Fuel oil filter for oil water separation, precise filtration

A fuel filter and oil-water separation technology, which is applied in the field of filters, can solve the problems of reducing fuel quality, aggravating engine wear, and easy carbon deposition in the engine, and achieves the effects of prolonging service life, good separation effect, and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

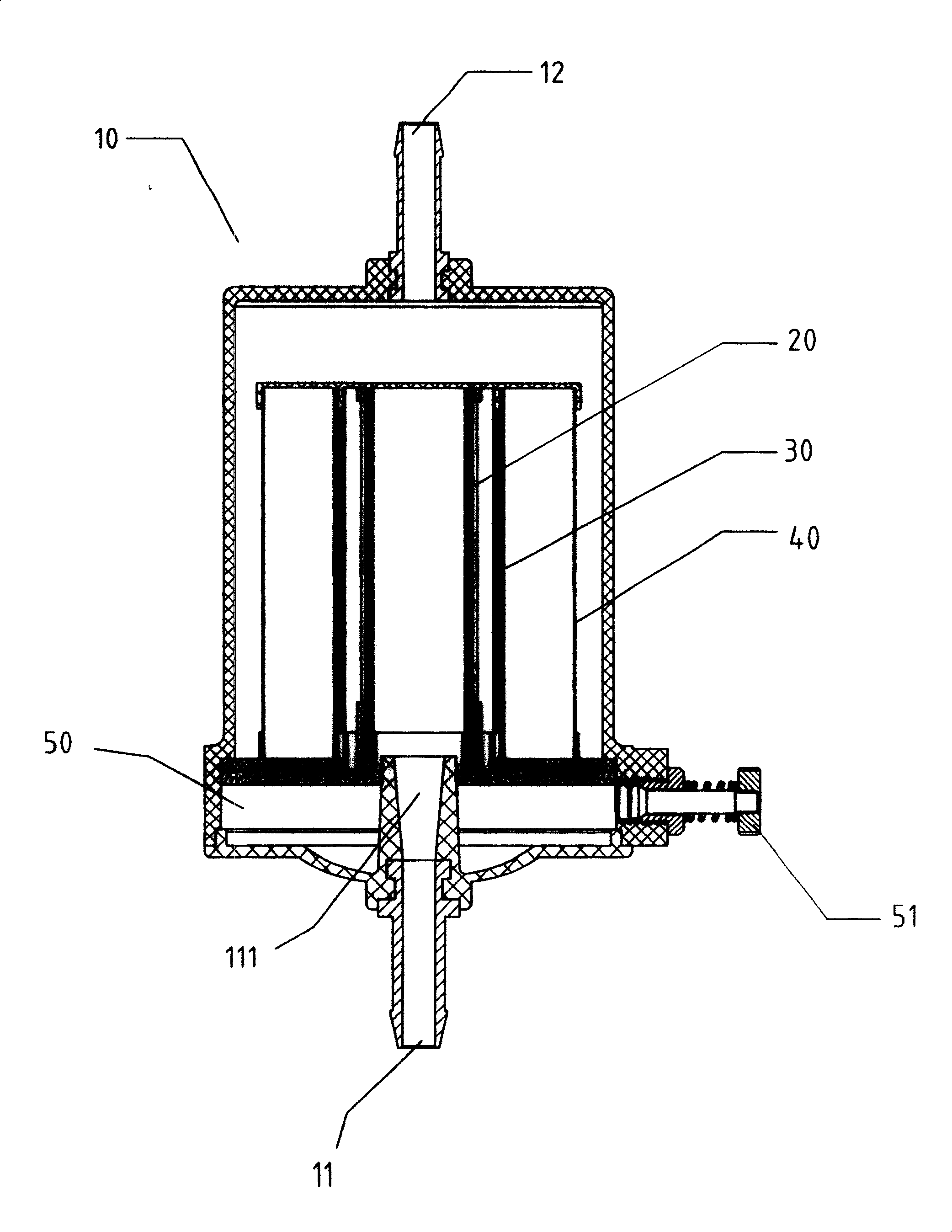

[0011] See the accompanying drawings, the present invention includes a body 10, the body 10 is hollow, and its two ends are respectively combined with an oil inlet 11 and an oil outlet 12, and the middle part of the body 10 is sequentially provided with nickel alloy foamed metal nano superstructures along the direction of oil flow. The hydrophilic filter screen 20 , the oil-water separation filter layer 30 and the fuel filter paper screen 40 , and the bottom of the main body 10 is provided with a sediment collection space 50 .

[0012] When working, the fuel oil enters the fuel filter through the lower oil inlet 10, and the runoff section is increased through the trumpet-shaped open pipe 111 to reduce the flow velocity.

[0013] The fuel oil enters the nickel alloy metal foam nano-superhydrophilic filter 20 in a laminar flow, and the water particles contained in the oil are affinity and agglomerated with the filter screen, and gradually become larger. At the same time, the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com