Permanent magnet non-arching AC contactor

An AC contactor and permanent magnet technology, which is applied in the direction of non-polar relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of inability to fundamentally eliminate arcs, high conduction loss, and high prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

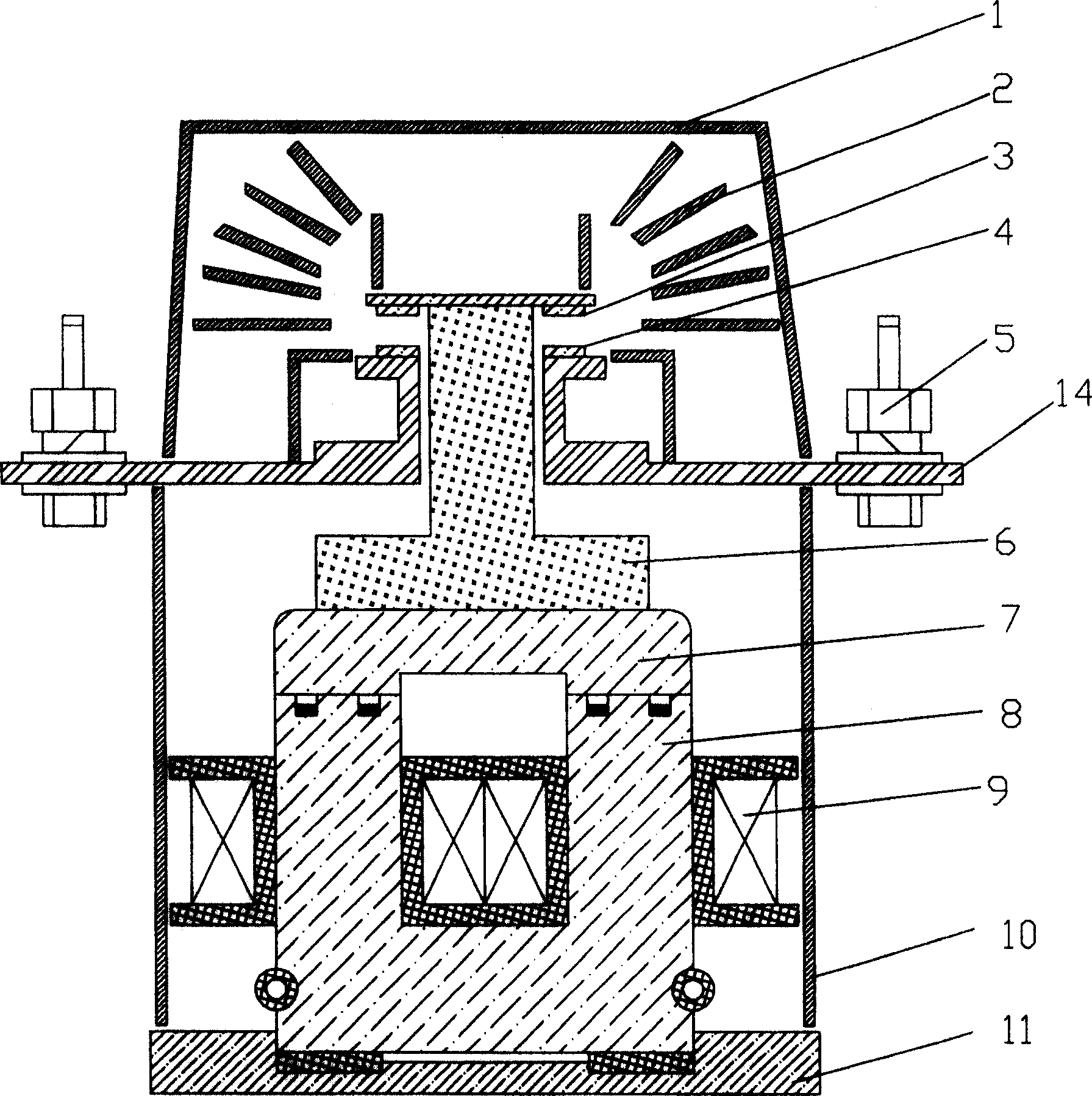

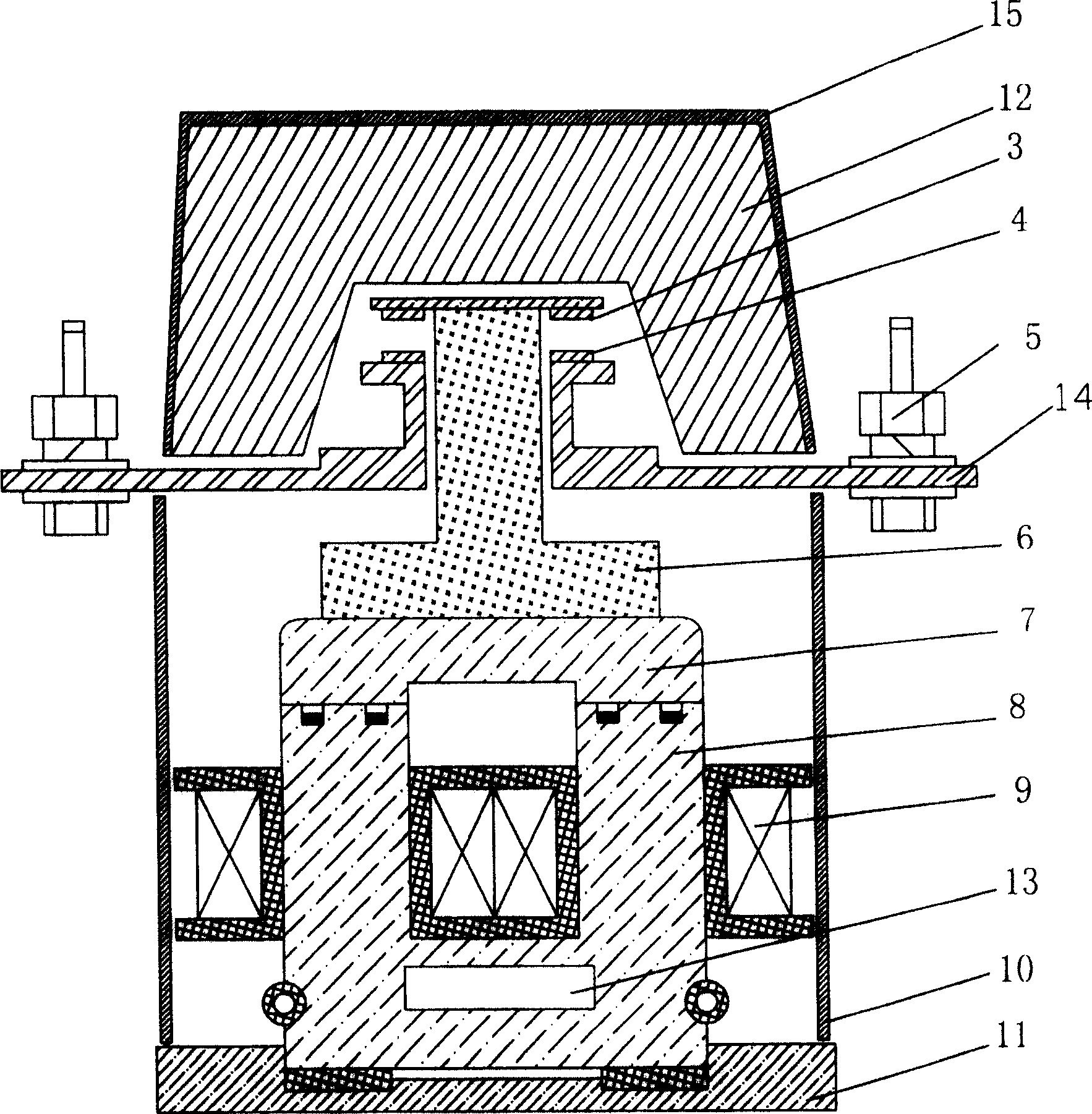

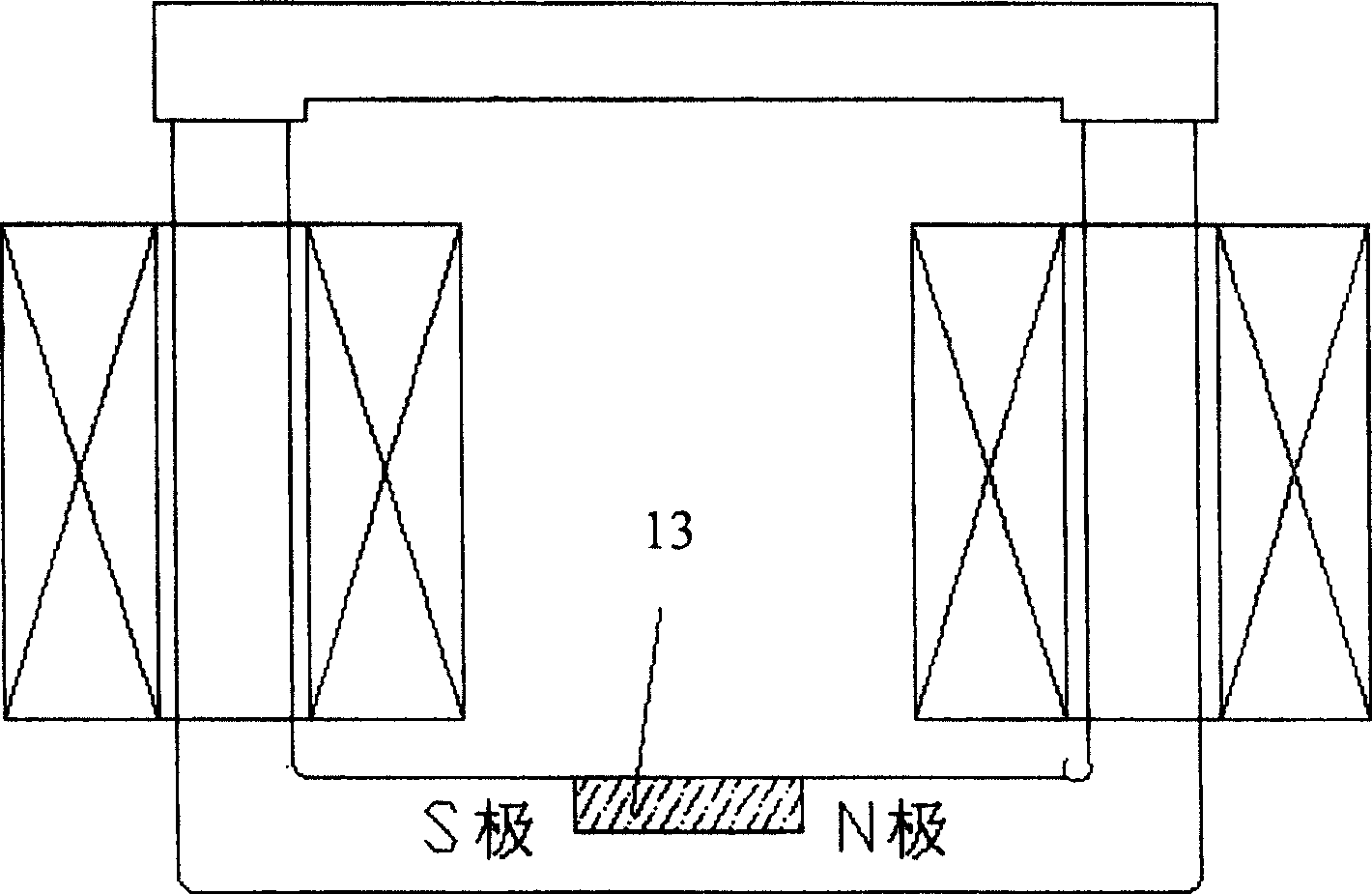

[0021] figure 2 Shown is a schematic cross-sectional view of the structure of this embodiment, which includes an upper end cover, a thyristor and a control part, a moving contact, a static contact, a main contact terminal, a movable support, a conductive rod, an armature, an iron core, a coil, and a permanent magnet. , shell and base, in which the thyristor and the control module replace the arc extinguishing part of the existing contactor, and a permanent magnet is added at the bottom of the iron core. The casing 10 is covered on the base 11 to form a cavity. In the cavity, the iron core 8 is fixed on the center of the base 11. The iron core 8 is concave, and the bottom of the iron core has a square groove for placing the permanent magnet 13. Coils 9 surround the two uprights, the tops of the two uprights form a closed magnetic path with the armature 7, the armature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com