Piston type air motor

一种发动机、活塞式的技术,应用在活塞式气压发动机领域,能够解决降低压缩气体做功能量的利用率、降低动力输出、发动机结霜等问题,达到提高能量利用率、降低阻力、增加吸气和压缩行程的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

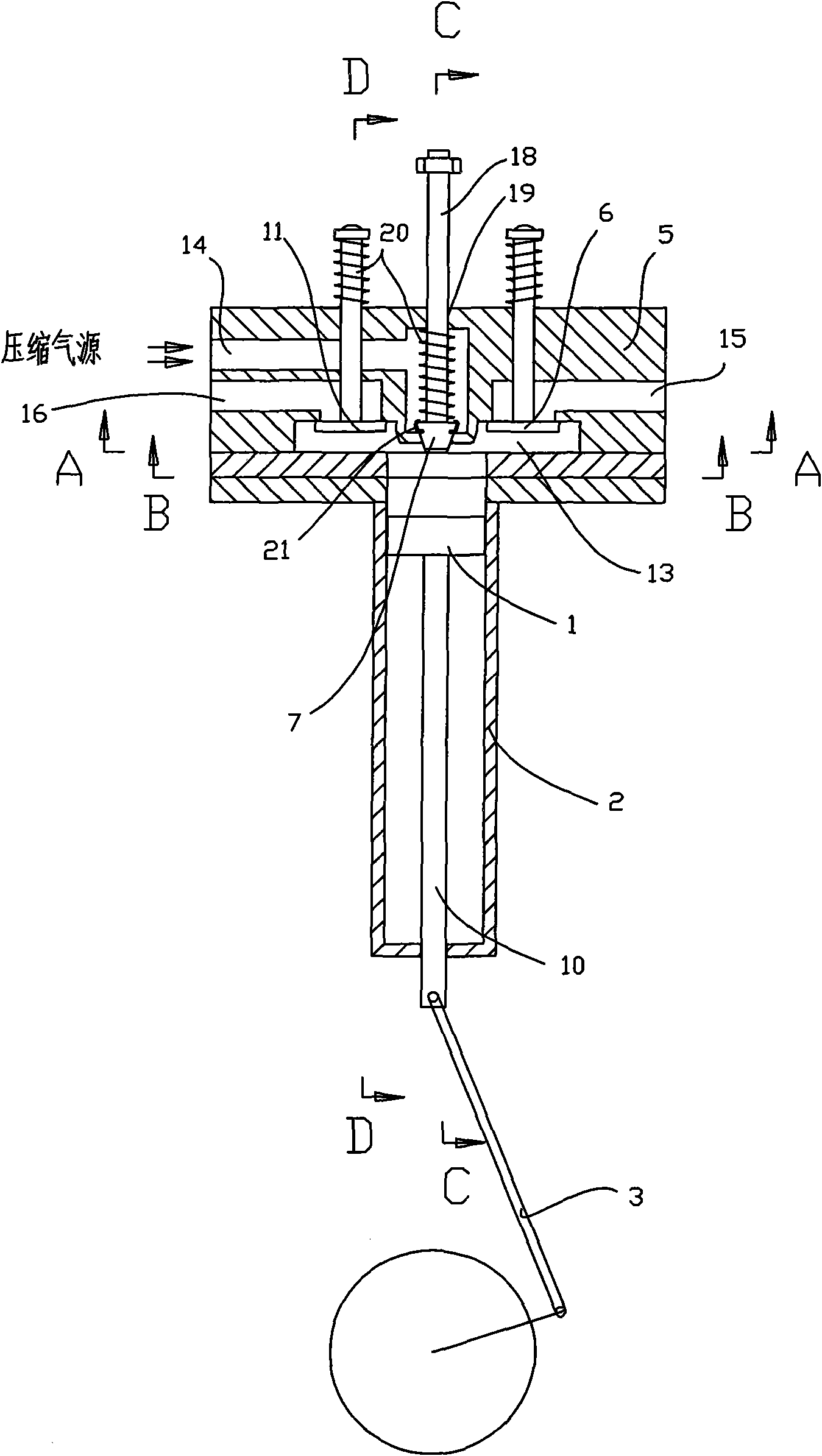

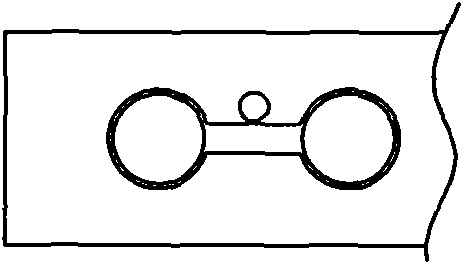

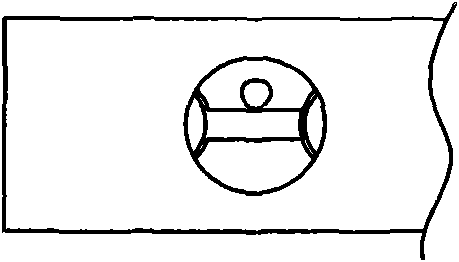

[0031] Such as figure 1 As shown, the piston-type pneumatic engine embodiment one of the present invention comprises a piston 1, a cylinder 2, a crankshaft connecting rod 3 and a camshaft intake and exhaust valve opening and closing device, and the cylinder 2 is covered with a cylinder head 5, which corresponds to There is a groove 13 at the cylinder mouth, and the inlet, exhaust, and suction ports are opened on the inner wall of the groove, and the inlet, exhaust, and suction channels 14, 15, and 16 are respectively opened for each air port, and the air intake channel 14 is externally connected with compressed air. The source, suction and exhaust passages 15, 16 are externally connected to the atmosphere, and the inward-opening compressed gas intake valve 7 and the exhaust and suction valves 6, 11 are correspondingly arranged at the inlet, exhaust, and suction ports on the inner wall of the groove. , Exhaust valves 11 and 6 are opened in the groove (see Figure 5 , 6 ), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com