Axle bush and axle sleeve

A technology of bearing bushes and bushings, applied in the field of hot-dip galvanizing equipment, can solve the problems of iron-based materials being not resistant to wear, short service life, and not resistant to wear, and achieve good thermal fatigue resistance, improved service life, Effect of low thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

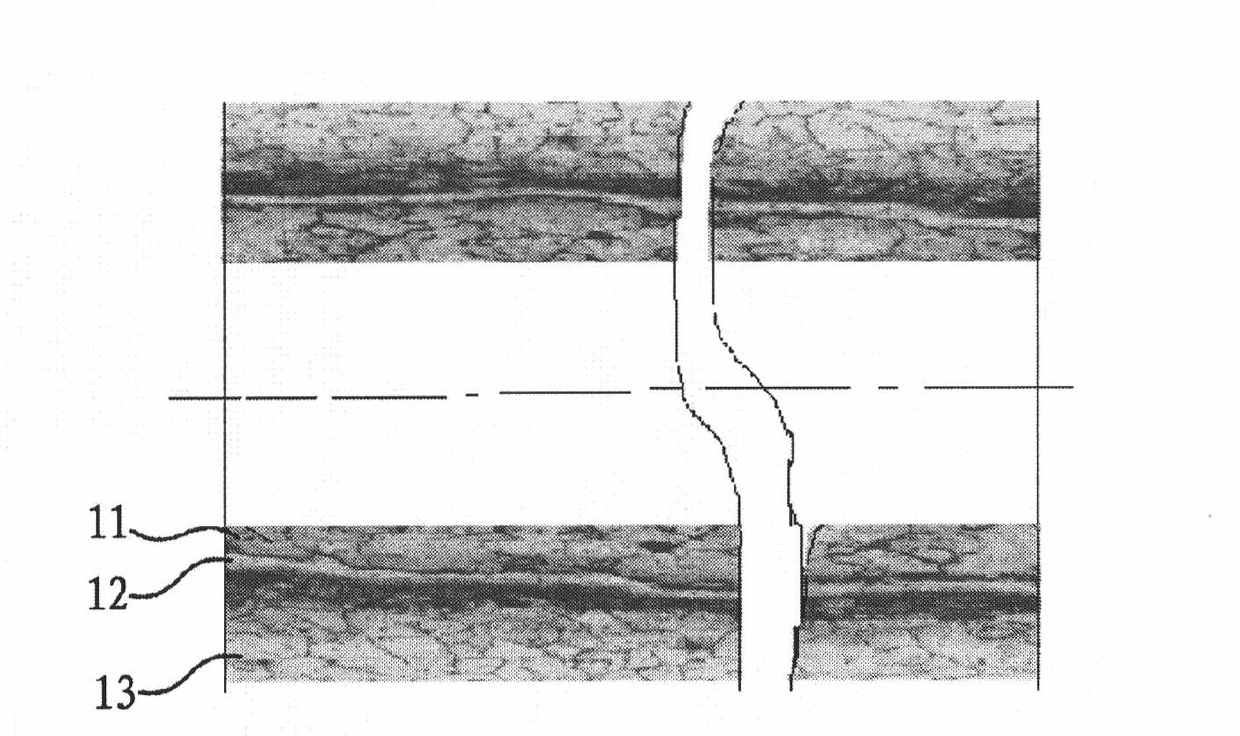

[0043] The bearing shell and bushing matrix of the sinking roller and the stabilizing roller are made of 00Cr17Ni14Mo2 stainless steel, and its chemical composition is C≤0.03wt%, Cr 16wt%~18wt%, Ni 10wt%~14wt%, Mo 2.00wt%~3.00wt%, Mn ≤2.00wt%, Si≤1.00wt%; the working surface layers of the bearing pads and bushings of the sinking roll and the stabilizing roll are cobalt-based alloys, and the composition of the cobalt-based alloys is: Cr 25wt%, Ni 5wt%, W 3wt%, Mo 3wt% %, V 0.1wt%, Ti 0.1wt%, C 0.6wt%, Fe 6wt%, Si 0.5wt%, Mn 0.3wt%, Al 0.5wt%, Nb 1.5wt%, P<0.07wt%, S<0.07 wt%, the rest is Co.

[0044] The bearing bush and the axle sleeve of embodiment 1 and the bearing bush and the axle sleeve of the prior art (the bearing bush and the axle sleeve composition of the prior art are as follows: C 0.119wt%, Si 0.52wt%, Co 0.10wt%, Cr 15wt%, Mn 0.94wt%, Ni 9.6wt%, Cu 0.23wt%, Mo 2.1wt%, the rest are Fe and impurity elements). When used in the same unit, the usable time of the beari...

Embodiment 2

[0046] The bearing shell and bushing matrix of sinking roller and stabilizing roller are made of 1Cr17Mo ferritic heat-resistant stainless steel, and its chemical composition is C≤0.12wt%, Cr 16wt%~18wt%, Mo 0.75wt%~1.25wt%, Mn≤0.8 wt%, Si≤0.8wt%; the working surface layers of bearing pads and bushings of sinking rolls and stabilizing rolls are cobalt-based alloys, and the composition of cobalt-based alloys is: Cr 20wt%, Ni 3wt%, W 5wt%, Mo 2wt%, V 0.2wt%, Ti 0.2wt%, C 0.6wt%, Fe 12wt%, Al 0.5wt%, Mn 0.7wt%, Nb 1.0wt%, Si0.4wt%, P<0.07wt%, S<0.07wt% , and the rest are Co.

[0047] Bearing pad and shaft sleeve of embodiment 2 and prior art bearing pad and shaft sleeve (the components of bearing pad and shaft sleeve of prior art are as follows: C 0.176wt%, Si 0.53wt%, Co 0.41wt%, Cr 16wt%, Mn 0.87wt%, Ni 10wt%, Cu 0.19wt%, Mo 1.8wt%, the rest are Fe and impurity elements). When used in the same unit, the usable time of the bearing pad and bushing of this embodiment is more tha...

Embodiment 3

[0049] The bearing shell and bushing matrix of sinking roller and stabilizing roller is austenitic-ferritic duplex stainless steel 0Cr18Ni9Cu3, and its chemical composition is C≤0.08wt%, Si≤1.00wt%, Mn≤2.00wt%, P≤0.035wt% %, S≤0.030wt%, Ni 8.50wt%~10.50wt%, Cr 17.00wt%~19.00wt%, Cu 3.00wt%~4.00wt%; the working surface layer of the bearing bush and bushing of sinking roll and stabilizing roll is cobalt Cobalt-based alloy, the composition of cobalt-based alloy is: Cr 26wt%, Ni 3wt%, W 5wt%, Mo 2wt%, V 0.2wt%, Ti 0.2wt%, C 1.5wt%, Fe 12wt%, Al 0.8wt%, Mn 0.7wt%, Nb 1.0wt%, Si 1.0wt%, P<0.07wt%, S<0.07wt%, and the rest is Co.

[0050] The bearing bush and the axle sleeve of embodiment 3 and the bearing bush and the axle sleeve of the prior art (the bearing bush and the axle sleeve composition of the prior art are as follows: C 0.258wt%, Si 0.69wt%, W 0.92wt%, Co 0.26wt%, Cr 18wt%, Mn 1.0wt%, Ni 8.7wt%, Cu 0.37wt%, Mo 1.8wt%, and the rest are Fe and impurity elements). When used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com