Multi-layer ceramic laminar capacitor

A multilayer ceramic and capacitor technology, applied in the field of capacitors, can solve problems such as the difficulty of resisting high-voltage breakdown strength, and achieve the effects of avoiding electrode arcing, increasing effective distance, and reducing breakdown probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

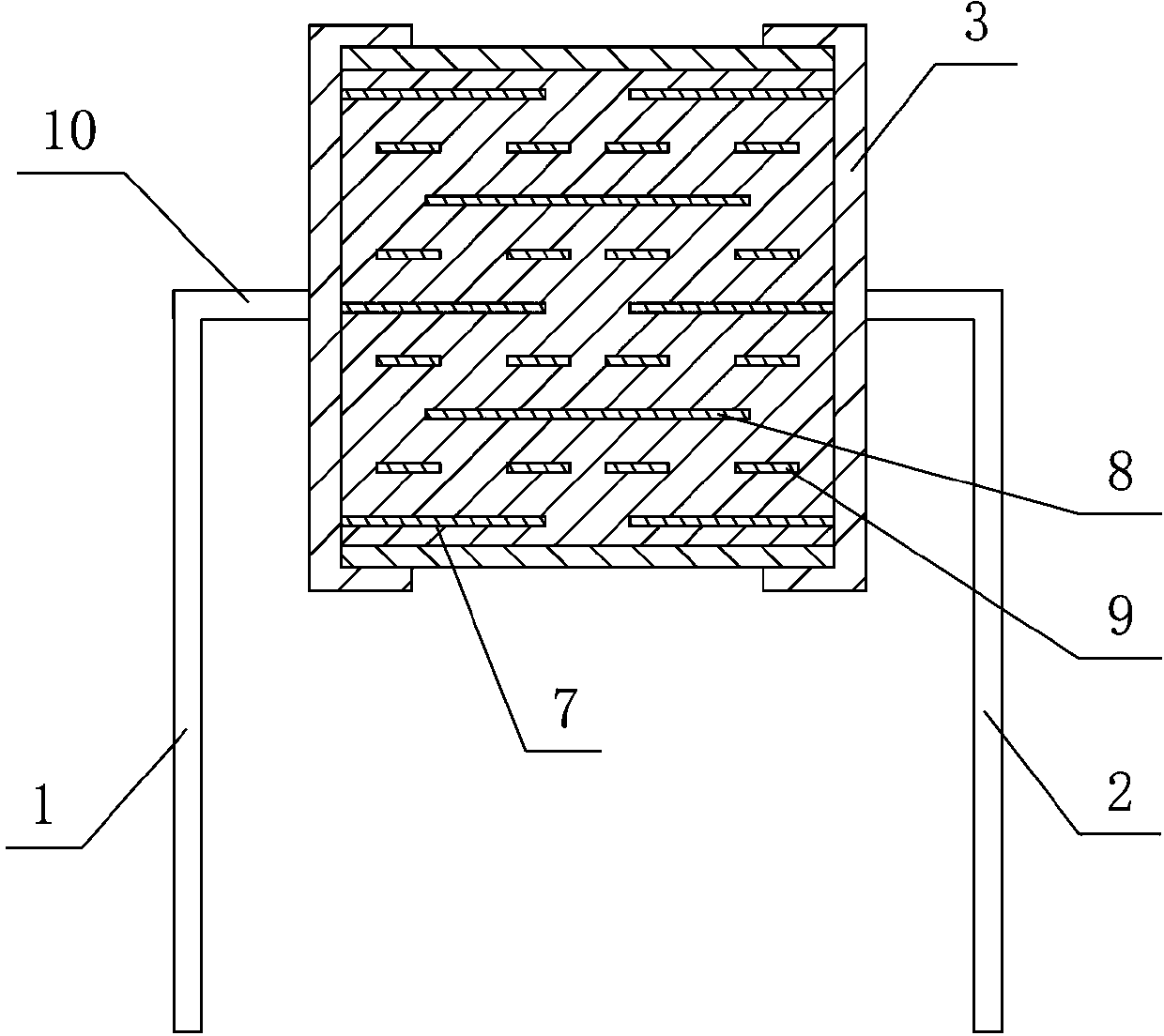

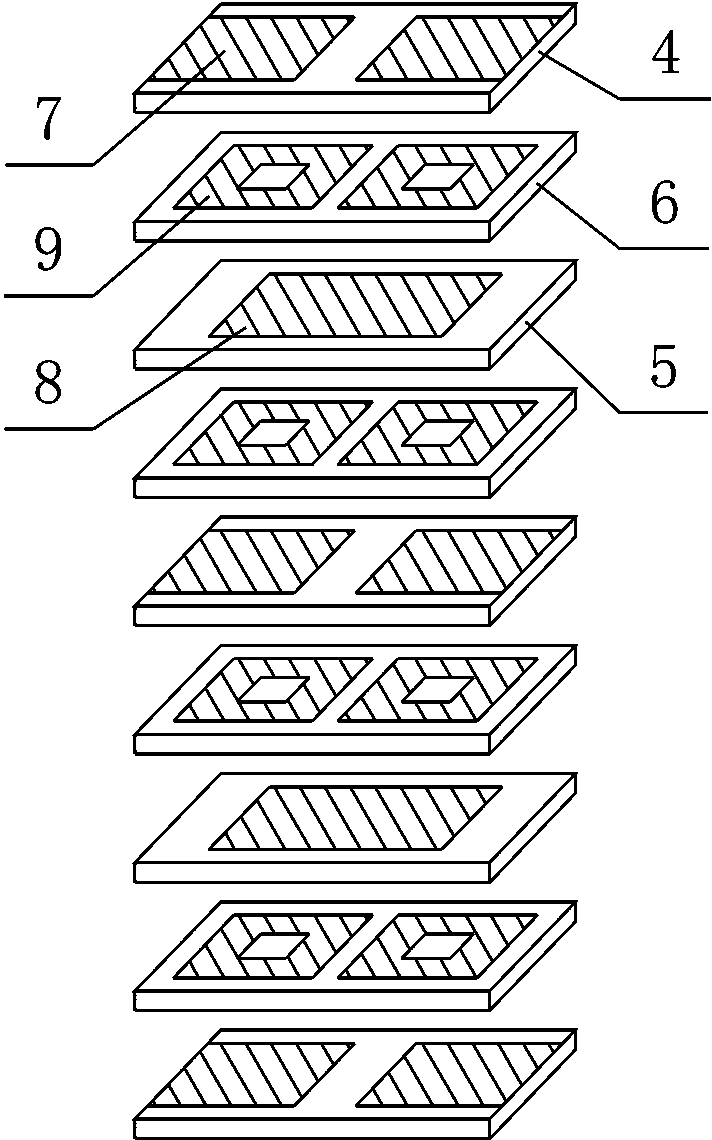

[0016] As an embodiment of the present invention, such as figure 1 with figure 2 As shown, a multilayer ceramic chip capacitor includes a chip body, a first lead 1 and a second lead 2, and the chip body includes two external electrodes 3 respectively located at its two ends and two external electrodes 3 Between the first dielectric layer 4, the second dielectric layer 5 and the third dielectric layer 6; the first lead 1 and the second lead 2 are respectively arranged outside the external electrode 3, and the part connecting the external electrode 3 is provided with a lateral The extension section 10 makes the first lead 1 and the second lead 2 have an L shape, and the lateral extension section 10 is vertically connected to the middle of the external electrode 3 .

[0017] The first dielectric layer 4 is printed with two internal electrodes a7 distributed at intervals and in the shape of a small rectangle, and the two internal electrodes a7 are connected to the two external e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com