Quick release device for rolling screen door

A rolling door and quick-release technology, applied in the field of rolling doors, can solve the problems of easy aging of batteries, strong resistance of users, high system cost, etc., and achieve the effect of simple reset and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

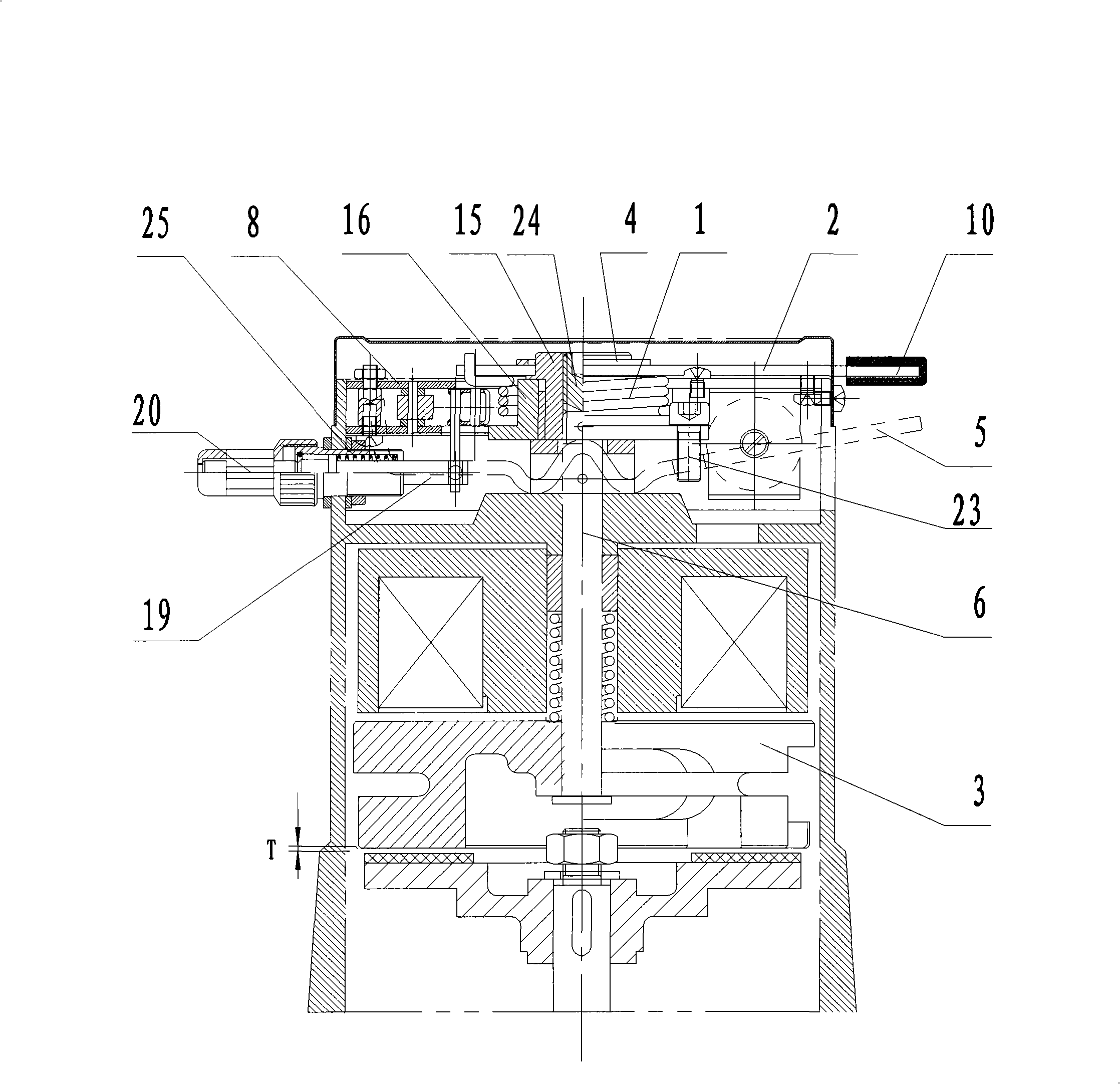

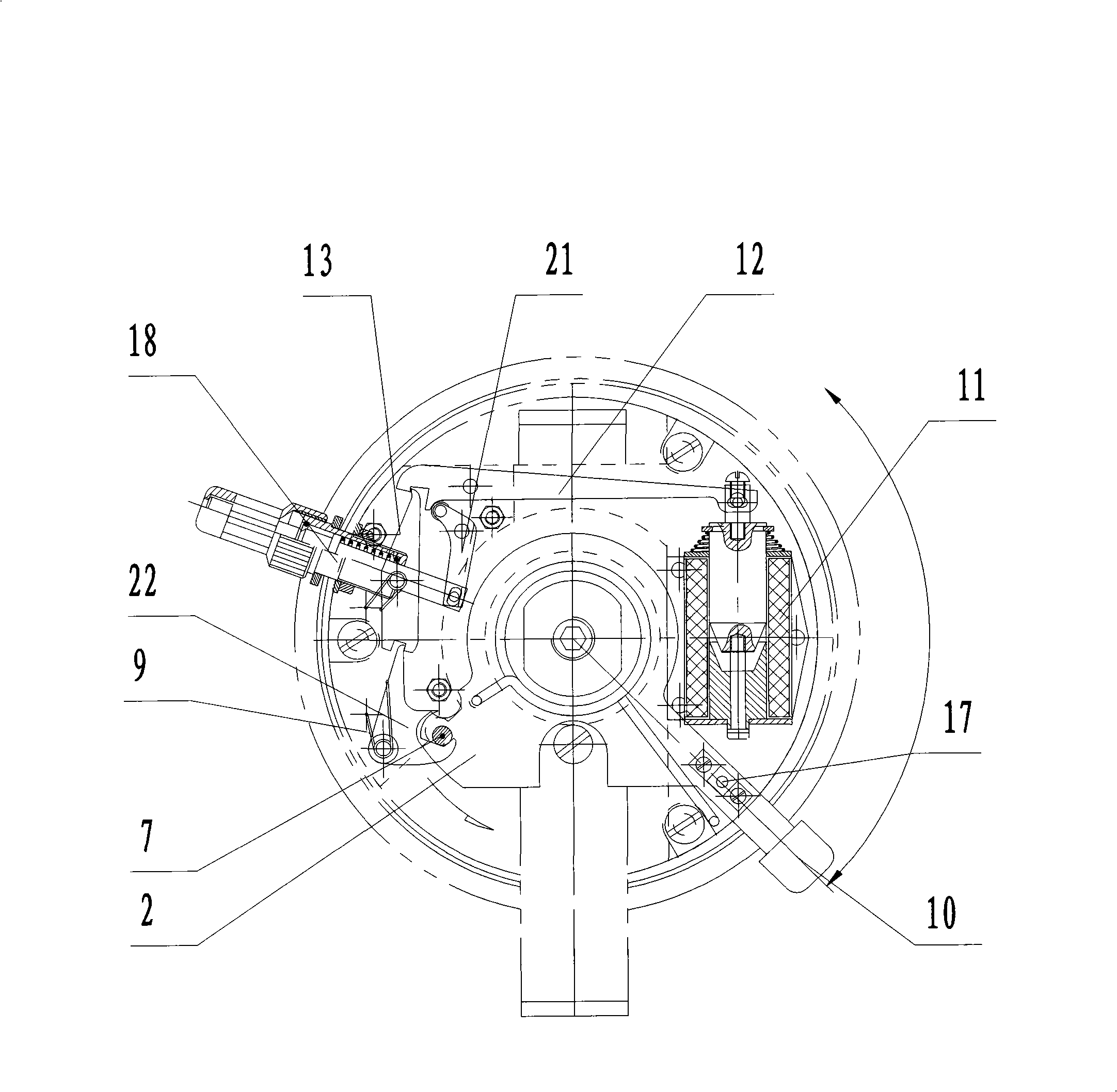

[0043] Example 1: see figure 1 , figure 2 and image 3 As shown, a quick-release device for rolling shutters of the present invention includes a drive plate 2, a mounting plate 8, a lifting mechanism and an electric control starting mechanism, and the lifting mechanism includes a rotating rod 15 and a positioning sleeve 16 that remains fixed. In a specific embodiment, the positioning sleeve 16 can be fixed on the mounting plate 8, the casing or other positions. One end of the rotating rod 15 is fixed on the top of the brake rod 6, and the other end is connected with the driving plate 2. The rotating rod 15 and the positioning sleeve 16 are threadedly connected, and the driving plate 2 drives the rotating rod 15 to rotate under the drive of the electric control starting mechanism. And utilize the screw thread lead angle between the positioning sleeve 16 to drive the brake lever 6 to move up and down. The driving plate 2 is connected with a torsion spring 1 fixed on the moun...

Embodiment 2

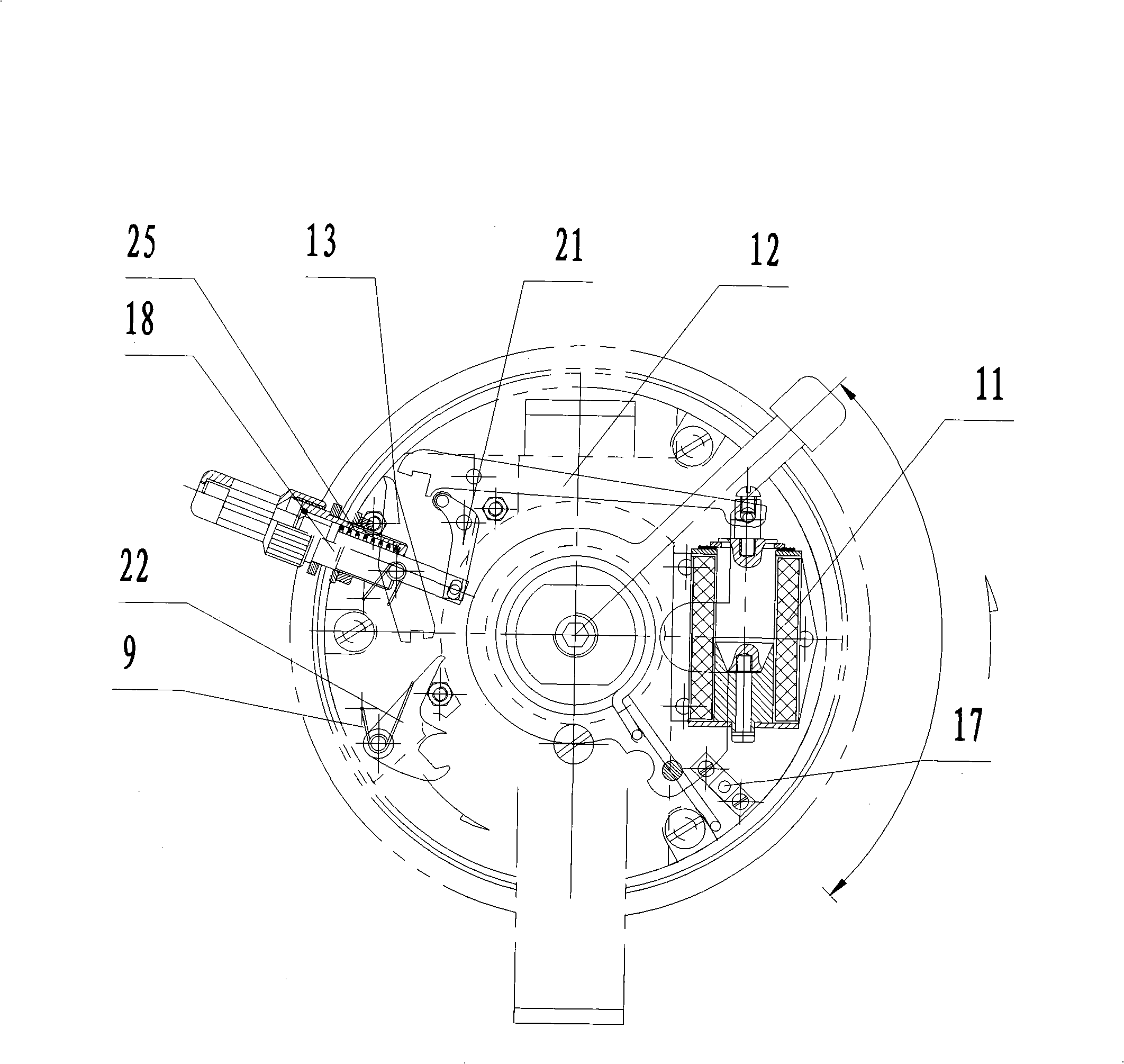

[0046] Example 2: see Figure 4 , Figure 5 and Figure 6 As shown, the structure is basically the same as that of Embodiment 1, and the difference is that the electronically controlled driving mechanism adopts an electric explosive head 14 connected to the control center, and the electric explosive head 14 is connected with a temperature-sensitive starting mechanism, and the temperature-sensitive starting mechanism includes a fixed The temperature sensing device 18 on the motor housing, the temperature sensing starting rod 19 and the stage clip 25, the stage clip 25 is enclosed within on the temperature sensing starting rod 19, the electric explosive head 14 is fixed on the driving plate 2, and the driving plate 2 passes through the electric Explosive head 14 is buckled on the temperature-sensitive starting rod 19, and when temperature-sensitive starting rod 19 is pulled away or electric explosive head 14 bursts, driving plate 2 rotates under the effect of torsion spring 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com