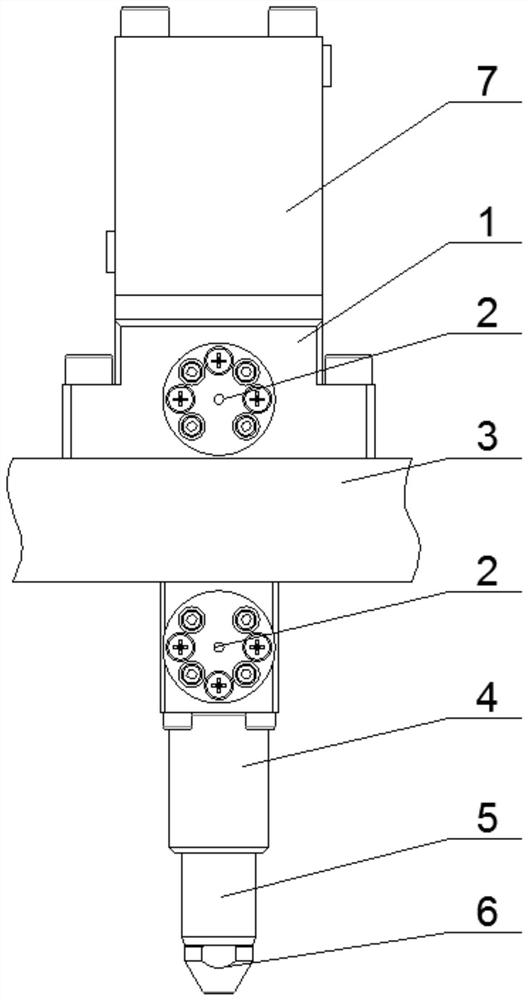

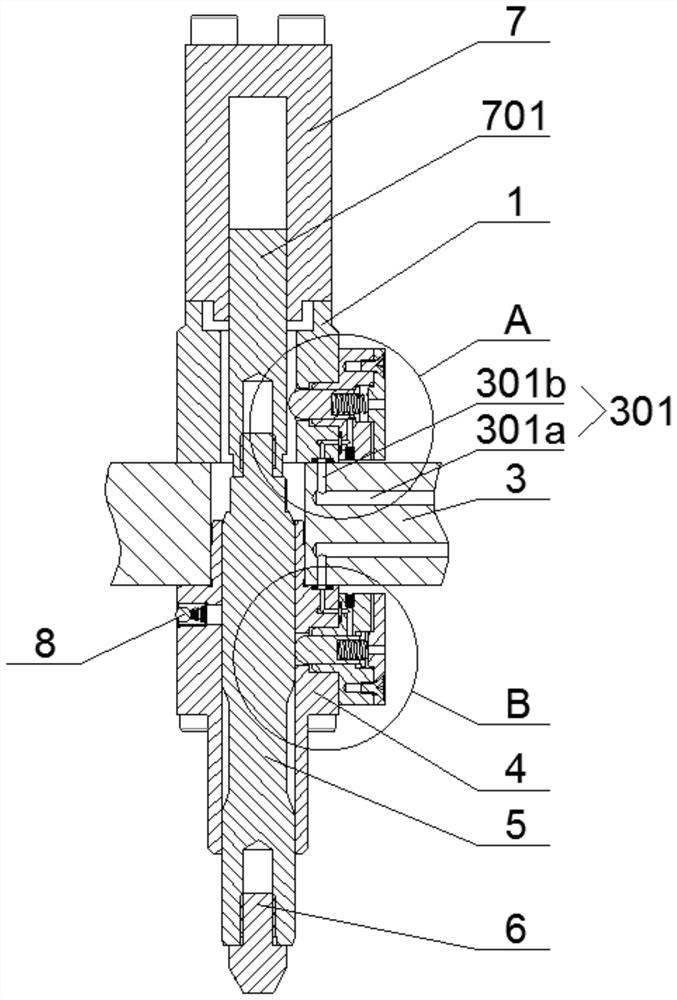

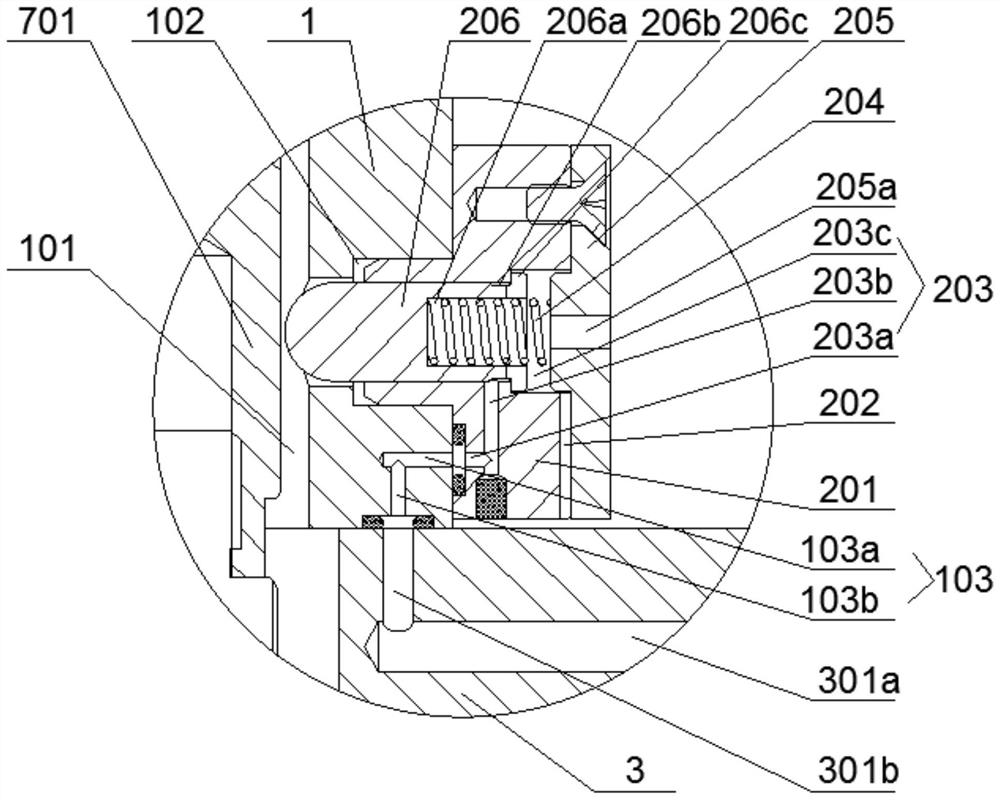

B-dot probe for vacuum diode electric current measurement

PendingCN106918734AAvoid short circuitEasy to use and disassembleCurrent measurements onlyEngineeringInduction coil

The invention discloses a B-dot probe for vacuum diode electric current measurement. The B-dot probe comprises a cable seat, a grounded shell, a connecting rob, a vacuum cable connector and an insulating sheet, and the cable seat and the grounded shell are fixedly connected through a bolt as one; a through hole is arranged on the axis of the cable seat, the vacuum cable connector is arranged in the through hole, the insulating sheet is arranged in the grounded shell, the grounded shell is connected with the cable seat through a bolt, a induction coil is arranged between the insulating sheet and the cable seat, one end of the induction coil is connected with the vacuum cable connector, and the other end of the induction coil is connected with the cable seat. According to the invention, the B-dot probe has advantages of good design, simple and easily-realized structure, convenient operation and relatively low maintenance cost, the B-dot probe has highlighted substantive features and remarkable progress, and the B-dot probe is suitable to be widely popularized and applied in the field of vacuum diode electric current measurement.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

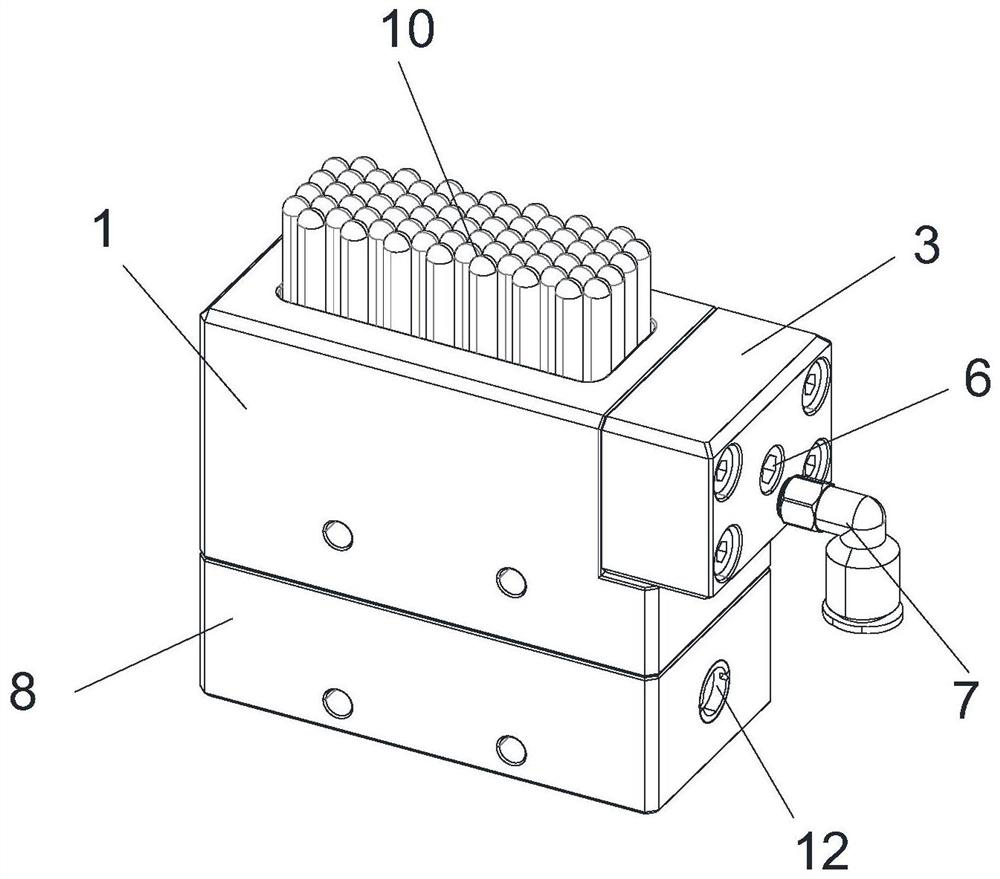

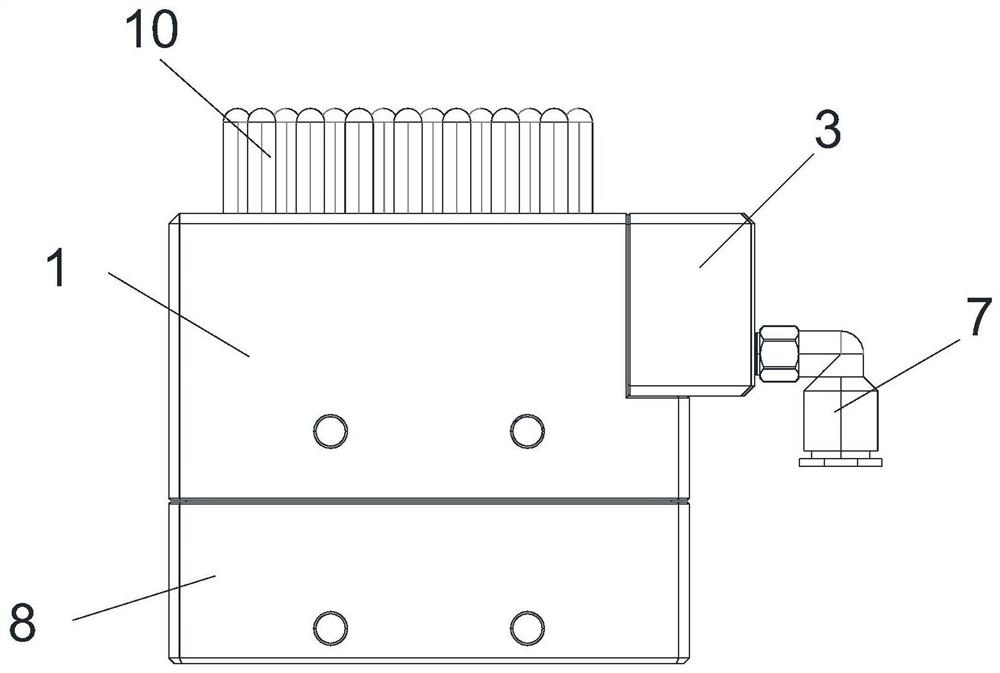

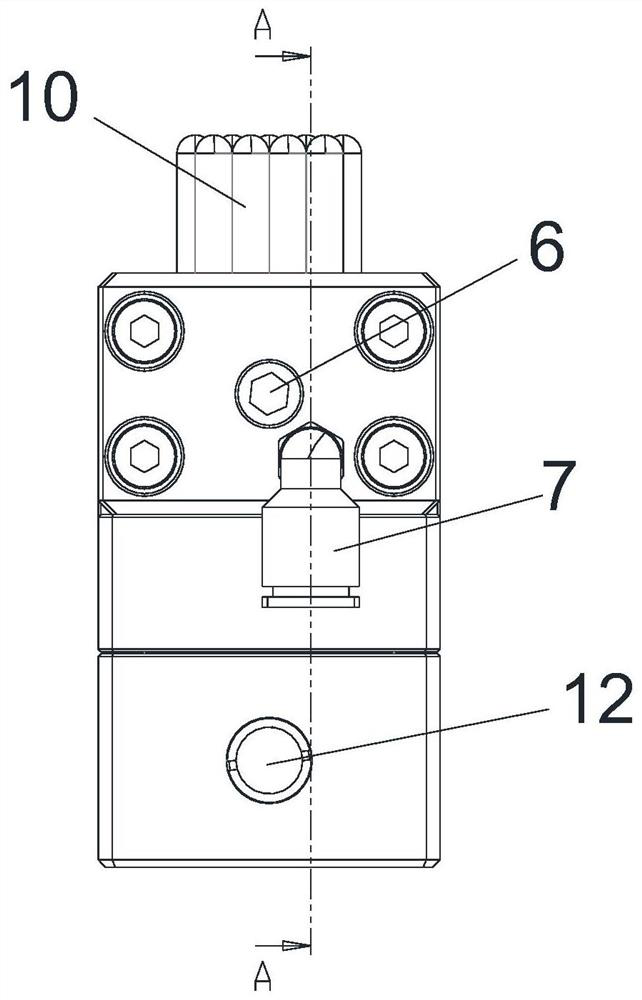

A flexible clamp combined with thread self-locking and pneumatic locking composite device

ActiveCN113829267BReduce volumeExtended service lifeWork holdersCleaning using toolsSlide plateScrew thread

The invention provides a flexible clamp combined with a threaded self-locking and pneumatic locking compound device, comprising an upper box body, a first through hole is arranged on the right side of the upper box body, and a sliding plate is slidably arranged in the first through hole, A fixed box is arranged on the right side of the upper box, a cavity is arranged in the fixed box, a piston plate is slidably arranged in the cavity, a threaded hole and a first air hole are arranged on the right side of the cavity, and a screw hole is arranged in the threaded hole. Set the top wire, and the right side of the fixed box is provided with a quick-insert air nozzle. In the present invention, the original micro-miniature pneumatic piston plate design is designed together with the thread locking device, which hardly changes the external dimensions, and combines the height of the thread locking and pneumatic locking in a small space, reducing the flexible fixture The volume, in which the piston plate can not only move after ventilation through the quick-insert air nozzle, but also be used as a conductive part for thread locking. At the same time, manual locking and pneumatic locking are adopted to protect the threaded holes and prolong the service life of the flexible fixture.

Owner:深圳市拓野智能股份有限公司

Intelligent temperature measurement static contact device

PendingCN112924052ANo change in dimensionsAffect performanceThermometer detailsThermometer applicationsEngineeringMechanical engineering

The invention discloses an intelligent temperature measurement static contact device which is of an integrated structure comprising a static contact, a temperature measurement sensor and a metal electricity taking meter band element. The static contact is of a cylindrical structure, the static contact, the temperature measuring sensor and the metal electricity taking meter band element are assembled into a whole set, an annular band groove is formed in the surface of the static contact, and the annular band groove is provided with at least one temperature measuring sensor mounting groove and an annular metal electricity taking meter band fixing groove; and a temperature measurement sensor body is provided with a metal electricity taking meter band fixing groove, the temperature measurement sensor is correspondingly placed in a static contact installation groove, a temperature sensing element in the temperature measurement sensor is in reliable contact with the static contact, and a metal electricity taking ring penetrates through the sensor body and then is reliably fixed in the static contact installation groove. According to the static contact, the appearance size of an original static contact is not changed, and the wireless passive temperature measurement function is achieved; the temperature measuring point is close to the contact surface of the static contact and a tulip contact, so that the actual contact surface temperature can be accurately reflected; and the integrated structural design facilitates detection and replacement.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Method for improving FRP tendon concrete structure ductility

InactiveCN101672076BIncreased curvature ductilityOvercoming the defects of brittle failureShock proofingCompressive strengthUltimate tensile strength

Owner:SHANGHAI UNIV

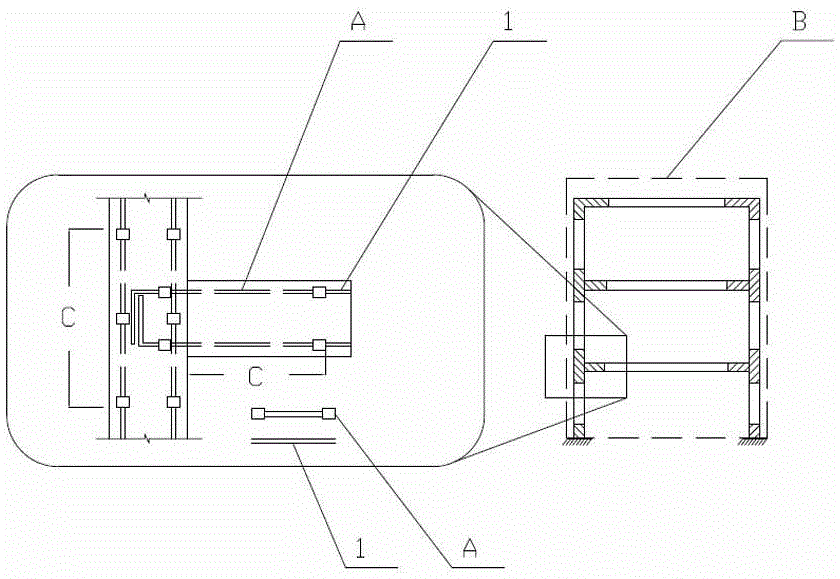

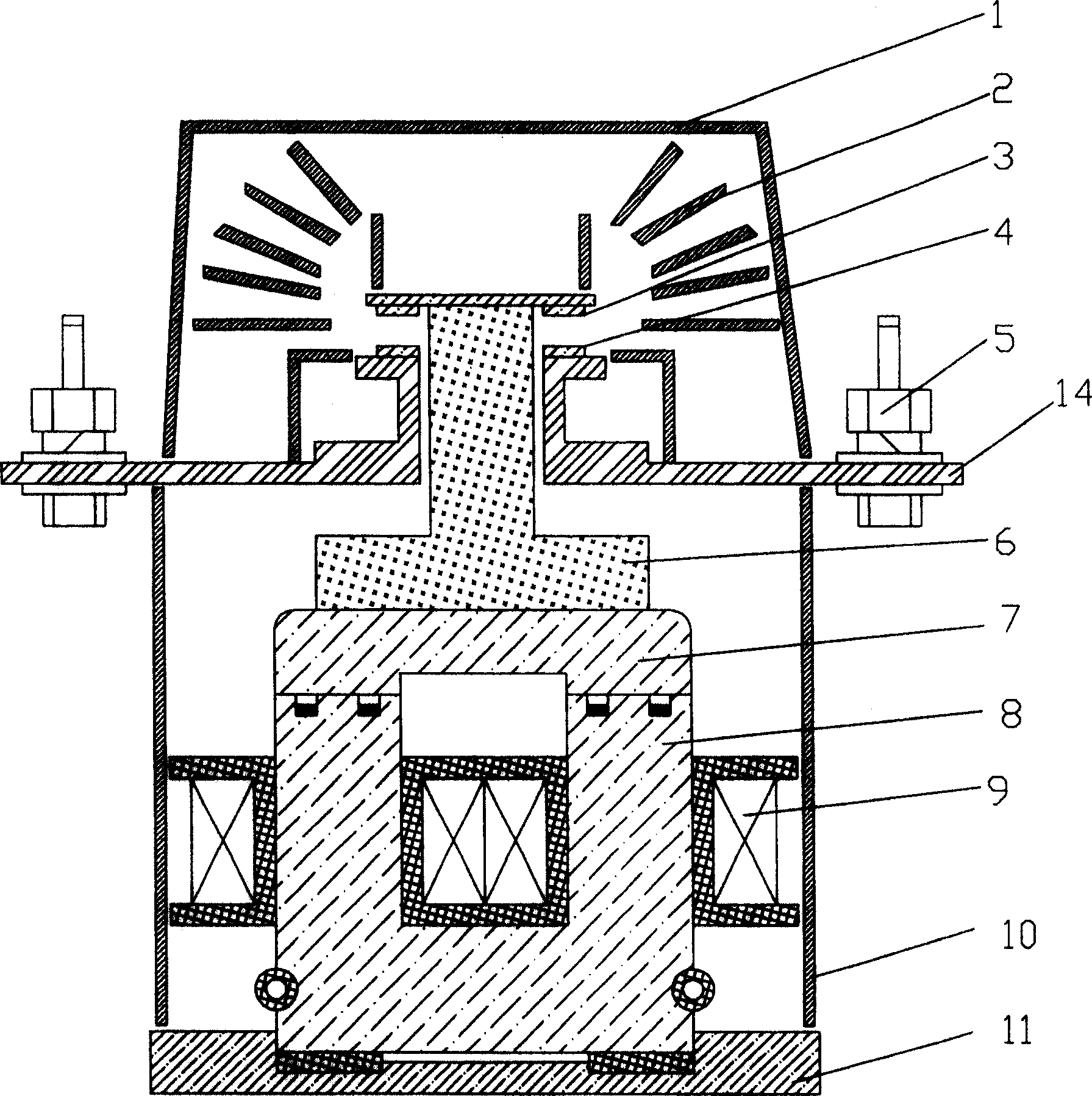

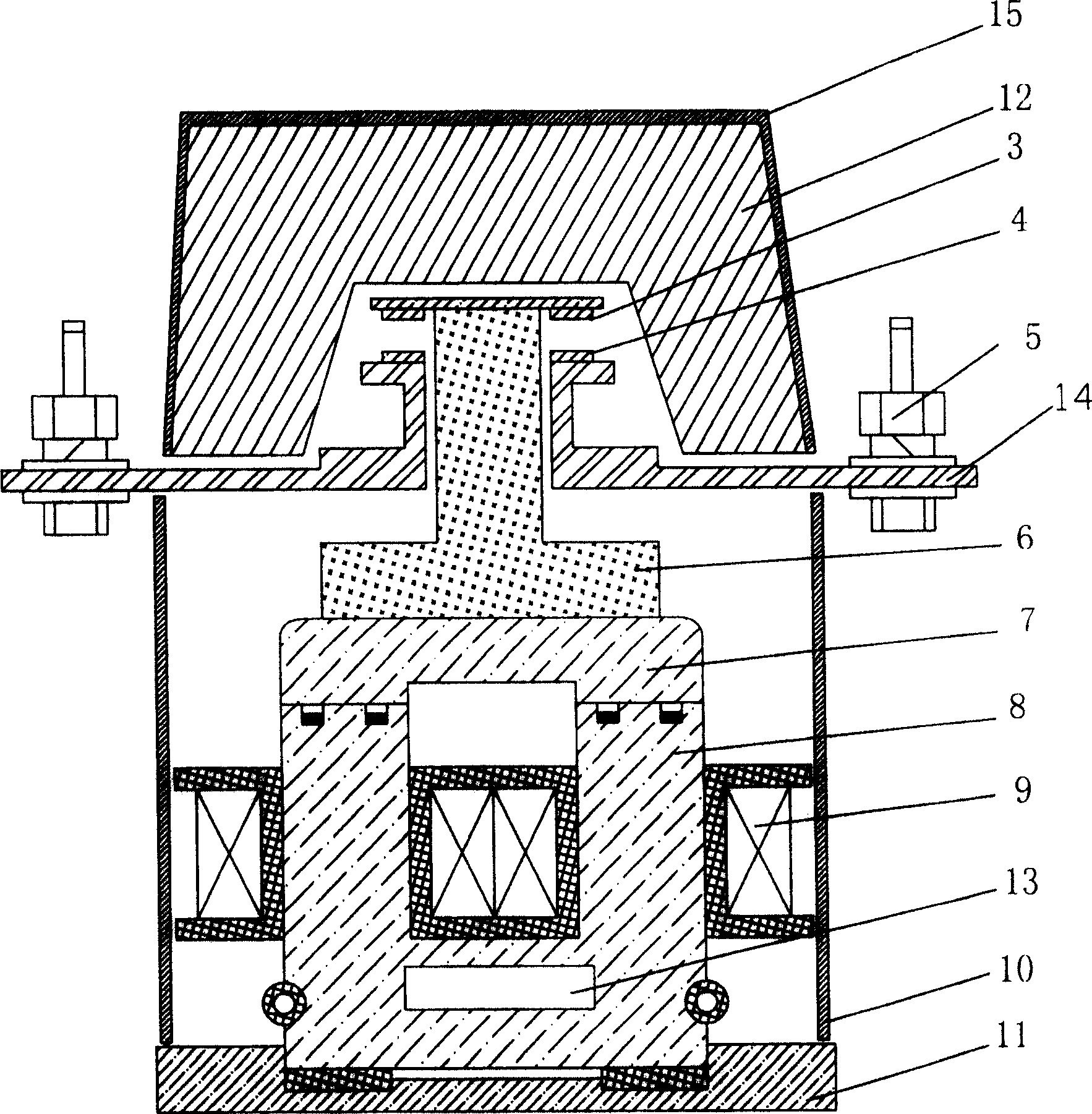

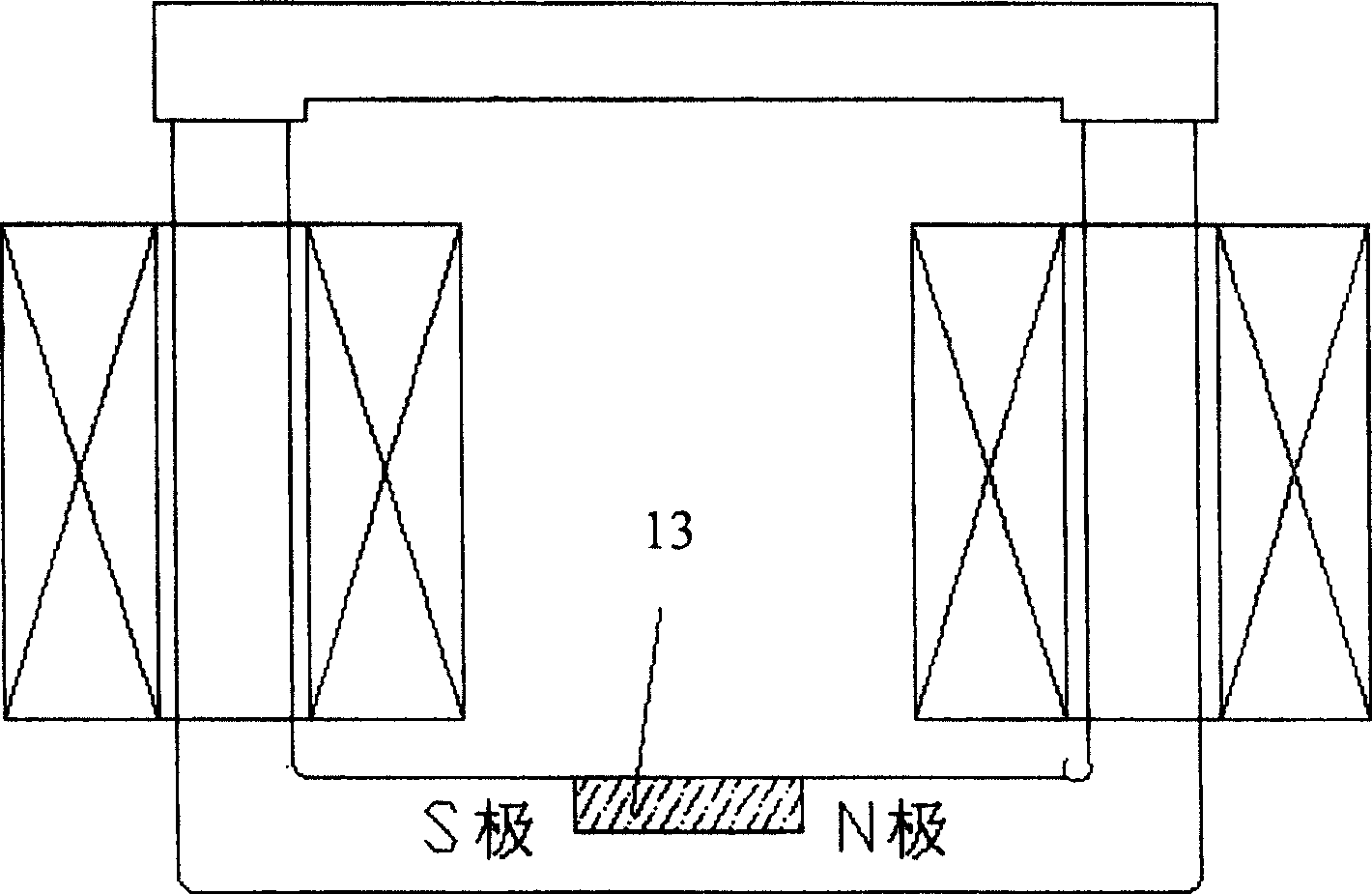

Permanent magnet non-arching AC contactor

InactiveCN100490043CNo change in dimensionsImprove electrical lifeElectromagnetic relay detailsNon-polarised relaysEngineeringThree-phase

This invention relates to a permanent magnet arcless AC contactor including a top cover, a thyristor and its control part, a magnet, a moving contactor, a static contactor, a primary contactor terminal, a moving bracket, a conduction rod, a gag bit, a core, a coil, a shell and a base, in which, the control part in the thyristor and the control part is composed of a control unit, a switch unit, an energy storage element and IGBT element, the control unit is connected with the thyristor, the switch element, energy storage element and the IGBT element, one end of which is connected with any phase in a three-phase voltage by a coil, the other end is connected to the other end of the voltage, both ends of the switch element and the energy storage element are connected with the coil, both ends of each contact point of the contactor are parallel to a pair of counter-parallel single-way thyristors then to be connected to the supply and the load.

Owner:SHENYANG POLYTECHNIC UNIV

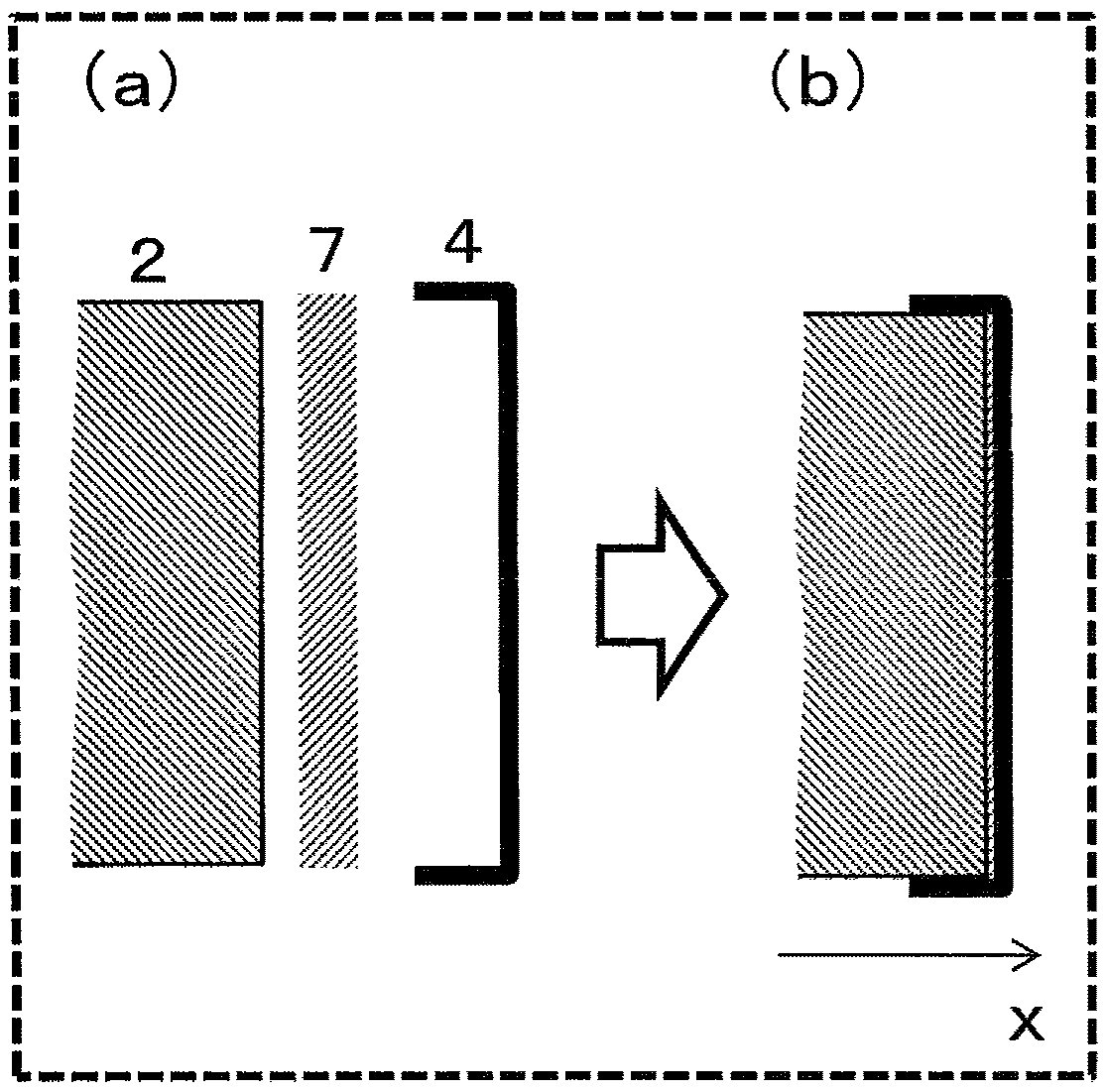

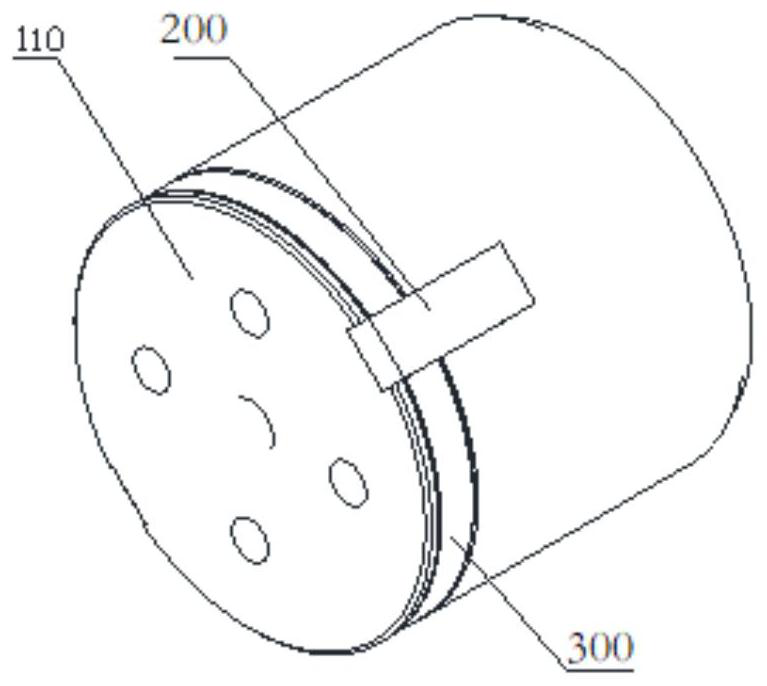

Forced lubrication bearing with distributed holes

ActiveCN111637161ANo change in dimensionsGood effectBearing componentsSliding contact bearingsEngineeringMaximum pressure

The invention provides a forced lubrication bearing with distributed holes. A header pipe is arranged in a bearing body, pressurization holes leading to the inner surface of the bearing body are axially and circumferentially formed in the bearing body, all the pressurization holes are gathered in the header pipe in the bearing body, the header pipe is connected with a pressure servo mechanism through a pipeline, if the bearing body is circumferentially spread, the pressurization holes form an M*N grid, the distances between the pressurization holes are not uniformly distributed in axial and circumferential directions, and the distances between the pressurization holes close to the maximum pressure point are decreased gradually. The pressure servo mechanism is started when detecting that ashaft system is under a low-speed operation condition, a pressurization medium is forcedly injected below the operating shaft system through the pressurization holes, so that the pressurization mediumsprayed out of the pressurization holes lifts a position with larger shaft system load, the shaft system is ensured to always form a liquid film with the bearing under the rotation condition, the poor lubrication state of the bearing is improved, and the frictional wear of the bearing is relieved.

Owner:HARBIN ENG UNIV

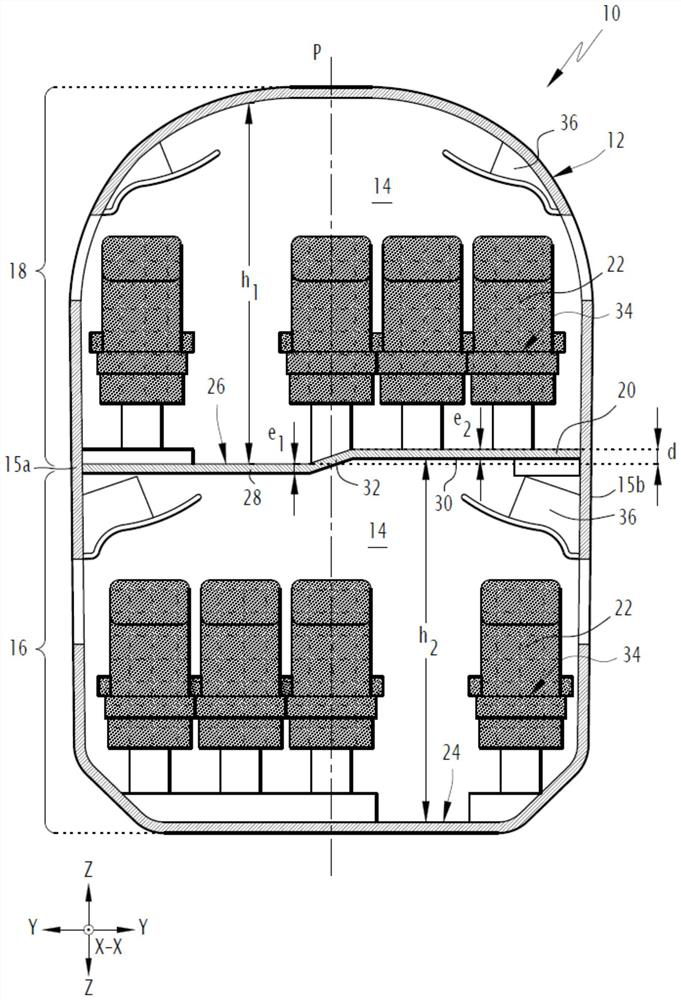

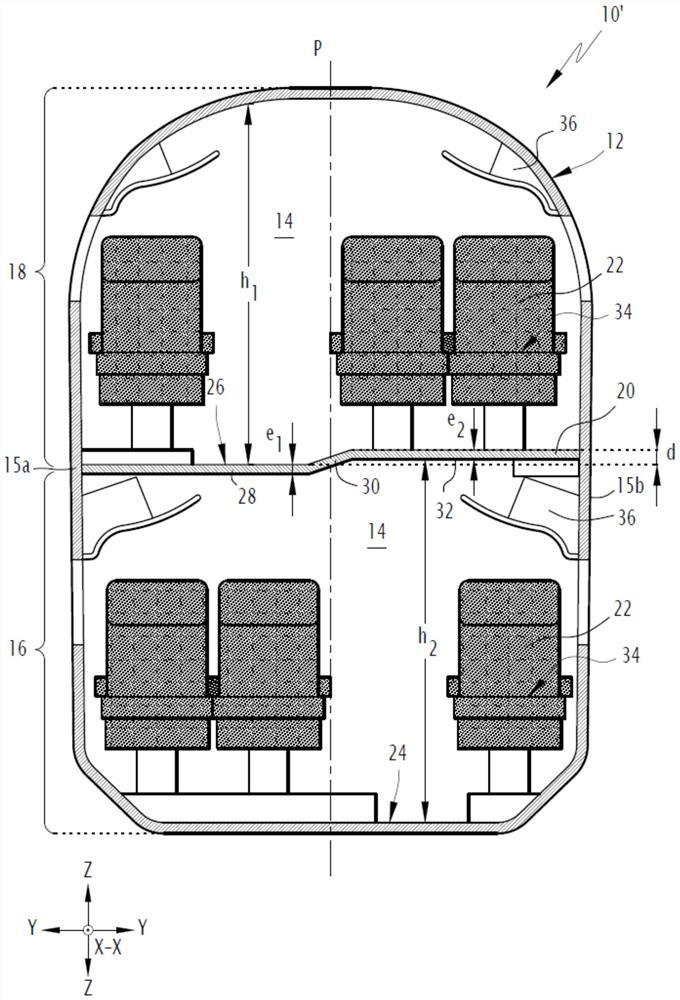

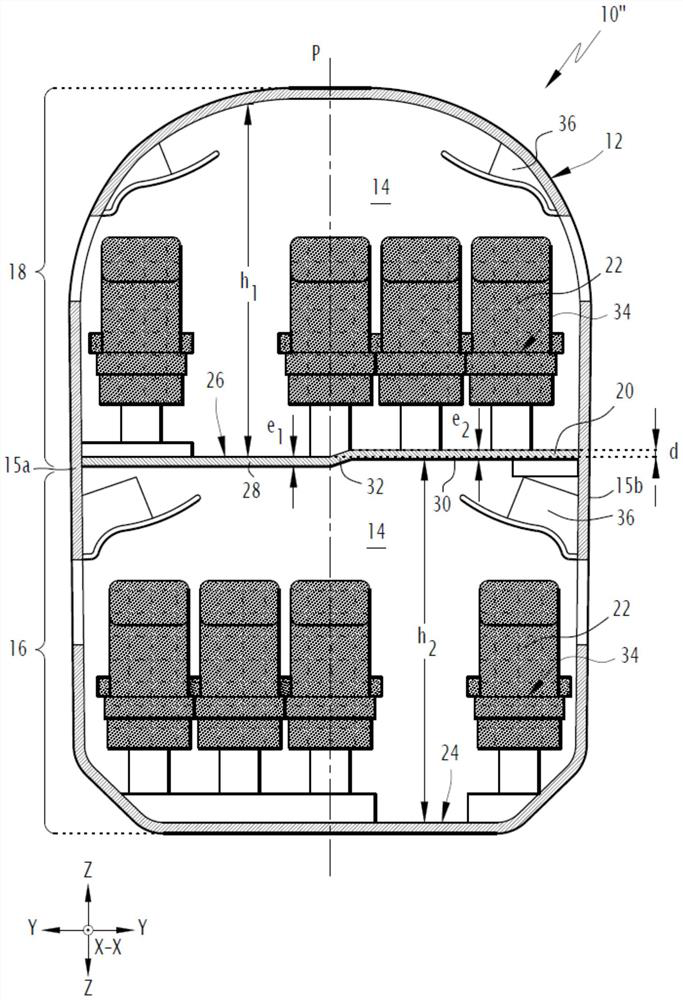

Multi-level car with staggered floor

PendingCN111703446ANo change in dimensionsIncrease heightAxle-box lubricationPassenger carriagesStructural engineeringMechanical engineering

The invention relates to a multi-level car with staggered floors. The car (10) comprises a lower layer (16) and an upper layer (18) separated by an intermediate floor (20), the intermediate floor comprising a lower portion (28), a higher portion (30) and a transition portion (32). The lower layer (16) comprises a lower aisle (24) for passage of passengers, which extends at a higher portion (30) ofthe floor (20), and the upper layer (18) comprises an upper aisle (26) for passage of passengers, which extends on a lower portion (28) of the floor (20). Each of the lower layer (16) and the upper layer (18) includes a seat (22) at a lower portion (28) of the floor (20) and a seat (22) at a higher portion (30) of the floor (20).

Owner:ALSTOM TRANSPORT TECH SAS

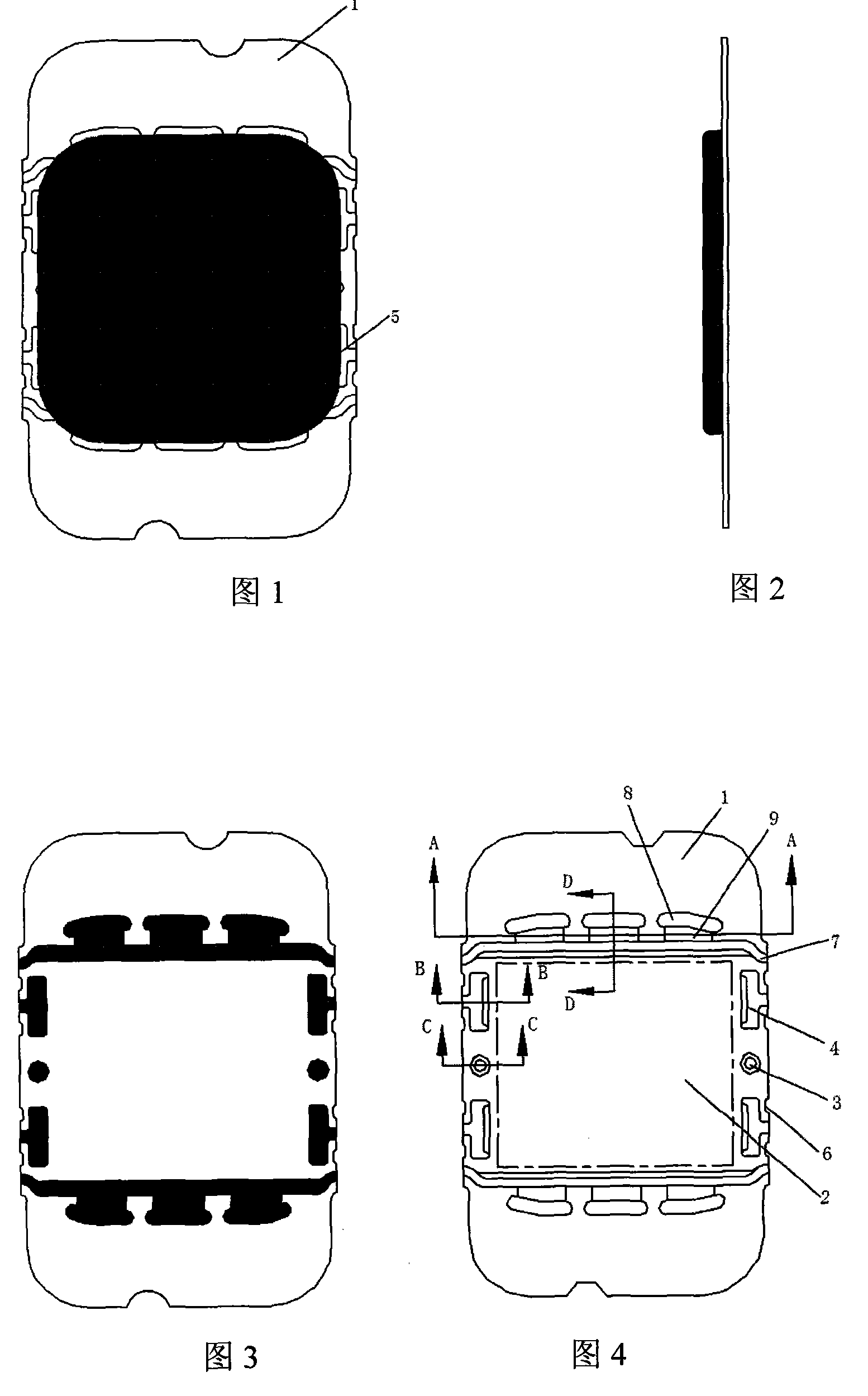

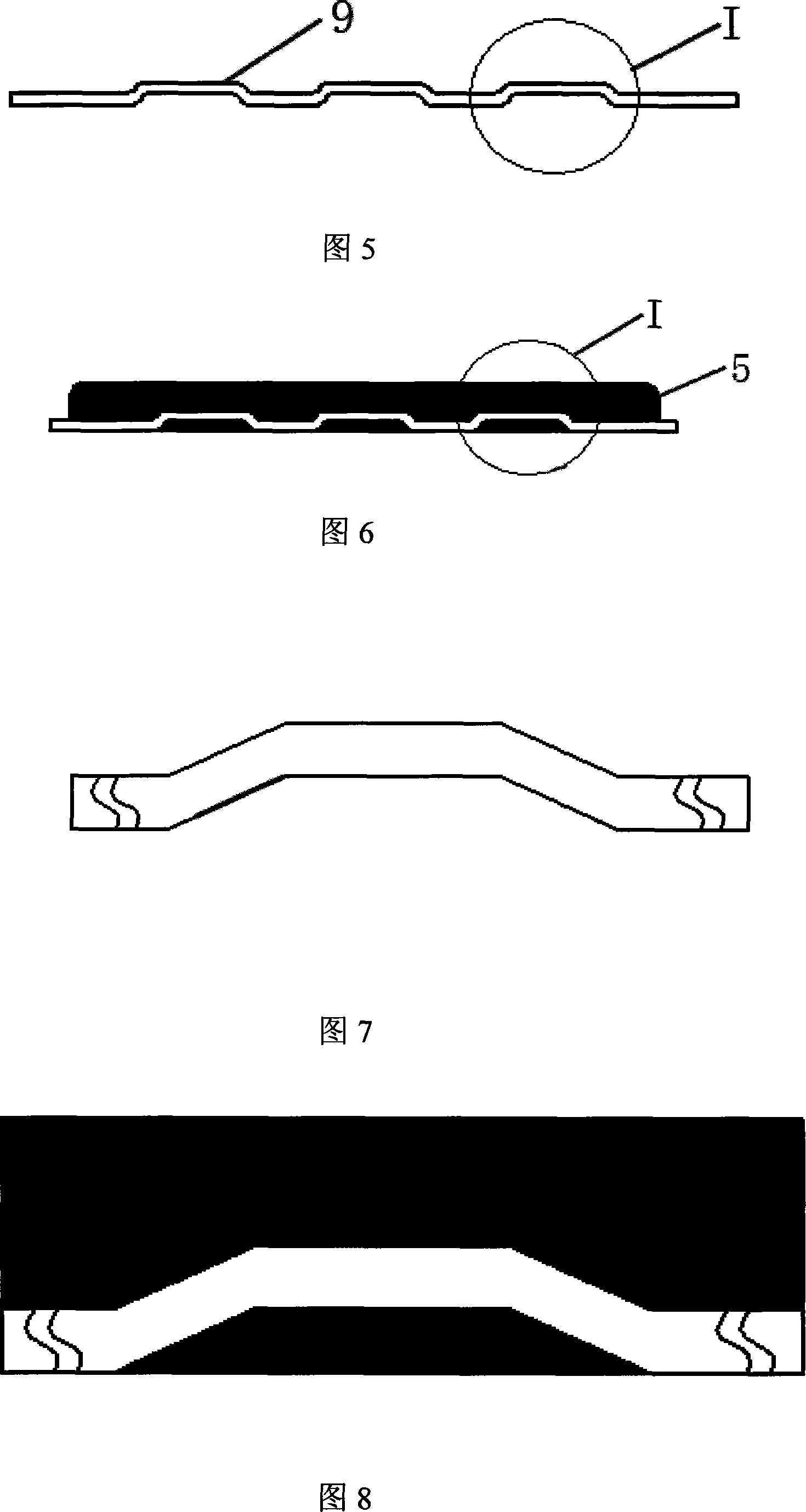

Metal carrier band for packaging noncontact module with large size

InactiveCN101447465BAvoid encapsulation processSize does not changeSemiconductor/solid-state device detailsSolid-state devicesChip sizeShell molding

The invention provides a metal carrier band for packaging a noncontact module with large size which is characterized in that the metal carrier band comprises a chip bearing region which can bear a chip of 3.9*4.5mm. The chip which is 1.5 times of the area of a common chip can be bear and packaged, and a module product with the same mechanical size is obtained. By the improvement of the metal carrier band and under the premise of the increased size of the packaged chip, the combining force of a mould body with the metal carrier band is improved to the maximum extent after the mould packaging, therefore, the mechanical force resistance of internal devices is improved greatly. The carrier band is packaged in a reeling way. Under the premise of not adding the investment, the present conventional packaging process and the existing equipment can be used for producing products with better quality, therefore, the application of high-end chips, such as noncontact intelligent electronic passport, EMV band card, and the like in the intelligent card field is expanded.

Owner:SHANGHAI CHANGFENG SMART CARD

Wall power socket

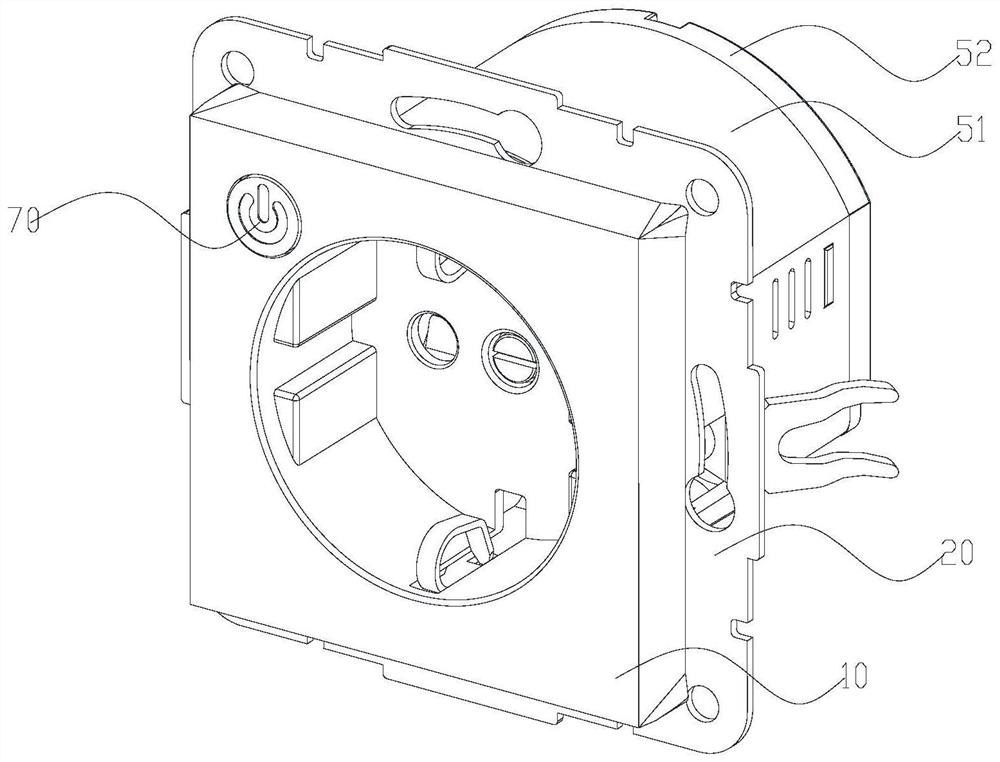

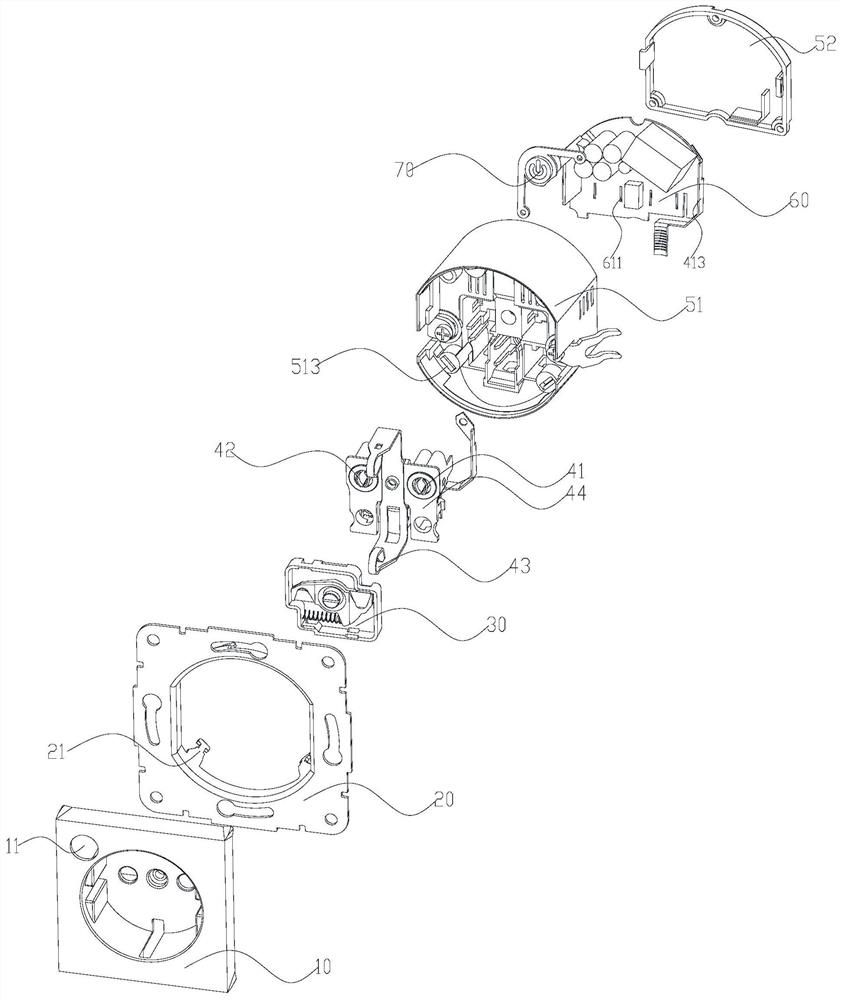

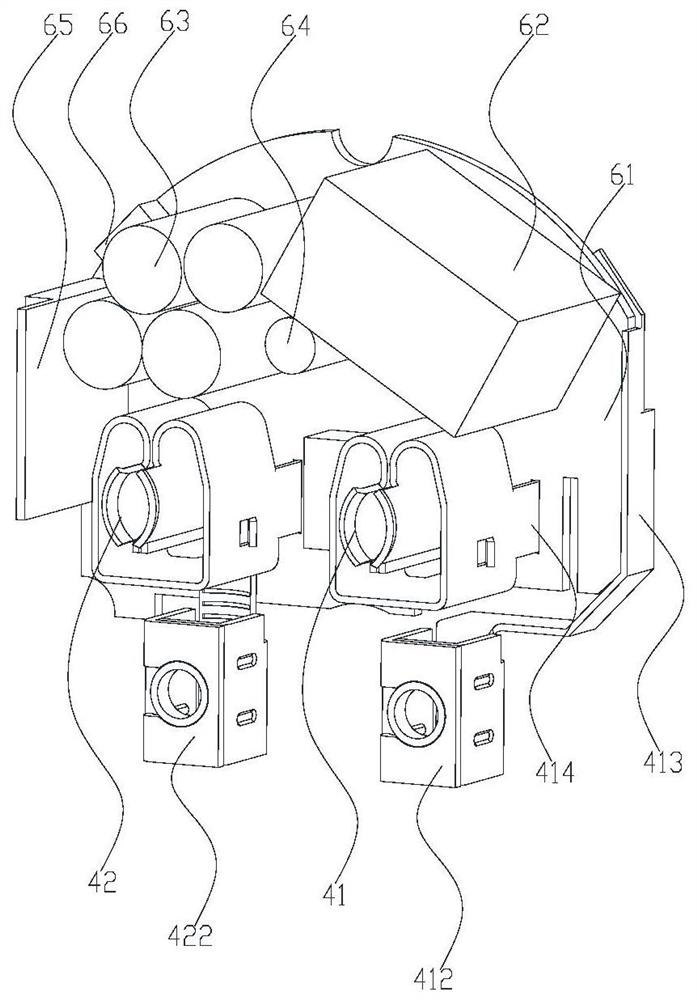

ActiveCN112952489ANo change in dimensionsNo reduction in quantityCoupling device detailsTwo-part coupling devicesStructural engineeringMechanical engineering

The invention provides a wall power socket. The wall power socket comprises a panel and a bottom cover arranged on the rear side of the panel. A WIFI switch control device is arranged on the upper side of an accommodating space formed by the panel and the bottom cover, and a power supply pin for inserting a plug of an external electric appliance is arranged on the lower side of the accommodating space; and the panel is provided with a power jack corresponding to the power supply pin in position and shape. The WIFI switch control device is arranged at the upper part of the accommodating space formed by the panel and the bottom cover, and the power supply pin is arranged below the WIFI switch control device. According to the arrangement, the internal space of the socket is arranged compactly and reasonably, so that the appearance of the wall power socket additionally provided with the WIFI switch control device is not changed, and the wall power socket can be directly replaced with a wall power socket which is only provided with a power jack connected with an external electric appliance plug; therefore, the single wall power socket also has the functions of WIFI switch control and power supply for external electric appliances, and is more suitable for the needs of modern life.

Owner:广州大将军智能科技有限公司

Method for improving index, antenna array and base station antenna

ActiveCN110444858BRatio before and after improvementFast convergenceAntenna arraysAntenna supports/mountingsHigh frequency radiationWireless

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Method for improving FRP tendon concrete structure ductility

InactiveCN101672076AIncreased curvature ductilityOvercoming the defects of brittle failureShock proofingBending momentDuctility

The invention relates to a method for improving FRP tendon concrete structure ductility, comprising the step of building an FRP tendon concrete structure. When the FRP tendon concrete structure is built, a component with effective compressive strength and formability is installed in a zone which has larger bending moment of the FRP tendon concrete structure so as to improve the ductility capability of the structure. Under the condition of constant FRP tendon formability, the invention effectively increases the deformation of the concrete compressive zone and the curvature ductility of a crosssection, overcomes the defect of the brittle failure of the FRP tendon concrete construction member to ensure that the FRP tendon can be widely applied. The invention does not change concrete appearance size, has convenient construction, is economically feasible and is a method for effectively improving the FRP tendon concrete structure ductility.

Owner:SHANGHAI UNIV

A Forced Lubricated Bearing with Distributed Pores

ActiveCN111637161BNo change in dimensionsGood effectBearing componentsSliding contact bearingsEngineeringMaximum pressure

Owner:HARBIN ENG UNIV

Method and structure for improving rigidity of subway vehicle antenna support

PendingCN111883902ALow densityIncreased bending stiffnessAntenna supports/mountingsAntenna adaptation in movable bodiesSteel tubeSpecific modulus

The invention discloses a method and structure for improving the rigidity of an antenna support of a subway vehicle. A carbon fiber reinforcing pipe is installed in a steel pipe of the antenna support, the carbon fiber reinforcing pipe is closely attached to the steel pipe. The method specifically comprises the steps: welding the steel pipe to form a frame of the antenna support; machining the inner wall of the steel pipe through a steel pipe inner wall machine, so that a concave-convex surface is formed on the inner wall of the steel pipe, the carbon fiber reinforced pipe is tightly attachedto the inner wall of the steel pipe, and the carbon fiber reinforced pipe is fixed in the steel pipe through a positioning block; and welding the end support to complete the overall assembly of the antenna bracket. According to the method, the characteristics of high specific modulus and low density of the carbon fibers are utilized, the bending rigidity of the antenna support is improved under the conditions that the boundary dimension of the antenna support is not changed and the structural quality of the antenna support is not greatly improved, then the bending vibration dominant frequencyof the antenna support is improved, and the problem that the antenna support is broken is solved; meanwhile, the structure design is simple, the structure process is mature, and the design and production requirements of the antenna support can be met.

Owner:CRRC NANJING PUZHEN CO LTD

Automobile cardan joint transmission shaft packaging paper box

Owner:GSP AUTOMOTIVE GRP WENZHOU

Linear cylinder motion detection device

ActiveCN113027865BRealize clamping/unclamping detection functionEnvironmental protectionFluid-pressure actuator testingMechanical engineeringPhysics

The invention provides a linear oil cylinder action detection device, which includes an upper guide seat, a detection head, an air intake base, a lower guide seat and a guide rod, and the air intake base is used to pass gas required for the action detection of the oil cylinder; The upper guide seat and the lower guide seat are respectively arranged on the upper and lower ends of the air intake base to realize the conduction of gas between the air intake base and the detection head; the guide rods pass through the upper guide seat in turn from top to bottom , air intake base and lower guide seat; the detection head is arranged on the side of the upper guide seat and / or the side of the lower guide seat, and the gap between the upper guide seat and the detection head or the lower guide seat and the detection head is realized by moving the guide rod up and down. gas on and off. The invention achieves the purpose of detecting the action state of the oil cylinder without changing the external dimensions of the oil cylinder, and has the advantages of convenient production and processing, strong versatility, low development cost, short development cycle and good economy.

Owner:WUXI BEST PRECISION MACHINERY

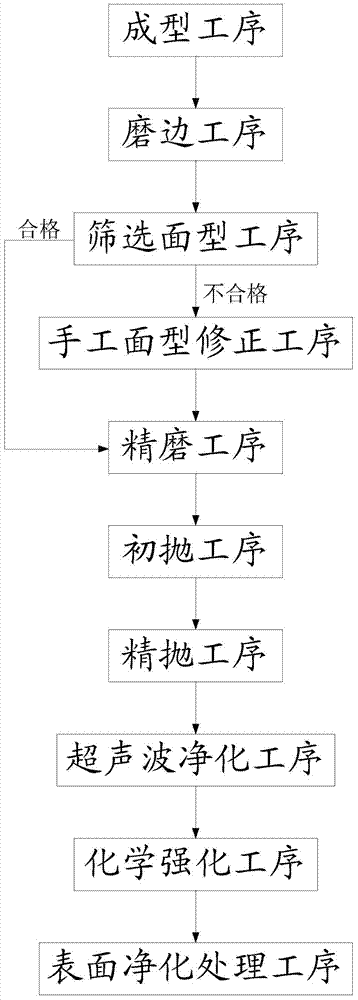

A kind of manufacturing process of glass master disc substrate

ActiveCN104616672BImprove compactnessIncrease prestressOptical record carrier manufactureSurface roughnessHardness

The invention discloses a manufacturing process of glass motherboard substrate. The manufacturing process of glass motherboard substrate comprises the following steps: molding step, edging operating step, surface shape screening step, handwork surface shape correcting step, accurate grinding step, early polishing step, precision polishing step, ultrasonic wave purifying step, chemistry strengthening step and surface purifying and processing step. The manufacturing process of glass motherboard substrate adopts the precision lens grinding core catching machine for executing the edging operating step, adopts the special grinding material and special technology parameter for executing the accurate grinding step and early polishing step, adopts the special additive formula and the special technology parameter for finishing the chemistry strengthening step, the surface roughness of the product can get to the nano grade standard, the consistency and the prestressing force of the glass are greatly raised, the hardness and shock resistance of the surface of the glass are increased and the degree of finish and the flatness of the glass surface can be kept, the outline size is not changed, the glass is not easy to scratch and break and the safety and reliability of the product are improved.

Owner:上海光和光学制造大丰有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com