Rubber bearing for low-speed heavy-load environment

A rubber bearing, low-speed and heavy-load technology, which is applied in the direction of rotating bearings, bearings, bearing components, etc., can solve the problems of difficult establishment of water film and low water viscosity, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

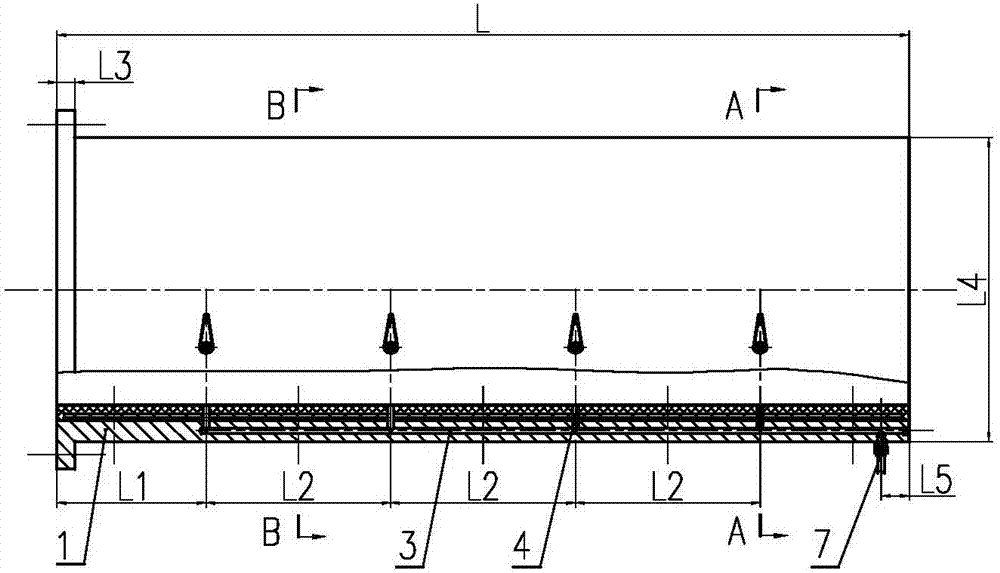

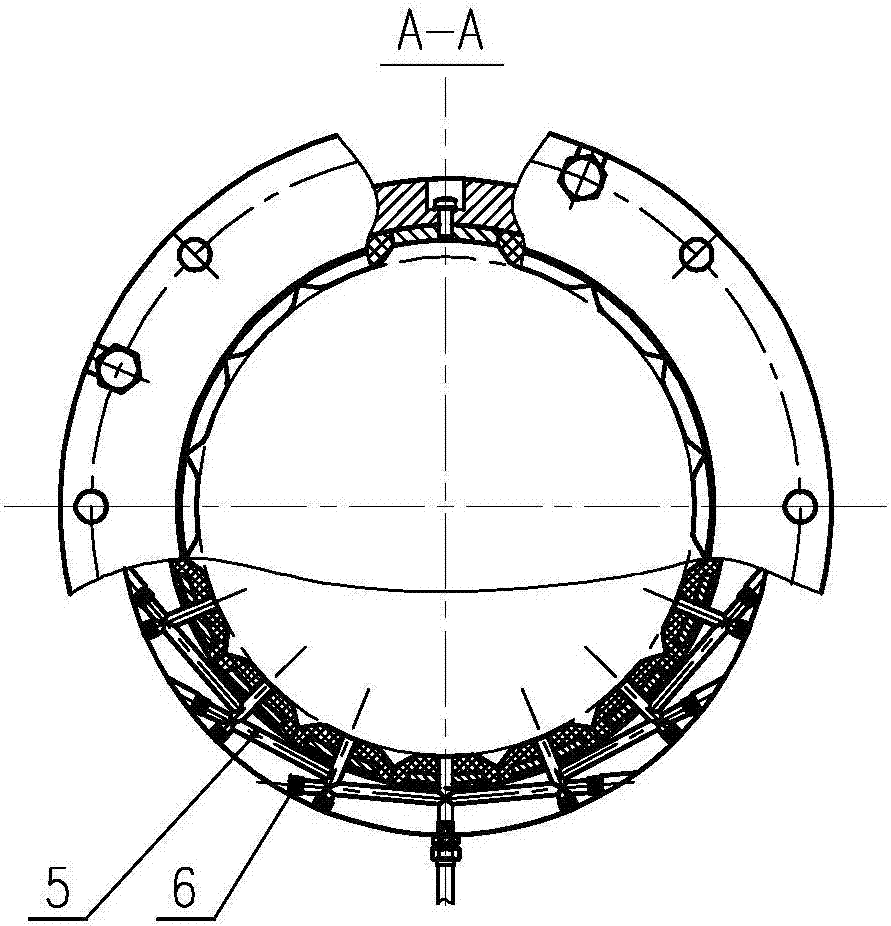

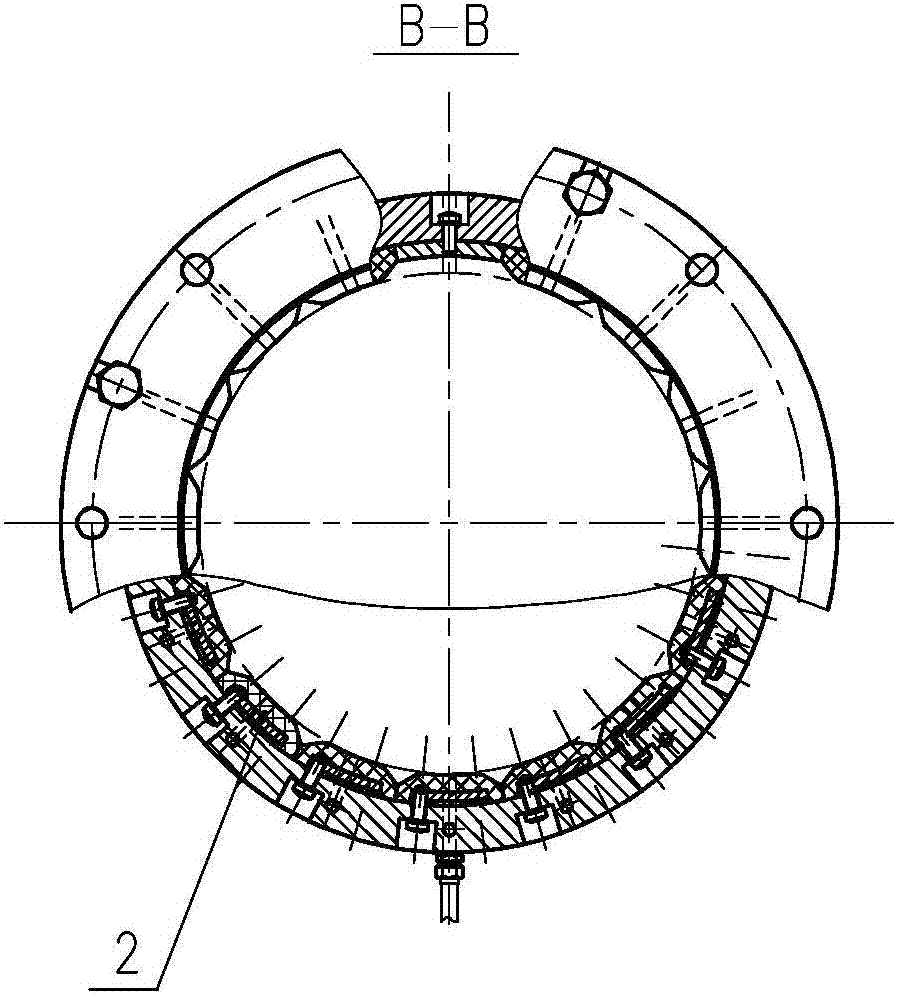

[0019] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0020] combine Figure 1-4 , The ship stern bearing device in the low-speed and heavy-load environment is mainly composed of the following two parts: the bearing body and the pressure water servo mechanism, and the two parts are connected by a water pipeline. This equipment is a general-purpose equipment, which can select the bearing and the diameter of the water flow hole on the bearing according to the actual size of the shafting of the ship, and adjust the water pressure of the pressure water servo mechanism according to the operating conditions of the shafting to realize the forced lubrication of the bearing.

[0021] The bearing body is composed of a bearing housing 1, slats 2, axial flow holes 3, radial flow holes 4, tangential flow holes 5, flow hole heads 6, and a main pipe 7. The wear area of the shaft and the bearing is mainly the lower surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com