Multiple layered sheet structured ceramic capacitor

A ceramic capacitor and multi-layer chip technology, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the problems that cannot meet the requirements of the electronic technology field, and the anti-electric breakdown strength is not ideal, so as to reduce the breakdown probability, the effect of improving the electric breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

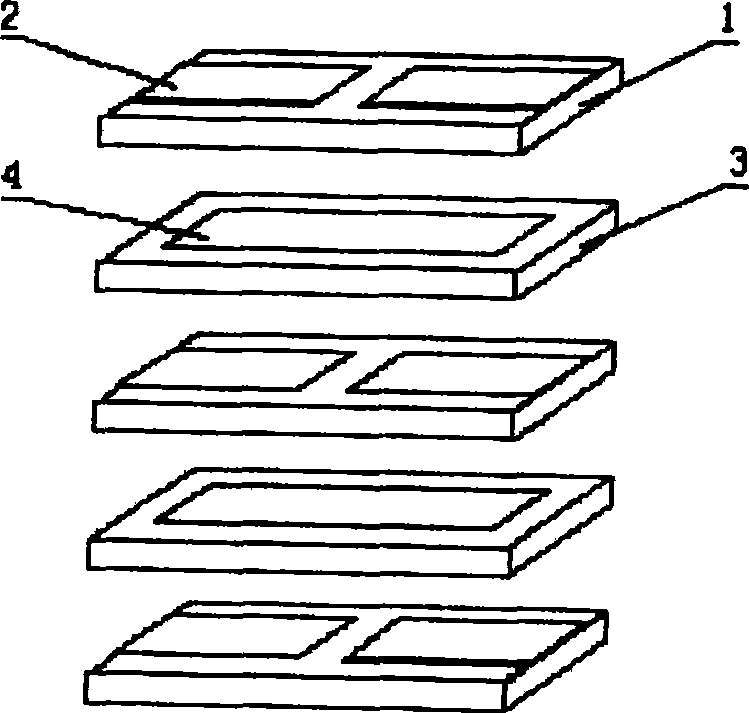

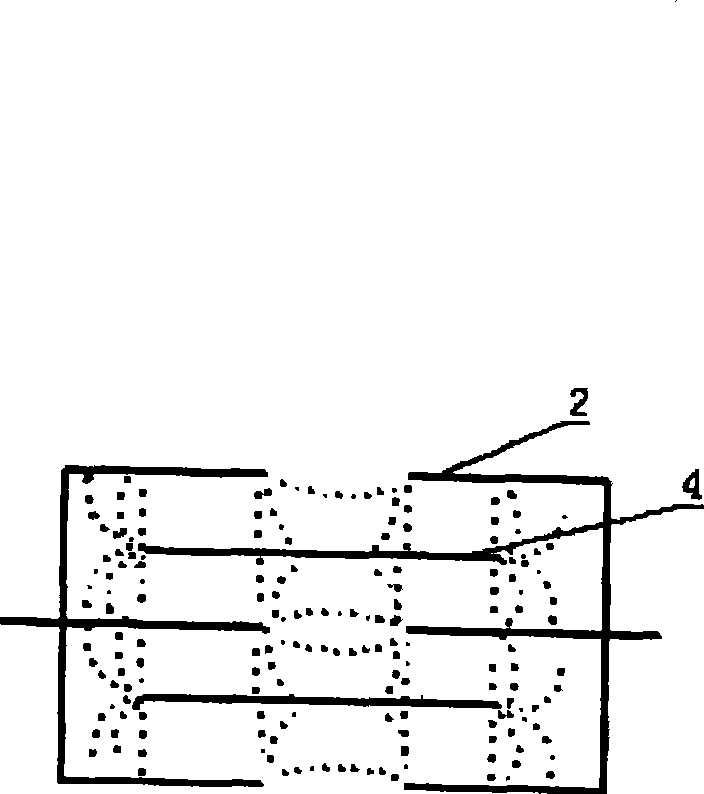

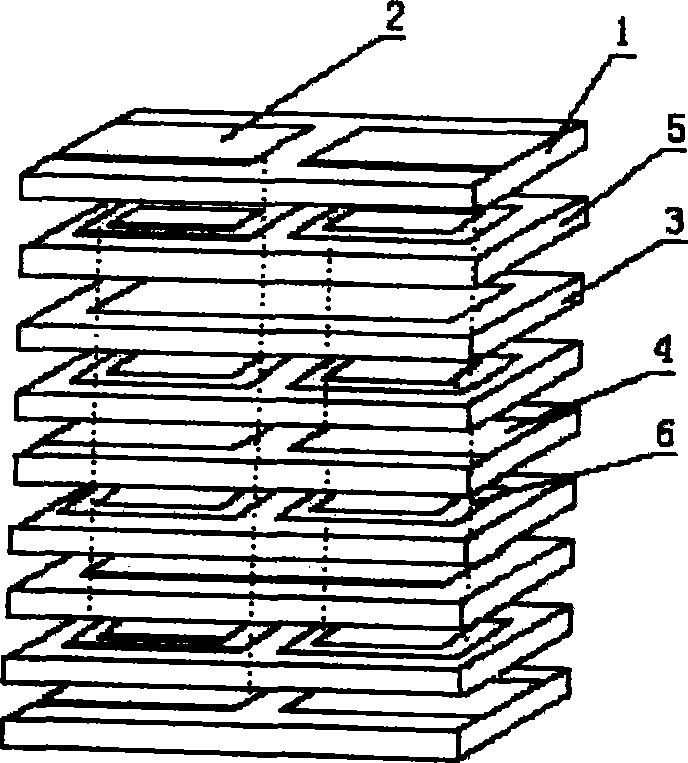

[0014] see image 3 and Figure 4 , The ceramic capacitor of the present invention includes a multi-sheet dielectric in the form of three types of internal electrodes and external electrodes at both ends made of ceramic materials. The internal electrodes 1 and 2 of one type of dielectric layer 1 are two small rectangles arranged at intervals, and the outer edges of each internal electrode 1 and 2 are respectively connected to the external electrodes at both ends; the internal electrodes 2 and 4 of the second type of dielectric layer 3 are in the shape of a The large rectangle corresponds to the printing position of the two small rectangles of the internal electrode 1, and the two ends of the internal electrode on the second type dielectric layer 3 are not connected to the external electrodes; the internal electrode 3 6 of the third type dielectric layer 5 is two frames In a quadrilateral shape, the third internal electrode 6 corresponds to the position of the printed coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com