A short-limb shear wall with partial joints for earthquake resistance

A shear wall and short-leg technology, applied in the direction of wall, seismic, building components, etc., can solve the problems of asymmetric configuration, weak seismic performance, wall ductility, poor energy consumption, etc., to improve seismic performance, increase curvature The effect of ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

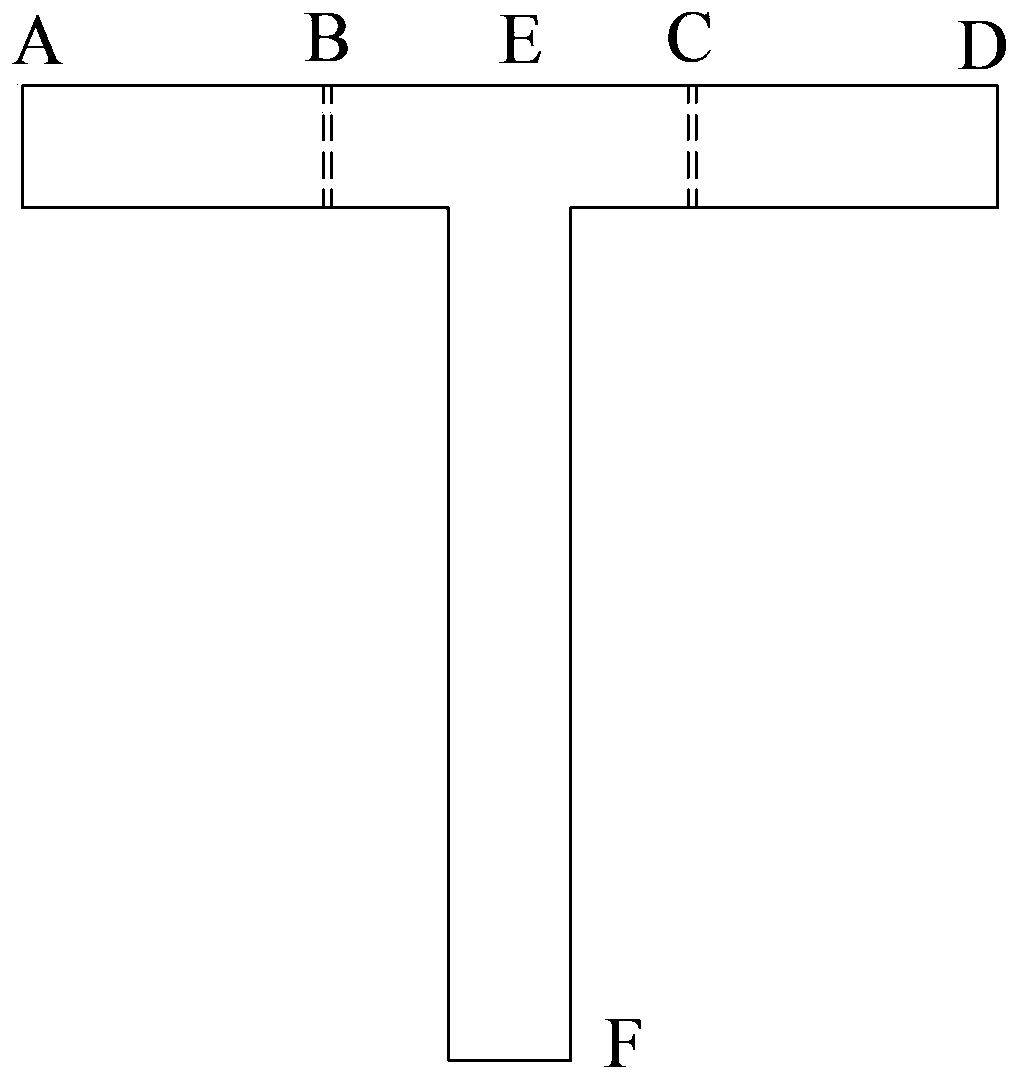

[0012] Embodiment one: Such as figure 1 As shown, the present invention is beneficial to the earthquake-resistant local seam short-limb shear wall, and the plastic hinge area at the bottom of the wall of the short-limb shear wall is provided with a vertical seam that runs through the wall, and the vertical seam is vertical from the bottom of the wall. Formed by extending upwards, the height of the vertical joint is within the range of the height of the plastic hinge of the wall. In this embodiment, the short limb shear wall is a short limb shear wall with a T-shaped section, and the vertical joints on the short limb shear wall with a T-shaped cross section include plastic hinge areas respectively arranged on the flange walls on both sides of the web. Vertical seam I (B) and vertical seam II (C) above, vertical seam I (B) and vertical seam II (C) are respectively set in the plastic hinge area at the bottom of the flange wall, and are perpendicular to the bottom of the flange ...

Embodiment 2

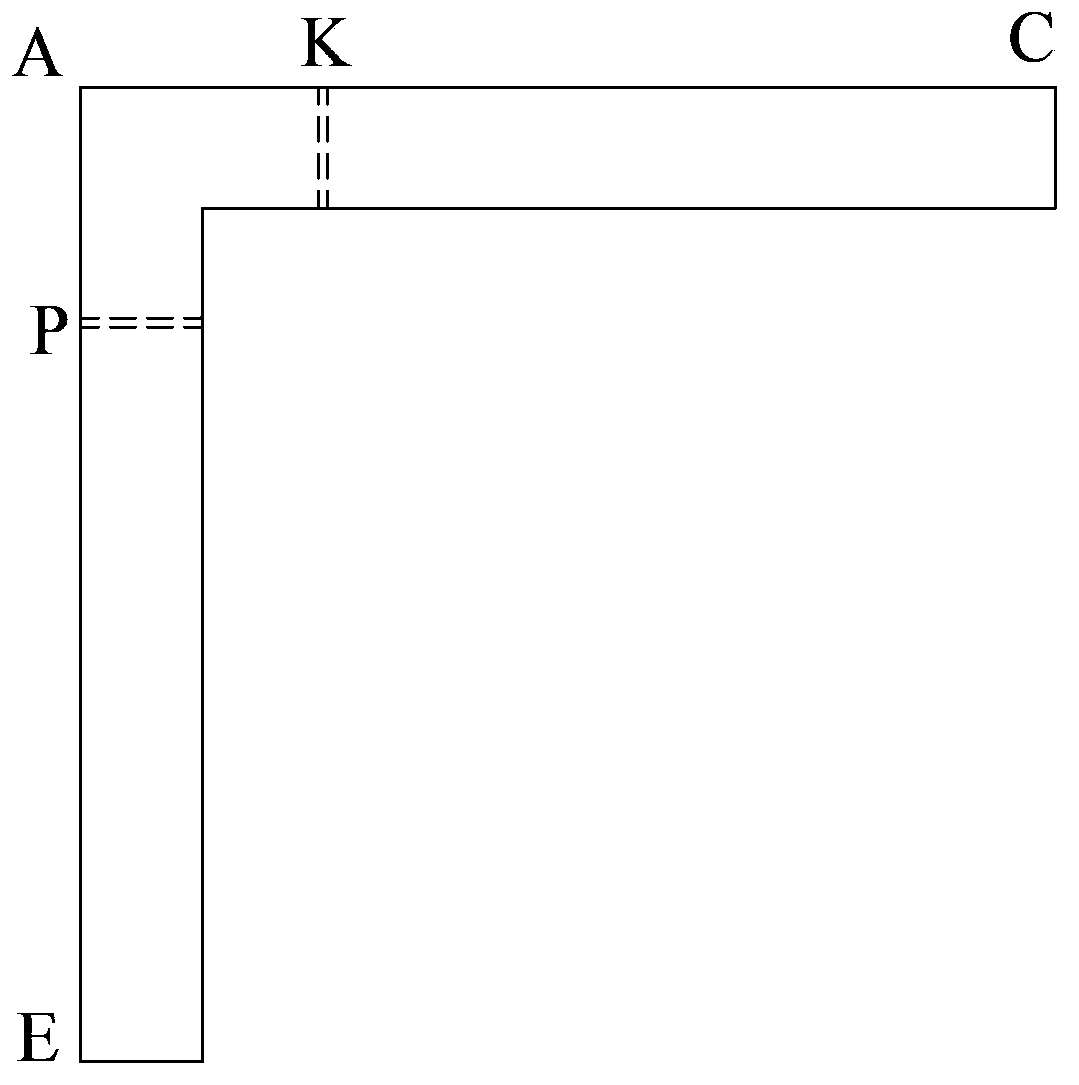

[0014] Embodiment two: Such as figure 2 As shown, the difference from Embodiment 1 is that in this embodiment, the short-leg shear wall is an L-shaped cross-section short-leg shear wall, and the vertical joints on the L-shaped cross-section short-leg shear wall include Vertical joints III (K) and vertical joints IV (P) on the plastic hinge areas of the two wall piers, vertical joints III (K) and vertical joints IV (P) are respectively set in the plastic hinge areas at the bottom of the respective walls, And it is formed by vertically extending upwards from the bottom of the wall bodies where they are located. The heights of the two vertical joints are within the range of the plastic hinge height of the wall.

[0015] Analysis of the principle of the present invention: before the vertical joints are set in the L-shaped cross-section short limb shear wall, when the horizontal force acts along the wall limb AE and the wall limb AC is on the tension side, the longitudinal rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com