Method for improving FRP tendon concrete structure ductility

A concrete structure, concrete technology, applied in the direction of building components, building structure, earthquake resistance, etc., can solve the problems of small deformation capacity, no plastic rotation capacity, etc., achieve the effect of increasing curvature ductility, overcoming the defects of brittle failure, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

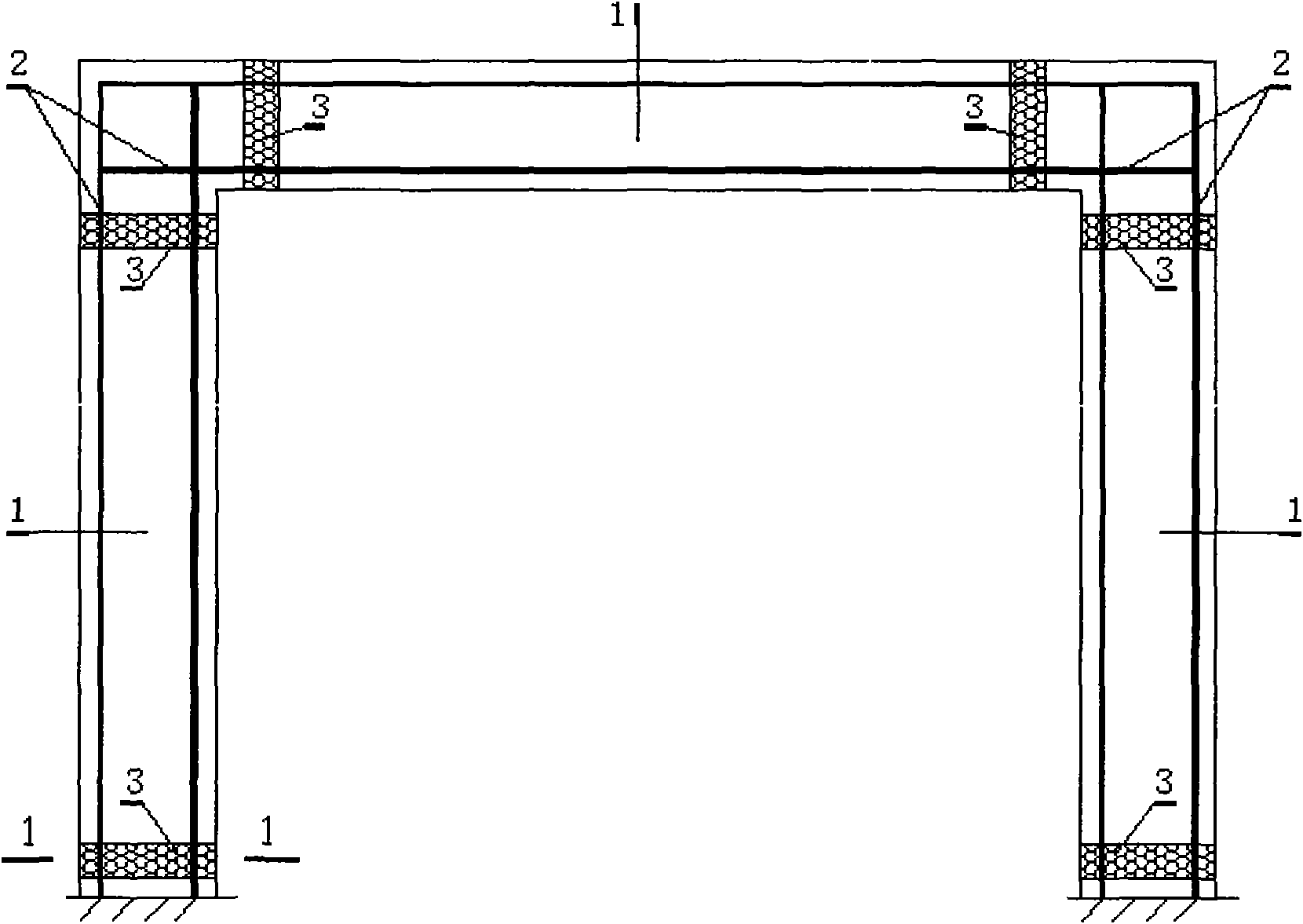

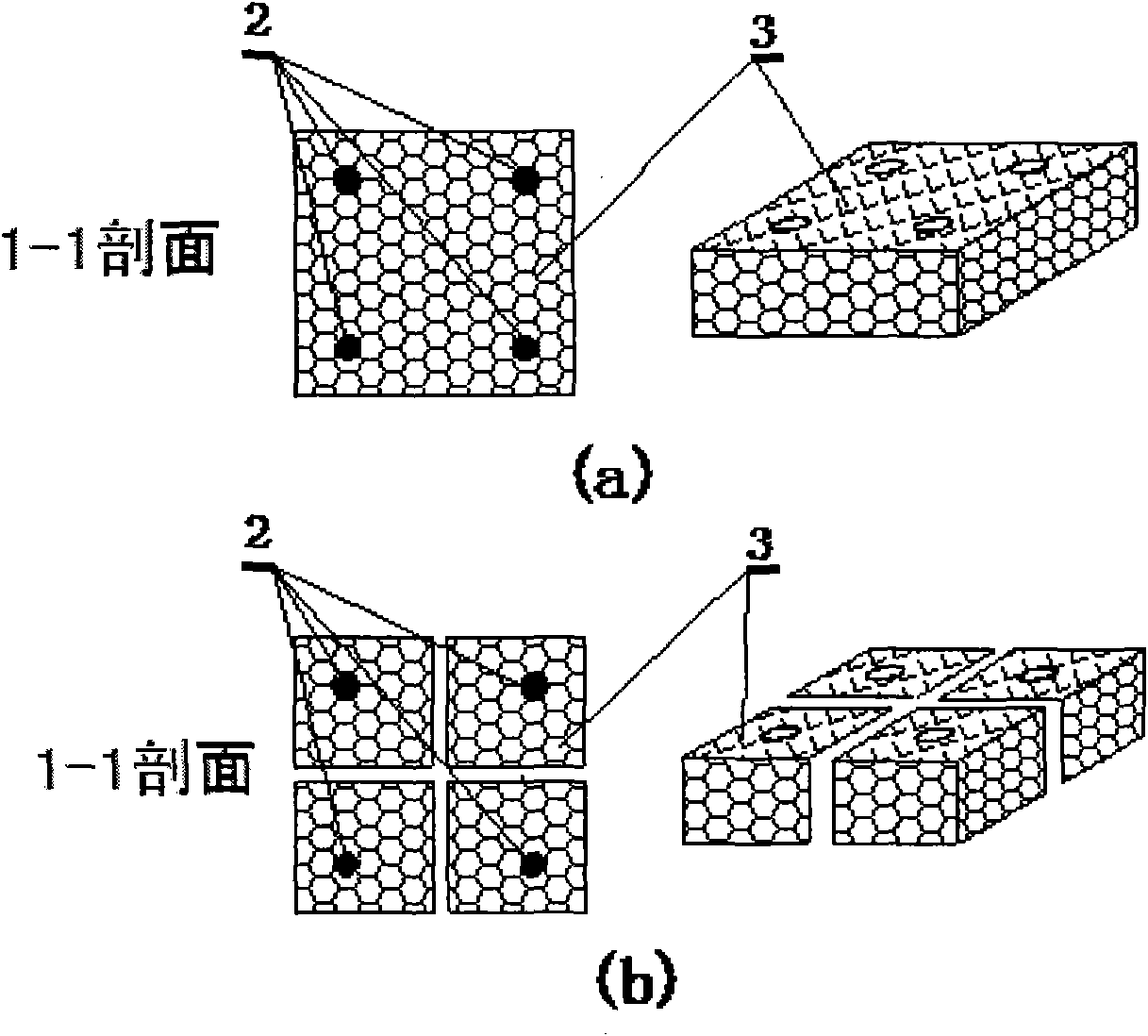

[0021] Embodiment one: see figure 1 , figure 2 , the method for improving the ductility of FRP-reinforced concrete structures is as follows: according to the cross-sectional size of FRP-reinforced concrete structure 1 and the quantity and diameter of FRP tendons 2, make the required element member 3 in this embodiment, and drill in element element 3 Corresponding hole, when installing FRP bar 2 in the FRP bar concrete structure, in figure 1 Install the fixed element 3 at the position of the required element 3 marked in , and then pour concrete to complete the construction of the FRP reinforced concrete structure. The specific operation steps are as follows:

[0022] (1) According to the cross-sectional size of the FRP reinforced concrete member 1 and the quantity and diameter of the FRP reinforced concrete member 2, the element member 3 (integral type) is made;

[0023] (2) drilling a hole perpendicular to the surface in the element member 3;

[0024] (3) When installing ...

Embodiment 2

[0026] Embodiment two: see figure 2 , this embodiment is basically the same as the above-mentioned embodiment, the difference is that the element component 3 is a separate type, that is, the element component 3 can be installed on each or every few FRP tendons, and the element component 3 can be installed in combination After finishing, the entire cross-sectional shape of the FRP reinforced concrete member 1 can still be assembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com