Device and method for mounting upright post of spanning frame

A technology of installation device and installation method, which is applied in the direction of overhead line/cable equipment, etc., can solve the problems of inaccurate positioning, poor stability, laborious process, etc., and achieve the effect of accurate vertical position, convenient operation and easy erection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Firstly, the lifting frame for installing the uprights of the spanning frame according to the present invention is manufactured.

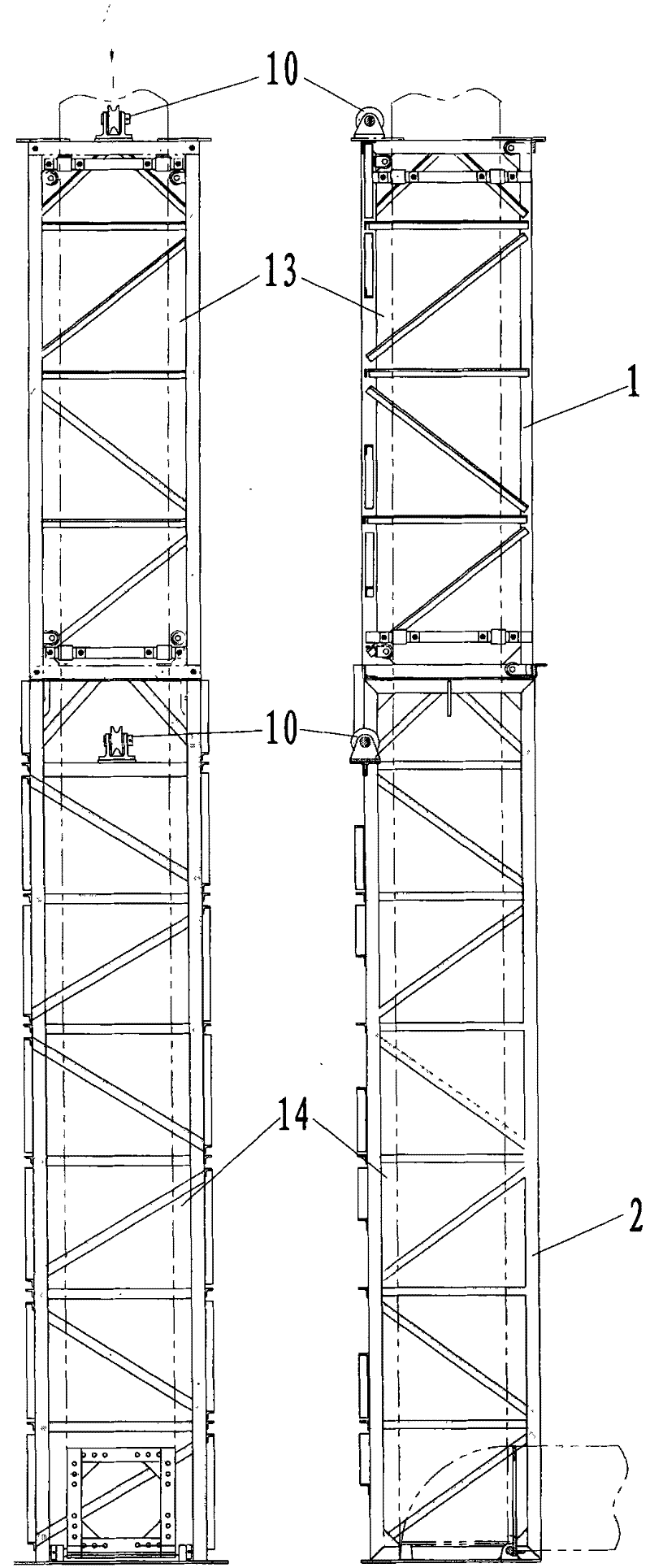

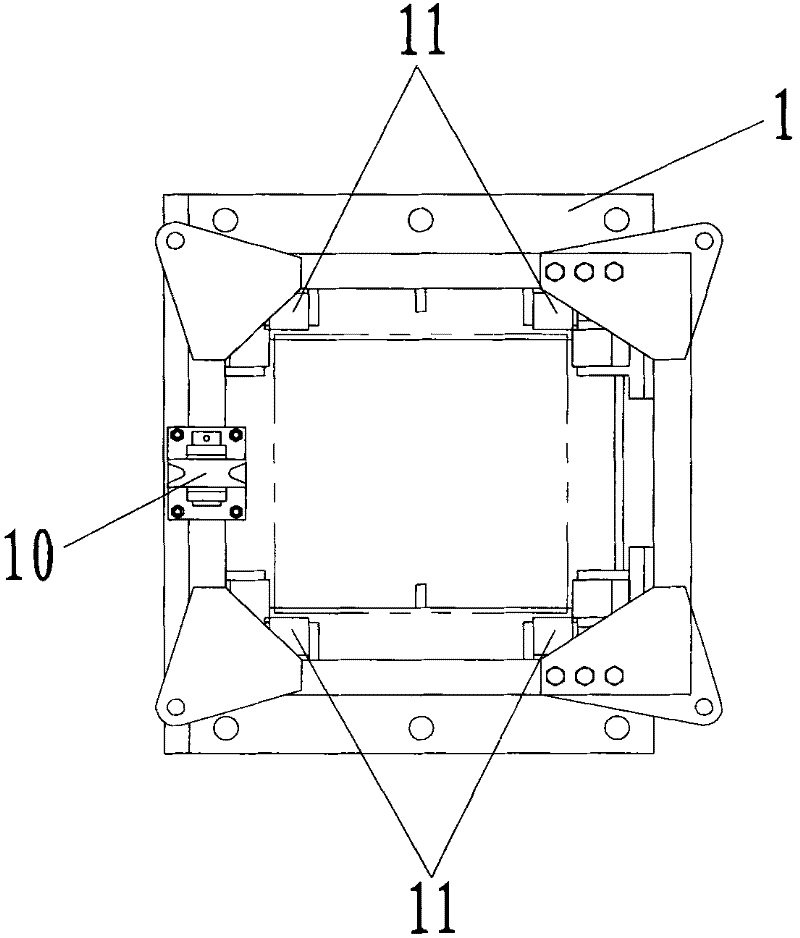

[0053] As shown in FIGS. 1 and 6 , the lifting frame of the present invention includes an upper lifting frame 1 and a lower lifting frame 2 .

[0054] The upper and lower lifting frames 1, 2 are frame-shaped steel frame structures with one side opening, and the opening side is used for erecting the working surface side of the spanning frame columns 13, 14 usefulness. The frame-shaped steel frame structure is composed of angle steel, which is used to form the uprights, crosspieces and diagonal bracing members of the frame-shaped steel frame structure. At the bottom of the lower lifting frame 2, a spanning frame column turning mechanism 3 is arranged.

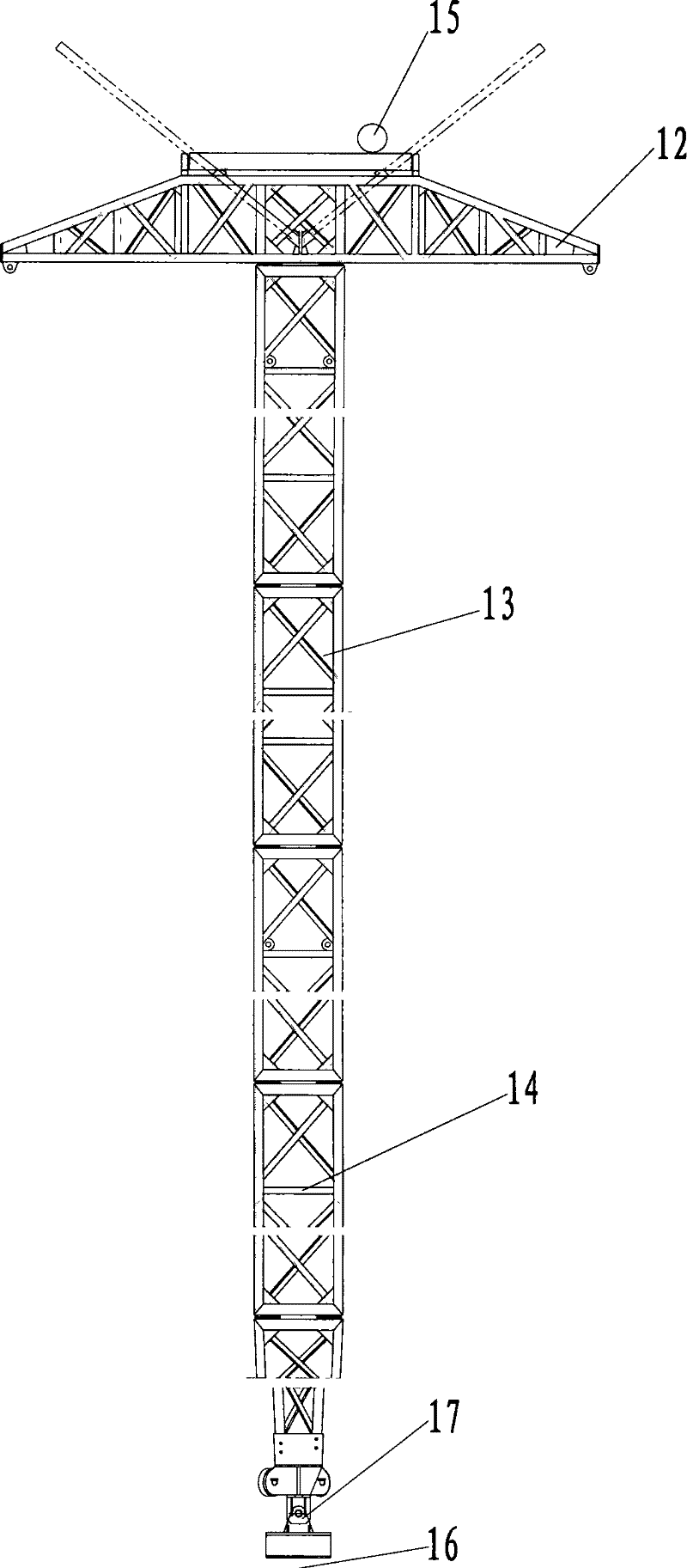

[0055] like image 3 As shown, the above-mentioned spanning frame column 13 to be erected is composed of a cylindrical column and a bow-shaped spanning frame 12 fixedly connected to its top. ...

Embodiment 2

[0077] Except that finally, the bottom of the spanning column of the bottom section is fixed on the column installation base 16 fixed on the ground through steel piles, the others are the same as in Embodiment 1, forming the spanning column lifting frame of the present invention.

Embodiment 3

[0079] Except that the roller set is provided with two rows of nylon rollers on each side wall, the distance between the upper and lower rollers of each row of rollers is 0.05m. In addition, except that the gap between each of the nylon rollers and the outer wall of the spanning frame column is 7mm, the others are the same as in Embodiment 1 to form the spanning frame column lifting frame of the present invention.

[0080] The hoisting frame for the crossing column of the present invention is a lifting and hoisting device for the crossing column of the ultra-high voltage transmission line of 220kv and above in the maintenance and construction of the special traffic facility road section, and is used for the crossing frame and the lifting frame. The installation of its columns. Due to the vertical rotation of the spanning frame column by the turning mechanism, there is no translation and sliding, and the lifting of the spanning frame column is by means of the slideway structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com