A kind of manufacturing process of glass master disc substrate

A manufacturing process and mastering technology, which is applied to the manufacturing process of glass master substrates, can solve the problems of glass flatness and parallelism deformation, optical indicators not up to standard, low product yield, etc., and is not easy to be scratched and broken. , maintain smoothness, improve the effect of density and prestress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

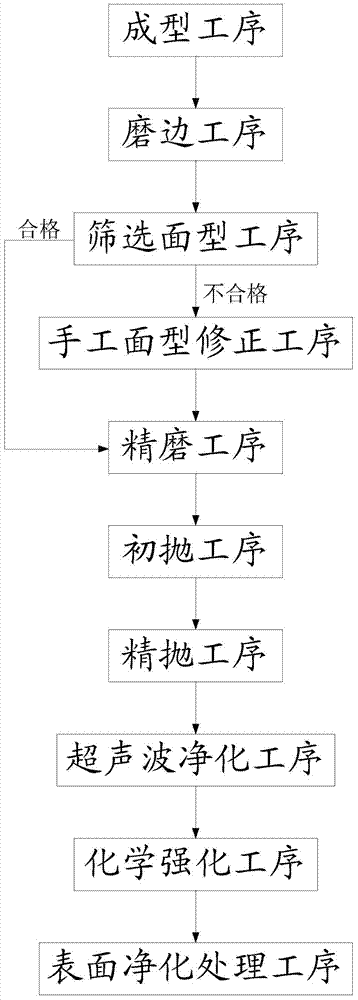

[0020] see figure 1 , the manufacturing process of a kind of glass mother disc substrate of the present invention, comprises the following operation that carries out in sequence: forming operation, edging operation, screen surface shape operation, manual surface shape correction operation, fine grinding operation, initial polishing operation, fine polishing process, ultrasonic cleaning process, chemical strengthening process and surface purification process.

[0021] During the forming process, a manual circular mirror machine is used to draw a circle according to the requirements of the drawing, and a diamond cutter head is used for the circle;

[0022] When performing the edging process, a core machine is used, the abrasive material is water-soluble coolant, the grinding wheel is a No. 380 diamond grinding wheel, and the speed of the driving motor of the grinding wheel i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com