Intelligent temperature measurement static contact device

A static contact and intelligent technology, applied in the direction of measuring devices, thermometers, measuring heat, etc., can solve the problems of reducing the reliability of switchgear operation, the installation reliability of temperature measuring components cannot be guaranteed, and unfavorable post-maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

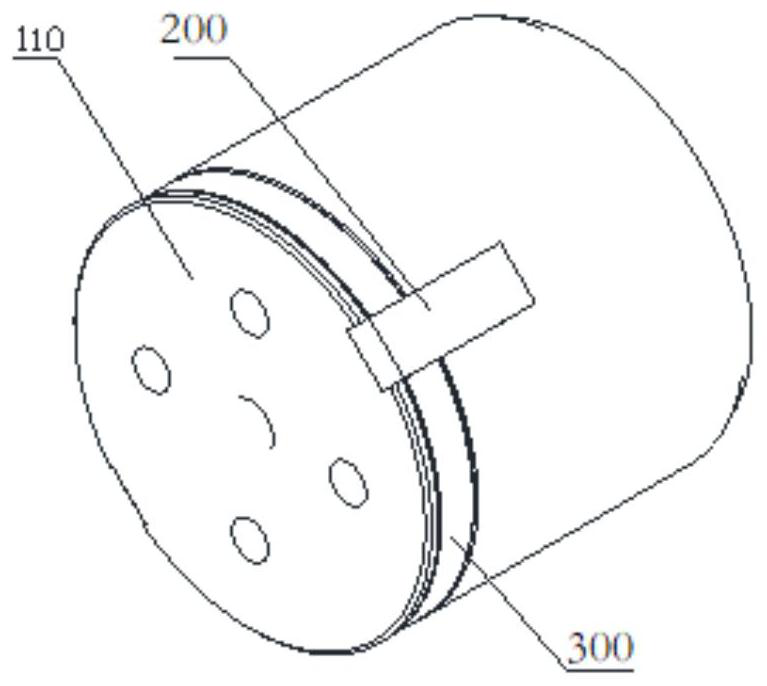

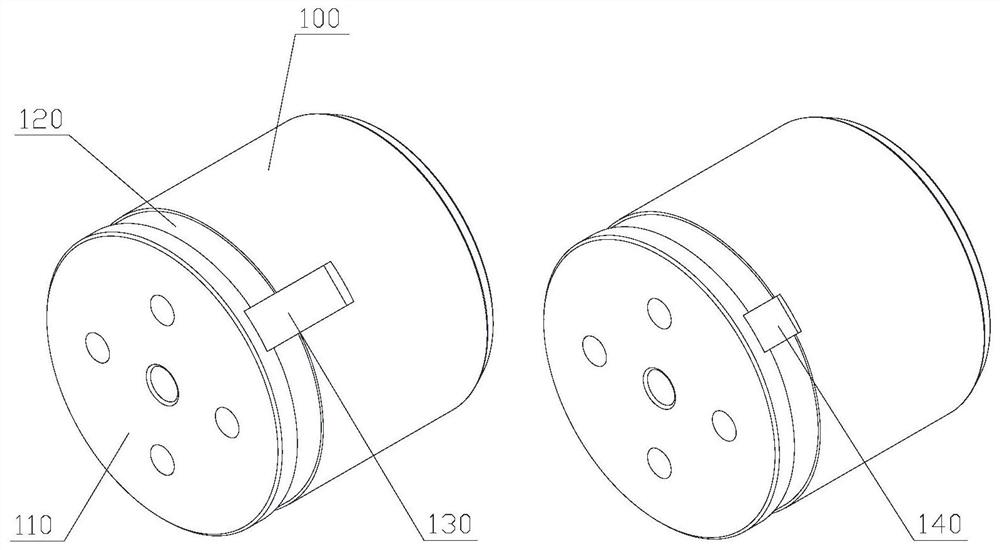

[0018] Such as Figure 1-4 The shown intelligent temperature measuring static contact device includes a cylindrical static contact 100, an annular belt groove 120 is arranged around the surface of the static contact 100, and sensor installation grooves 130 and The positions of the metal power-taking ring fixing groove 140, the sensor installation groove 130 and the metal power-taking ring fixing groove 140 can be determined as required.

[0019] The mounting surface 110 of the static contact 100 is provided with 1-5 mounting holes for fixing the contact box 400 and the copper bar 420 with fasteners. The specific number of mounting holes can be set according to the specifications of the static contacts.

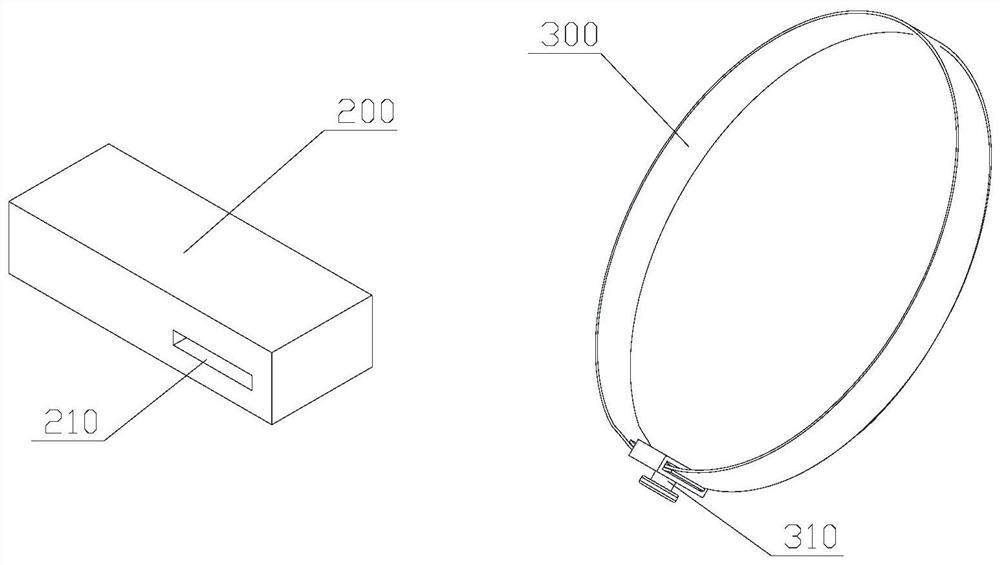

[0020] The body of the temperature measuring sensor 200 is provided with a metal power-taking strap installation hole 210. After the metal power-taking strap 300 passes through the installation hole 210 in the temperature measuring sensor 200, the temperature measuring sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com