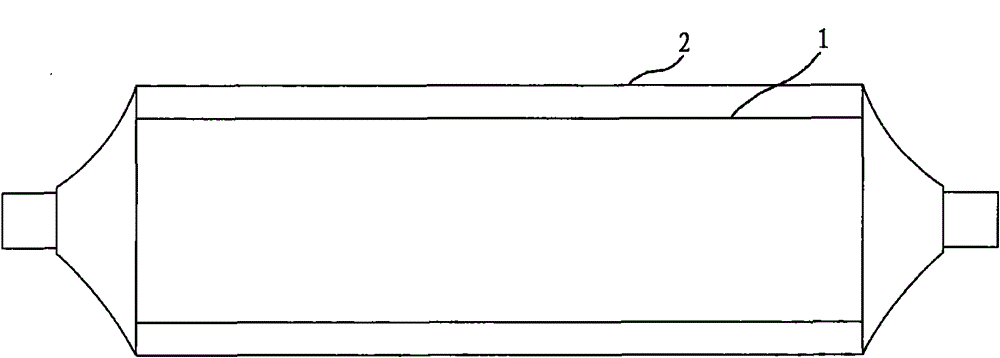

A sinking roller and a stabilizing roller

A sinking roll and stabilizing roll technology, applied in coating, metal material coating process, hot-dip coating process, etc., can solve problems such as spray coating failure, cracks, surface groove marks, uneven spangles, etc., and achieve heat resistance Good fatigue performance, low thermal expansion coefficient, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The substrate of sinking roller and stabilizing roller is 00Cr17Ni14Mo2 stainless steel (equivalent to austenitic ultra-low carbon stainless steel SUS316L), and its chemical composition is C≤0.03wt%, Cr 16wt%~18wt%, Ni10wt%~14wt%, Mo 2.00wt% %~3.00wt%, Mn≤2.00wt%, Si≤1.00wt%; the working surface layer of sinking roll and stabilizing roll is cobalt-based alloy, and the composition of cobalt-based alloy is: Cr 25wt%, Ni 0.2wt%, W 15wt% , Mo 3wt%, V 0.01wt%, Ti 0.1wt%, C 0.3wt%, Fe 6wt%, Si 2.0wt%, Mn 3.0wt%, Al 5.0wt%, Nb 5.0wt%, P<0.07wt%, S<0.07wt%, the rest is Co. Among them, the matrix of the sinking roll and the stabilizing roll accounts for 95% of the total thickness, the cobalt-based alloy accounts for 3% of the total thickness, and the transition layer between the matrix and the cobalt-based alloy accounts for 2% of the total thickness.

[0034] The sinking roll of embodiment 1 and the stabilizing roll are used in the same unit as the sinking roll of the prior ar...

Embodiment 2

[0036] The substrate of the sinking roller and the stabilizing roller is made of 1Cr17Mo ferritic heat-resistant stainless steel, and its chemical composition is C≤0.12wt%, Cr 16wt%~18wt%, Mo 0.75wt%~1.25wt%, Mn≤0.8wt%, Si ≤0.8wt%; the material of the working surface layer of the sinking roll and the stabilizing roll is a cobalt-based alloy, and the composition of the cobalt-based alloy is: Cr 20wt%, Ni 10wt%, W 0.2wt%, Mo 5.5wt%, V 3.0wt%, Ti 5.0wt%, C 0.6wt%, Fe 20wt%, Al 5.0wt%, Mn 0.2wt%, Nb 0.02wt%, Si 0.4wt%, P<0.07wt%, S<0.07wt%, the rest is Co. Among them, the matrix of the sinking roll and the stabilizing roll accounts for 50% of the total thickness, the cobalt-based alloy accounts for 49.99% of the total thickness, and the transition layer between the matrix and the cobalt-based alloy accounts for 0.01% of the total thickness.

[0037] The sinking roll and the stabilizing roll of embodiment 2 are used in the same unit as the sinking roll and the stabilizing roll of t...

Embodiment 3

[0039] The matrix of sinking roll and stabilizing roll is austenitic-ferritic stainless steel 0Cr18Ni9Cu3, and its chemical composition is C≤0.08wt%, Si≤1.00wt%, Mn≤2.00wt%, P≤0.035wt%, S≤0.030wt% %, Ni 8.50wt% ~ 10.50wt%, Cr 17.00wt% ~ 19.00wt%, Cu 3.00wt% ~ 4.00wt%; the working surface layer of the sinking roll and the stabilizing roll is a cobalt-based alloy, and the composition of the cobalt-based alloy is: Cr 30wt%, Ni15wt%, W 10wt%, Mo 0.1wt%, V 0.2wt%, Ti 3.0wt%, C 1.5wt%, Fe 12wt%, Al 0.02wt%, Mn 0.7wt%, Nb 3.0wt%, Si 3.0wt%, P<0.07wt%, S<0.07wt%, and the rest is Co. Among them, the matrix of the sinking roll and the stabilizing roll accounts for 76% of the total thickness, the cobalt-based alloy accounts for 14% of the total thickness, and the transition layer between the matrix and the cobalt-based alloy accounts for 10% of the total thickness.

[0040] The sinking roll and the stabilizing roll of embodiment 3 are used in the same unit as the sinking roll and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com